Preparation of A 240 ℃ Cement Slurry Filter Loss Reducer Prepared through Thermal Initiation Polymerization

-

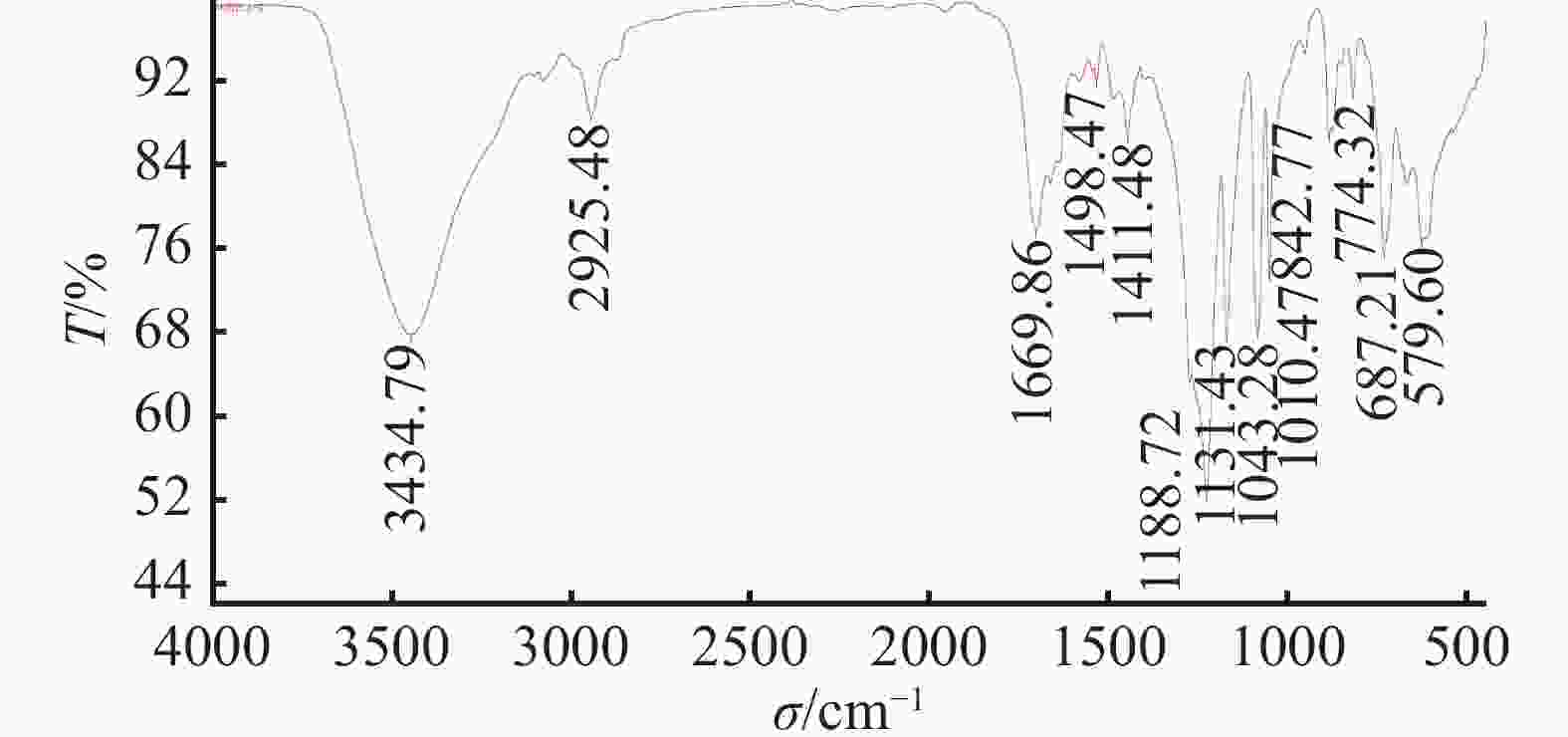

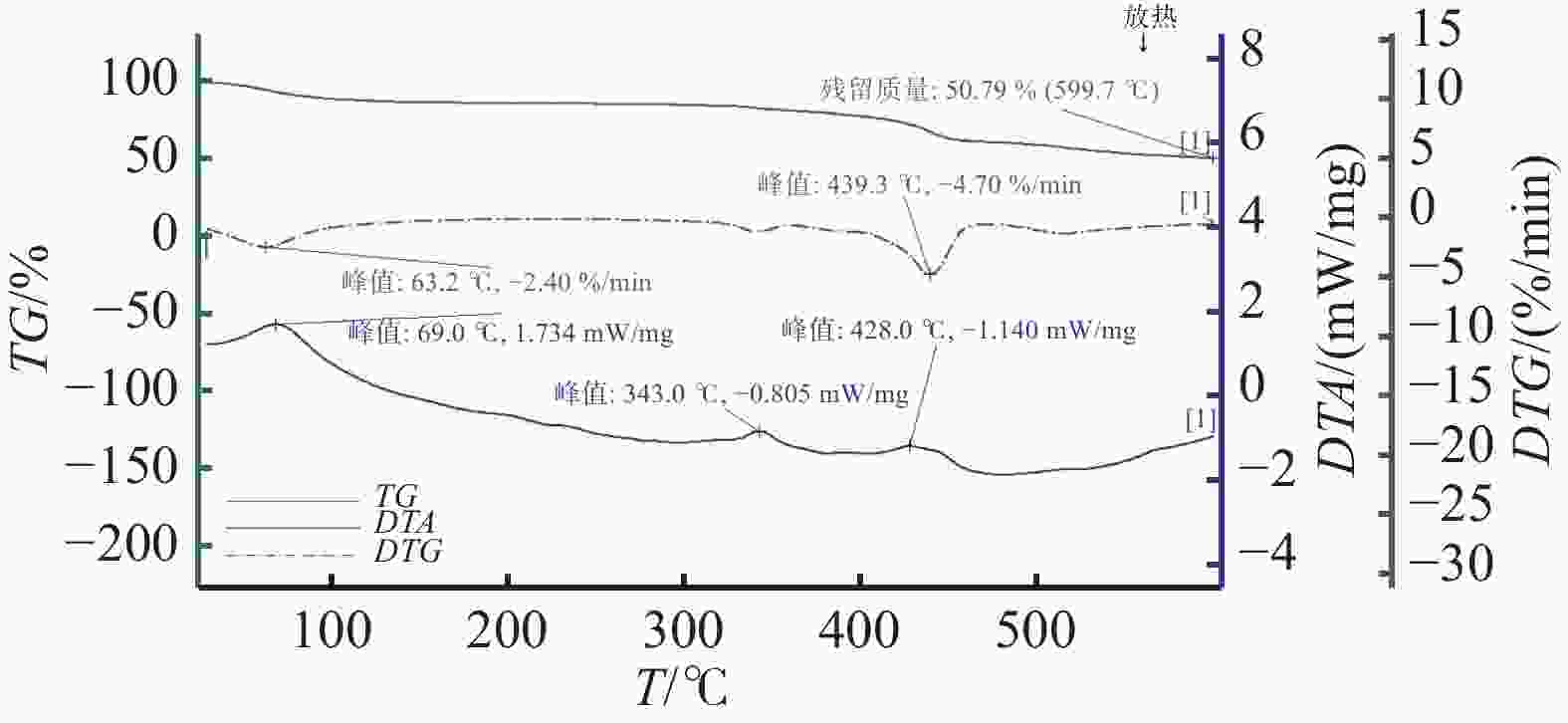

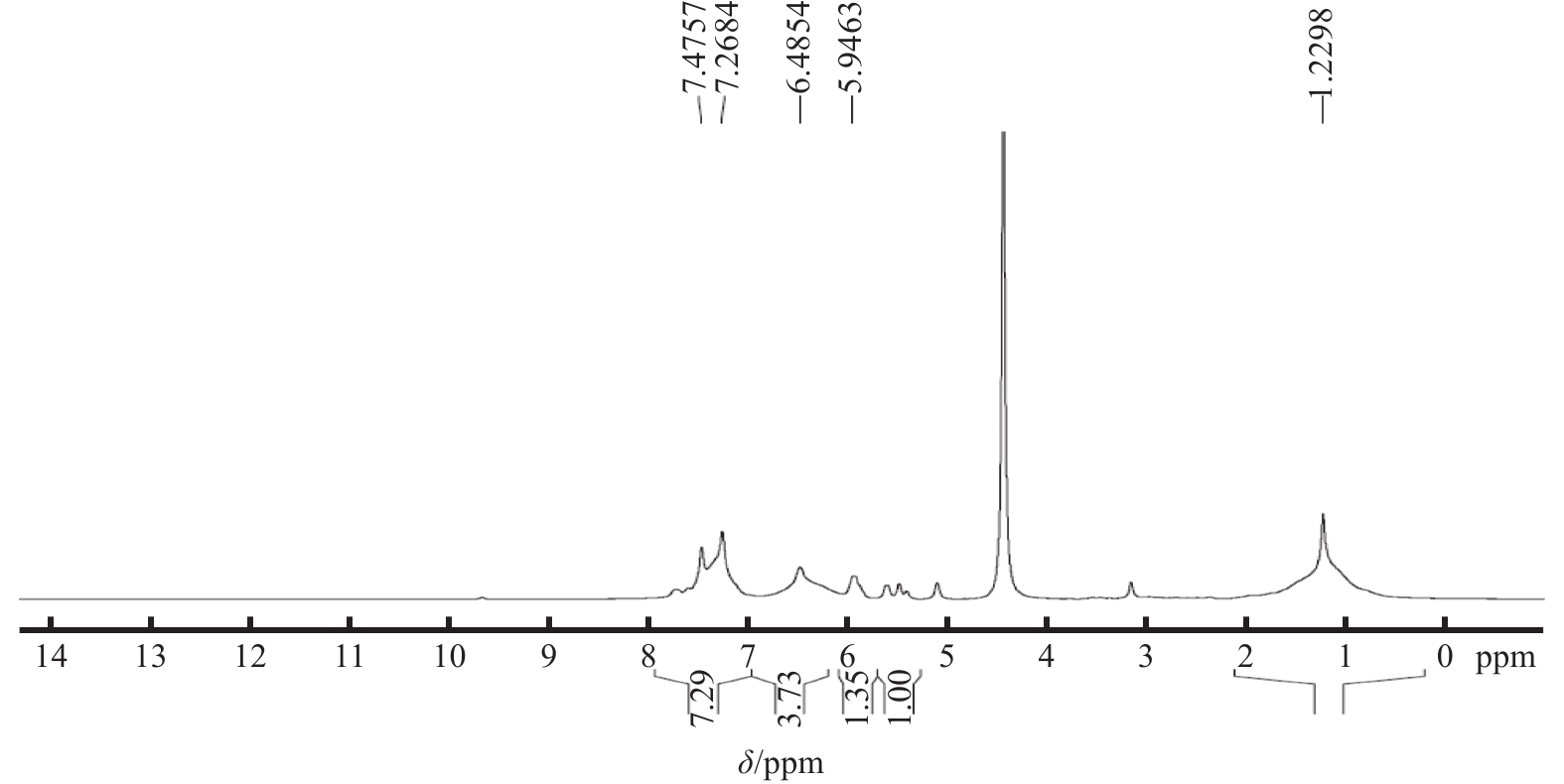

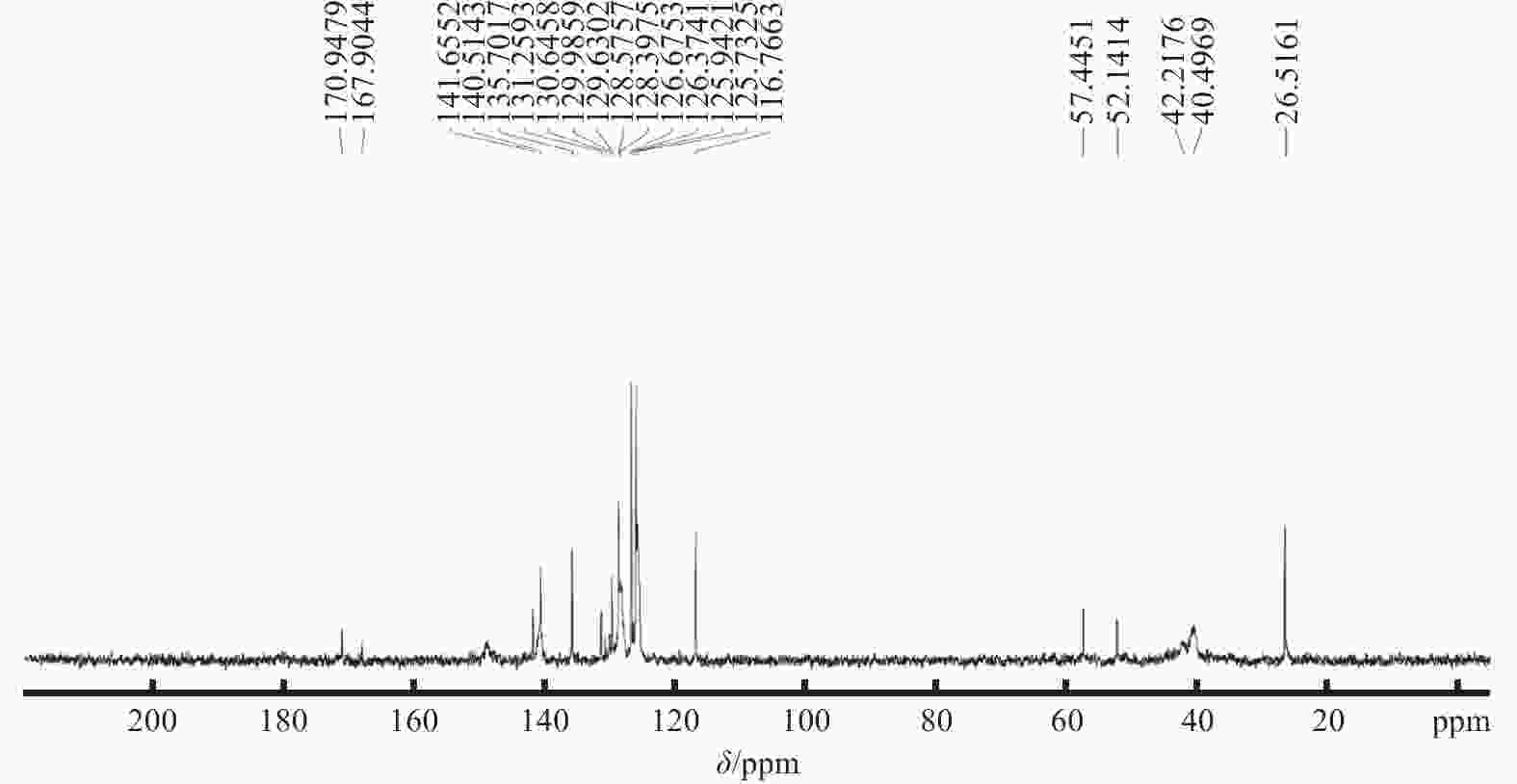

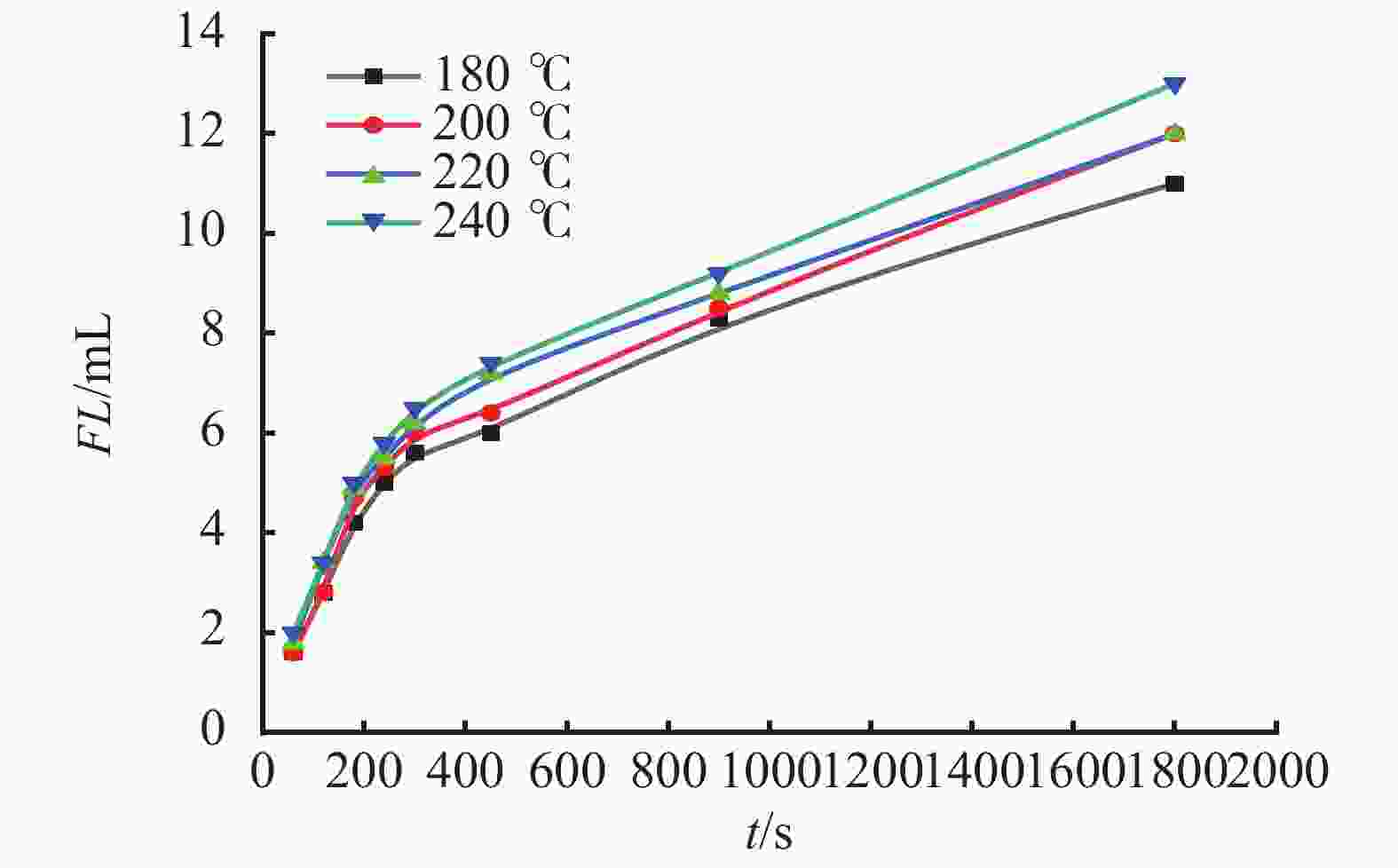

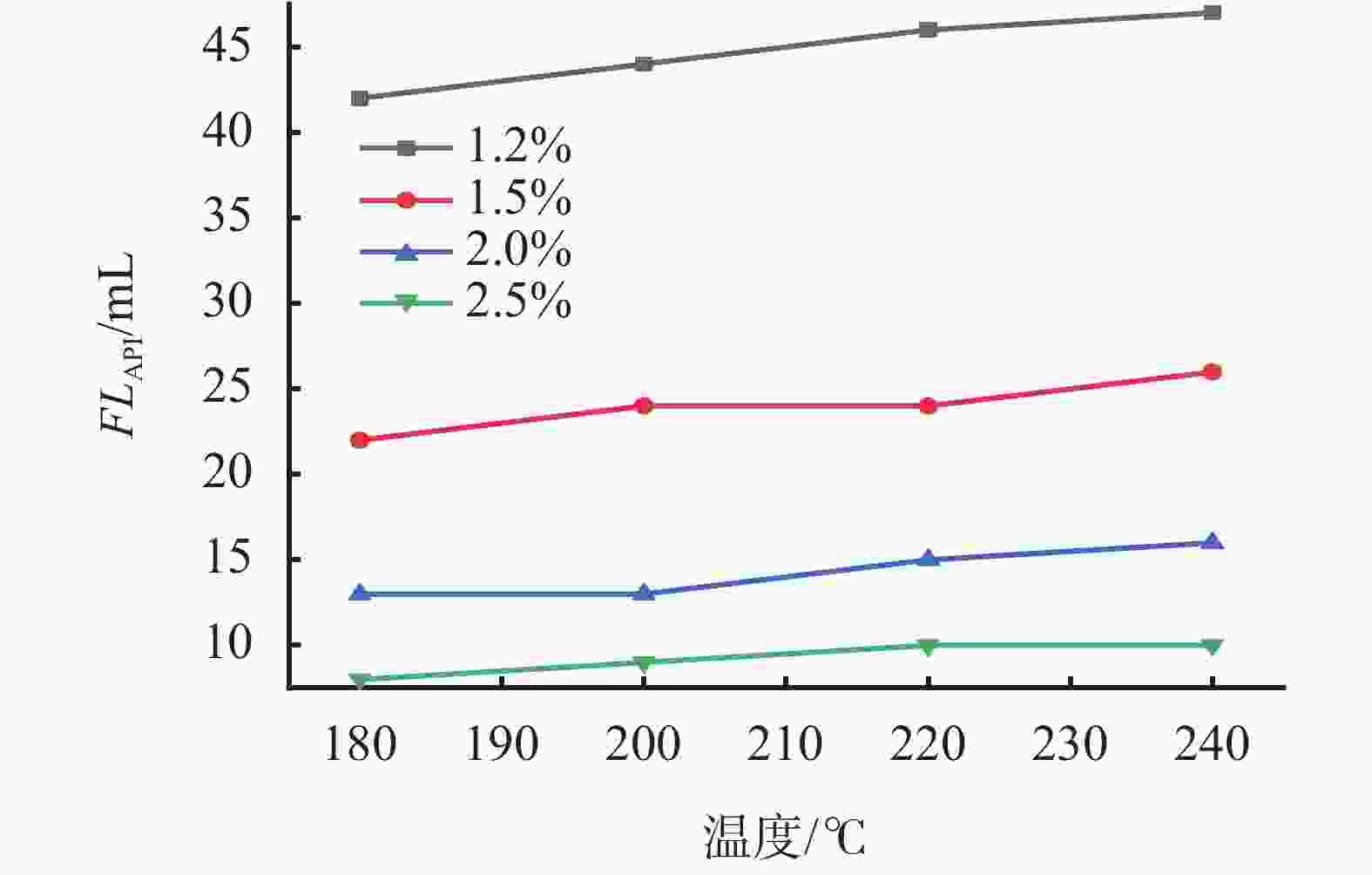

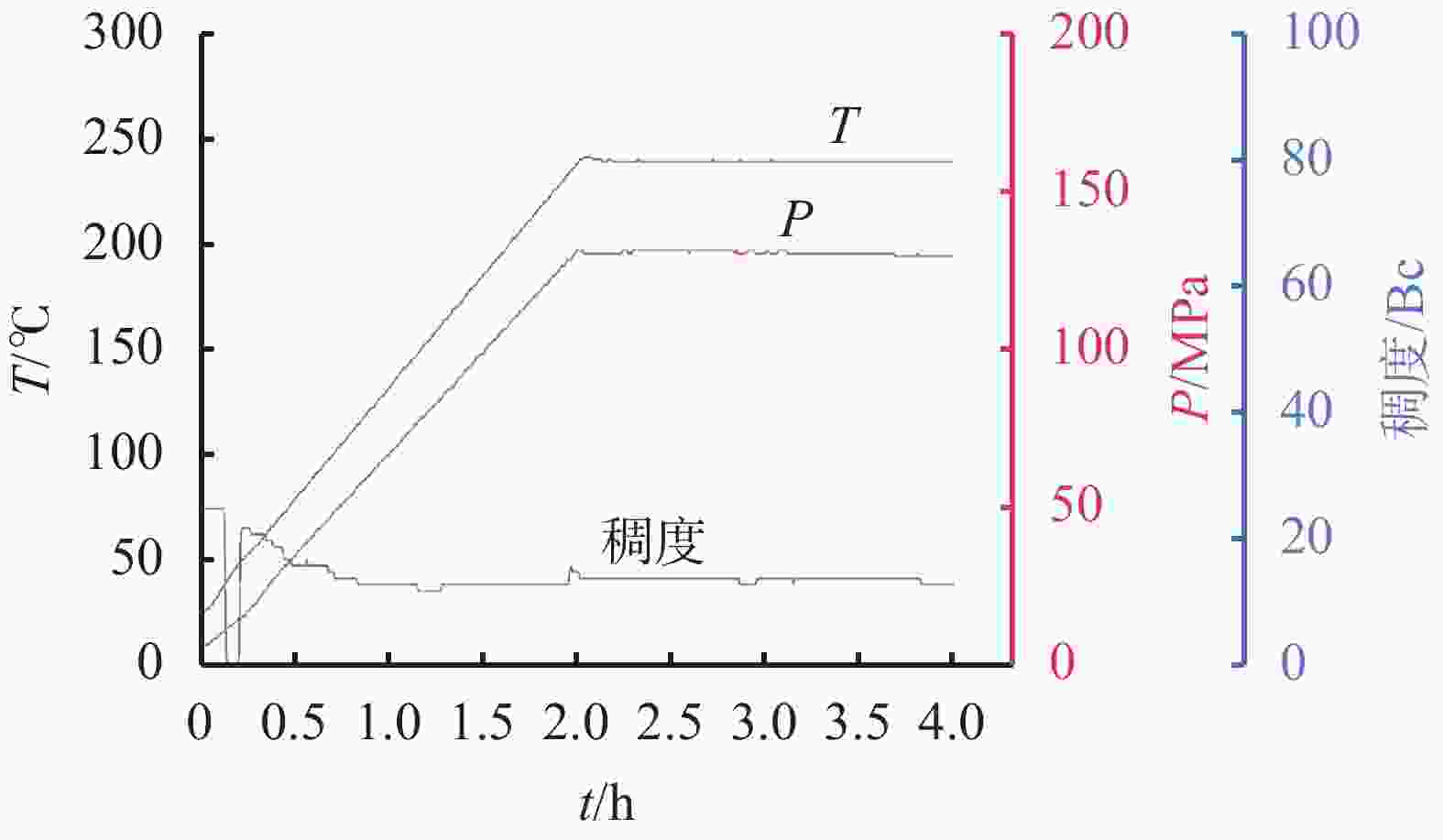

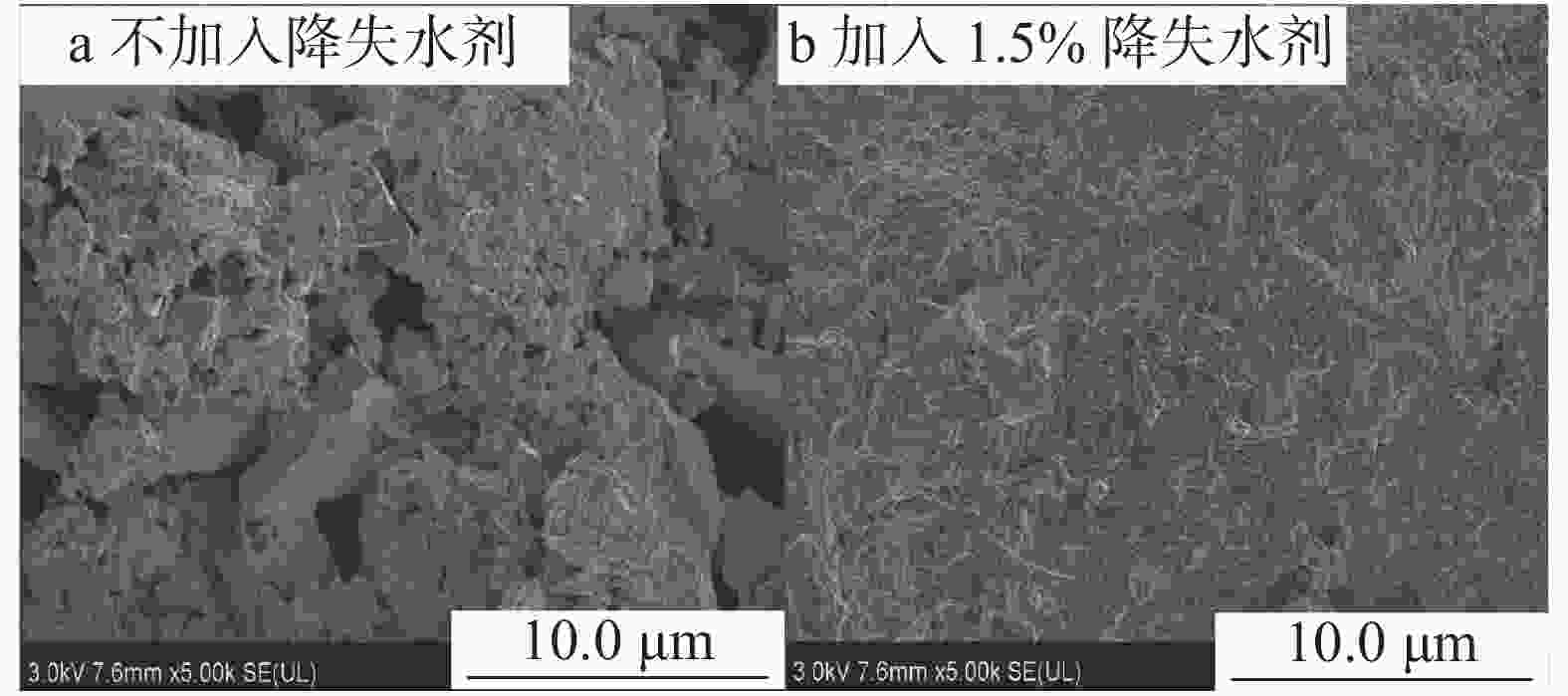

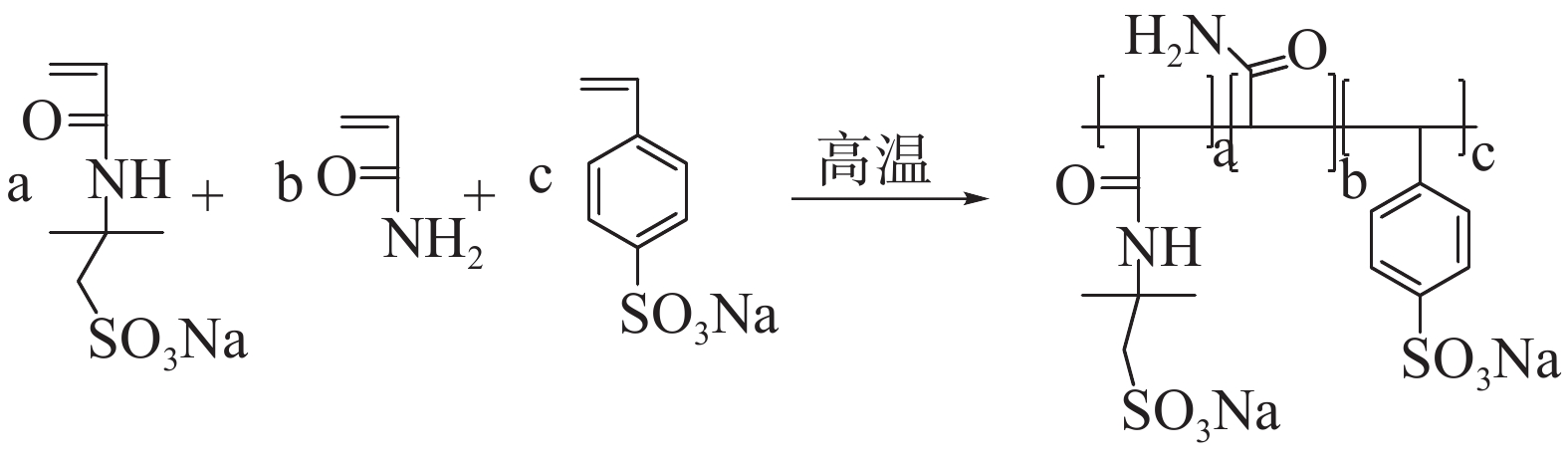

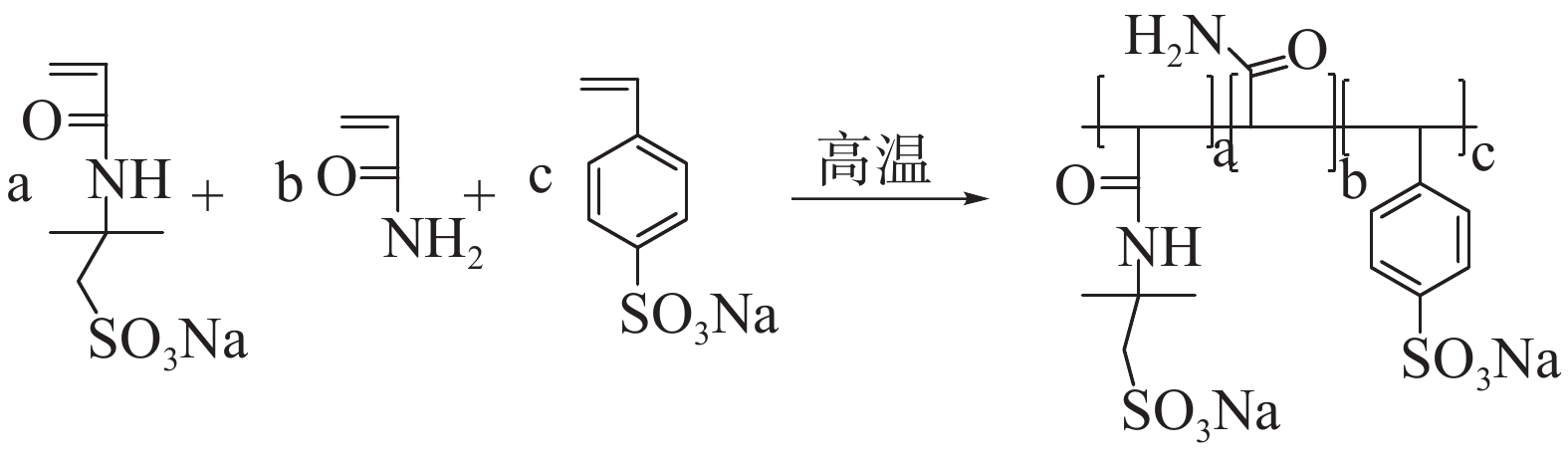

摘要: 针对现有水泥浆降失水剂耐高温性能不足的问题,以高温热引发聚合方法替代传统水溶液引发剂聚合方法,设计并合成了抗温为240 ℃的三元水泥浆降失水剂HTFLA-A。通过实验确定了HTFLA-A的最佳合成条件:水与单体总质量比1∶1,控制温度为150 ℃,体系pH值为9,反应时间为32 h。并采用红外光谱(FT-IR)、热重分析(DSC/TGA)及核磁共振谱对HTFLA-A进行了表征。结果表明,HTFLA-A为目标预期产物,在439 ℃时的热失重仅为23.80%,这是由于高温合成过程中去除了单体中不稳定结构和有机合成过程中副反应产物,提升了高分子材料的抗温性能。对HTFLA-A的性能评价结果表明,当HTFLA-A加量为1.2%,可将水泥浆在180 ~ 240 ℃、6.9 MPa时API失水量控制在50 mL以内。Abstract: A terpolymer cement slurry filter loss reducer HTFLA-A is developed to deal with the poor thermal stability of the cement slurry filter loss reducers presently in use. HTFLA-A is designed and synthesized through high temperature thermally induced polymerization instead of the conventional water solution initiation polymerization. HTFLA-A works normally at temperatures up to 240 ℃. The optimal synthesis condition of HTFLA-A is: mass ratio of water to the monomers is 1:1, reaction temperature is 150 ℃, pH of the reaction system is 9, and the reaction time is 32 h. The molecular structure of HTFLA-A is characterized with FT-IR, DSC/TGA and NMR. The results of the study show that the final synthesis product HTFLA-A is the expected product. Weight loss on heating of HTFLA-A at 439 ℃ is only 23.80%. The reason for this low weight loss on heating is because in the high temperature synthesis, the unstable structures in the monomer molecules and the by-products of the synthesis process are all removed from the final product, thus improving the high temperature stability of the target product. Performance evaluation of HTFLA-A shows that at a concentration of 1.2%, HTFLA-A can control the API filtration rate of a cement slurry to below 50 mL at test condition of 180-240 ℃ and 6.9 MPa.

-

表 1 不同温度下AMPS/AM/SSS三元聚合物分子量的变化

T/ ℃ t聚合/h 分子量/104 Da FLAPI /mL 100 48 41 13.0 110 45 44 13.0 120 43 49 10.4 130 39 54 10.0 140 36 65 7.0 150 34 72 5.8 160 33 70 5.6 170 32 71 5.6 180 29 68 5.8 190 26 64 6.8 200 24 58 9.6 表 2 不同pH下聚合对于产物分子量的影响

pH值 分子量/104 Da FLAPI/mL 5 81 4.6 6 70 5.4 7 62 7.2 8 56 8.8 9 53 10 表 3 不同热引发聚合时间下的高分子材料分子量

聚合时间/h 分子量/104Da FL API/mL 8 21 34.0 16 45 11.4 24 51 10.0 32 53 10.0 -

[1] 李文龙,高德利,杨进,等. 深水超深井钻井井筒温度剖面预测[J]. 石油钻采工艺,2020,42(5):558-563.LI Wenlong, GAO Deli, YANG Jin, et al. Prediction of the borehole temperature profile in ultra- deep drilling under ocean deepwater conditions[J]. Oil Drilling & Production Technology, 2020, 42(5):558-563. [2] 秦紫函. 攻关前沿技术进军万米深地[N]. 中国石化报, 2023-06-19(005).QIN Zihan. Tackling cutting-edge technologies and advancing to a depth of 10000 meters[N]. China Petrochemical News, 2023-06-19(005). [3] 王明华,贺立勤,卓云,等. 川渝地区9000m级超深超高温超高压地层安全钻井技术实践与认识[J]. 天然气勘探与开发,2023,46(2):44-50.WANG Minghua, HE Liqin, ZHUO Yun, et al. Practices and understandings on safe drilling technologies for 9000-m-level super deep and ultra high temperature and pressure strata, Sichuan-Chongqing area[J]. Natural Gas Exploration and Development, 2023, 46(2):44-50. [4] 于永金,夏修建,王治国,等. 深井、超深井固井关键技术进展及实践[J]. 新疆石油天然气,2023,19(2):24-33.YU Yongjin, XIA Xiujian, WANG Zhiguo, et al. Progress and application of the key technologies of deep and ultra-deep well cementing[J]. Xinjiang Oil & Gas, 2023, 19(2):24-33. [5] 夏修建,李鹏鹏,于永金,等. 侧链对油井水泥降失水剂性能的影响及机理研究[J]. 钻井液与完井液,2022,39(6):748-753.XIA Xiujian, LI Pengpeng, YU Yongjin, et al. Effects of polymer sidechains on performance of oil well cement filter loss reducers and studies on mechanisms of the effects[J]. Drilling Fluid & Completion Fluid, 2022, 39(6):748-753. [6] 李鹏飞,李晓维,王建伟. AMPS水溶性共聚物抗盐降失水剂的合成与评价[J]. 化工技术与开发,2022,51(7):10-13. doi: 10.3969/j.issn.1671-9905.2022.07.003LI Pengfei, LI Xiaowei, WANG Jianwei. Synthesis and evaluation of AMPS water-soluble copolymer anti-salt fluid loss agent[J]. Technology & Development of Chemical Industry, 2022, 51(7):10-13. doi: 10.3969/j.issn.1671-9905.2022.07.003 [7] 赵建胜,代清,霍锦华,等. 高温固井水泥浆用降失水剂GT-1的制备及性能[J]. 钻井液与完井液,2022,39(2):234-240. doi: 10.12358/j.issn.1001-5620.2022.02.017ZHAO Jiansheng, DAI Qing, HUO Jinhua, et al. Preparation and application of fluid loss additive GT-1 for high temperature cementing slurry[J]. Drilling Fluid & Completion Fluid, 2022, 39(2):234-240. doi: 10.12358/j.issn.1001-5620.2022.02.017 [8] 程凯, 袁翊, 何涛. 川渝地区抗200 ℃高温抗盐高密度水基钻井液技术研究与应用[C]//2022油气田勘探与开发国际会议论文集Ⅳ. 西安: 陕西省石油学会, 2022: 525-529.CHENG Kai, YUAN Yi, HE Tao. Research and application of 200 ℃ high temperature salt resistant high density water-based drilling fluid in Sichuan and Chongqing area[C]//Proceedings of the 2022 International Conference on Oil and Gas Field Exploration and Development Ⅳ. Xi’an: Shaanxi Petroleum Institute, 2022: 525-529. [9] 于永金,薛毓铖,夏修建,等. 一种抗240 ℃超高温固井缓凝剂的研发与评价[J]. 天然气工业,2023,43(3):107-112.YU Yongjin, XUE Yucheng, XIA Xiujian, et al. Research & development and evaluation of a cementing retarder resistant to 240 ℃ ultra-high temperature[J]. Natural Gas Industry, 2023, 43(3):107-112. [10] 陈灿灿,孙灵辉,刘先贵,等. 碱对部分水解聚丙烯酰胺分子聚集形态的转变影响[J]. 应用化工,2023,52(1):295-299,308.CHEN Cancan, SUN Linghui, LIU Xiangui, et al. Effect of alkali on transformation of aggregation morphology of partially hydrolyzed polyacrylamide[J]. Applied Chemical Industry, 2023, 52(1):295-299,308. [11] 谢启源,陈丹丹,丁延伟. 热重分析技术及其在高分子表征中的应用[J]. 高分子学报,2022,53(2):193-210.XIE Qiyuan, CHEN Dandan, DING Yanwei. Thermogravimetric analysis and its applications in polymer characterization[J]. Acta Polymerica Sinica, 2022, 53(2):193-210. [12] 于永金,张航,夏修建,等. 超高温固井水泥浆降失水剂的合成与性能[J]. 钻井液与完井液,2022,39(3):352-358. doi: 10.12358/j.issn.1001-5620.2022.03.014YU Yongjin, ZHANG Hang, XIA Xiujian, et al. Synthesis and study of an ultra-high temperature filtrate reducer for cement slurries[J]. Drilling Fluid & Completion Fluid, 2022, 39(3):352-358. doi: 10.12358/j.issn.1001-5620.2022.03.014 [13] 郭锦棠,刘振兴,何军,等. 新型耐温抗盐降失水剂LX-1的研制与性能评价[J]. 天津大学学报(自然科学与工程技术版),2021,54(3):318-323.GUO Jintang, LIU Zhenxing, HE Jun, et al. Synthesis and properties of a new high-temperature and salt-resistant fluid loss additive LX-1[J]. Journal of Tianjin University (Science and Technology) , 2021, 54(3):318-323. [14] BAI X D, LI K, HU H, et al. Synthesis and properties of poly (acrylamide-co-N-vinylpyrrolidone-co-sodium p-styrene sulfonate) as an anionic fluid loss additive[J]. Journal of Polymer Research, 2023, 30(5):180. doi: 10.1007/s10965-023-03558-0 [15] 黄丽,朱慧霞,王淮,等. 爆聚反应对聚甲丙烯酸铵酯Ⅰ单体残留影响的研究[J]. 现代化工,2022,42(1):184-188,194.HUANG Li, ZHU Huixia, WANG Huai, et al. Study on effect of explosive polymerization on monomer residue in methacrylic acid copolymer Ⅰ[J]. Modern Chemical Industry, 2022, 42(1):184-188,194. [16] 王茂功,颜星,彭洁. 爆聚法合成抗高温抗盐水基降滤失剂及性能评价[J]. 钻井液与完井液,2019,36(2):148-152.WANG Maogong, YAN Xing, PENG Jie. High temperature salt resistant filter loss reducers for water base drilling fluids: synthesis with explosive polymerization method and performance evaluation[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):148-152. [17] 刘锋报,孙金声,王建华. 国内外深井超深井钻井液技术现状及发展趋势[J]. 新疆石油天然气,2023,19(2):34-39.LIU Fengbao, SUN Jinsheng, WANG Jianhua. A global review of technical status and development trend of drilling fluids for deep and ultra-deep wells[J]. Xinjiang Oil & Gas, 2023, 19(2):34-39. [18] LUO Y H, LIN L, LUO P Y, et al. Polymer nanocomposite ADA@SM as a high-temperature filtrate reducer for water-based drilling fluids and its filtration loss mechanism[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2023, 672:131701. doi: 10.1016/j.colsurfa.2023.131701 [19] ZHANG H, HU M, LI P P, et al. Covalently bonded AMPS-based copolymer-C-S-H hybrid as a fluid loss additive for oilwell saline cement slurry in UHT environment[J]. Construction and Building Materials, 2023, 378:131177. doi: 10.1016/j.conbuildmat.2023.131177 -

下载:

下载: