An Environmentally Friendly Oil Base Mud

-

摘要: 针对目前油基钻井液存在因所含矿物油和处理剂的生物毒性大,而被限制或禁止排放的问题,制备出生物毒性低的油基钻井液基油,合成高效低毒的一体化乳化剂和新型高凝胶改性有机土,并对钻井液处理剂及加量进行优选,最终形成了一套环保型油基钻井液体系。该钻井液体系的生物毒性LC50达到15 000 mg/L以上,生物可降解性好;体系的流变性良好,破乳电压达到800 V以上,高温高压滤失量小于6 mL;钻井液体系能抗5%石膏、5%钻屑和15%盐水污染;该油基钻井液应用性良好,油水比可在60/40~90/10的范围内调节,密度可在1.25~2.0 g/cm3范围内调节,抗温可达220 ℃,高温稳定性良好。研究结果表明,环保型油基钻井液具有低毒环保、可降解等优势,抗污染、抗高温、稳定性强、可调节范围广,完全可满足较复杂地层和环境保护要求高区块对钻井液的要求。Abstract: Mineral oils and several oil base mud additives presently in use are highly biologically toxic and the discharge of oil base muds formulated with them are prohibited or limited. To minimize the toxicity of oil base muds, an environmentally friendly oil base mud was formulated with a weakly biologically toxic base oil, a high efficiency low-toxicity all-in-one emulsifier, a new modified high-gel organophilic clay and other additives developed. The concentrations of these additives were optimized to obtain an oil base mud with satisfactory performance. The oil base mud has LC50 of greater than 15,000 mg/L and is biologically degradable. The oil base mud has good rheology, and its electrical stability is at least 800 V. The HTHP filtration rate is less than 6 mL. This oil base mud is resistant to contamination from 5% gypsum or 5% drilled cuttings or 15% salt water. The oil/water ratio of the mud can be adjusted between 60/40 and 90/10, and the density can be controlled between 1.25 g/cm3 and 2.0 g/cm3. This oil base mud has good high temperature stability, it functions normally at 220 ℃. These properties can satisfy the needs of drilling in wells penetrating complex formations and in area with stringent environment protection requirements.

-

Key words:

- Oil base mud /

- Base oil /

- Emulsifier /

- Biological toxicity /

- Organophilic clay /

- High temperature /

- Settling stability

-

油基钻井液相对于水基钻井液具有抑制水化分散能力强、润滑效果好、抗高温和抗污染能力强以及储层保护性能好等优点,在国内外已广泛应用于高温高压井、大位移水平井等高难度复杂井的勘探开发[1-2]。目前油基钻井液一般用柴油和白油作为基础油,存在芳烃含量较高,环境保护性差,钻屑废弃物处理困难等问题。随着环境保护力度的不断加强,其应用受到一定限制。气制油合成基钻井液以天然气制油作为基油,具备油基钻井液的优点,而且对环境的毒副作用较小。但是,气制油合成基钻井液也存在基油成本较高,乳化和提切困难,在高温下容易稠化,黏度较高、切力较低、重晶石沉降严重等问题[3]。通过制备性能与气制油相似、成本较低的钻井液基油,并研制出生物毒性较低、乳化效果好、使用方便的一体化乳化剂和在基油中分散、凝胶效果好的改性有机土,最后优选出各种油基钻井液添加剂,形成了环保型油基钻井液体系。室内评价表明,该钻井液能满足高环保要求和高温深井、大位移井等复杂地层对钻井液的技术要求。

1. 环保油基钻井液体系的构建

1.1 油基钻井液基油

1.1.1 基油V170制备

在一定温度压力下,对H2∶CO=2∶1的合成气催化进行费托合成反应。对费托合成产品按低(160~220 ℃)、中(220~270 ℃)、高(270~310 ℃)3种温度蒸馏切割成几种馏分油,对高温度馏分油进行异构化(异构化程度≥90%)处理,然后将异构化处理后的高温度馏分油和低、中温度馏分油按一定比例调和,最后将调和的馏分油在160 ℃下进行蒸馏得到基油V170。

1.1.2 理化性能

表1是几种油基基油的理化性能。

表 1 油基钻井液基油的理化性能基油 闪点/

℃ρ/

g·cm−3运动黏度/

mm2/s芳烃含

量/%苯胺

点/℃倾点/

℃V170 85 0.76 20.0 <0.01 >85 −24 0#柴油 80 0.76 58.4 19.40 −3 5#白油 112 0.82 32.9 3.90 60 0 Saraline 185V 110 0.81 28.0 <0.01 >85 −20 注:密度为20 ℃测得,运动黏度为40 ℃测得 从表1可以看出,基油V170的闪点大于80 ℃,能保证储存和现场使用的安全;运动黏度较低,有利于实现钻井液流变性的调节;芳烃含量较低、苯胺点较高,说明基油的环保性较好;倾点较低,基油在低温下流动性较好,有利于低温储存和施工。总体来说,作为油基钻井液基油,V170明显优于白油和柴油,与天然气制油Saraline 185V的性能相当。

由表1还可以看出,基油V170的闪点大于80 ℃,能保证储存和现场使用的安全;运动黏度较低,有利于钻井液流变性的调节;芳烃含量较低、苯胺点较高,说明基油的环保性较好;倾点较低,基油在低温下流动性较好,有利于低温储存和施工。总体来说,作为油基钻井液基油,V170明显优于白油和柴油,与天然气制油Saraline 185V的性能相当。

1.1.3 生物毒性

依据GB/T 18420.2—2009《海洋石油勘探开发污染物生物毒性 第二部分:检测方法 卤虫法》,采用天津丰年公司海水孵化24 h的商用卤虫幼体在96 h的半数致死浓度LC50值来评价基油的生物毒性。卤虫法检测生物毒性具有与糠虾法相关性良好、操作简单方便、重复率高、易于大批毒性测试的优点[4-6]。测量的0#柴油、5#白油、V170和Saraline 185V的LC50值分别为3000、12 000、25 000和24 000 mg/L。说明V170基油生物毒性与Saraline 185V相当,高于一级海域容许值15 000 mg/L。

1.2 油基钻井液核心处理剂

1.2.1 环保油基乳化剂

市面常用乳化剂主要针对柴油基和白油基钻井液,对V170基油的乳化效果较差,且生物毒性较大,不太适合在环保型油基钻井液体系中使用。而且在作业过程中需同时加入主乳化剂和辅乳化剂,钻井液配制程序复杂,不利于现场施工。因此,研制出了高效低毒一体化乳化剂EF-EMUL。EF-EMUL是非离子型表面活性剂,同时具有亲水和亲油基团,HLB值在3~8之间,乳化效果高效;引入抗温性强的如酰胺基类基团,同时在亲油基团中引入不饱和双键来提高乳化剂的生物降解性,减少乳化剂生物毒性;具有较多亲水性吸附基团,来增强乳化剂和亲水性固相之间的吸附力,从而在提高钻井液流变性能的同时,生物毒性也相对较小[7]。对乳化剂的生物毒性和在体系中的作用进行评价[8]。评价配方如下,热滚条件为150 ℃、16 h,结果见表2。

表 2 乳化剂EF-EMUL对钻井液生物毒性和性能的影响EF-EMUL/

%LC50/

mg·L−1实验

条件φ600/

φ300AV/

mPa·sPV/

mPa·sYP/

PaES/

V0 >30 000 热滚前 76/45 38 31 7 523 热滚后 82/47 41 35 6 412 1 3800 热滚前 74/45 37 29 8 567 热滚后 76/45 38 31 7 602 2 2000 热滚前 84/50 42 34 8 766 热滚后 90/51 45 39 6 658 3 1400 热滚前 90/55 45 35 10 863 热滚后 86/51 43 35 8 850 4 800 热滚前 96/60 48 36 12 937 热滚后 90/53 45 37 8 930 注:热滚条件为150 ℃、16 h V170基油+26%CaCl2盐水+EF-EMUL +2%有机土+3%降滤失剂+3%CaO+重晶石,密度为1.8 g/cm3,油水比为85∶15

通过表2可以看出,3%加量的乳化剂LC50值为1400 mg/L,生物毒性低于市面常用的DF-FSEMUL等乳化剂;乳状液的破乳电压随着乳化剂加量增加而升高,体系的沉降稳定性也明显提高;当乳化剂的加量控制在3%时,乳化液的破乳电压达到800 V以上,流动性良好。

1.2.2 环保油基有机土

有机土既可提高体系的黏度和切力,又能降低滤失量,是油基钻井液体系不可缺少的添加剂[9]。现用有机土多用于柴油和白油,在V170基油中的胶体率较低。笔者研制出高分散凝胶型、适用于V170基油的有机土MOGEL。制备有机土关键在于优选高质量钙基膨润土和钠基膨润土有机改性剂。所以选择离子交换量大的钙质蒙脱土,加入一定量的Na2CO3进行钠化改性后优选合适的有机改性剂。有机改性剂目前主要用的是烷基链中碳原子数为12~18的季铵盐阳离子,采用N-十八烷基对苯二甲酸钠作为有机改性剂。为了提升制备有机土在油基基油中的分散凝胶效果,在加入N-十八烷基对苯二甲酸钠的同时可以加入异构十三醇聚氧乙烯醚硫酸盐和小分子聚乙二醇。N-十八烷基对苯二甲酸钠通过离子交换进入钠基土层间,而异构十三醇聚氧乙烯醚硫酸盐可以通过浓度差进入钠基土层间,小分子聚乙二醇的羟基和羰基,可以与膨润土间层产生氢键桥接,增强制备蒙脱土的稳定性[10-12]。与单一季铵盐阳离子型有机土相比,新型改性有机土MOGEL层间间距更大、剥离明显,使制备的有机土具有更好的热稳定性和凝胶性能[13-14],而且生物毒性很低。对有机土MOGEL进行性能评价,将加量为2%的有机土MOGEL分别加入基油中,测量胶体率,然后在150 ℃下热滚16 h,结果见表3。

表 3 加入2%改性有机土后油基钻井液的性能基础油 LC50/

mg·L−1实验

条件φ600/

φ300AV/

mPa·sPV/

mPa·sYP/

Pa胶体

率/%柴油 >30 000 热滚前 26/17.0 13 9.0 4 98 热滚后 24/15.5 12 8.5 3 白油 >30 000 热滚前 28/18.5 14 9.5 4 88 热滚后 26/18.0 13 8.0 5 V170基油 >30 000 热滚前 28/19.0 14 9.0 5 80 热滚后 26/17.0 13 9.0 4 注:热滚条件为150 ℃、16 h 从表3可以看出,制备的有机土MOGEL在普通柴油、白油中具有良好的成胶性能,在V170基油中胶体率在80%以上。改性有机土老化前后的切力、黏度变化不大,说明该有机土具有良好的凝胶稳定性和抗温性能。

1.3 油基钻井液配方优化

以V170基油、EFEMUL和MOGEL为核心,优选合适的降滤失剂和封堵剂。根据如下基础配方对不同种类的降滤失剂、封堵剂[15-17]的生物毒性和在钻井液中性能进行评价,热滚条件为150 ℃、16 h,如表4所示。

表 4 处理剂优选实验处理剂 LC50/

mg·L−1AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL降滤失剂 HIFLO-1 8000 61 51 10 1507 4.8 HIFLO-2 30 000 65 55 10 1103 7.8 HIFLO-3 40 000 40 33 7 976 4.2 HIFLO-4 50 000 70 64 6 1167 8.2 封堵剂 HISEAL-1 30 000 48 40 8 984 4.2 HISEAL-2 40 000 46 38 8 1053 3.6 HISEAL-3 50 000 52 43 9 873 4.6 HISEAL-4 40 000 44 36 8 905 4.4 注:热滚条件为150 ℃、16 h V170基油+3.0%EFEMUL+2%MOGEL+3%降滤失剂+3%封堵剂+ 3%CaO+26%CaCl2盐水+重晶石,密度为1.8 g/cm3,油水比为85∶15

由表4可以看出,HIFLO-3的高温高压滤失量和生物毒性较小,所以选用HIFLO-3作为体系的降滤失剂;HISEAL-2的高温高压滤失量较小,生物毒性较低,所以选择HISEAL-2作为体系的封堵剂。

最后构建环保油基钻井液配方为V170基油+3.0%EFEMUL+2%MOGEL+3%HIFLO-3+3%HISEAL-2+26%氯化钙盐水+3%氧化钙+重晶石。

2. 环保油基钻井液性能评价

2.1 基本性能

对环保型油基钻井液体系在不同密度、不同温度、不同油水比情况下的基本性能进行评价[18]。

2.1.1 加重性能

测定了该体系在不同密度下的性能,结果见表5,该体系配方油水比为85∶15,在150 ℃下热滚老化16 h。

表 5 不同密度环保型油基钻井液性能ρ/

g·cm−3实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL1.25 热滚前 30.5 25 5.5 554 3.8 热滚后 28.0 22 6.0 678 1.5 热滚前 37.0 31 6.0 846 3.2 热滚后 38.0 30 8.0 691 1.8 热滚前 46.0 39 7.0 764 3.0 热滚后 50.0 41 9.0 1145 2.0 热滚前 52.0 45 7.0 927 3.6 热滚后 60.0 50 10.0 831 注:热滚条件为150 ℃、16 h 从表5可以看出,该钻井液在密度为1.25~2.0 g/cm3的范围内,流变性能变化较小,破乳电压较高,说明乳化体系的稳定性较好;同时,不同密度的高温高压滤失量小于4 mL,有利于解决泥页岩地层因滤失过大引起的井壁稳定问题。

2.1.2 油水调节性能

油包水钻井液的油相含量高,体系较稳定,滤失量较小,有利于钻井液性能的发挥和储层保护,但其黏度较小,不利于悬浮钻屑和重晶石等。油基钻井液的密度为1.8 g/cm3,在150 ℃下热滚16 h后测定其流变性、滤失量以及电稳定性等性能来确定油水比范围,结果见表6。

表 6 不同油水比环保型油基钻井液性能油水比 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL90∶10 热滚前 38 32 6 847 4.0 热滚后 40 33 7 1099 85∶15 热滚前 46 38 8 764 3.2 热滚后 50 40 10 1145 80∶20 热滚前 52 43 9 723 4.8 热滚后 60 51 10 1126 70∶30 热滚前 64 54 10 676 5.2 热滚后 68 56 12 988 60∶40 热滚前 69 60 9 532 7.6 热滚后 71 63 8 657 注:热滚条件为150 ℃、16 h 从表6可知,油水比降低后,体系的表观黏度、塑性黏度有所增大,破乳电压小幅度降低,高温高压滤失量增大,体系的流变性变化较大,稳定性降低,但基本能保持一定的性能,说明体系的乳化稳定性较好,能抗地层水侵入,有利于现场通过油水比调控钻井液性能。

2.1.3 抗温性能

抗高温性能是评价油基钻井液最主要的性能之一,抗温性能强的钻井液能满足一些高温深井的要求。表7是不同温度下油基钻井液体系的性能。

表 7 不同温度环保型油基钻井液性能T/

℃实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL150 热滚前 46 40 6 764 3.2 热滚16 h 50 42 8 1145 160 热滚前 47 40 7 865 4.4 热滚16 h 59 51 8 1233 180 热滚前 45 39 6 945 5.4 热滚16 h 68 61 7 1245 200 热滚前 48 41 7 768 6.2 热滚16 h 62 56 6 1135 220 热滚前 46 39 7 857 7.6 热滚16 h 72 68 4 988 由表7可以看出,该钻井液体系在220 ℃下流变性好,破乳电压较高,高温高压滤失量小于8 mL,所以该体系能够适用于高温高压深井等复杂井中。

2.2 抗污染评价

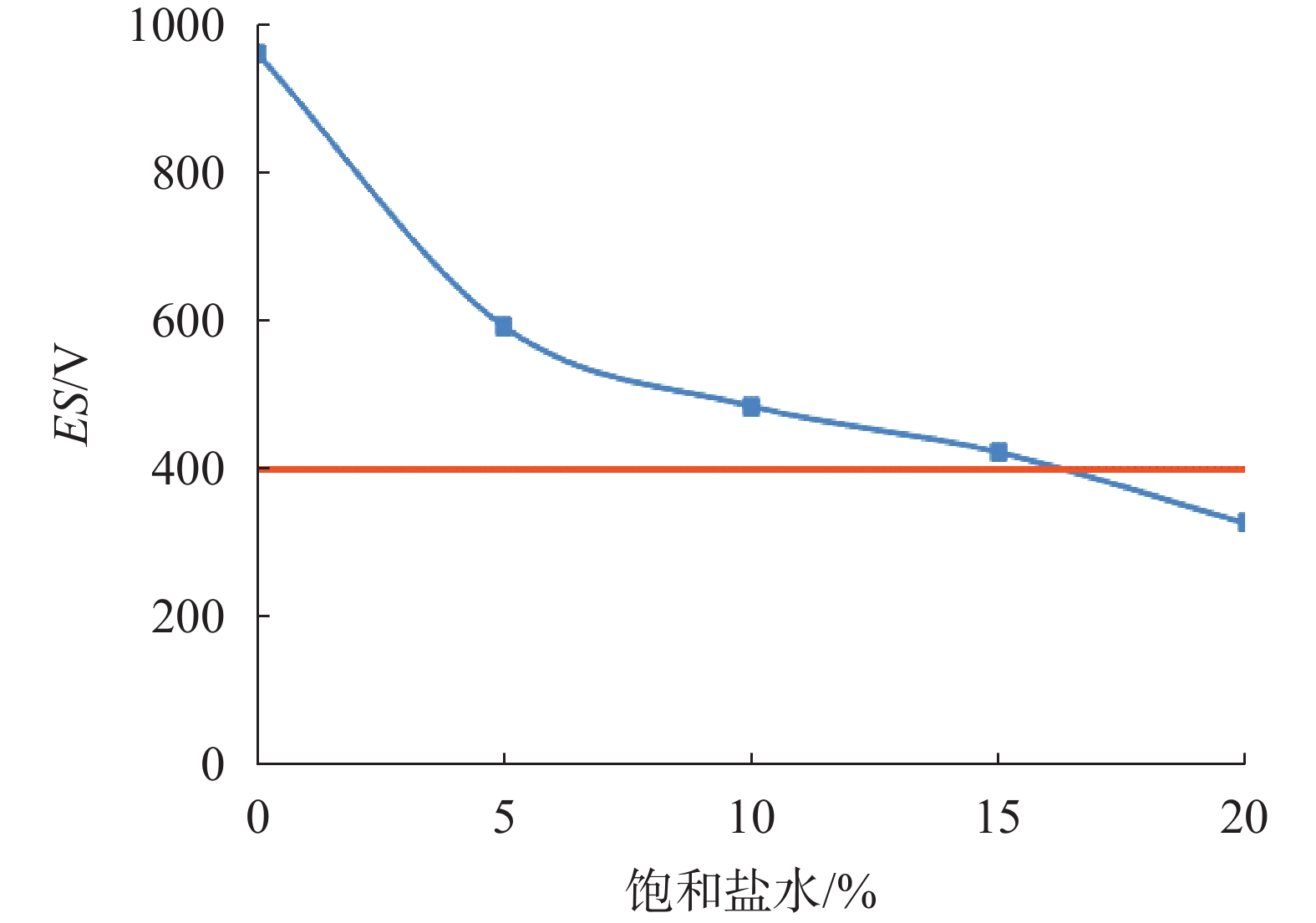

在钻井过程中,地层岩石里的石膏、岩盐、芒硝等可溶性盐类经常会进入钻井液中,使钻井液发生污染而影响性能。油基钻井液应该具有一定的抗盐侵性能,以保证发生盐侵后仍能正常钻进[19-21]。在配制的钻井液中加入CaSO4、NaCl、钻屑等污染物,测定其流变性、滤失量以及电稳定性等性能,以评价钻井液的抗污染性能,见表8。由表8可知,钻井液在受到5%CaSO4、NaCl、钻屑污染后,破乳电压有所下降,但流变性能变化较小,说明钻井液具有较强的抗污染能力。又在钻井液中分别加入不同浓度的饱和盐水,通过测量污染后钻井液性能来评价体系抗盐水污染性能,见图1。

表 8 体系抗污染性能评价污染物 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

V备注 5%CaSO4 热滚前 61 55 6 622 无沉淀 污染后 65 57 8 603 热滚后 73 70 3 723 5%NaCl 热滚前 54 48 6 701 无沉淀 污染后 62 55 7 621 热滚后 75 70 5 555 5%钻屑 热滚前 62 55 7 662 少量沉淀 污染后 65 57 8 733 热滚后 85 73 12 1001 注:热滚条件为150 ℃、16 h 由图1可以看出,当饱和盐水加量在10%及以下时,体系的破乳电压逐渐下降但还在400 V以上,流变性能也能保持基本稳定;当加量达到15%时,体系增稠严重,老化后产生沉淀;当加量达到20%时,体系才开始破乳。说明体系在部分含盐膏层和海水侵入的地层也能使用。

2.3 高温沉降稳定性评价

油基钻井液一般在现场的使用周期比较长,这就要求钻井液在高温情况下具有良好的沉降稳定性。通过测定在150 ℃下静置不同时间钻井液的流变性以及电稳定性等性能来评价其高温稳定性,见表9。由表9可知,随着静置时间的增长,破乳电压升高后比较平稳,表观黏度和塑性黏度均有一定程度增大,高温高压滤失量升高但小于8 mL,体系仍然能够流动,静置超过168 h后体系的沉降因子小于0.52,说明体系的高温沉降稳定性良好,能够满足高温高压深井长时间作业的技术要求。

表 9 环保油基钻井液高温稳定性评价t静置/

hAV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL沉降因

子SF备注 0 48 41 7 642 / 0.502 / 16 57 50 7 941 5.0 0.504 流动性较好 24 61 53 8 1033 5.6 0.505 流动良好 48 66 55 11 1057 6.4 0.507 流动良好 72 71 59 12 1166 6.8 0.518 有少量沉淀 168 76 66 10 1031 7.6 0.510 稍稠,部分

沉淀2.4 抑制性能评价

钻遇泥页岩等易水化地层,需要提高钻井液的抑制性能,减少地层的水化膨胀,井眼掉块失稳等问题。环保油基钻井液的页岩线性膨胀性能和滚动回收性能评价如图2所示,可以看出,环保油基钻井液滚动回收率比白油钻井液还略高,线性膨胀性较低,说明环保油基钻井液体系的抑制性能很好。

2.5 环保性能评价

测得环保油基钻井液LC50值为18 500 mg·L−1,浸出液的BOD5/COD值为12.3%,可知该环保型油基钻井液符合一级海区的钻井液生物毒性容许值要求,而且生物可降解,钻井液体系可以在环保要求高的海域等区块作业。

3. 结论

1. 通过对基油制备和乳化剂、有机土的研制,优化形成环保型油基钻井液配方为V170基油+3.0%EFEMUL+2%MOGEL+3%HIFLO-3+3%CaO+3%HISEAL-2+26%CaCl2盐水+重晶石。

2. 该环保油基钻井液基本性能良好,密度为1.25~2.0 g/cm3,油水比为90∶10~60∶40,抗温性能达到220 ℃,抗污染和高温沉降稳定性能强,生物毒性LC50大于15 000 mg/L。体系能够满足高温高压井、大位移井等多种复杂结构井和复杂地层下的钻井液技术需求,而且环保性能好,可在环保要求高的海域进行应用,具有良好的应用前景。

-

表 1 油基钻井液基油的理化性能

基油 闪点/

℃ρ/

g·cm−3运动黏度/

mm2/s芳烃含

量/%苯胺

点/℃倾点/

℃V170 85 0.76 20.0 <0.01 >85 −24 0#柴油 80 0.76 58.4 19.40 −3 5#白油 112 0.82 32.9 3.90 60 0 Saraline 185V 110 0.81 28.0 <0.01 >85 −20 注:密度为20 ℃测得,运动黏度为40 ℃测得 表 2 乳化剂EF-EMUL对钻井液生物毒性和性能的影响

EF-EMUL/

%LC50/

mg·L−1实验

条件φ600/

φ300AV/

mPa·sPV/

mPa·sYP/

PaES/

V0 >30 000 热滚前 76/45 38 31 7 523 热滚后 82/47 41 35 6 412 1 3800 热滚前 74/45 37 29 8 567 热滚后 76/45 38 31 7 602 2 2000 热滚前 84/50 42 34 8 766 热滚后 90/51 45 39 6 658 3 1400 热滚前 90/55 45 35 10 863 热滚后 86/51 43 35 8 850 4 800 热滚前 96/60 48 36 12 937 热滚后 90/53 45 37 8 930 注:热滚条件为150 ℃、16 h 表 3 加入2%改性有机土后油基钻井液的性能

基础油 LC50/

mg·L−1实验

条件φ600/

φ300AV/

mPa·sPV/

mPa·sYP/

Pa胶体

率/%柴油 >30 000 热滚前 26/17.0 13 9.0 4 98 热滚后 24/15.5 12 8.5 3 白油 >30 000 热滚前 28/18.5 14 9.5 4 88 热滚后 26/18.0 13 8.0 5 V170基油 >30 000 热滚前 28/19.0 14 9.0 5 80 热滚后 26/17.0 13 9.0 4 注:热滚条件为150 ℃、16 h 表 4 处理剂优选实验

处理剂 LC50/

mg·L−1AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL降滤失剂 HIFLO-1 8000 61 51 10 1507 4.8 HIFLO-2 30 000 65 55 10 1103 7.8 HIFLO-3 40 000 40 33 7 976 4.2 HIFLO-4 50 000 70 64 6 1167 8.2 封堵剂 HISEAL-1 30 000 48 40 8 984 4.2 HISEAL-2 40 000 46 38 8 1053 3.6 HISEAL-3 50 000 52 43 9 873 4.6 HISEAL-4 40 000 44 36 8 905 4.4 注:热滚条件为150 ℃、16 h 表 5 不同密度环保型油基钻井液性能

ρ/

g·cm−3实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL1.25 热滚前 30.5 25 5.5 554 3.8 热滚后 28.0 22 6.0 678 1.5 热滚前 37.0 31 6.0 846 3.2 热滚后 38.0 30 8.0 691 1.8 热滚前 46.0 39 7.0 764 3.0 热滚后 50.0 41 9.0 1145 2.0 热滚前 52.0 45 7.0 927 3.6 热滚后 60.0 50 10.0 831 注:热滚条件为150 ℃、16 h 表 6 不同油水比环保型油基钻井液性能

油水比 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL90∶10 热滚前 38 32 6 847 4.0 热滚后 40 33 7 1099 85∶15 热滚前 46 38 8 764 3.2 热滚后 50 40 10 1145 80∶20 热滚前 52 43 9 723 4.8 热滚后 60 51 10 1126 70∶30 热滚前 64 54 10 676 5.2 热滚后 68 56 12 988 60∶40 热滚前 69 60 9 532 7.6 热滚后 71 63 8 657 注:热滚条件为150 ℃、16 h 表 7 不同温度环保型油基钻井液性能

T/

℃实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL150 热滚前 46 40 6 764 3.2 热滚16 h 50 42 8 1145 160 热滚前 47 40 7 865 4.4 热滚16 h 59 51 8 1233 180 热滚前 45 39 6 945 5.4 热滚16 h 68 61 7 1245 200 热滚前 48 41 7 768 6.2 热滚16 h 62 56 6 1135 220 热滚前 46 39 7 857 7.6 热滚16 h 72 68 4 988 表 8 体系抗污染性能评价

污染物 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaES/

V备注 5%CaSO4 热滚前 61 55 6 622 无沉淀 污染后 65 57 8 603 热滚后 73 70 3 723 5%NaCl 热滚前 54 48 6 701 无沉淀 污染后 62 55 7 621 热滚后 75 70 5 555 5%钻屑 热滚前 62 55 7 662 少量沉淀 污染后 65 57 8 733 热滚后 85 73 12 1001 注:热滚条件为150 ℃、16 h 表 9 环保油基钻井液高温稳定性评价

t静置/

hAV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL沉降因

子SF备注 0 48 41 7 642 / 0.502 / 16 57 50 7 941 5.0 0.504 流动性较好 24 61 53 8 1033 5.6 0.505 流动良好 48 66 55 11 1057 6.4 0.507 流动良好 72 71 59 12 1166 6.8 0.518 有少量沉淀 168 76 66 10 1031 7.6 0.510 稍稠,部分

沉淀 -

[1] 王中华. 国内外油基钻井液研究与应用进展[J]. 断块油气田,2011,18(4):533-537.WANG Zhonghua. Research and application progress of oil-based drilling fluid at home and abroad[J]. Fault-Block Oil & Gas Field, 2011, 18(4):533-537. [2] 石磊. 适合海洋深水钻井的全油钻井液体系研究[J]. 内蒙古石油化工,2012(1):1-2.SHI Lei. Research on all oil drilling fluid system suitable for offshore deep water drilling[J]. Inner Mongolia Petrochemical Industry, 2012(1):1-2. [3] 王茂功,徐显广,孙金声,等. 气制油合成基钻井液关键处理剂研制与应用[J]. 钻井液与完井液,2016,33(3):30-34. doi: 10.3969/j.issn.1001-5620.2016.03.006WANG Maogong, XU Xianguang, SUN Jinsheng, et al. Development and application of key treatment agent for synthetic drilling fluid from gas to oil[J]. Drilling Fluid & Completion Fluid, 2016, 33(3):30-34. doi: 10.3969/j.issn.1001-5620.2016.03.006 [4] 黄雪静,崔茂荣,周长虹,等. 钻井液生物毒性评价方法对比[J]. 气田环境保护,2006,16(4):25-27.HUANG Xuejing, CUI Maorong, ZHOU Changhong, et al. Comparson of biological toxicity assessment methods for drilling fluids[J]. Environmental Protection of Oil & Gas Fields, 2006, 16(4):25-27. [5] 刘丽萍,褚春莹,张前前,等. 卤虫在钻井液毒性检测中的应用[J]. 中国海洋大学学报,2010,40(9):96-100.LIU Liping, CHU Chunying, ZHANG Qianqian, et al. Assessment of biotoxicity of drilling fluids using artemia salina[J]. Periodical of Ocean University of China, 2010, 40(9):96-100. [6] 尹翠玲,张秋丰,赵文,等. 钻井液对四种水生生物的急性毒性研究[J]. 水产科学,2015,34(1):53-57.YIN Cuiling, ZHANG Qiufeng, ZHAO Wen, et al. Acute toxicity of drilling fluids to four species of aquatic organisms[J]. Fisheries Science, 2015, 34(1):53-57. [7] EVANS N, LANGLOIIS B, AUDIBERT-HAYET A, et al. High performance emulsifiers for synthetic based muds[J]. Society of Petroleum Engineers, 2000. [8] 王学川,邱白玉. 表面活性剂的毒性问题[J]. 日用化学品科学,2005,28(6):22-26. doi: 10.3969/j.issn.1006-7264.2005.06.008WANG Xuechuan, QIU Baiyu. Problems of surfactants' toxicity[J]. Detergent & Cosmetics, 2005, 28(6):22-26. doi: 10.3969/j.issn.1006-7264.2005.06.008 [9] 曹杰,邱正松,徐加放,等. 有机土研究进展[J]. 钻井液与完井液,2012,29(3):81-84, 98. doi: 10.3969/j.issn.1001-5620.2012.03.025CAO Jie, QIU Zhengsong, XU Jiafang, et al. Study progresses in organic clay[J]. Drilling Fluid & Completion Fluid, 2012, 29(3):81-84, 98. doi: 10.3969/j.issn.1001-5620.2012.03.025 [10] 胡成军,可点,周书胜,等. 一种气制油合成基钻井液用有机土的合成与评价[J]. 化学工程与装备,2020(3):30-32.HU Chengjun, KE Dian, ZHOU Shusheng, et al. Synthesis and evaluation of an organic soil for drilling fluid based on gas to oil synthesis[J]. Chemical Engineering & Equipment, 2020(3):30-32. [11] 宋海明,李静静,陈杰. 低毒油包水钻井液用耐高温有机土的研制[J]. 钻井液与完井液,2015,32(3):13-15.SONG Haiming,LI Jingjing,CHEN Jie. Development of a high temperature low toxicity W/O organophilic clay[J]. Drilling Fluid & Completion Fluid, 2015, 32(3):13-15. [12] 孙中富,王卫东,李小迪,等. 生物柴油钻井液用有机土的制备[J]. 钻井液与完井液,2015,32(6):11-13.SUN Zhongfu,WANG Weidong,LI Xiaodi,et al. Study on organophilic clay for bio-diesel oil base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2015, 32(6):11-13. [13] 管俊芳,陆琦,陈林丽,等. 膨润土深加工的研究进展[J]. 化工矿产地质,2002,24(1):23-27. doi: 10.3969/j.issn.1006-5296.2002.01.005GUAN Junfang, LU Qi, CHEN Linli, et al. Present study and prospect of further processing of bentonite[J]. Geology of Chemical Minerals, 2002, 24(1):23-27. doi: 10.3969/j.issn.1006-5296.2002.01.005 [14] 崔明磊. 抗高温白油基钴井液用有机土的研制及性能研究[J]. 广州化工,2014,42(6):70-72. doi: 10.3969/j.issn.1001-9677.2014.06.026CUI Minglei. The development and testing of new organic clay with high temperature resistant ability in oil- based drilling fluid[J]. Guangzhou Chemical Industry and Technology, 2014, 42(6):70-72. doi: 10.3969/j.issn.1001-9677.2014.06.026 [15] 吴鑫磊,闫丽丽,王立辉,等. 环保型钻井液用降滤失剂研究进展[J]. 钻井液与完井液,2018,35(3):8-16. doi: 10.3969/j.issn.1001-5620.2018.03.002WU Xinlei, YAN Lili, WANG Lihui, et al. Research progress of filtrate reducer for environmental protection drilling fluid[J]. Drilling Fluid & Completion Fluid, 2018, 35(3):8-16. doi: 10.3969/j.issn.1001-5620.2018.03.002 [16] 徐同台,卢淑芹,何瑞兵,等. 钻井液用封堵剂的评价方法及影响因素[J]. 钻井液与完井液,2009,26(2):60-68. doi: 10.3969/j.issn.1001-5620.2009.02.019XU Tongtai, LU Shuqin, HE Ruibing, et al. Methods for evaluating drilling fluid sealing and plugging agents and the influential factors[J]. Drilling Fluid & Completion Fluid, 2009, 26(2):60-68. doi: 10.3969/j.issn.1001-5620.2009.02.019 [17] 王建华,李建男,闫丽丽,等. 油基钻井液用纳米聚合物封堵剂的研制[J]. 钻井液与完井液,2013,30(6):5-8. doi: 10.3969/j.issn.1001-5620.2013.06.002WANG Jianhua, LI Jiannan, YAN Lili, et al. Development of nano polymer plugging agent for oil-based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2013, 30(6):5-8. doi: 10.3969/j.issn.1001-5620.2013.06.002 [18] 庄严,熊汉桥,丁峰,等. 油水比对油基钻井液流变性的影响[J]. 科学技术与工程,2016,16(12):238-242. doi: 10.3969/j.issn.1671-1815.2016.12.039ZHUANG Yan, XIONG Hanqiao, DING Feng, et al. Impact of water / oil ratio on the rheological of oil based drilling fluid[J]. Science Technology and Engineering, 2016, 16(12):238-242. doi: 10.3969/j.issn.1671-1815.2016.12.039 [19] 李建成,杨鹏,关键,等. 新型全油基钻井液体系[J]. 石油勘探与开发,2014,41(4):490-496. doi: 10.11698/PED.2014.04.16LI Jiancheng, YANG Peng, GUAN Jian, et al. New all oil based drilling fluid system[J]. Petroleum Exploration and Development, 2014, 41(4):490-496. doi: 10.11698/PED.2014.04.16 [20] 解宇宁. 低毒环保型油基钻井液体系室内研究[J]. 石油钻探技术,2017,45(1):45-50.XIE Yuning. Experimental study on low-toxicity and environment-friendly oil-based drilling fluids[J]. Petroleum Drilling Techniques, 2017, 45(1):45-50. [21] 李家学,蒋绍宾,晏智航,等. 钻完井液静态沉降稳定性评价方法[J]. 钻井液与完井液,2019,36(5):575-580. doi: 10.3969/j.issn.1001-5620.2019.05.009LI Jiaxue, JIANG Shaobin, YAN Zhihang, et al. Evaluation method of static settlement stability of drilling and completion fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):575-580. doi: 10.3969/j.issn.1001-5620.2019.05.009 期刊类型引用(8)

1. 赵伟,冯小波,沈大均,喻璐,郭劲松,杨文昊,高俊敏. 陆上天然气生产过程中的产污分析及防控策略. 化学工业与工程. 2024(04): 76-87 .  百度学术

百度学术2. 周忠亚. 复兴地区页岩气井油基钻井液井壁稳定和防漏堵漏技术. 钻井液与完井液. 2024(03): 305-317 .  本站查看

本站查看3. 陈晓森,胡文芹,陈宝财,陈璐,安娜. 新型钻井液加重化学剂在石油钻井中的应用. 当代化工. 2024(09): 2050-2053 .  百度学术

百度学术4. 任亮亮,罗健生,李超,徐博韬,郭磊. 油水比对油基/合成基钻井液体系性能的影响. 广州化工. 2023(09): 150-152+163 .  百度学术

百度学术5. 任亮亮,陈晨,李超,何卓芯,胡悦悦,徐博韬,罗健生,高二虎. 加重材料对抗高温高密度合成基钻井液性能的影响. 钻井液与完井液. 2023(05): 551-555 .  本站查看

本站查看6. 郭荣欣,邓超,陈潇,王年禧,刘研萍. 油基钻井固废组分与健康风险的关系分析. 当代化工研究. 2022(24): 15-18 .  百度学术

百度学术7. 李昕潼,郑文武,刘福,孙中伟,王松. 一种致密油气层保护剂的研制与应用. 钻井液与完井液. 2022(05): 565-572 .  本站查看

本站查看8. 张县民,姜雪清,黄宁,刘文堂,郭建华,王中华. 油基钻井液堵漏用共混聚合物研究. 钻井液与完井液. 2021(05): 593-597 .  本站查看

本站查看其他类型引用(2)

-

下载:

下载:

下载:

下载:

百度学术

百度学术