First Application of the Synthetic-Based Drilling Fluid BIODRILL S in Block Kenli of Bohai Oilfield

-

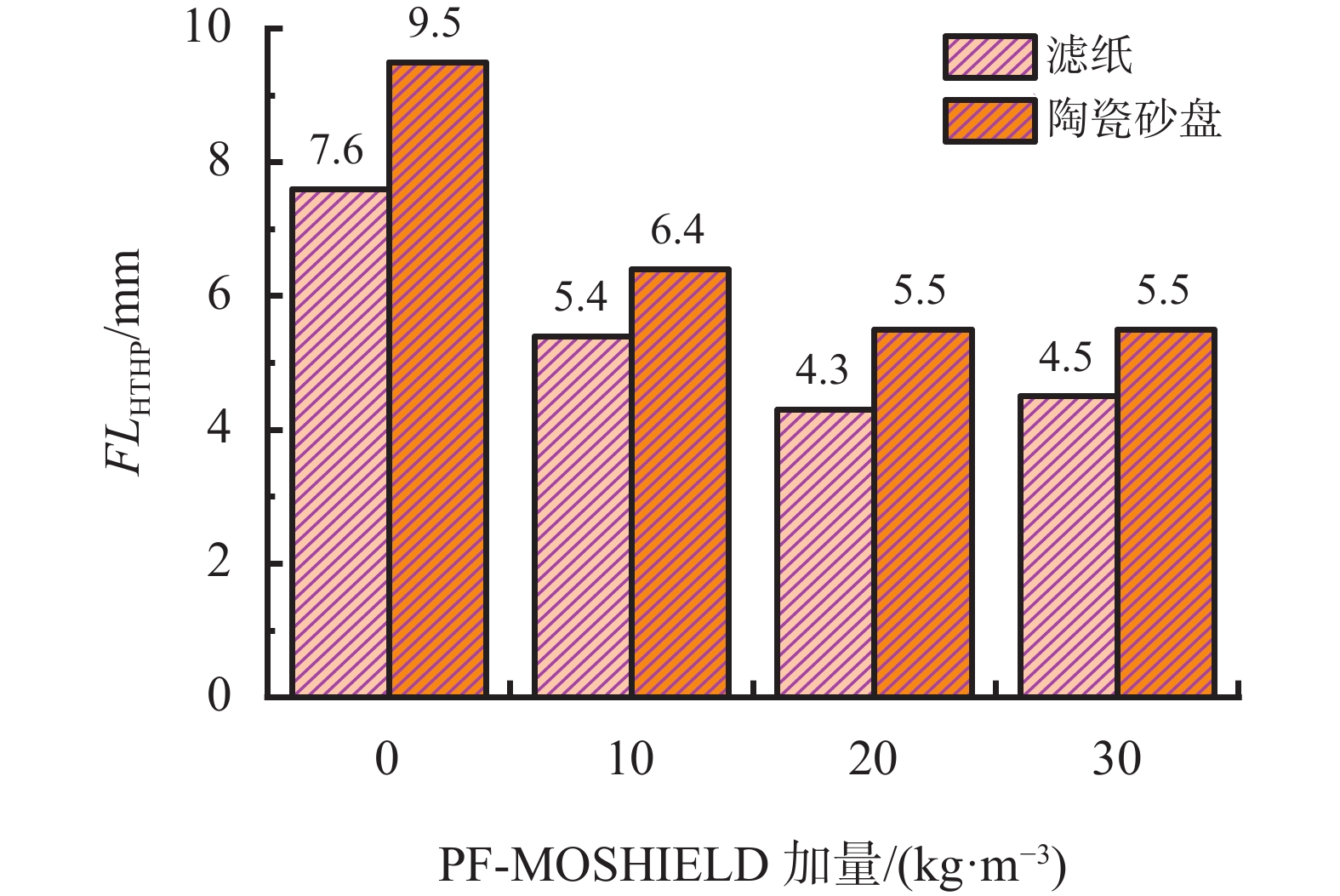

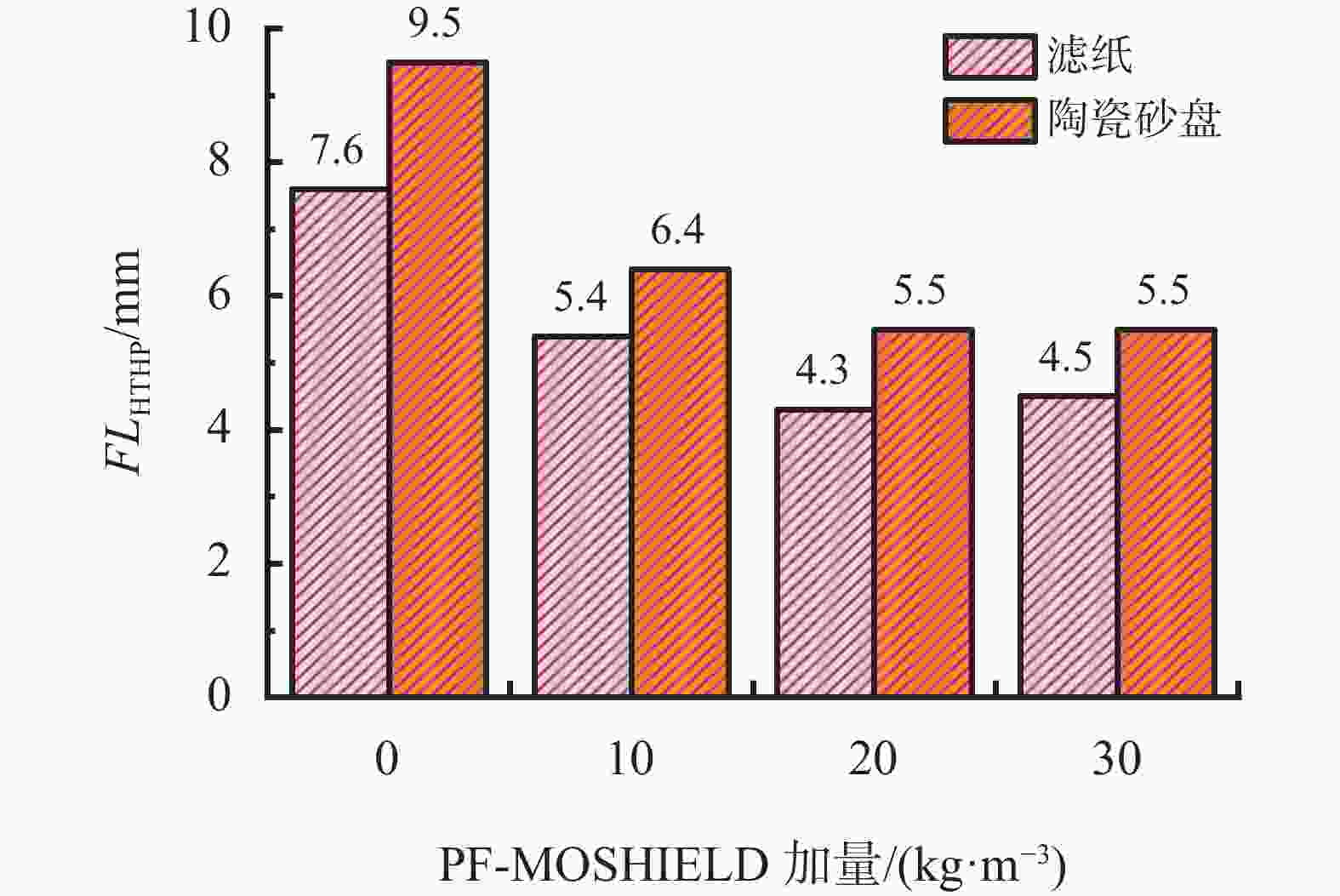

摘要: 渤海油田垦利9-1区块地层岩性复杂,且存在断层带,钻井过程中易发生泥岩水化分散和砂岩层井眼缩径等问题,井壁垮塌风险极大。针对该区块地层岩性特点和技术难题并结合环保要求,制备了一种复合型封堵材料PF-MOSHIELD,构建了BIODRILL S合成基钻井液体系。该体系流变性能良好,抗钙、抗岩屑污染达26%和15%,封堵性、沉降稳定性、润滑性优异,高温高压砂盘滤失量3.2 mL,静置7 d沉降因子为0.53,极压润滑系数0.082。BIODRILL S首次在渤海湾垦利9-1区块进行了现场应用,结果表明:该体系解决了垦利9-1区块泥页岩水化和砂岩层井眼缩径问题,垦利9-1北-3定向探井三开井段上部地层钻屑完整,钻屑达4~7 cm;井眼清洁性能良好,钻井液动塑比超过0.59 Pa/mPa·s,φ6和φ3读数均超过9,剪切稀释性强,提高了井眼净化效率,有效避免形成“岩屑床”;润滑性能优异,在大井斜段(55°、70°、67°)可实现直接起钻。

-

关键词:

- 合成基钻井液 /

- BIODRILL S /

- 渤海油田 /

- 垦利区块

Abstract: Drilling operation in the Block Kenli 9-1 of the Bohai Oilfield has long been faced with high risks of borehole wall collapse resulted from complex formation lithologies, fault zones, shales that are easy to hydrate and disperse, as well as sandstones in which tight hole problem is frequently encountered. To deal with the borehole wall collapse problem a BIODRILL S synthetic based drilling fluid has been formulated. The BIODRILL S synthetic based drilling fluid is formulated with a base oil which is synthetic oil of choice, a composite plugging additive PF-MOSHIELD, as well as other drilling fluid additives, taking into account the formation lithology and environmental protection requirement. The BIODRILL S drilling fluid has good rheology , and is resistant to 26% calcium contamination and 15% cuttings contamination. Furthermore, it has excellent plugging capacity, settling stability and lubricity. The HTHP filter loss tested on a sand plate tester is 3.2 mL. The sag index of the mud after standing for 7 d is 0.53, and the extreme coefficient of friction is 0.082. BIODRILL S was first used in the Block Kenli 9-1. The application showed that: 1) the BIODRILLS can be used to solve the shale hydration problem and the tight hole problem in the sandstone formation encountered previously in this block; the drilled cuttings produced in drilling the formations in and above the third section are intact, with sizes distributed between 4 cm and 7 cm. 2) Hole cleaning is well done with the BIODRILL S drilling fluid, the ratio of YP/PV is greater than 0.59 Pa/mPa∙s, the φ6 and the φ3 reading are all greater than 9, and the drilling fluid has good shear thinning property. All these properties result in good hole cleaning and the prevention of the occurrence of cuttings bed. 3) The drilling fluid has excellent lubricity, making possible the direct tripping (out of hole) through the high angle (55°, 70° and 67°) well sections.-

Key words:

- Synthetic base drilling fluids /

- BIODRILL S /

- Bohai oilfield /

- Block Kenli

-

表 1 不同加量的PF-MOSHIELD对 钻井液流变和电稳定性影响

加量/(kg·m−3) AV/mPa·s PV/mPa·s YP/Pa Gel/(Pa/Pa) ES/V 0 11.0 9.0 2.0 2.5/4.5 785 10 12.0 9.5 2.5 3.0/5.0 850 20 13.0 10.0 3.0 4.0/5.0 967 30 15.0 12.0 3.0 4.0/5.5 975 表 2 BIODRILL S钻井液性能

T/℃ AV/mPa·s PV/mPa·s YP/Pa Gel /(Pa/Pa) ES/V 25 17.5 14 3.5 5/14 615 65 12.5 10 2.5 5/12 648 表 3 水相中CaCl2加量对合成基钻井液性能影响

配方 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V滚动回收率/

%1#

(20%CaCl2)老化前 23.0 14 9.0 5.0/11.0 970 老化后 22.0 16 6.0 4.5/10.0 0.4 950 98.4 2#

(22%CaCl2)老化前 26.0 16 10.0 8.0/14.0 930 老化后 22.0 17 5.0 7.0/11.0 0.6 1030 98.6 3#

(24%CaCl2)老化前 25.0 15 10.0 7.0/11.5 780 老化后 21.5 18 3.5 6.5/10.5 1.0 1150 97.9 4#

(26%CaCl2)老化前 25.5 16 9.5 7.0/13.5 740 老化后 20.0 15 5.0 6.5/11.0 1.2 1400 97.8 注:老化时间为80 ℃ × 16 h。 表 4 添加不同浓度岩屑对合成基钻井液性能影响

配方 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaES/

V基础配方 老化前 22.0 13 9.0 4.5/7.0 840 80 ℃/16 h 17.0 13 4.0 4.0/8.5 700 80 ℃/56 h 15.0 13 2.0 3.0/6.5 670 80 ℃/7 d 15.5 13 2.5 2.5/5.5 570 80 ℃/13 d 14.5 13 1.5 1.0/7.0 660 10% 钻屑 老化前 23.5 12 11.5 6.5/9.0 1020 80 ℃/16 h 18.5 13 5.5 6.0/11.5 996 80 ℃/56 h 17.0 13 4.0 5.0/9.5 570 80 ℃/7 d 17.0 13 4.0 4.5/9.5 620 80 ℃/13 d 17.0 13 4.0 4.5/9.0 700 15% 钻屑 老化前 26.5 13 13.5 7.5/11.0 1047 80 ℃/16 h 20.5 14 6.5 8.0/11.5 941 80 ℃/56 h 18.5 13 5.5 5.5/11.5 865 80 ℃/7 d 18.5 14 4.5 5.5/12.0 800 80 ℃/13 d 18.0 14 4.0 5.0/11.5 820 表 5 BIODRILL S体系沉降因子评价结果

t静置/d ρ上层/(g·cm−3) ρ下层/(g·cm−3) SF 1 1.239 1.256 0.503 3 1.230 1.267 0.507 5 1.225 1.272 0.509 7 1.215 1.280 0.513 表 6 合成基钻井液BIODRILL S的封堵性能评价

石英砂直径/

mm侵入深度/mm 陶瓷砂盘

孔径/μmFLHTHP/

mL老化前 80 ℃×16 h 0.28~0.45 25 27 3 2.0 0.18~0.28 18 21 5 2.5 0.154~0.18 11 12 10 3.2 表 7 垦利9-1北-3定向探井BIODRILL S合成基钻井液性能

井深/

mFV/

sρ/

g·cm-3PV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sφ6/φ3 Gel/

Pa/Pa碱度 FLHTHP/

mLES/

V837 50 1.18 11 9.5 0.86 10/9 9/11 3.0 2.8 660 1280 48 1.18 11 8.5 0.77 11/10 8/10 3.0 2.4 990 1474 49 1.20 13 9.0 0.69 12/11 9/11 2.8 2.0 640 1955 56 1.26 17 10.0 0.59 13/12 10/12 2.8 1.8 550 2213 58 1.28 18 11.5 0.64 17/16 12/15 2.8 1.4 590 -

[1] 陈斌,周姗姗,赵远远,等. 适用于大位移井新型水基钻井液室内研究[J]. 钻井液与完井液,2021,38(1):42-46.CHEN Bin, ZHOU Shanshan, ZHAO Yuanyuan, et al. Laboratory study on new water base drilling fluid for extended reach wells[J]. Drilling Fluid & Completion Fluid, 2021, 38(1):42-46. [2] 张磊,张羽臣,董平华,等. 渤海油田浅层大位移水平井钻井关键技术研究[J]. 非常规油气,2022,9(1):10-17.ZHANG Lei, ZHANG Yuchen, DONG Pinghua, et al. Research on key drilling technology of shallow extended reach horizontal well in Bohai oilfield[J]. Unconventional Oil & Gas, 2022, 9(1):10-17. [3] 邱春阳,李波,王伟,等. 抗高温强封堵合成基钻井液在胜利渤南页岩油区块的应用[J]. 天然气勘探与开发,2022,45(4):121-127.QIU Chunyang, LI Bo, WANG Wei, et al. Application of synthetic-based drilling fluid with high temperature resistance and high plugging performance in Bo'nan shale oil block, Shengli oilfield[J]. Natural Gas Exploration and Development, 2022, 45(4):121-127. [4] 谢中成,付建红,李进,等. 东海油气田超深大位移气井钻井关键技术[J]. 石油钻采工艺,2018,40(4):417-424.XIE Zhongcheng, FU Jianhong, LI Jin, et al. Key drilling technologies for the ultradeep extended reach well in east China sea oil and gas field[J]. Oil Drilling & Production Technology, 2018, 40(4):417-424. [5] WANG C Q, LIN X Y, HE M, et al. Environmental performance, mechanical and microstructure analysis of concrete containing oil-based drilling cuttings pyrolysis residues of shale gas[J]. Journal of Hazardous Materials, 2017, 338:410-427. doi: 10.1016/j.jhazmat.2017.05.051 [6] 龚天帆. 海洋钻井液技术研究与应用现状及发展趋势[J]. 中国石油和化工标准与质量,2023,43(6):176-178.GONG Tianfan. Current status and development trend of research and application of offshore drilling fluid technology[J]. China Petroleum and Chemical Standard and Quality, 2023, 43(6):176-178. [7] RAZALI S Z, YUNUS R, ABDUL RASHID S, et al. Review of biodegradable synthetic-based drilling fluid: progression, performance and future prospect[J]. Renewable and Sustainable Energy Reviews, 2018, 90:171-186. doi: 10.1016/j.rser.2018.03.014 [8] 赵春花,罗健生,夏小春,等. 高性能合成基钻井液体系的研制及性能研究[J]. 钻井液与完井液,2018,35(3):25-31.ZHAO Chunhua, LUO Jiansheng, XIA Xiaochun, et al. Development of and study on a high performance synthetic base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2018, 35(3):25-31. [9] 罗健生,刘刚,李超,等. 深水FLAT-PRO合成基钻井液体系研究及应用[J]. 中国海上油气,2017,29(3):61-66.LUO Jiansheng, LIU Gang, LI Chao, et al. Research and application of FLAT-PRO synthetic based drilling fluid system in deep water[J]. China Offshore Oil and Gas, 2017, 29(3):61-66. [10] 马磊,袁学强,张万栋,等. 乌石17-2油田强封堵合成基钻井液体系[J]. 钻井液与完井液,2022,39(5):558-564.MA Lei, YUAN Xueqiang, ZHANG Wandong, et al. A synthetic based drilling fluid with strong plugging capacity for block wushi17-2[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):558-564. [11] 李晓东,熊正强,万汉平,等. 深部地热抗高温甲酸盐钻井液体系研究[J]. 地质与勘探,2022,58(5):1091-1098.LI Xiaodong, XIONG Zhengqiang, WAN Hanping, et al. Anti-high temperature formate drilling fluid system for deep geothermal resources[J]. Geology and Exploration, 2022, 58(5):1091-1098. -

下载:

下载: