Research on Cementing and Loss Prevention Drilling Fluid Technology During Drilling in the Sea Basin

-

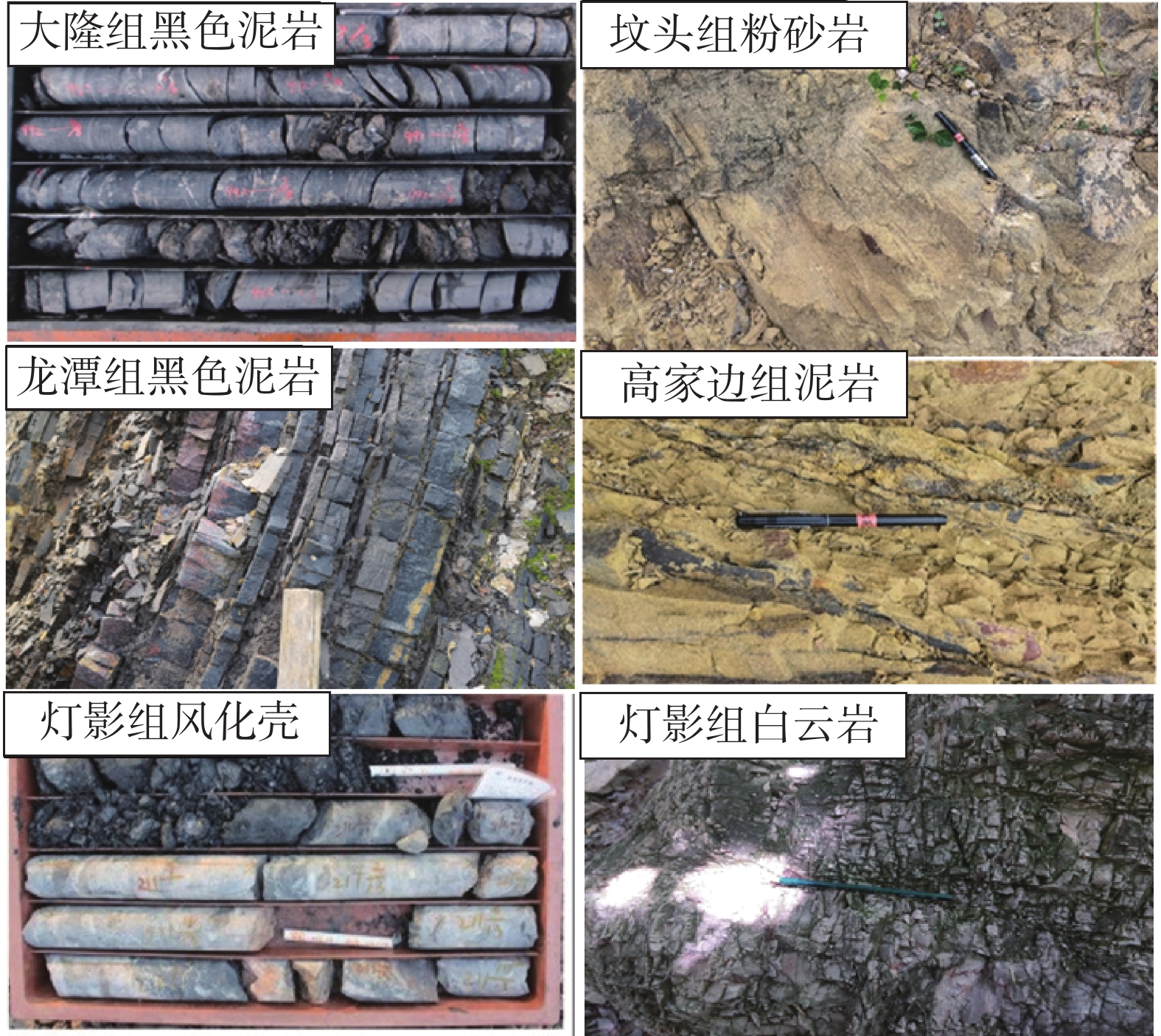

摘要: 分析了我国海上某盆地地质特征和历史井漏情况,明确了该盆地钻井防漏堵漏难点:地层裂缝发育且存在微米级至毫米级的多尺度裂缝,甚至裂缝和孔、洞并存,导致堵漏材料选配难、一次堵漏成功率低;地层发育大段风化壳、部分地层破碎严重、钻井中裂缝极易二次发育等,导致恶性漏失甚至失返性漏失等复杂情况。针对上述难点,以聚乙烯醇、聚丙烯酸以及含邻苯二酚结构的有机物为原料,合成了一种胶结型堵漏剂BFD-1。实验结果表明,人造疏松岩心在加有4% BFD-1的水溶液中浸泡后,岩心抗压强度提高率达19.34%。以BFD-1为核心,复配现场常用堵漏材料,构建了适用于不同尺寸范围漏失通道的防漏堵漏钻井液体系,具良好的防漏堵漏性、胶结性,并可有效阻止压力传递。研究成果可为该地区钻井井漏防治提供有力技术支撑。Abstract: This paper analyzes the geological features and drilling fluid loss situations in the China's Sea Basin, identifying the challenges in leak prevention and plugging technology in this area. These include prevalent formation fractures with micro to millimeter-scale multi-scale cracks, and even the coexistence of fractures and cavities, which pose difficulties in choosing appropriate plugging materials and lead to a low success rate for first-time plugging. Moreover, there are extensive sections of weathered crust in the formation, coupled with highly developed fractures and severe fragmentation in some strata, resulting in secondary development of fractures, critical fluid loss or even non-return fluid loss. In response to these challenges, this paper synthesizes a type of gelation plugging agent, BFD-1, using polyvinyl alcohol, polypropylene acid, and organics with hydroquinone structures as raw materials. Experimental results show that the compressive strength of the artificial loose rock core increased by 19.34% after being soaked in 4% BFD-1 aqueous solution. Based on BFD-1, field plugging materials were combined to create drilling fluid systems for leak prevention and plugging for lost channels with different size. The drilling fluid exhibits excellent circulation-lost-control and cementing capabilities, and effectively prevents pressure transmission. The research results provide support for the subsequent lost-circulation control technology in this area.

-

Key words:

- Cementing /

- Leak Prevention and Plugging /

- Water-Based Drilling Fluid /

- Plugging Agent

-

表 1 目标盆地钻井井漏情况及堵漏工艺总结

井号 漏失层位 漏失深度/m 漏失速度/(m3·s−1) 漏失类型 漏失原因 堵漏工艺 东X井 幕府 6022.00 10.80 渗漏、裂缝性漏失 灰质白云岩裂缝发育 静止堵漏 山组 灯影组 6128.44 15.90 渗漏、裂缝性漏失 灯影组裂缝发育,

且顶部发育风化壳静止堵漏 CZ-X井 灯影组 6129.47 9.04 渗漏、裂缝性漏失 浅灰色白云岩发育溶蚀

孔洞和裂缝静止堵漏 青龙组 1189.74 6~40 渗漏-恶性漏失、裂缝性漏失 三叠系青龙组顶部风化壳

发育、裂缝尺度大静止堵漏+

挤注水泥青龙组 1326.89 钻具放空 失返恶性漏失恶性漏失、溶洞性漏失 发育溶洞 海水强钻 表 2 人造疏松岩心在不同测试液高温 (150 ℃)浸泡后的单轴抗压强度

岩心 浸泡介质 单轴抗压强度/MPa 平均值/MPa 1# 清水 1.75 1.81 2# 清水 1.86 1# 4% BFD-1溶液 2.13 2.16 2# 4% BFD-1溶液 2.19 表 3 不同防漏堵漏钻井液在不同尺寸缝板下的承压以及累计漏失量

缝板尺寸及

类型堵漏

体系在不同压力(MPa)下的累计漏失量/mL 1 2 3 4 5 6 7 8 1 mm

梯形缝板6# 12 15 19 19 20 21 21 21 7# 9 11 15 17 18 18 18 18 1 mm

直角缝板6# 23 27 30 35 37 39 40 40 7# 21 26 29 31 35 36 37 38 3 mm

梯形缝板6# 132 159 176 193 205 211 219 222 7# 83 105 111 121 129 135 147 150 3 mm

直角缝板6# 258 360 450 全漏 7# 190 218 235 256 264 268 269 270 表 4 防漏堵漏钻井液选配对策

漏失通道尺寸 堵漏材料配方 使用方案 小于521.3 μm 1%BFD-1+1.5%SZDL+1.5%SEAL+

1.5%BLN1+2%果壳+2%云母片从混合漏斗处加入一定比例的复合堵漏剂 521 μm~1 mm 1% BFD-1+2%SZDL+2%SEAL+2%BLN1+

2%果壳+2%云母片从混合漏斗处加入一定比例的复合堵漏剂 1~3 mm 1.5%BFD-1+2.5%SZDL+3%SEAL+2%BLN1+

2%BLN2+2%BLN3+3%果壳+5%云母片+5%蛭石从混合漏斗处加入一定比例的复合堵漏剂后,

适当停钻以待胶结固化充分 -

[1] 孙金声,杨景斌,白英睿,等. 裂缝性地层桥接堵漏技术发展综述与展望[J]. 石油科学通报,2023,8(4):415-431.SUN Jinsheng, YANG Jingbin, BAI Yingrui, et al. Review and prospect of bridging plugging technology in fractured formation[J]. Petroleum Science Bulletin, 2023, 8(4):415-431. [2] 雷少飞,孙金声,白英睿,等. 裂缝封堵层形成机理及堵漏颗粒优选规则[J]. 石油勘探与开发,2022,49(3):597-604.LEI Shaofei, SUN Jinsheng, BAI Yingrui, et al. Formation mechanisms of fracture plugging zone and optimization of plugging particles[J]. Petroleum Exploration and Development, 2022, 49(3):597-604. [3] 吕开河,王晨烨,雷少飞,等. 裂缝性地层钻井液漏失规律及堵漏对策[J]. 中国石油大学学报(自然科学版),2022,46(2):85-93.LYU Kaihe, WANG Chenye, LEI Shaofei, et al. Dynamic behavior and mitigation methods for drilling fluid loss in fractured formations[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2022, 46(2):85-93. [4] 许成元,阳洋,蒲时,等. 基于高效架桥和致密填充的深层裂缝性储层堵漏配方设计方法研究[J]. 油气藏评价与开发,2022,12(3):534-544.XU Chengyuan, YANG Yang, PU Shi, et al. Design method of plugging formula for deep naturally fractured reservoir based on efficient bridging and compact filling[J]. Petroleum Reservoir Evaluation and Development, 2022, 12(3):534-544. [5] JIANG G C, SUN J S, HE Y B, et al. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs[J]. Engineering, 2022, 18:129-142. doi: 10.1016/j.eng.2021.11.014 [6] 汤志川,邱正松,钟汉毅,等. 新型壳聚糖-邻苯二酚化学固壁剂合成与性能评价[J]. 钻井液与完井液,2019,36(5):534-541.TANG Zhichuan, QIU Zhengsong, ZHONG Hanyi, et al. Synthesis and evaluation of a new chemical borehole wall strengthener made from chitosan-catechol[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):534-541. [7] 朱金智,任玲玲,陆海英,等. 桥接堵漏材料及其配方粒度分布预测新方法[J]. 钻井液与完井液,2021,38(4):474-478.ZHU Jinzhi, REN Lingling, LU Haiying, et al. A new method of predicting the bridging lost circulation materials and their particle size distribution[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):474-478. [8] 蒋官澄,董腾飞,崔凯潇,等. 智能钻井液技术研究现状与发展方向[J]. 石油勘探与开发,2022,49(3):577-585. doi: 10.11698/PED.20210666JIANG Guancheng, DONG Tengfei, CUI Kaixiao, et al. Research status and development directions of intelligent drilling fluid technologies[J]. Petroleum Exploration and Development, 2022, 49(3):577-585. doi: 10.11698/PED.20210666 [9] 艾磊,宫臣兴,谢江锋,等. 超分子聚合物堵漏技术在长庆油田恶性漏失井的应用[J]. 钻井液与完井液,2021,38(6):705-714.AI Lei, GONG Chenxing, XIE Jiangfeng, et al. Application of supramolecular polymer plugging technology in Changqing oilfield[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):705-714. [10] 王勇,蒋官澄,杜庆福,等. 超分子化学堵漏技术研究与应用[J]. 钻井液与完井液,2018,35(3):48-53. doi: 10.3969/j.issn.1001-5620.2018.03.008WANG Yong, JIANG Guancheng, DU Qingfu, et al. Study and application of supramolecule chemical LCM technology[J]. Drilling Fluid & Completion Fluid, 2018, 35(3):48-53. doi: 10.3969/j.issn.1001-5620.2018.03.008 [11] 蒋官澄,刘冲,贺垠博,等. 随钻堵漏用疏水缔合聚合物的作用机理分析[J]. 钻井液与完井液,2017,34(1):50-53,59. doi: 10.3969/j.issn.1001-5620.2017.01.009JIANG Guancheng, LIU Chong, HE Yinbo, et al. Analysis of the mechanism of hydrophobically associating polymer used as LCM while drilling[J]. Drilling Fluid & Completion Fluid, 2017, 34(1):50-53,59. doi: 10.3969/j.issn.1001-5620.2017.01.009 [12] 刘凡,刘钦政,郝惠军,等. 高强度可固化树脂堵漏剂PMMM研制与评价[J]. 钻井液与完井液,2021,38(6):671-676,683.LIU Fan, LIU Qinzheng, HAO Huijun, et al. Synthesis and evaluation of a high strength curable resin LCM PMMM[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):671-676,683. -

下载:

下载: