Conductivity Prediction Based on Fracture Closure Theory and 3D Printing

-

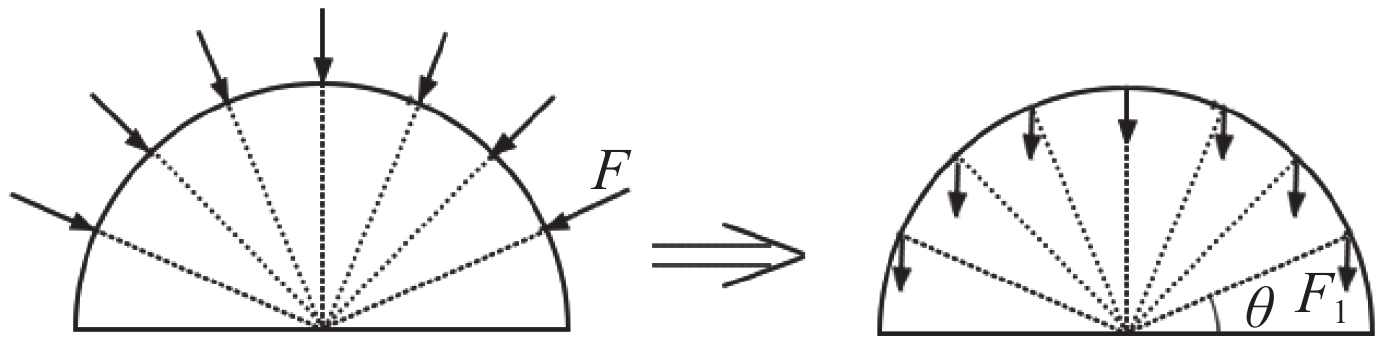

摘要: 酸蚀裂缝导流能力对于酸压方案的优化和产能评估具有十分重要的意义,但是在酸蚀导流能力测试过程中存在高闭合压力下岩心柱破裂情况,影响实验数据的准确性。基于以上问题,综合采用3D扫描和3D打印技术以及受压情况下裂缝闭合理论对酸蚀裂缝导流能力进行研究。首先对岩样进行酸蚀实验,通过逆向建模技术获取到酸蚀后岩心三维模型,采用SLA3D打印技术制备含粗糙壁面的三维岩心模型,对酸蚀岩心和3D打印岩心开展不同围压下渗流实验。运用离散化数据处理方法,结合赫兹接触模型和N-K模型编写导流能力预测界面,使用数值模拟方法反映闭合应力下裂缝形变情况。研究结果表明,结合真实岩体三维数字模型及SLA3D打印技术制备真实岩样,为制作复杂裂缝岩心模型提供了有效途径;酸蚀岩心和3D打印岩心导流能力实验结果、3D打印岩心实验结果和数值模拟结果误差均小于7.7%,数值模拟与碳酸盐岩心实验值的误差小于9.6%;以低闭合压力下实验和模拟结果为基础可以预测高闭合压力下裂缝导流能力,提出的研究方法为定量化表征酸蚀裂缝导流能力提供了可靠途径。Abstract: The conductivity of acid-etched fractures is important to the optimization of acid-fracturing program and the production evaluation of a well. In testing the conductivity of acid-etched fractures, the core column under test may break down at high closure pressures and this will cause the test results to become inaccurate. To deal with this problem, the conductivity of acid-etched fractures is studied using the 3D scanning and 3D printing technologies as well as the theory on the closure of fractures under pressure. In the study, the core samples were first acid etched. Using reverse modeling technology, the 3D model of the acid-etched cores was obtained. Using the SLA3D printing technology, a 3D core model with rough walls was prepared. Then seepage experiment was conducted under different confining pressures on the acid-etched cores and the 3D printed cores. Using the discretized data processing method, the deformation of the fractures under the action of the closure stress was presented using numerical simulation in combination with the Hertz contact model and a conductivity prediction interface programed with the N-K model. The study results show that the 3D digital model of the real rocks and the real core samples made with the SLA3D printing technology together can be an effective way of preparing complex fractured core models. The errors of the conductivity test made on the acid-etched cores and the 3D printed cores, the test made on the 3D printed cores as well as the numerical simulation are all less than 7.7%, and the errors between the numerical simulation results and the carbonate core test results are less than 9.6%. The experiment and numerical simulation results obtained under low closure pressures can be used to predict the conductivity of the fractures under high closure pressures. The study method proposed provides a reliable approach for quantitatively characterizing the conductivity of acid-etched fractures.

-

Key words:

- Carbonate rock /

- Acid-etching fractures /

- 3D printing /

- Flow conductivity

-

表 1 实验设计数据

模拟参数 实际参数 实验室参数 缝长(L) 80 m 50 mm 缝宽(w) 10 mm 2 mm 缝高(h) 80 m 25 mm 流量(Q) 5 m3/min 7.81 mL/min 表 2 打印过程参数

正常层厚/mm 精密制造层厚/mm 打印机精度/mm 打印材料 打印方式 0.1 0.05~0.1 ±0.10 光敏树脂 立体光固化成型 表 3 打印材料性能参数

热变形

温度/℃杨氏模量/

MPa泊松比 吸水率/% 弯曲强度/

MPa38~50 2460 0.25 1~3 67~74 表 4 不同缝面形态酸蚀结果

岩组编号 缝隙形态 酸蚀前形态 酸蚀后形态 三维扫描形态 1# 矿物分布相对均值面

2# 矿物分布非均质面

3# 矿物分布非均质面,裂缝发育

-

[1] 崔波,冯浦涌,荣新明,等. 碳酸盐岩酸液注入段塞组合方式及其协同效应[J]. 大庆石油地质与开发,2023,42(1):100-107.CUI Bo, FENG Puyong, RONG Xinming, et al. Combination mode and its synergistic effect of acid slug injection into carbonate rock[J]. Petroleum Geology & Oilfield Development in Daqing, 2023, 42(1):100-107. [2] 纪国法,张公社,李英存,等. 考虑非达西和气水相渗的页岩气支撑裂缝缝内气相导流能力研究[J]. 科学技术与工程,2016,16(33):34-39.JI Guofa, ZHANG Gongshe, LI Yingcun, et al. Research of gas phase conductivity under non-Darcy and gas-water flow condition in shale gas reservoir propped fracture[J]. Science Technology and Engineering, 2016, 16(33):34-39. [3] 纪国法,张公社,许冬进,等. 页岩气体积压裂支撑裂缝长期导流能力研究现状与展望[J]. 科学技术与工程,2016,16(14):78-88.JI Guofa, ZHANG Gongshe, XU Dongjin, et al. Research and prospect of long-term fracturing conductivity in volumetric fracturing for shale gas reservoir[J]. Science Technology and Engineering, 2016, 16(14):78-88. [4] 郑昕. 考虑壁面酸蚀形态的酸蚀裂缝导流能力研究[D]. 成都: 西南石油大学, 2019.ZHENG Xin. Study on acid-fracture conductivity considering the acid etched surface topography[D]. Chengdu: Southwest Petroleum University, 2019. [5] RAVEN K G, GALE J E. Water flow in a natural rock fracture as a function of stress and sample size[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1985, 22(4):251-261. [6] 李宪文,侯雨庭,古永红,等. 白云岩储层酸蚀裂缝导流能力实验研究[J]. 油气地质与采收率,2021,28(1):88-94.LI Xianwen, HOU Yuting, GU Yonghong, et al. Experimental study on conductivity of acid etched fractures in dolomite reservoirs[J]. Petroleum Geology and Recovery Efficiency, 2021, 28(1):88-94. [7] GANGI A F. Variation of whole and fractured porous rock permeability with confining pressure[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1978, 15(5):249-257. [8] NIERODE D E, KRUK K F. An evaluation of acid fluid loss additives retarded acids, and acidized fracture conductivity[C]//Fall Meeting of the Society of Petroleum Engineers of AIME. Las Vegas, Nevada: SPE, 1973: SPE-4549-MS. [9] 冯炜,杨晨,陶善浔,等. 碳酸盐岩酸蚀裂缝表面形态特征的实验研究[J]. 岩性油气藏,2020,32(3):166-172.FENG Wei, YANG Chen, TAO Shanxun, et al. Experimental study on the surface feature of acid-etched fractures in carbonate rocks[J]. Lithologic Reservoirs, 2020, 32(3):166-172. [10] 李莹. 裂缝间距分布规律对导流能力的影响研究[D]. 成都: 成都理工大学, 2013.LI Ying. Research on the influence of the distribution law of fracture interval upon conductivity[D]. Chengdu: Chengdu University of Technology, 2013. [11] 李春月,李沁,李德明,等. 顺北碳酸盐岩储层长期酸蚀裂缝导流能力预测方法[J]. 钻井液与完井液,2022,39(5):646-653.LI Chunyue, LI Qin, LI Deming, et al. Method of predicting flow conductivity of long-term acid-etched fractures in carbonate reservoirs in Shunbei oilfield[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):646-653. [12] ZHU J B, ZHOU T, LIAO Z Y, et al. Replication of internal defects and investigation of mechanical and fracture behaviour of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography[J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 106:198-212. doi: 10.1016/j.ijrmms.2018.04.022 [13] ZHOU T, ZHU J B. An experimental investigation of tensile fracturing behavior of natural and artificial rocks in static and dynamic Brazilian disc tests[J]. Procedia Engineering, 2017, 191:992-998. doi: 10.1016/j.proeng.2017.05.271 [14] 熊祖强,江权,龚彦华,等. 基于三维扫描与打印的岩体自然结构面试样制作方法与剪切试验验证[J]. 岩土力学,2015,36(6):1557-1565.XIONG Zuqiang, JIANG Quan, GONG Yanhua, et al. A method for preparing natural joints of rock mass based on 3D scanning and printing techniques and its experimental validation[J]. Rock and Soil Mechanics, 2015, 36(6):1557-1565. [15] TAN W H, WANG P F. Experimental study on seepage properties of jointed rock-like samples based on 3D printing techniques[J]. Advances in Civil Engineering, 2020, 2020:9403968. [16] 黄娜,蒋宇静,程远方,等. 基于3D打印技术的复杂三维粗糙裂隙网络渗流特性试验及数值模拟研究[J]. 岩土力学,2021,42(6):1659-1668,1680.HUANG Na, JIANG Yujing, CHENG Yuanfang, et al. Experimental and numerical study of hydraulic properties of three-dimensional rough fracture networks based on 3D printing technology[J]. Rock and Soil Mechanics, 2021, 42(6):1659-1668,1680. [17] 王晨蕾,乔雯钰,胡浩,等. 3D打印聚乳酸材料力学性能的研究[J]. 塑料工业,2020,48(S1):115-119.WANG Chenlei, QIAO Wenyu, HU Hao, et al. Study on mechanical properties of 3D printing PLA materials[J]. China Plastics Industry, 2020, 48(S1):115-119. [18] 赵健,刘效朋,王泽武. 基于3D打印的PLA材料力学性能研究[J]. 塑料工业,2020,48(7):139-143.ZHAO Jian, LIU Xiaopeng, WANG Zewu. Research on mechanical properties of PLA material based on 3D printing[J]. China Plastics Industry, 2020, 48(7):139-143. [19] 李晶晶,马世博,梁帅,等. 工艺参数对SLA成型制件力学性能的影响[J]. 工程塑料应用,2019,47(10):75-79.LI Jingjing, MA Shibo, LIANG Shuai, et al. Effect of process parameters on mechanical properties of SLA molding parts[J]. Engineering Plastics Application, 2019, 47(10):75-79. [20] WANG Lehua, HU Yongbo, FU Yintao, et al. Application and prospect of 3D printing technology in rock mechanics test[J/OL]. China Civil Engineering Journal: 1-19. [21] 刘日成,李博,蒋宇静,等. 等效水力隙宽和水力梯度对岩体裂隙网络非线性渗流特性的影响[J]. 岩土力学,2016,37(11):3165-3174.LIU Richeng, LI Bo, JIANG Yujing, et al. Effects of equivalent hydraulic aperture and hydraulic gradient on nonlinear seepage properties of rock mass fracture networks[J]. Rock and Soil Mechanics, 2016, 37(11):3165-3174. [22] 卢聪,罗扬,郭建春,等. 基于三维形态仿真的自支撑裂缝闭合规律数值模拟研究[J]. 中国科学基金,2022,36(1):137-144.LU Cong, LUO Yang, GUO Jianchun, et al. Numerical model of self-propped fracture closure based on 3D simulation of fracture surface[J]. Bulletin of National Natural Science Foundation of China, 2022, 36(1):137-144. [23] 崔溦,邹旭,李正,等. 分形岩石裂隙中渗流扩散运动的试验研究[J]. 岩土力学,2020,41(11):3553-3562.CUI Wei, ZOU Xu, LI Zheng, et al. Experimental study on seepage diffusion movement in fractal rock fractures[J]. Rock and Soil Mechanics, 2020, 41(11):3553-3562. -

下载:

下载: