Ultra-high Temperature Resistant Cement Slurry and Its Application in Hot Dry Rock

-

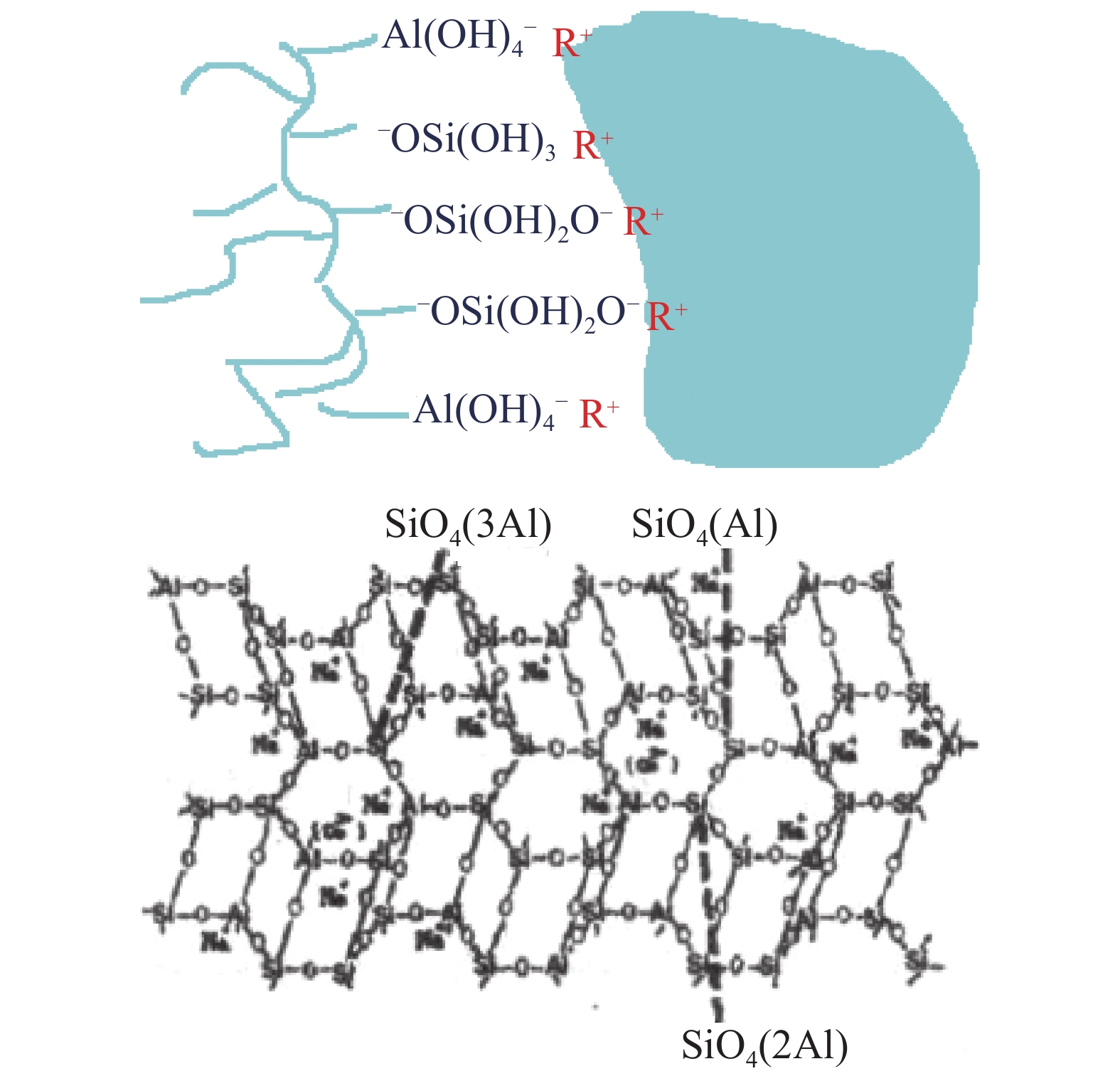

摘要: 干热岩长期高温导致水泥石强度衰退,易造成套管挤毁或窜流,严重影响钻井的安全。针对200 ℃以上常规加砂水泥石强度衰退难题,基于硅铝键结合增强效应,通过优化水泥物相组成,开发了超高温增强材料SCKL,可以满足210~300 ℃下固井要求,不仅抑制了水泥石强度衰退,且促进了水泥石强度长期发育,300 ℃、48 h的抗压强度为18.2 MPa,30 d抗压强度高达23.2 MPa,探索了超高温增强材料对水泥石微观结构的影响,揭示了超高温水泥石微观作用机制。研选了温度广谱型缓凝剂,开发了大温差防衰退水泥浆体系,可以满足干热岩100 ℃温差下安全固井需求,并在青海共和盆地成功应用5口井,固井质量均为优质,为干热岩井筒水泥环密封完整性提供了安全保障。Abstract: It is easy to cause the strength retrogression of cement sheath, especially at the long-term high temperature condition of dry hot rock. At present, the method of adding sand to strengthen cement is widely used in high temperature cementing operations. However, the strength retrogression of cement still exists when the temperature is above 200 ℃, resulting in casing collapse and annular flow, which seriously affects the wellbore safety. To solve the problem of cement strength retrogression at the ultra-high temperature, a new high-temperature stabilizer (SCKL) was developed by optimizing the phase composition of cement based on the enhanced effect of silica aluminum bonding. The effect of SCKL on the inhibition of set cement strength retrogression at high temperatures was evaluated. The results showed that the compressive strength of set cement was 18.2 MPa at 48-hour age for 300 ℃ curing temperature. And the strength reached 23.2 MPa after 30 days, which inhibited the strength retrogression of cement under long-term high temperature conditions. The influence of temperature on the microstructure and hydrates of set cement was revealed based on the XRD and SEM tests. Finally, a new durable heat-resistant cement system was developed. The cement slurry had very good settlement stability and could meet the requirement of safe cementing in DHR wells at a temperature difference of 100 ℃. The durable heat-resistant cement system has been successfully applied in five wells in Gonghe Basin, Qinghai Province. The cementing qualities are very good, which provides a guarantee for the integrity of cement sheath sealing in dry hot rock.

-

Key words:

- Hot dry rock /

- Cement slurry /

- Strength retrogression /

- High temperature

-

表 1 含不同钙-硅-铝的超高温增强材料

材料 SiO2 Al2O3 CaO 石英砂SiO2 100 地聚物材料SCM 66.72 14.2 9.98 地聚物材料SCKL 57.74 35.2 1.91 表 2 缓凝剂SCR-4加量对稠化时间的影响

SCR-4/% t稠化/min 30 Bc 100 Bc 过渡时间 8 156 159 3 9 166 168 2 10 263 264 1 11 377 378 1 注:稠化时间测试条件为180 ℃、70 MPa。 表 3 青海共和盆地高温防衰退水泥浆体系应用效果

井号 井深/

mT井底/

℃T循环/

℃ρ水泥浆/

g/cm3固井

质量GH-01 4002.88 209 180 1.83 优质 GH-02 4000.00 182 160 1.83 优质 GH-03 4000.00 202 160 1.82~1.83 优质 GH-04 4016.00 176 160 1.82~1.83 优质 GH-05 4032.00 190 160 1.82~1.83 优质 -

[1] 李根生,武晓光,宋先知,等. 干热岩地热资源开采技术现状与挑战[J]. 石油科学通报,2022,7(3):343-364.LI Gensheng, WU Xiaoguang, SONG Xianzhi, et al. Status and challenges of hot dry rock geothermal resource exploitation[J]. Petroleum Science Bulletin, 2022, 7(3):343-364. [2] 曾义金. 干热岩热能开发技术进展与思考[J]. 石油钻探技术,2015,43(2):1-7.ZENG Yijin. Technical progress and thinking for development of hot dry rock (HDR) geothermal resources[J]. Petroleum Drilling Techniques, 2015, 43(2):1-7. [3] 杨远光,陈大钧. 高温水热条件下水泥石强度衰退的研究[J]. 石油钻采工艺,1992(5):33-39. doi: 10.13639/j.odpt.1992.05.009YANG Yuanguang, CHEN Dajun. Research on strength decay of cement stone under high temperature hydrothermal conditions[J]. Oil Drilling & Production Technology, 1992(5):33-39. doi: 10.13639/j.odpt.1992.05.009 [4] 李全双,王治国,邹书强. 适用于干热岩固井抗高温高强度水泥浆体系研究[J]. 中国石油和化工标准与质量,2020,40(10):164-167,169. doi: 10.3969/j.issn.1673-4076.2020.10.080LI Quanshuang, WANG Zhiguo, ZOU Shuqiang. Research on high temperature and high strength cement slurry system suitable for dry hot rock cementing[J]. China Petroleum and Chemical Standard and Quality, 2020, 40(10):164-167,169. doi: 10.3969/j.issn.1673-4076.2020.10.080 [5] 刘会斌, 李建华, 庞合善, 等. 青海共和盆地干热岩GR1井超高温固井水泥浆技术[J]. 钻井液与完井液, 2020, 37(2): 202-208.LIU Huibin, LI Jianhua, PANG Heshan, et al. Ultra-high temperature cement slurry for cementing well GR1 penetrating hot dry rock formations in Gonghe basin, Qinghai[J]. Drilling Fluid & Completion Fluid, 2020, 37(2): 202-208. [6] ALLAHVIRDIZADEH P. A review on geothermal wells: well integrity issues[J]. Journal of Cleaner Production, 2020, 275:124009. [7] 李宁,庞学玉,艾正青,等. 200 ℃加砂硅酸盐水泥配方优化设计及强度衰退机理[J]. 硅酸盐学报,2020,48(11):1824-1833.LI Ning, PANG Xueyu, AI Zhengqing, et al. Composition optimization and strength decline mechanism of oil well cement slurry at 200 ℃[J]. Journal of the Chinese Ceramic Society, 2020, 48(11):1824-1833. [8] 耿晨梓,姚晓,代丹,等. SiO2晶态物性对高温水泥石力学性能的影响[J]. 钻井液与完井液,2020,37(6):777-783. doi: 10.3969/j.issn.1001-5620.2020.06.018GENG Chenzi, YAO Xiao, DAI Dan, et al. Effects of physical properties of SiO2 crystalline state on mechanical properties of high temperature set cement[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):777-783. doi: 10.3969/j.issn.1001-5620.2020.06.018 [9] 姚晓,葛荘,汪晓静,等. 加砂油井水泥石高温力学性能衰退机制研究进展[J]. 石油钻探技术,2018,46(1):17-23. doi: 10.11911/syztjs.2018008YAO Xiao, GE Zhuang, WANG Xiaojing, et al. Research progress of degradation of mechanical properties of sand-containing cement in high temperature regimes[J]. Petroleum Drilling Techniques, 2018, 46(1):17-23. doi: 10.11911/syztjs.2018008 [10] 路飞飞,李斐,田娜娟,等. 复合加砂抗高温防衰退水泥浆体系[J]. 钻井液与完井液,2017,34(4):85-89. doi: 10.3969/j.issn.1001-5620.2017.04.016LU Feifei, LI Fei, TIAN Najuan, et al. High temperature anti strength retrogression cement slurry with compounded silica powder[J]. Drilling Fluid & Completion Fluid, 2017, 34(4):85-89. doi: 10.3969/j.issn.1001-5620.2017.04.016 [11] 周崇峰,费中明,李德伟,等. 一种新型超高温固井水泥石抗强度衰退材料[J]. 钻井液与完井液,2022,39(1):71-75. doi: 10.12358/j.issn.1001-5620.2022.01.012ZHOU Chongfeng, FEI Zhongming, LI Dewei, et al. Research on a new material to prevent the strength decline of set cement under ultra-high temperature[J]. Drilling Fluid & Completion Fluid, 2022, 39(1):71-75. doi: 10.12358/j.issn.1001-5620.2022.01.012 -

下载:

下载: