Research on A Water-based Drilling Fluid for Shale Gas Drainage and Strong Blocking

-

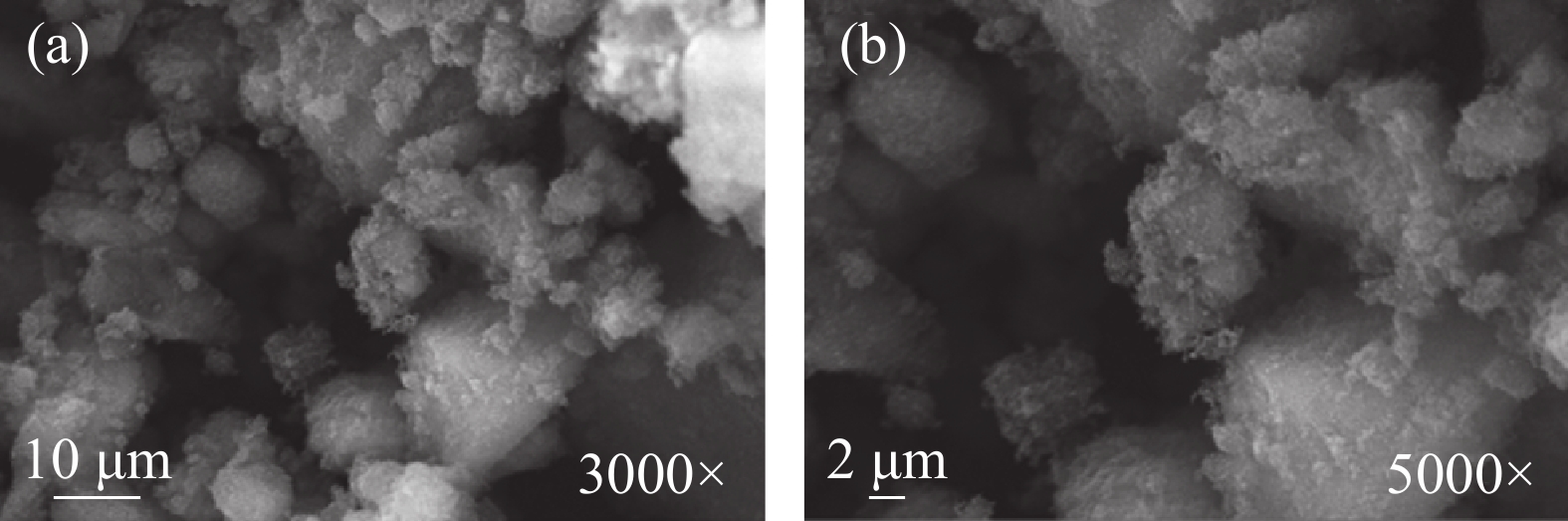

摘要: 四川龙马溪组页岩地层水敏性强、微裂缝及裂缝发育,钻井过程中井壁坍塌事故频发,严重制约了页岩气的高效开发。为解决上述难题,引入了一种既能抑制页岩水化膨胀与分散,又能封堵孔隙、微裂缝及裂缝,同时使页岩表面疏水的改性二氧化硅封堵剂。并以该封堵剂为核心,优选降滤失剂、润滑剂等,研制了一种疏水强封堵水基钻井液。该钻井液既具有良好的流变性、降滤失性,又具有优异的抑制、封堵、疏水和抗污染能力。该钻井液的页岩回收率达90.2%,对40~60目砂床渗入深度仅为1.5 cm,密度为2.2 g/cm3时高温高压滤失量为7.2 mL。Abstract: The shale formation of the Longmaxi Formation in Sichuan is highly water sensitive,with micro-cracks and cracks developed. During the drilling process, the shaft wall collapsed frequently,which severely restricted the efficient development of shale gas.In order to solve the above problems, this paper introduces a hydrophobically modified silica plugging agent that can not only inhibit shale hydration expansion and dispersion, but also block pores,micro-cracks and cracks, and make the shale surface hydrophobic.And with the core of the plugging agent, combined with fluid loss additives, lubricants, etc., a hydrophobic and strong plugging water-based drilling fluid was studied. The drilling fluid not only has good rheology and fluid loss reduction properties, but also has excellent inhibition, plugging,hydrophobic and anti-pollution capabilities. The shale recovery rate of the drilling fluid is 90.2%, the penetration depth into the 40-60 mesh sand bed is only 1.5 cm, and the high temperature and high pressure filtration loss is 7.2 mL when the density is 2.2 g/cm3.

-

Key words:

- Shale /

- Water-based drilling fluid /

- Hydrophobic /

- Plugging /

- Suppression

-

表 1 页岩全岩分析

% 石英 斜长石 方解石 铁白云石 黄铁矿 黏土矿物 66 2 17 7 1 7 表 2 页岩黏土矿物分析

% 高岭石 绿泥石 伊利石 伊/蒙混层 混层比 6 3 64 27 20 表 3 不同密度疏水强封堵钻井液性能(120 ℃、16 h)

ρ/

g/cm3AV/

mPa·sPV/

mPa·sYP/

mPa·sFLAPI/

mLFLHTHP/

mL1.4 42 37 5 3.0 6.0 1.6 51 38 13 3.2 6.2 1.8 62 41 21 3.2 6.2 2.0 72 42 30 4.4 6.8 2.2 81 41 40 5.0 7.2 表 4 疏水强封堵钻井液的抗污染实验(120 ℃、16 h)

污染物 实验条件 AV/mPa·s PV/mPa·s YP/mPa·s Cel/(Pa/Pa) FLAPI/mL FLHTHP/mL 5%氯化钠 老化前 37.5 32.0 5.5 4/11 3.6 老化后 27.5 23.0 4.5 3/11 3.0 8.4 5%膨润土 老化前 57.5 44.0 13.5 10/29 4.4 老化后 49.0 43.0 6.0 4/15 3.2 8.2 5%钻屑 老化前 51.0 44.0 7.0 6/15 3.4 老化后 40.0 36.0 4.0 3/12 2.8 9.0 10%钻屑 老化前 59.0 48.0 11.0 6/13 3.6 老化后 45.5 38.0 7.5 4/14 3.2 9.8 20%钻屑 老化前 74.5 57.0 17.5 11/21 4.6 老化后 49.5 44.0 5.5 4/15 4.0 10.2 -

[1] TIAN Gong. My country's dependence on foreign gas exceeds 45%[J]. Natural Gas Industry, 2019. [2] 常宏. 中国页岩气勘探开发现状与展望[J]. 西部探矿工程,2018,030(8):55-56.CHANG Hong. Current status and prospects of shale gas exploration and development in China[J]. West China Exploration Engineering, 2018, 030(8):55-56. [3] 鲁娇,方向晨,王安杰,等. 国外聚胺类钻井液用页岩抑制剂开发[J]. 现代化工,2012,32(4):1-5.LU Jiao, XIANG Xiangchen, WANG Anjie, et al. Development of shale inhibitors for polyamine drilling fluids abroad[J]. Modern Engineering, 2012, 32(4):1-5. [4] 刘敬平,孙金声. 川滇页岩气水平井水基钻井液技术[J]. 钻井液与完井液,2017,34(2):9-14.LIU Jingping, SUN Jinsheng. Water-based drilling fluid technology for horizontal shale gas wells in Sichuan and Yunnan[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):9-14. [5] 冷朝君. 强抑制性聚合醇钻井液体系在水平井钻井中的应用[J]. 西部探矿工程,2019,31(10):77-79. doi: 10.3969/j.issn.1004-5716.2019.10.027LENG Chaojun. Application of strong inhibitory polyalcohol drilling fluid system in horizontal well drilling[J]. Western Exploration Engineering, 2019, 31(10):77-79. doi: 10.3969/j.issn.1004-5716.2019.10.027 [6] 孙俊,艾加伟,舒义勇,等. FDM-1成膜封堵剂的实验评价及应用[J]. 钻井液与完井液,2020,37(1):54-58.SUN Jun, AI Jiawei, SHU Yiyong,et al. Experimental evaluation and application of FDM-1 film-forming plugging agent[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):54-58. [7] 徐博韬,向兴金,舒福昌,等. 钻井液用成膜封堵剂HCM的性能评价及现场应用[J]. 化学与生物工程,2012,29(9):72-74.XU Botao, XIANG Xingjin, SHU Fuchang, et al. Performance evaluation and field application of film-forming plugging agent HCM for drilling fluid[J]. Chemistry and Biology Engineering, 2012, 29(9):72-74. [8] 张殿印, 吕开河, 吴艳艳. 纳米碳酸钙表面改性方法及在钻井液中的应用. 中国化学会. 中国化学会第十六届胶体与界面化学会议论文摘要集——第二分会: 功能微纳米材料[C]. 中国化学会: 中国化学会, 2017: 10.ZHANG Dianyin, LYU Kaihe, WU Yanyan. Surface modification method of nano-calcium carbonate and its application in drilling fluid. Chinese Chemical Society. Abstracts of the 16th Chinese Chemical Society Colloid and Interface Chemistry Conference——Second Session: Functional micro-nano materials[C]. Chinese Chemical Society: Chinese Chemical Society, 2017: 10. [9] 刘国然. 三种新型堵漏剂[J]. 石油知识,1994(2):23-23.LIU Guoran. Three new plugging agents[J]. Petroleum Knowledge, 1994(2):23-23. [10] 李佳,蒲晓林,戎克生,等. 一种小阳离子有机胺页岩抑制剂的合成及性能研究[J]. 现代化工,2017,37(1):128-131.LI Jia, PU Xiaolin, RONG Kesheng, et al. Synthesis and performance of a small cationic organic amine shale inhibitor[J]. Modern Engineering, 2017, 37(1):128-131. [11] 刘敬平,孙金声. 钻井液活度对川滇页岩气地层水化膨胀与分散影响[J]. 钻井液与完井液,2016,33(2):31-35.LIU Jingping, SUN Jinsheng. Impact of drilling fluids activity on hydration expansion and dispersion in gasshale formations in Chuan or Dian[J]. Drilling Fluid & Completion Fluid, 2016, 33(2):31-35. [12] EDWIN A R, HACKETT J L. A laboratory technique for screening shale swelling inhibitors[C]. SPE 11117-MS, 1982. [13] ZHANG J G, CHENEVERT M E, BAZALI T A, et al. A new gravimetric-swelling test for evaluating water and ion uptake in shales[C]. SPE 89831-MS, 2004. [14] BAKLY O, AHMED S. Custom designed water-based mud systems help minimize hole washouts in high temperature wells-case history from western desert, Egypt[C]. SPE 108292-MS, 2007. [15] 康长瑞,王玲玲. 纳米二氧化硅溶胶粒子的制备研究[J]. 信息记录材料,2012,13(3):8-10.KANG Changrui, WANG Lingling. Preparation study of nanosize silica sol[J]. Information Recording Materials, 2012, 13(3):8-10. -

下载:

下载: