Study on Characterization of the Performance of Fracturing Fluids in Large Scale Volumetric Fracturing

-

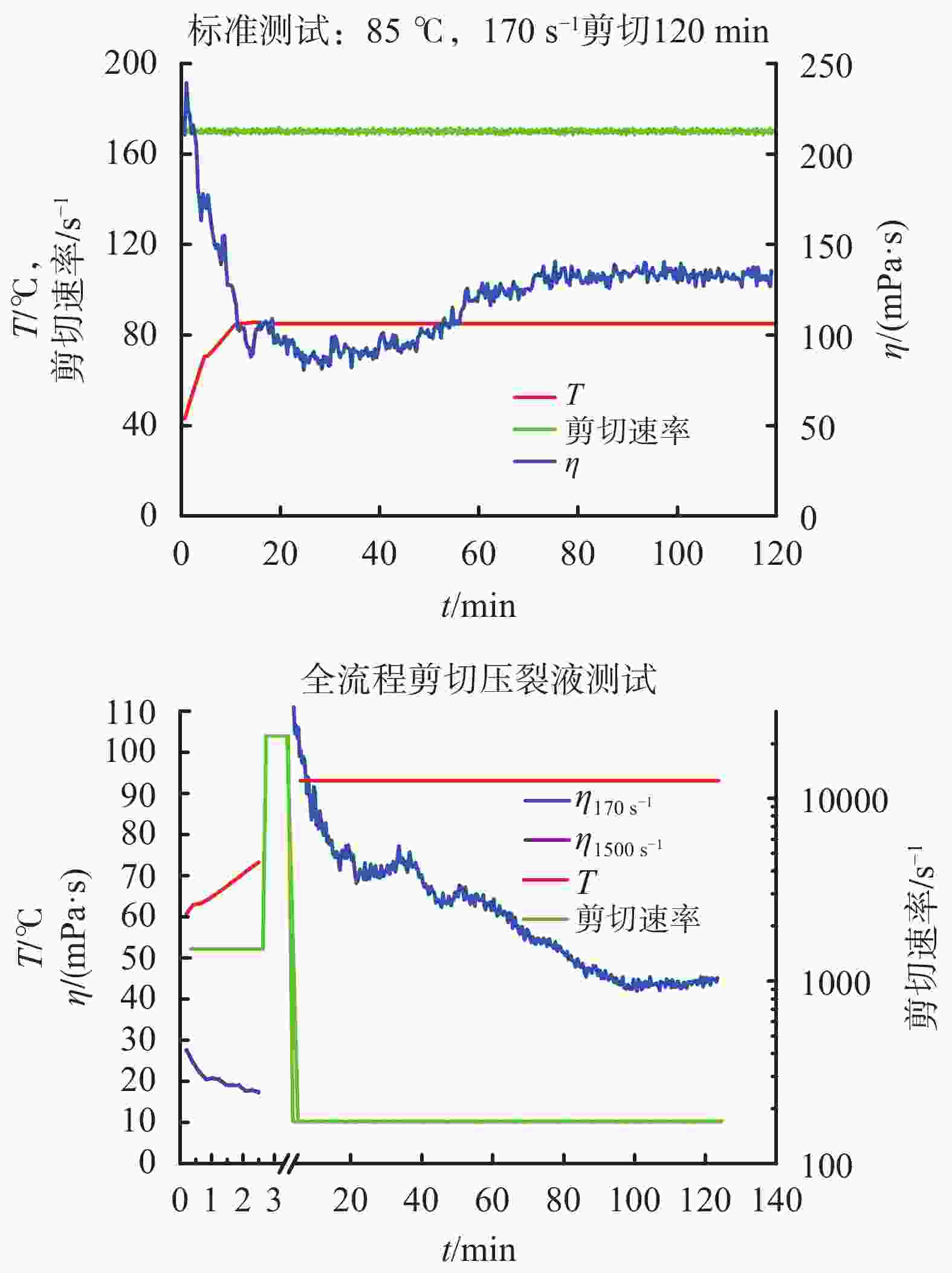

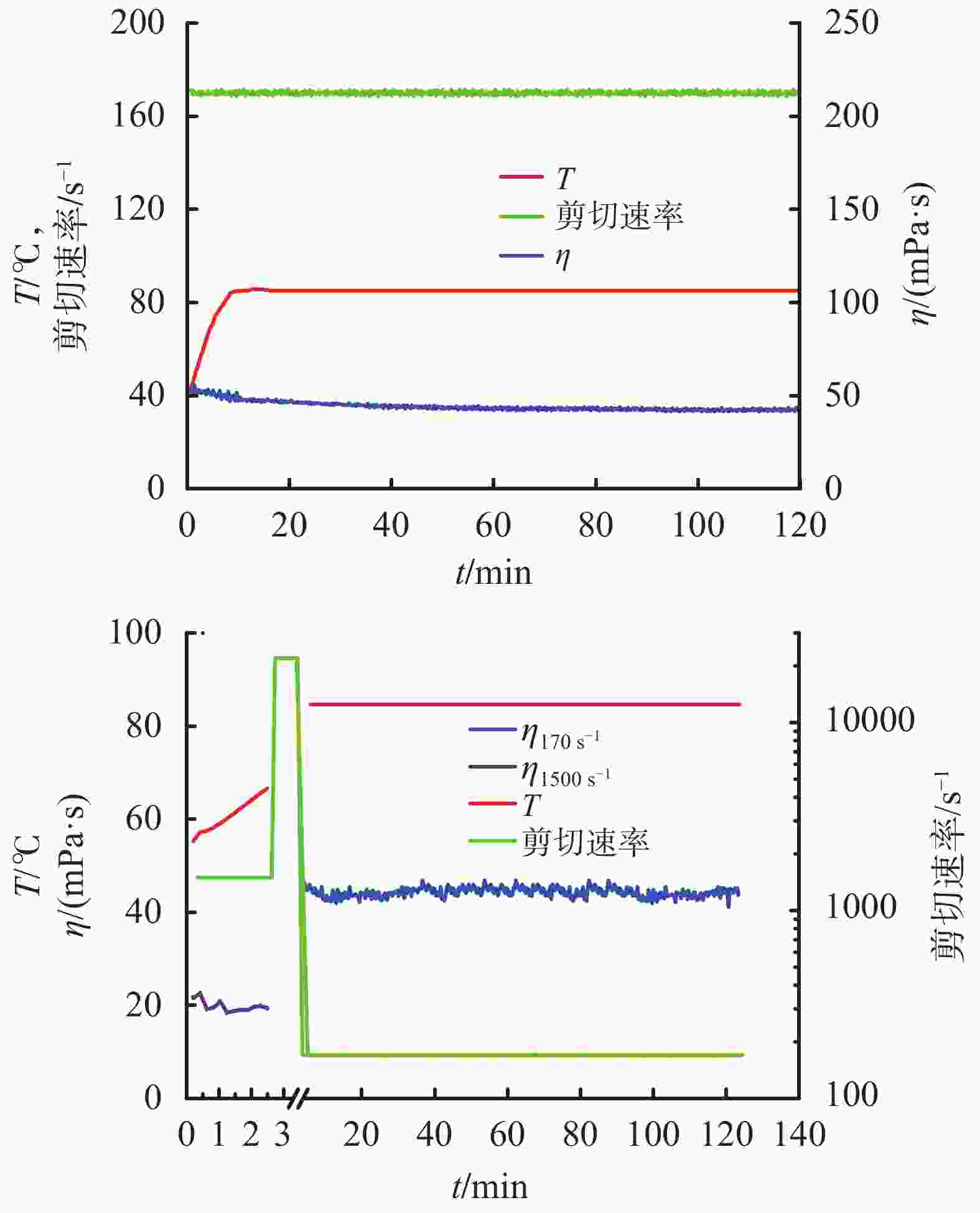

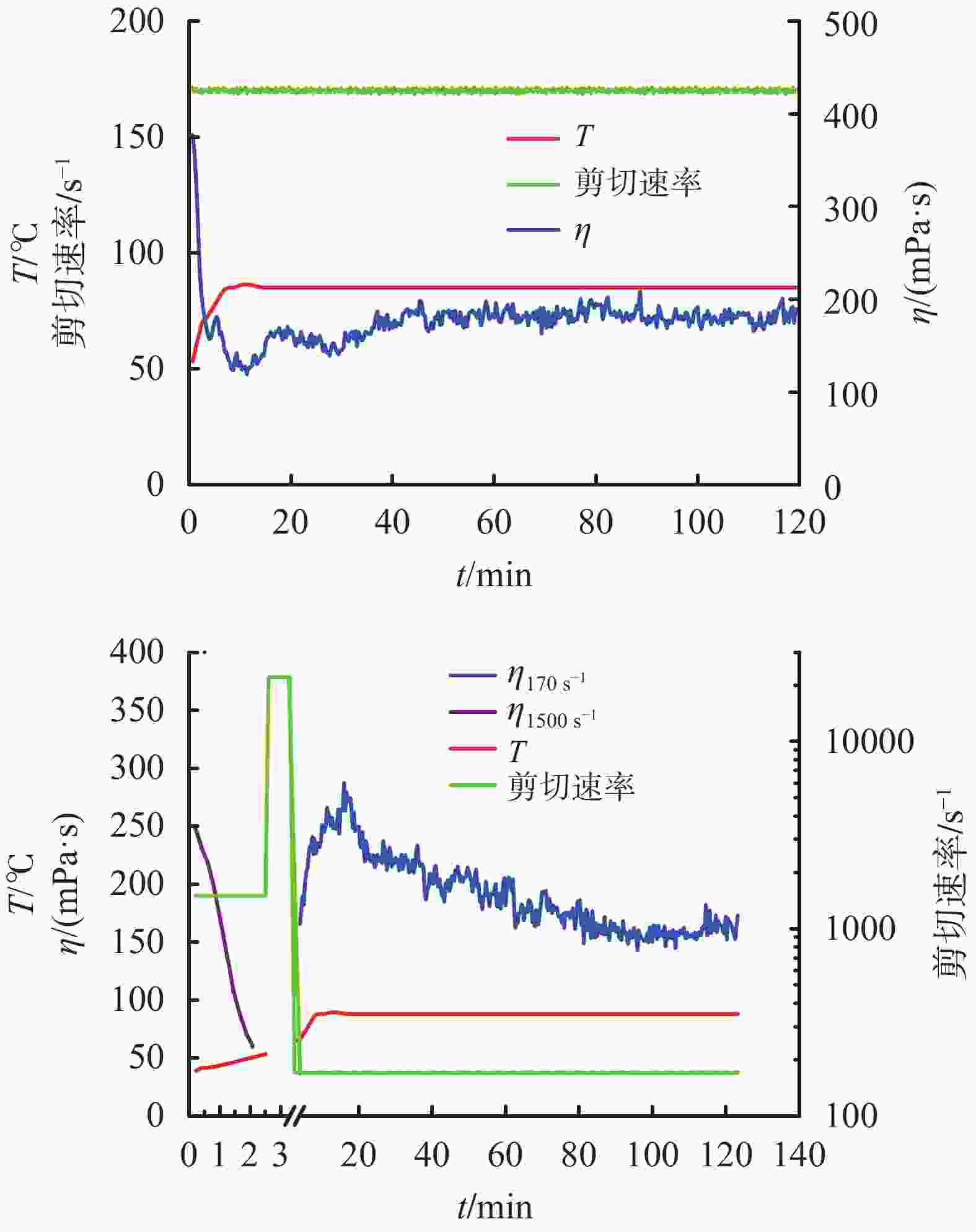

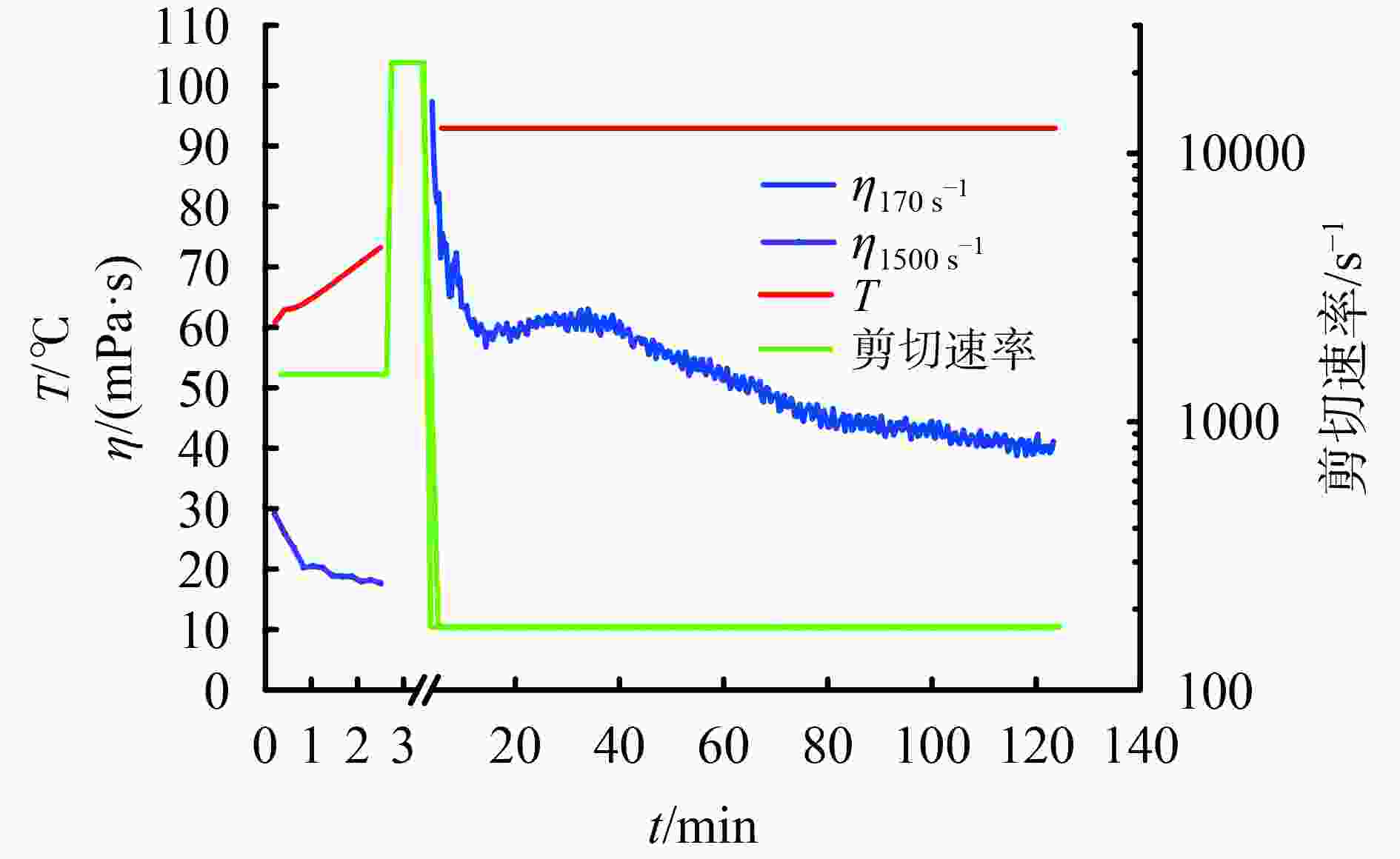

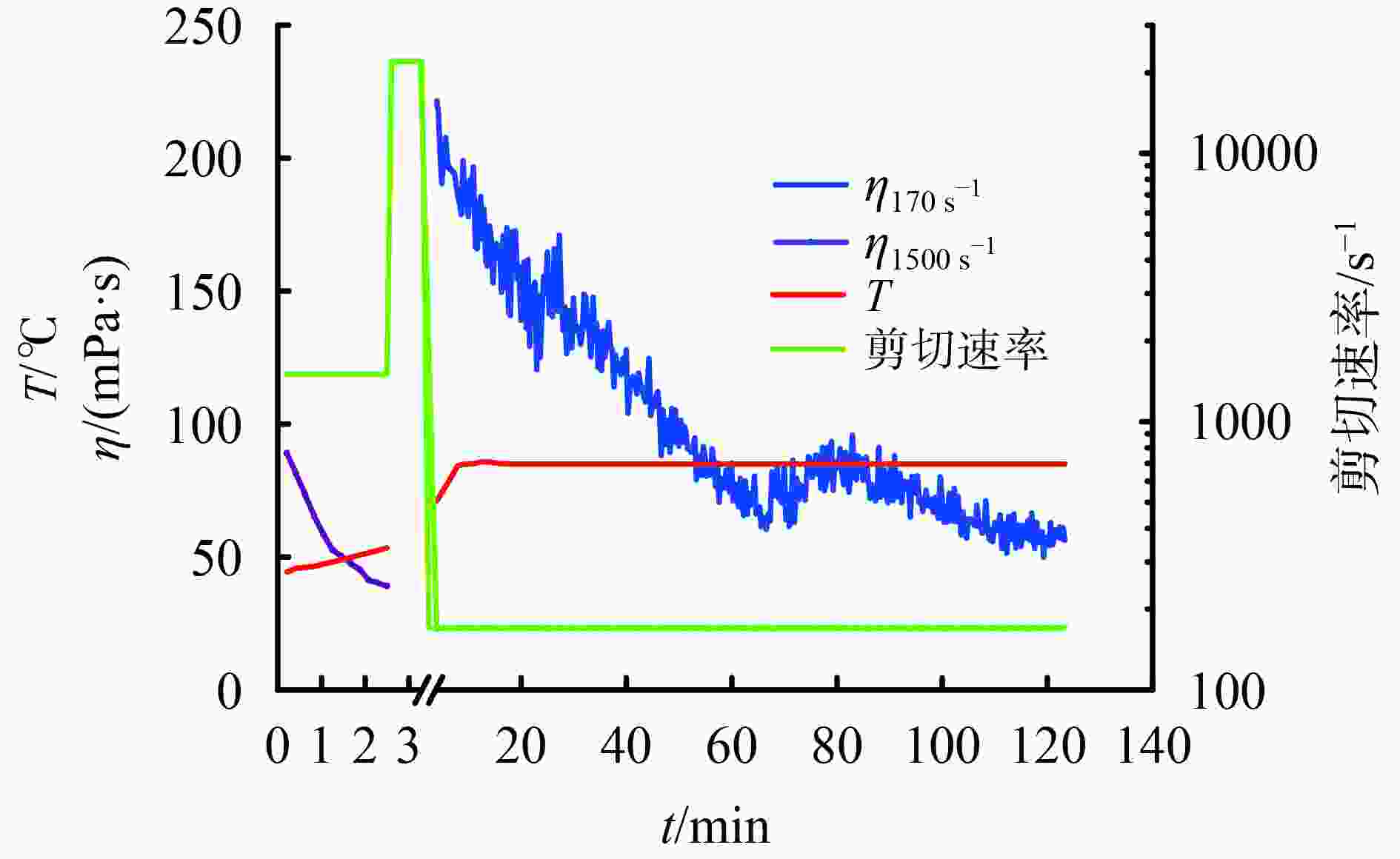

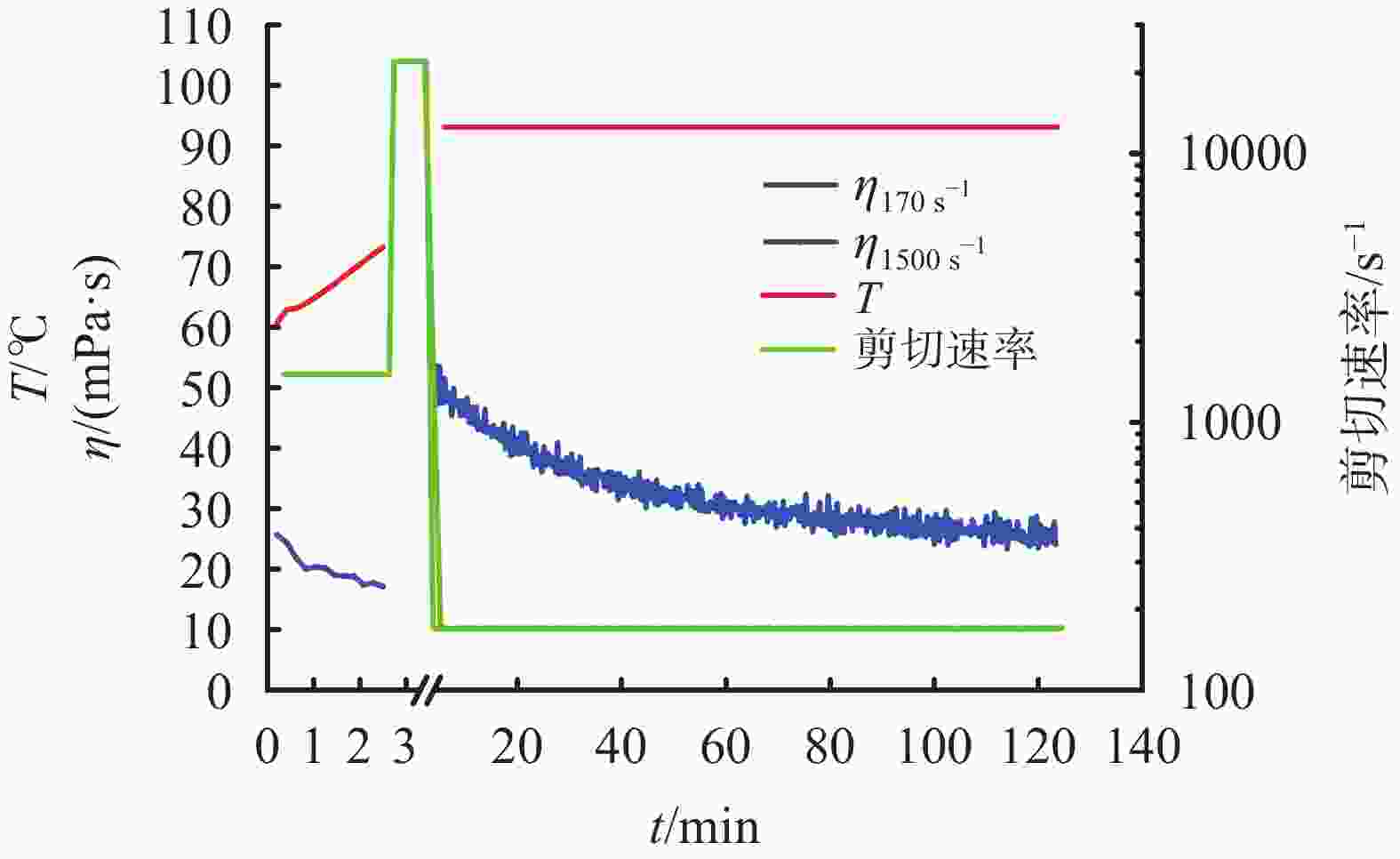

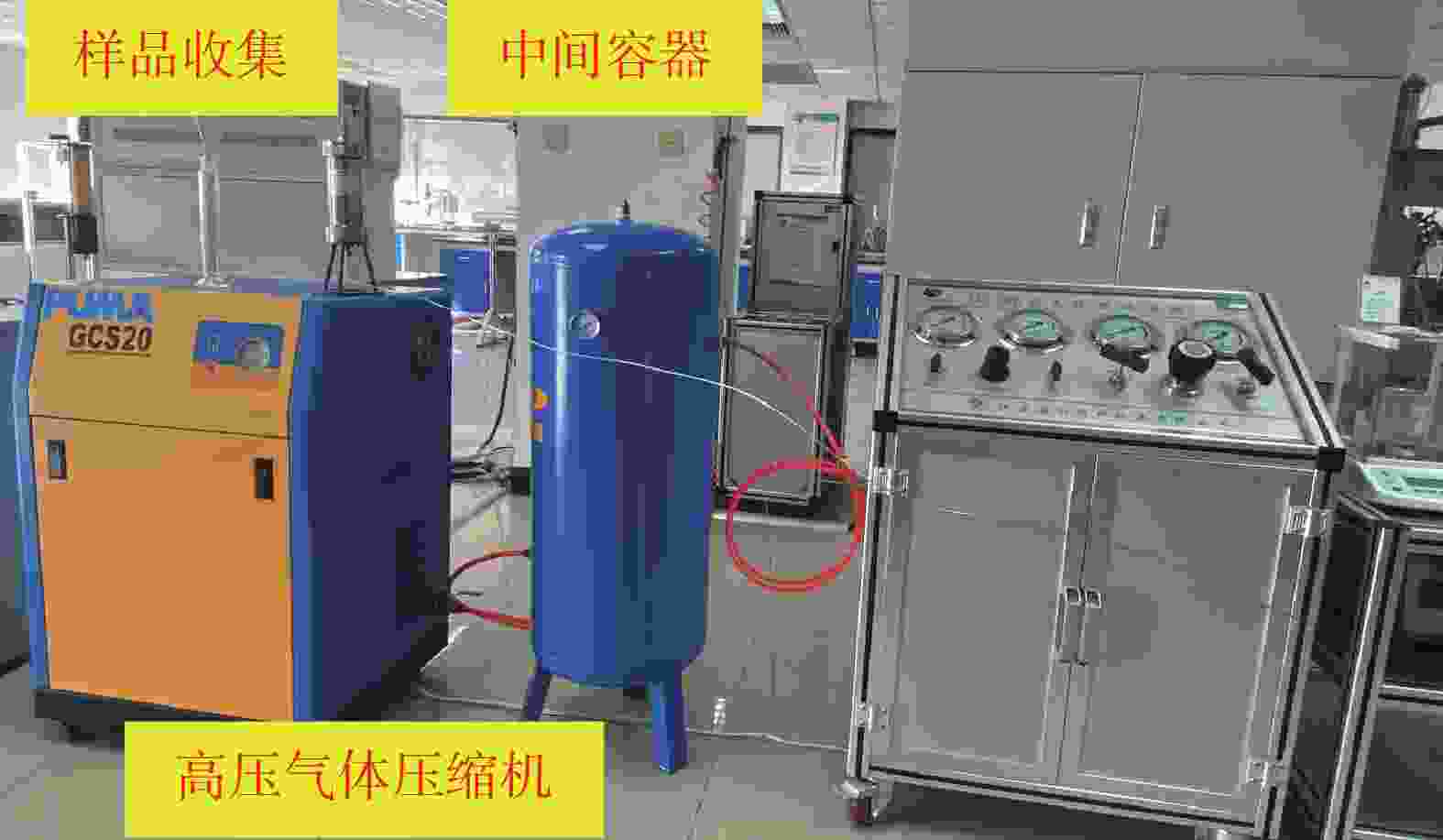

摘要: 针对SY/T 5107-2016《水基压裂液性能评价方法》压裂液性能评价标准未能模拟大规模体积压裂过程中压裂液剪切历史,尤其缺少过炮眼高速剪切对压裂液性能影响的重要环节,项目开展模拟体积压裂施工全过程压裂液体系性能测试方法探索性研究。参照现场实际施工排量,模拟压裂液流经管柱、炮眼和裂缝不同阶段的剪切历史,同时,以压裂液破胶低伤害为前提进行破胶剂量优化,在此基础上进行压裂液流变性能测试,保证压裂液满足施工过程具备携砂性能和施工结束后一段时间内完全破胶的双重要求;采用透明平行板模型,考察使用条件下压裂液动态携砂性能,测试结果为大规模体积压裂“全裂缝支撑”提供设计依据。新方法测试结果表明,复合交联瓜胶压裂液体系和交联聚合物压裂液体系通过高速炮眼后黏度损失较大;乳液缔合型压裂液体系对破胶剂敏感,在满足破胶低伤害的前提下,动态携砂性能难以满足裂缝远端支撑剂铺置要求;低浓度瓜胶压裂液体系添加优化用量破胶剂,体系在施工排量下动态携砂性能良好,满足裂缝远端支撑剂铺置的技术目标。Abstract: In the national standard “The evaluation measurement for properties of water based fracturing fluid” (SY/T 5107-2016), the shearing history of a fracturing fluid in large scale volumetric fracturing and the high shear rate of the fracturing fluid when it passes through a perforation cannot be simulated. A study has been performed on the investigation of how to measure the performance of a fracturing fluid in the whole process of volumetric fracturing job. Based on the actual flow rates in field fracturing operation, the shear history of a fracturing fluid flowing through pipes, perforation and formation fractures was simulated. Meanwhile, the dosage of gel breaker was optimized in an effort to find the concentration of the gel breaker when the lowest damaging to the reservoir is required. Thus, the evaluation of a fracturing fluid should be able to quantify two parameters; sand carrying capacity of the fracturing fluid which satisfy the needs of fracturing job and thorough breaking of the gel some time after the fracturing job is completed. Using the transparent parallel board model, the dynamic sand carrying capacity of a fracturing fluid was investigated, and the test results will provide a design basis for the “full fracture propping” in large scale volumetric fracturing. The results of the new evaluation method show that the compound crosslinked guar gum fracturing fluid and the crosslinked polymer fracturing fluid have the highest viscosity losses when passing through perforations at high flow velocity. The emulsion association fracturing fluid is sensitive to gel breaker, if the formation damage caused by gel breaking process is low, the dynamic sand carrying performance will not be able to satisfy the needs of placing proppant particles into the distal end in a fracture. A low concentration guar gum fracturing fluid treated with optimized amount of gel breaker will have good dynamic sand carrying capacity at flow rates prevailing in field operations, and thus satisfy the technical goals of placing proppants into the distal end of a fracture.

-

表 1 现场施工剪切速率计算

测试条件 测试阶段 剪切速率/s−1 剪切时间/min 3500 m, 16 m3/min 井筒剪切阶段 1519.60 2.53 15 mm 过单炮眼阶段 22132.36 瞬间 15 mm, 10 m 缝内剪切 177.08 125.00 表 2 室内过炮眼模拟测试参数

驱动压力/MPa 孔眼/mm 流量/(mL·s−1) 剪切速率/s−1 3 1.5 60 22635.4 表 3 室内平行板动态测试参数

单裂缝 动态

缝宽/

mm动态

缝高/

m平行板 平行板

缝宽/

mm平行

板高/

m15 10 5 0.2 缝内线速度/(m·s−1) 0.889 0.750 0.667 0.556 0.500 施工排量/(m3·min−1) 16.0 13.5 12.0 10.0 9.0 室内测试流量/(L·h−1) 3200 2700 2400 2000 1800 表 4 低浓度胍胶压裂液体系破胶性能优化

t破胶/

hT/

℃低浓度胍胶压裂液体系(配方3) 过硫酸铵/(mg·L−1) 10 15 20 30 40 50 60 80 100 0.5 85 冻胶 冻胶 冻胶 冻胶 冻胶 冻胶 拉丝 拉丝 拉丝 1 冻胶 冻胶 冻胶 冻胶 弱胶 弱胶 拉丝 拉丝 4.92 2 冻胶 弱胶 弱胶 弱胶 弱胶 拉丝 5.01 3.33 3.18 4 弱胶 弱胶 弱胶 水化含残胶 水化含残胶 水化含残胶 6 弱胶 弱胶 弱胶 水化含残胶 水化含残胶 6.11 24 弱胶 弱胶 水化含残胶 水化含残胶 7.31 4.31 48 水化含残胶 水化含残胶 水化含残胶 水化含残胶 3.21 72 水化含残胶 水化含残胶 水化含残胶 水化含残胶 120 14.98 13.88 10.04 6.99 168 14.21 12.97 9.85 6.71 表 5 乳液缔合物压裂液体系破胶性能优化

t破胶/

hT/

℃乳液缔合物压裂液体系(配方2) 过硫酸铵/(mg·L−1) 2.5 5 7.5 10 12.5 25 50 75 100 0.5 85 拉丝 拉丝 拉丝 拉丝 14.33 5.07 4.71 3.06 2.84 1 33.96 28.67 13.66 10.84 8.21 4.15 2.73 2.28 2.45 2 32.01 21.47 9.73 5.46 4.28 4 15.30 10.21 6.11 4.84 6 14.06 9.15 5.31 24 13.75 5.08 2.31 48 13.31 4.21 72 10.92 120 10.81 168 10.02 表 6 平行板压裂液动态携砂性能测试结果

压裂液

类型AV/

mPa·s

(室温170 s−1)施工

排量/

m3·min−1测试

流速/

L·h−1测试

时间/

s动态沉

降速率/

cm·s−1低浓度

胍胶压

裂液66a 16 3200 600 无明显沉砂 13.5 2700 600 无明显沉砂 12 2400 600 无明显沉砂 10 2000 600 无明显沉砂 9 1800 600 无明显沉砂 39b 16 3200 600 0.00598 13.5 2700 600 0.00641 12 2400 600 0.00672 10 2000 480 0.00706 9 1800 300 0.00982 乳液缔

合压裂

液体系45c 16 3200 480 无明显沉砂 13.5 2700 480 无明显沉砂 12 2400 480 无明显沉砂 10 2000 300 0.00479 9 1800 300 0.00769 30d 16 3200 600 0.00725 13.5 2700 600 0.00788 12 2400 600 0.00833 10 2000 600 0.01192 9 1800 480 0.01351 注:a:依据低浓度胍胶压裂液体系添加 40 mg/L 破胶剂流变性能测试结果;b:依据低浓度胍胶压裂液体系添加 50 mg/L 破胶剂流变性能测试结果;c:依据未添加破胶剂乳液缔合压裂液体系流变性能测试结果;d:依据添加 5 mg/L 破胶剂乳液缔合压裂液体系流变性能测试结果 -

[1] RAE. P, DI G. Fracturing fluids and breaker systems-a review of the state-of-the-art[R]. SPE 37359, 1996. [2] 蒋廷学,卞晓冰,王海涛,等. 深层页岩气水平井体 积压裂技术[J]. 天然气工业,2017,37(1):90-96. doi: 10.3787/j.issn.1000-0976.2017.01.011JIANG Tingxue, BIAO Xiaobing, WANG Haitao, et al. Volume fracturing of deep shale gas horizontal wells[J]. Natural Gas Industry, 2017, 37(1):90-96. doi: 10.3787/j.issn.1000-0976.2017.01.011 [3] 周仲建,于世虎,张晓虎. 页岩气用复合增效压裂液的研究与应用[J]. 钻采工艺,2019(4):89-92. doi: 10.3969/J.ISSN.1006-768X.2019.04.13ZHOU Zhongjian, YU Shihu , ZHANG Xiaohu. R&D composite synergistic fracturing fluid for shale gas and application[J]. Drilling &Production Technology, 2019(4):89-92. doi: 10.3969/J.ISSN.1006-768X.2019.04.13 [4] 周德胜,张争,惠峰,等. 滑溜水压裂主裂缝内支撑剂输送规律实验及数值模拟[J]. 石油钻采工艺,2017,39(4):499-508.ZHOU Desheng, ZHANG Zheng, HUI Feng, et al. Experiment and numerical simulation on transportation laws of proppant in major fracture during slick water fracturing[J]. Oil Drilling & Production Technology, 2017, 39(4):499-508. [5] SY/T5107-2016: 2017《水基压裂液性能评价方法》.SY/T5107-2016 :2017, The evaluation measurement for properties of water-based fracturing fluid. [6] LI L, ZHOU J, SUN H, et al. A novel slow-release rheology modifier for well treatment fluids[M]. 2014. [7] 米卡尔J. 埃克诺米德斯, 肯尼斯G. 诺尔特. 油藏增产措施: 第三版[M]. 张保平, 蒋阗, 刘立云, 等译. 北京: 石油工业出版社, 2002: 266MICHAEL J. ECONOMIDES , KENNETH G. NOLTE. "Reservoir Stimulation Third Edition"[M]. New York: John Wiley & Sons, 2000. [8] ISO13503-1: 2011《完井液的黏度特性测量》.ISO 13503-1:2011Completion fluids and materials - Part 1: Measurement of viscous properties of completion fluids. [9] ISO13503-4: 2006《增产液和砾石充填静态滤失测量程序》.ISO 13503-4:2006 Petroleum and natural gas industries - Completion fluids and materials - Part 4: Procedure for measuring stimulation and gravel-pack fluid leakoff under static conditions. [10] SY/T 5107-2005: 2006 水基压裂液性能评价方法.SY/T 5107-2005:2006 Recommended practices on measuring the properties of water-based fracturing fluid. [11] 周成裕,陈馥,黄磊光,等. 一种高温抗剪切聚合物压裂液的研制[J]. 钻井液与完井液,2008,25(1):67-68. doi: 10.3969/j.issn.1001-5620.2008.01.022ZHOU Chengyu, CHEN Fu, HUANG Leiguang,. The development of a high temperature and shearing resistant polymer fracturing fluid[J]. Drilling Fluid & Completion Fluid, 2008, 25(1):67-68. doi: 10.3969/j.issn.1001-5620.2008.01.022 [12] 刘通义, 谭坤, 陈光杰. 交联压裂液抗剪切性能评价方法探讨[C]//全国流变学学术会议. 中国化学会;中国力学学会, 2002.LIU Tongyi, TAN Kun , CHEN Guangjie. Discuss for evaluate method of fracturing fluid shear property[C]//. Lang fang: The Seventh National Rheology Conference, 2002. [13] 张国忠,张足斌. 管流液体的有效剪切速率[J]. 油气田地面工程,2000,19(1):1-3. doi: 10.3969/j.issn.1006-6896.2000.01.001ZHANG Guozhon,ZHANG Zubin. The effective shear rate of the fluid flowing through the pipe[J]. Oil-Gas field Surface Engineering, 2000, 19(1):1-3. doi: 10.3969/j.issn.1006-6896.2000.01.001 [14] NASR-EL-DIN H, AL-MOHAMMED A, AL-AAMRI A, et al. A study of gel degradation, surface tension, and their impact on the productivity of hydraulically fractured gas wells[C]//2007. [15] SARWAR M U, CAWIEZEL K E , NASR-EL-DIN H A . Gel degradation studies of oxidative and enzyme breakers to optimize breaker type and concentration for effective break profiles at low and medium temperature ranges[C]. SPE Hydraulic Fracturing Technology Conference - The Woodlands, Texas, USA , 2011.01 [16] 赵莉,胡军,尤颖颖,等. 确定破胶剂加量的动态模拟实验方法的研究和现场应用[J]. 内蒙古石油化工,2020,46(9):16-18.ZHAO Li, HU Jun, YOU Yingying, et al. Study on dynamic simulation experiment method to fix breaker dosage and its field application[J]. Inner Mongolia Petrochemical Industry, 2020, 46(9):16-18. [17] SYT 6376-2008 《压裂液通用技术条件》.SYT 6376-2008, General technical specifications of fracturing fluids. [18] 温庆志,高金剑,刘华,等. 滑溜水携砂性能动态实验[J]. 石油钻采工艺,2015,37(2):97-100.WEN Qingzhi, GAO Jinjian, LIU Hua, et al. Dynamic experiment on slick-water prop-carrying capacity[J]. Oil Drilling & Production Technology, 2015, 37(2):97-100. [19] 黄彩贺. 压裂液携砂性能和交联过程流变动力学研究[D]. 上海: 华东理工大学, 2015HUANG Caihe. Study on the fracturing fluids proppant carrying property and rheo-kinetics of crosslinking process[D]. Shang Hai: East China University of Science and Technology, 2015. [20] GALINDO, TANHEE. "Does higher viscosity improve proppant transport?" [R]. SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, Oklahoma, USA, April 2019. -

下载:

下载: