Study on Salt-Resistant High Density Cement Slurry Technology for Ultra-Deep Wells

-

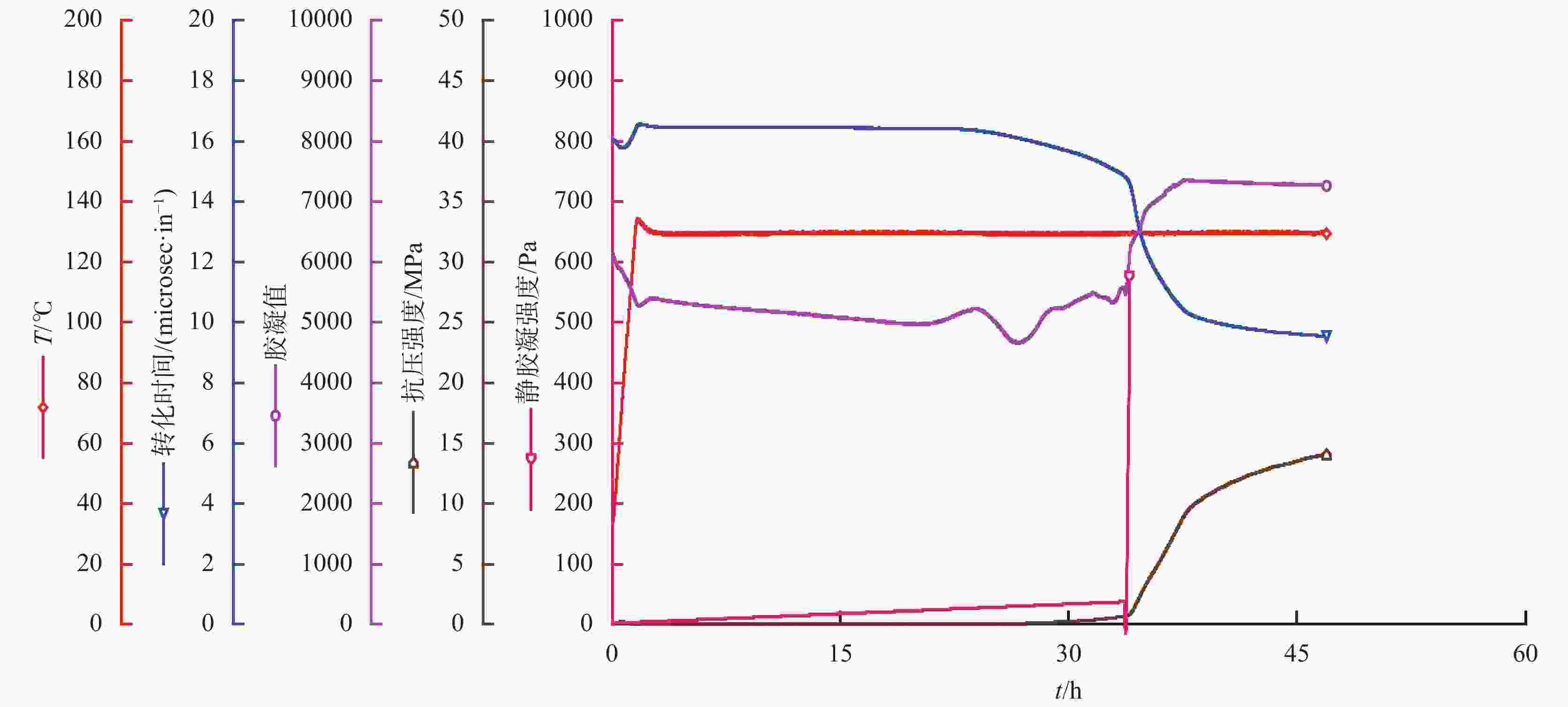

摘要: 塔里木油田克深井区超深井固井存在井下盐膏层发育、窄间隙、高压、高温、大温差等固井技术难题,固井质量无法保证。为解决固井难题,完善了井眼准备通井技术,修正了刚度比计算公式,控制套管下放设计,通过室内实验开展加重材料的优选及合理配比、优选抗盐抗高温添加剂体系、采取针对性技术措施提高水泥石抗高温强度衰退性能,研究出了超高密度抗盐抗高温防气窜水泥浆体系,并对其进行性能评价。结果表明,该水泥浆体系流动度为18~22 cm,水泥浆上下密度差为0.03 g/cm3,其具有流动性能良好、稳定性较好、防窜性能良好、早期强度高、长期强度无衰退等优点,形成了克深井区超深井盐膏层尾管固井技术。该固井技术在现场应用5井次,测声幅固井质量良好。克深井区超深井窄间隙盐膏层尾管固井技术,不但可以解决该区块固井难题,还封固了高压盐水层,保障了该区块的安全、高效开发。Abstract: Cementing of ultra-deep wells in the Keshen block in Tarim Basin is faced with many downhole problems such as salt and gypsum formation to be cemented, narrow clearance between casing string and borehole walls, high pressure, high temperature and big temperature difference etc., and poor quality of well cementing job is frequently seen in this area. Several measures have been taken to solve the problems encountered in well cementing. First, the borehole to be cemented was well prepared by engineered wiper trip, the formula for calculating the stiffness ratio was revised and the running of casing string was well controlled. Second, Laboratory experiment was conducted in selecting weighting agents and cement additives that are resistant to salt contamination and high temperature. Third, specific techniques were adopted to improve the resistance to high temperature and strength decline of set cement. Based on the experiment, an ultra-high density cement slurry was developed. Laboratory evaluation showed that this cement slurry has a fluidity of 18-22 cm. The difference of density between the top and the bottom of the cement slurry is 0.03 g/cm3. It has many advantages such as good flowability, high stability, good gas-channeling prevention capacity, high early strength and no long-term strength decline. The cementing technology based on this cement slurry and measures of using it formed the base of high quality well cementing job in Keshen block where ultra-deep wells were drilled through salt and gypsum formations. Five well times of field application gave high quality cementing job as indicated by sonic logging. The technology for cementing ultra-deep well penetrating salt/gypsum formations and with narrow clearance between liner string and borehole walls not only helped solve the difficulties encountered in well cementing, but also helped cement the high-pressure saltwater zones, ensuring the safe and efficient development of the Keshen block.

-

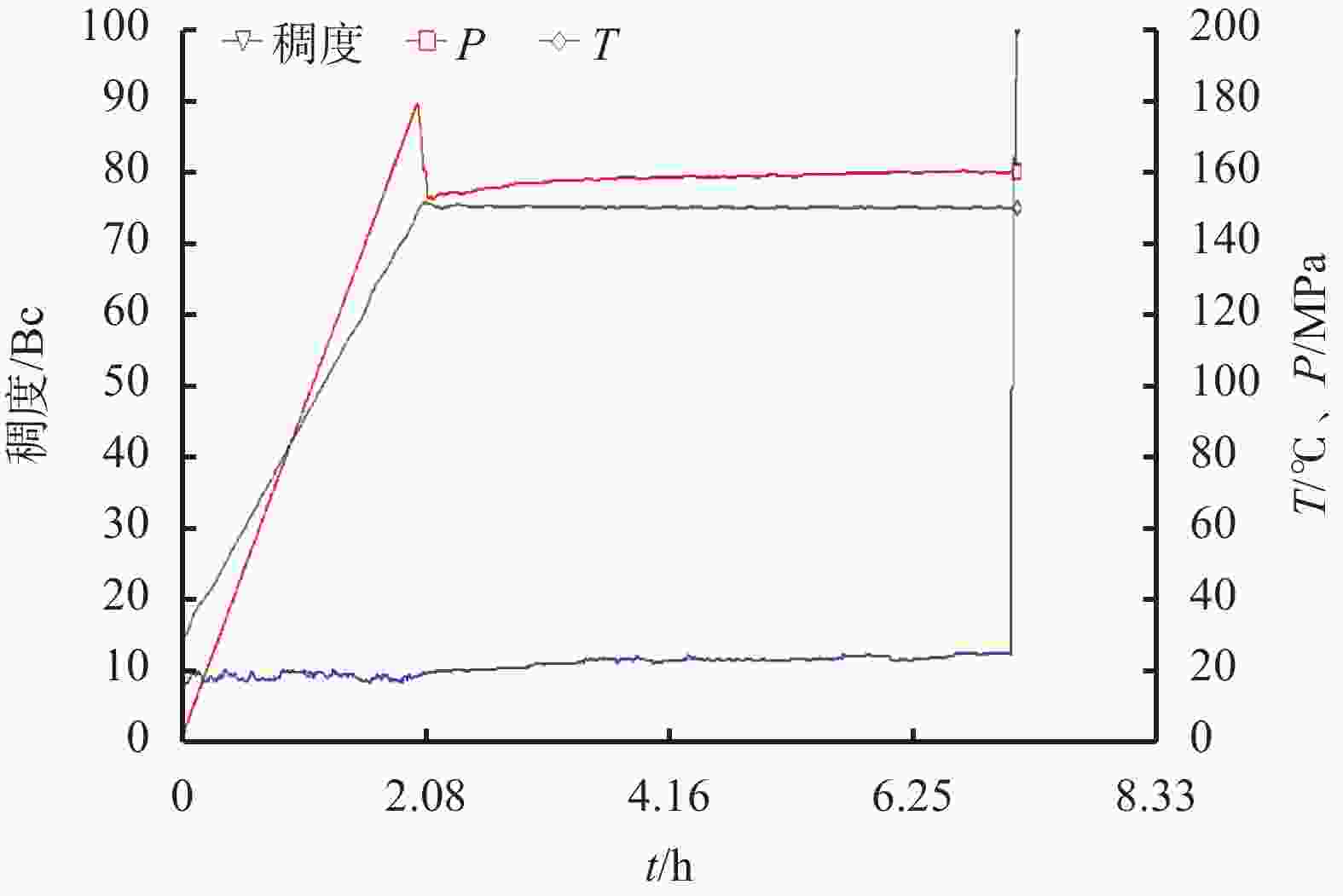

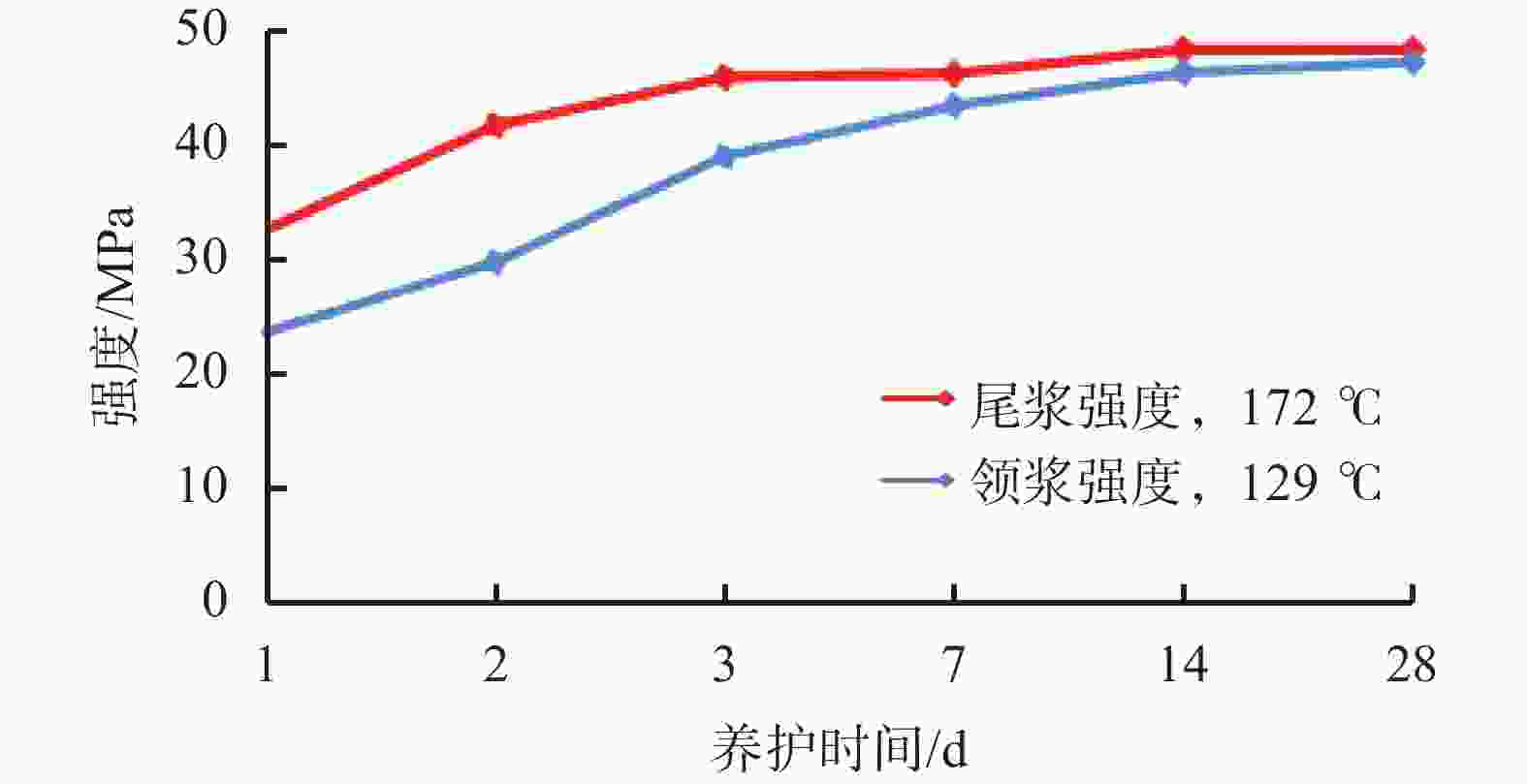

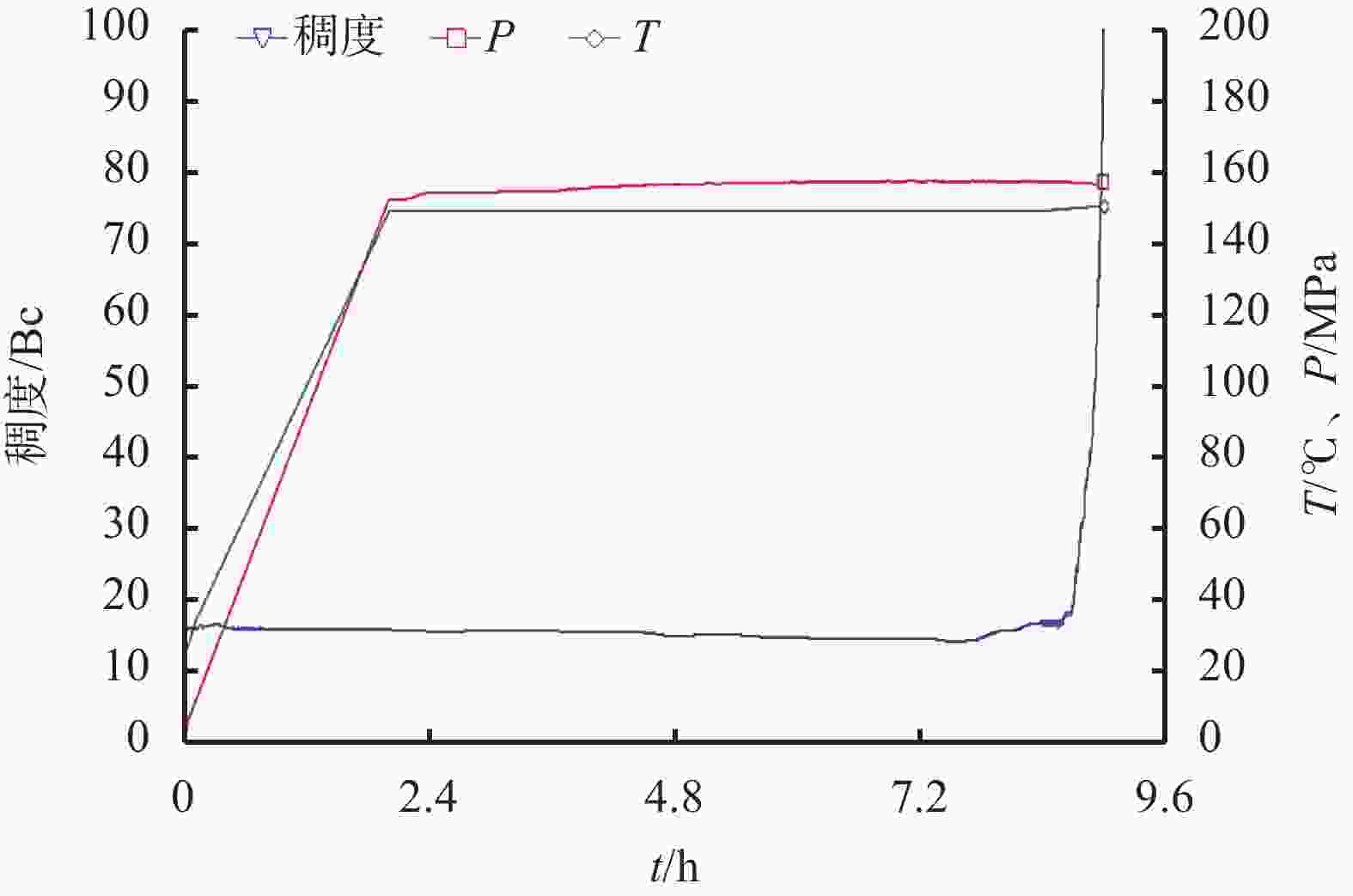

表 1 双凝抗盐抗高温防气窜超高密度水泥浆性能

水泥浆 ρ/

g·cm−3游离液/

%FL/

mLt稠化/

min流动度/

cm△ρ/

g·cm−3p/

MPa领浆 2.53 0 44 542 20 0.03 12.9(48 h) 尾浆 2.53 0 42 341 20 0.03 19.2(24 h) 表 2 水泥浆流变性能

浆体名称 T/℃ φ600 φ300 φ200 φ100 φ6 φ3 n K/

Pa·sn领浆 常温 >300 252 187 106 10 8 0.67 1.55 尾浆 >300 262 192 109 11 9 0.65 1.78 领浆 升温至145 ℃

养护20 min

后降至

93 ℃测量278 156 116 65 9 6 0.82 0.46 尾浆 287 166 122 76 11 9 0.78 0.64 表 3 隔离液的流变性能

实验

条件φ600 φ300 φ200 φ100 φ6 φ3 n K/

Pa·snΔρ/

g·cm−3常温 >300 292 272 156 16 15 0.6 2.5 0.02 93 ℃ 141 82 61 38 10 9 0.82 0.21 0.03 注:高温稳定性及流变是经稠化仪149 ℃养护后冷却至93 ℃测量,隔离液流动度为20 cm -

[1] 周开吉, 郝俊芳. 钻井工程设计[M]. 山东: 石油大学出版社.ZHOU Kaiji, HAO Junfang. Drilling engineering design [M]. Shandong: Petroleum University Press. [2] 张宏军,张明昌,刁胜贤,等. 高温抗盐水泥浆体系在胜利油田深探井的应用[J]. 钻井液与完井液,2005,22(S0):75-77.ZHANG Hongjun, ZHANG Mingchang, DIAO Shengxian, et al. Application of high temperature and salt resistant cement slurry system in deep exploration wells of Shengli oilfield[J]. Drilling Fluid & Completion Fluid, 2005, 22(S0):75-77. [3] 郭小阳, 张玉隆. 水泥浆失重与气侵的机理探讨[C]//中国石油工程学会钻井基础理论学组第三届年会论文集, 1994: 67-77.GUO Xiaoyang, ZHANG Yulong. Discussion on the mechanism of cement slurry weightlessness and gas influx [C]//Proceedings of the third annual meeting of drilling basic theory group, Chinese petroleum engineering society, 1994: 67-77. [4] 王景建,冯克满,许前富,等. 高温下加砂G级油井水泥强度发展规律研究[J]. 长江大学学报(自然版),2011,8(3):52-54.WANG Jingjian, FENG Keman, XU Qianfu, et al. Study on the strength development of G-grade oil well cement with sand under high temperature[J]. Journal of Yangtze University(Natural Science Edition) , 2011, 8(3):52-54. [5] 屈建省, 许树谦, 郭小阳, 等. 特殊固井技术[M]. 北京: 石油工业出版社, 2006.QU Jiansheng, XU Shuqian, GUO Xiaoyang, et al. Special cementing technology [M]. Beijing: Petroleum Industry Press, 2006. [6] 代奎,孙超,张景富,等. 高温下G级油井水泥强度的衰退及合理的硅砂加量[J]. 大庆石油学院学报,2004,28(5):98-100.DAI Kui, SUN Chao, ZHANG Jingfu, et al. Decline of cement stone strength and the right amount of silica sand added to cement slurry at high temperature[J]. Journal of Daqing Petroleum Institute, 2004, 28(5):98-100. [7] 杨远光,陈大钧. 高温水热条件下水泥石强度衰退的研究[J]. 石油钻采工艺,1992,14(5):33-39.YANG Yuanguang, CHEN Dajun. Study on strength decline of cement stone under high temperature and hydrothermal condition[J]. Oil Drilling & Production Technology, 1992, 14(5):33-39. [8] 沈伟. 各种因素对水泥石抗压强度的影响[J]. 钻井液与完井液,2000,17(1):20-24. doi: 10.3969/j.issn.1001-5620.2000.01.007SHEN Wei. Influence of various factors on compressive strength of cement stone[J]. Drilling Fluid & Completion Fluid, 2000, 17(1):20-24. doi: 10.3969/j.issn.1001-5620.2000.01.007 [9] 牛新明,张可坚,丁世东,等. 川东北地区高压防气窜固井技术[J]. 石油钻探技术,2008,36(3):10-15. doi: 10.3969/j.issn.1001-0890.2008.03.003NIU Xinming, ZHANG Kejian, DING Shidong, et al. Gas migration prevention cementing technologies in Northeast Sichuan area[J]. Petroleum Drilling Technology, 2008, 36(3):10-15. doi: 10.3969/j.issn.1001-0890.2008.03.003 [10] 补成中,樊朝斌,彭刚. 川东北地区高压气井固井防气窜技术分析[J]. 钻井液与完井液,2008,25(1):81-84. doi: 10.3969/j.issn.1001-5620.2008.01.027BU Chengzhong, FAN Chaobin, PENG Gang. Gas-channeling prevention in high-pressure well cementing in north-east Sichuan[J]. Drilling Fluid & Completion Fluid, 2008, 25(1):81-84. doi: 10.3969/j.issn.1001-5620.2008.01.027 [11] KHALID Al-BURAIK. Prevention of shallow gas migration through cement[C]. SPE 47775, 1998. [12] 杨小华,王中华. 国内近15年油井水泥外加剂研究与应用进展[J]. 油田化学,2004(3):290-296. doi: 10.3969/j.issn.1000-4092.2004.03.028YANG Xiaohua, WANG Zhonghua. Advances in preparation and uses of oilwell cement additives in China in recent 15 years[J]. Oilfield Chemistry, 2004(3):290-296. doi: 10.3969/j.issn.1000-4092.2004.03.028 [13] 黄柏宗. 油井水泥及其外加剂的进展[J]. 钻井液与完井液,1994,11(3):8-10.HUANG Bozong. Development of oil well cement and additives[J]. Drilling Fluid & Completion Fluid, 1994, 11(3):8-10. [14] 姚晓. 几种油井水泥外加剂的作用机理[J]. 油田化学,1993,10(1):78-80.YAO Xiao. Action mechanism of several additives for oil well cement[J]. Oilfield Chemistry, 1993, 10(1):78-80. [15] 王中华. 国内油井水泥外加剂研究与应用进展[J]. 精细与专用化学品,2011,19(10):45-49. doi: 10.3969/j.issn.1008-1100.2011.10.018WANG Zhonghua. Advances in preparation and uses of oil well cement additives in China[J]. Fine and Special Chemicals, 2011, 19(10):45-49. doi: 10.3969/j.issn.1008-1100.2011.10.018 [16] 张景富, 徐明, 高丽丽, 等. 温度及外加剂对水泥浆流变性的影响[J]. 钻井液与完井液, 2003, 20(1): 34-36.ZHANG Jingfu, XU Ming, GAO Lili, et al. Affects of temperature and additives on rheology of cement slurry[J]. Drilling Fluid & Completion Fluid, 2003, 20 (1):34-36. [17] 何世明,刘崇建,邓建民,等. 温度压力对水泥浆流变性的影响规律研究[J]. 石油钻采工艺,1999,21(6):7-13.HE Shiming, LIU Chongjian, DENG Jianmin, et al. Study on influence of temperature and pressure on slurry rheology[J]. Oil Drilling & Production Technology, 1999, 21(6):7-13. [18] 黄柏宗. 紧密堆积理论的微观机理及模型设计[J]. 石油钻探技术,2007,35(1):5-11. doi: 10.3969/j.issn.1001-0890.2007.01.002HUANG Bozong. Micromechanism and model design of close packing theory[J]. Petroleum Drilling Technology, 2007, 35(1):5-11. doi: 10.3969/j.issn.1001-0890.2007.01.002 -

下载:

下载: