Ultra-High Temperature Drilling Fluid Technology for Second Sidetracking of the Well Shunbei-16X

-

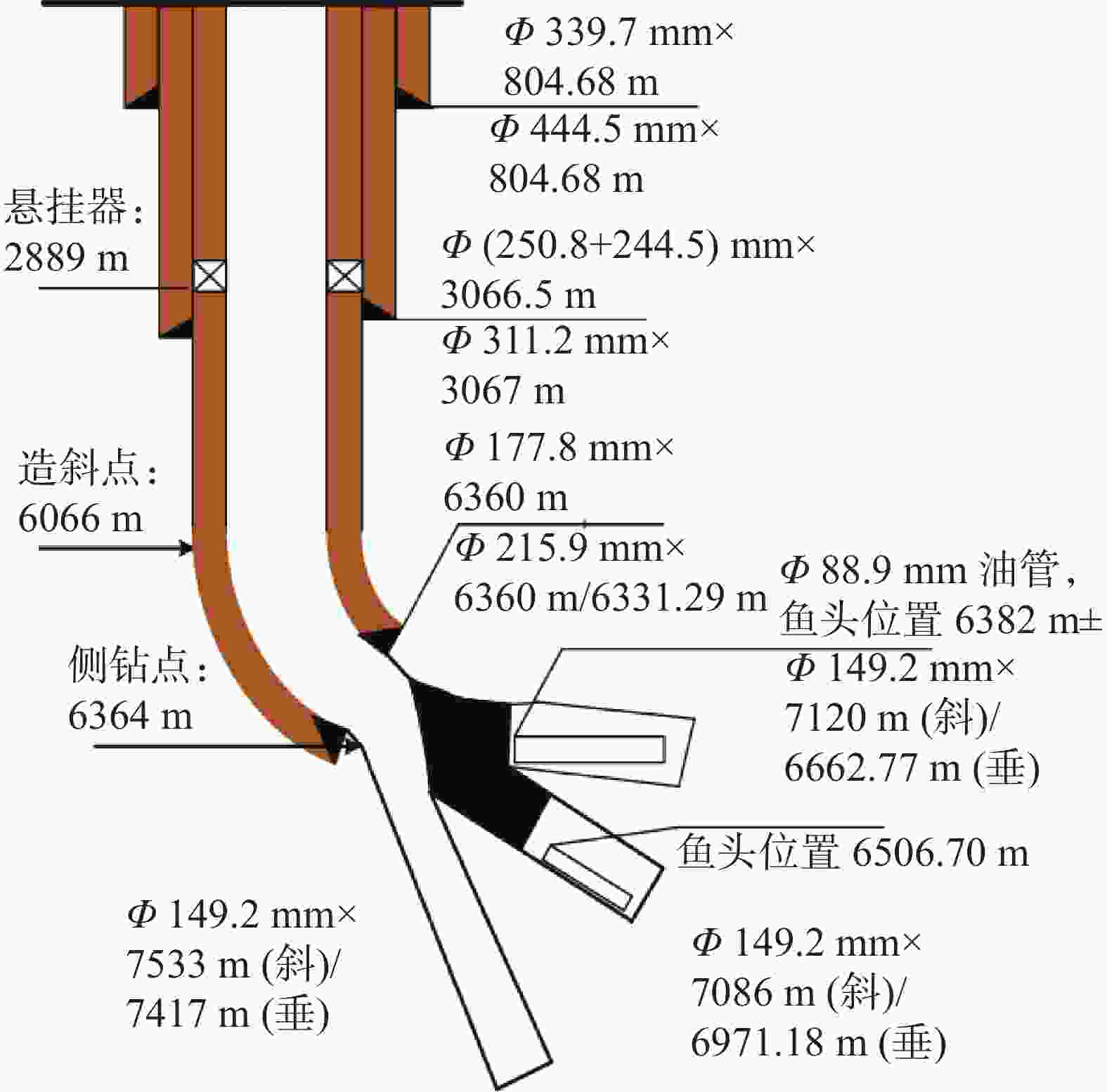

摘要: 顺北16X井是西北油田分公司部署在顺北16号断裂带的一口四开制斜井探井,完钻层位为奥陶系鹰山组,地质预测顺北16X井井底温度为168.9 ℃/6680 m。该井钻至设计井深6777 m后加深钻进,加深钻进使用ENVIROTHERM NT高性能水基钻井液,卡钻回填后采用油基钻井液进行第一次侧钻,测试未见产,再次回填采用抗高温钻井液体系。第二次侧钻实钻完钻井深7533 m(斜)/7417 m(垂),实测井底温度达209 ℃,钻井液密度最高为1.75 g/cm3,属极高温超高压地层。通过采用抗超高温钻井液体系,保障了超高温下钻井液优良的流变性和沉降稳定性,同时抗CO2、盐水污染能力优良。该井第二次侧钻顺利完钻,钻井液性能稳定,井下正常。Abstract: The well Shunbei-16X is a well drilled in the #16 fault zone in Shunbei area by Sinopec Northwest Petroleum Bureau. This is a four-interval deviated exploration well drilled to the Yingshan formation of the Ordovician system. The temperature at 6,680 m was predicted to be 168.9 ℃. After drilling to the designed depth of 6,777 m, decision was made to deepen the well with a high performance drilling fluid ENVIROTHERM NT. The drill pipe got stuck and the well was plugged, then sidetracked with an oil -based drilling fluid. Well test showed no industrial oil production. The well was then re-plugged and sidetracked again with a high temperature drilling fluid. The second sidetracking of the well was done to 7,533 m MD/7,417 m TVD, the bottom hole temperature measured was 209 ℃, and the maximum mud density was 1.75 g/cm3, indicating that the formation at the total depth of the well is an extremely high temperature ultra-high pressure formation. The high performance drilling fluid used to drill the sidetracked section of the well had excellent rheology and settling stability at extremely high formation temperatures as well as excellent resistance to CO2 and formation water contamination. The second sidetracking was successful, and no downhole troubles were ever encountered.

-

Key words:

- Ultra-high temperature /

- CO2 contamination /

- Saltwater contamination /

- Settling stability

-

表 1 邻井井温及顺北16X井第一次侧钻温度

井号 三开 四开 五开 T74位置/

mT/

℃垂深/

m地温梯度/

℃/100 mT/

℃垂深/

m地温梯度/

℃/100 mT/

℃垂深/

m地温梯度/

℃/100 m顺南7 142 6369 2.20 184 7020 5.70 193 7276 2.65 6348 顺南4 145 6300 2.30 169 6681 6.30 2.53 6325 顺南蓬1 155 6076 2.60 185 7080 3.34 208 7661 2.72 6096 顺北16X

第一次侧钻165 6331 2.60 183 6662 5.4 2.75 6339 表 2 在井浆中加入不同处理剂老化(200 ℃、12 h)后性能

钻井液 PV/

mPa·sYP/

PaGel/

Pa/Pa备注 井浆 固化,无流动性 1#+6%SMP-Ⅲ 42 15.0 7.0/15.0 开罐流动性较差,

底部有1 cm软沉淀1#+6%HTASP 39 4.5 1.5/5.0 开罐流动性好,

玻璃棒自由到底注:1#配方为:井浆+1%烧碱+6%SMC。 表 3 180 ℃抗高温沉降稳定性钻井液配方优选实验

CaCl2/

%t热滚/

hAV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mL备注 0 24 25.0 22 3.0 1.0/2.5 8.0 底部1 cm稠化 48 22.5 20 2.5 0.5/2.5 8.2 底部10 cm稠化,

少量硬沉淀0.4 24 19.0 16 3.0 0.5/1.5 8.8 上下均匀 48 15.0 13 2.0 0.5/2.5 9.0 上部1 cm清液,

底部微稠化注:基浆:2%膨润土+1%烧碱+8%SMP-Ⅲ+8.0%SMC+0.3%MMT+3%KH-n+3%KCl+0.3%季胺聚合物AHB+加重剂。 表 4 200 ℃抗高温沉降稳定性钻井液配方的优选实验

HTASP/% EHBPS-L/% MMT/% 实验条件 AV/mPa·s PV/mPa·s YP/Pa Gel/(Pa/Pa) FLHTHP/mL 备注 6 0.5 1.0 老化前 73.0 60.0 11.0 5.0/15.0 老化后 46.0 42.0 3.0 1.0/2.0 13 底部3 cm稠化 8 0.5 1.0 老化前 75.0 63.0 12.0 5.5/15.0 老化后 47.5 44.0 3.5 1.5/3.0 12 上部1 cm清液,底部微稠化 8 1.0 1.0 老化前 106.0 91.0 15.0 5.0/18.0 老化后 54.5 53.0 1.5 1.5/2.0 10 上下均匀 8 0.5 1.5 老化前 106.0 91.0 15.0 5.0/18.5 老化后 54.5 53.0 1.5 1.5/2.0 8 上部1 cm清液,底部微稠化 注:基浆:2.0%膨润土+1.5%烧碱+10.0%SMC+3%KH-n+5%KCl+1%CaCl2+加重剂。 表 5 220 ℃抗高温沉降稳定性钻井液配方评价实验

HTASP/% 实验条件 AV/mPa·s PV/mPa·s YP/Pa Gel/(Pa/Pa) FLHTHP/mL 备注 10 老化前 78.0 67.0 11.0 4.0/19.0 老化后 58.0 49.0 9.0 3.5/9.0 2 无硬沉淀,中下层稠化,搅拌恢复 15 老化前 106.0 89.0 17.0 5.5/21.0 老化后 44.5 42.0 2.5 1.0/8.0 1.8 无硬沉淀,下部黏滞强,搅拌恢复 注:基浆:2.0%膨润土+1.5%烧碱 +15.0%SMC+1%EHBPS-L+1%MMT +3%沥青粉+5%KCl+1%CaCl2+加重剂。 表 6 顺北16X井侧钻期间钻井液性能变化及处理后性能

井深/

mCl−/

mg·L−1ρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaFL/

mL7348 44 791 1.43 40 30 0 0/1.0 1.4 维护后 48 630 1.49 52 31 1.5 1.0/2.5 1.0 7460 55 360 1.17(盐水混浆) 30 4 1.0 0/0 2.0 维护后 49 981 1.49 47 25 1.0 0.5/1.5 1.0 7465 51 296 1.28(盐水混浆) 68 42 15.0 2.0/5.0 1.6 维护后 48 630 1.48 46 22 3.0 1.0/2.0 0.8 表 7 顺北16X井7460 m后效CO2污染调整后钻井液性能

井深/

mρ/

g·cm−3ρ后效/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaCO2/

%Ca2+/

mg·L−1FL/

mL6544 1.60 1.47 60 33 2 2.0/5.5 0.8 300 1.2 7460 1.47 1.34 47 23 3 1.0/3.5 11.3 100 0.6 7533 1.47 1.74 84 75 12 2.5/7.0 2.9 100 0.6 注:CO2为后效气测CO2含量。 表 8 井浆与静置110 h后循环返出后效性能对比

类别 ρ/

g·cm−3FV/

sAV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFL/

mL井浆 1.47 50 26 23 3 1.0/3.5 0.6 返出后效 1.47 80 42 25 5 2.0/5.0 0.6 -

[1] 王中华. 超高温钻井液体系研究(Ⅰ)抗高温钻井液处理剂设计思路[J]. 石油钻探技术,2009,37(3):1-7.WANG Zhonghua. Studies on ultra-high-temperature drilling fluid system (1): design ultra-high-temperature drilling fluid additives[J]. Petroleum Drilling Techniques, 2009, 37(3):1-7. [2] 杨小华. 国内超高温钻井液研究与应用进展[J]. 中外能源,2012,17(3):42-46.YANG Xiaohua. Study and application of ultra high temperature drilling fluid in China[J]. Sino-Global Energy, 2012, 17(3):42-46. [3] 胡小燕,王旭,周乐群,等. 超高温超高密度钻井液室内研究[J]. 精细石油化工进展,2013,14(1):5-8.HU Xiaoyan, WANG Xu, ZHOU Lequn, et al. Laboratory research on drilling fluid with ultra-high temperature-resistance and ultra-high density[J]. Advances in Fine Petrochemicals, 2013, 14(1):5-8. [4] 王中华,王旭,杨小华. 超高温钻井液体系研究(Ⅱ)——聚合物降滤失剂的合成与性能评价[J]. 石油钻探技术,2009,37(4):1-6.WANG Zhonghua, WANG Xu, YANG Xiaohua. Ultra high temperature drilling fluid system study(2):synthesis and evaluation of a polymer fluid loss additives[J]. Petroleum Drilling Techniques, 2009, 37(4):1-6. [5] 王中华,王旭. 超高温钻井液体系研究(Ⅲ)——抗盐高温高压降滤失剂研制[J]. 石油钻探技术,2009,37(5):5-9.WANG Zhonghua, WANG Xu. Studies on ultra-high temperature drilling fluid system (3)——development of the salt-resistant high temperature and high pressure fluid loss reagent[J]. Petroleum Drilling Techniques, 2009, 37(5):5-9. [6] 王中华. 国内外超高温高密度钻井液技术现状与发展趋势[J]. 石油钻探技术,2011,39(2):1-7.WANG Zhonghua. Status and development trend of ultra-high temperature and high density drilling fluid at home and abroad[J]. Petroleum Drilling Techniques, 2011, 39(2):1-7. [7] 王旭,王中华,周乐群,等. 240 ℃超高温饱和盐水钻井液室内研究[J]. 钻井液与完井液,2011,28(4):19-21,93.WANG Xu, WANG Zhonghua, ZHOU Lequn, et al. Laboratory study on the 240 ℃ ultra-high temperature saturated brine drilling fluid[J]. Drilling Fluid & Completion Fluid, 2011, 28(4):19-21,93. [8] 王中华,王旭,杨小华. 超高温钻井液体系研究(Ⅳ)——盐水钻井液设计与评价[J]. 石油钻探技术,2009,37(6):1-5.WANG Zhonghua, WANG Xu, YANG Xiaohua. A study on ultra high temperature drilling fluid system(Ⅳ):brine drilling fluid design and evaluation[J]. Petroleum Drilling Techniques, 2009, 37(6):1-5. [9] 毛惠. 超高温超高密度水基钻井液技术研究[D]. 中国石油大学(华东), 2017.MAO Hui. Research on the technology of ultra-high temperature and ultra-high density water based drilling fluid[D]. Qingdao: China University of Petroleum(East China), 2017. [10] 张斌.超深井、超高温钻井液技术研究[D]. 北京:中国地质大学(北京),2010.ZHANG Bin. The research on drilling fluid technology under ultra-deep well and ultra-temperature[D]. Beijing: China University of Geosciences(Beijing), 2010. [11] 林四元,卢运虎,张立权. 琼东南盆地高温高压井强承压堵漏技术[J]. 钻井液与完井液,2023,40(3):363-367.LIN Siyuan, LU Yunhu, ZHANG Liquan. Mud loss control technology in Qiongdongnan basin under high temperature and high pressure bearing conditions[J]. Drilling Fluid & Completion Fluid, 2023, 40(3):363-367. [12] 李雄,董晓强,金军斌,等. 超高温高密度钻井液体系的研究与应用[J]. 钻井液与完井液,2020,37(6):694-700.LI Xiong, DONG Xiaoqiang, JIN Junbin, et al. Study and application of an ultra-high temperature high density drilling fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):694-700. [13] 刘鹭. 水基钻井液抗高温温度保护剂和降失水剂研究[D]. 成都:西南石油大学,2014.LIU Lu. Study on high temperature protection agent and water loss agent of water-based drilling fluid[D]. Chengdu: Southwest Petroleum University, 2014. [14] 刘晓栋,刘涛. 钻井液高温流变性能测试仪器与测试方法[J]. 钻井液与完井液,2021,38(3):280-284.LIU Xiaodong, LIU Tao. Equipment and methods of measuring high temperature rheology of drilling fluids[J]. Drilling Fluid & Completion Fluid, 2021, 38(3):280-284. [15] 孙强,邱正松,李自立,等. 高密度钻井液沉降稳定性的模拟试验研究[J]. 能源化工,2020,41(6):49-55.SUN Qiang, QIU Zhengsong, LI Zili, et al. Simulation study on sedimentation stability of high density drilling fluid[J]. Energy Chemical Industry, 2020, 41(6):49-55. [16] 任亮亮,陈晨,李超,等. 加重材料对抗高温高密度合成基钻井液性能的影响[J]. 钻井液与完井液,2023,40(5):551-555.REN Liangliang, CHEN Chen, LI Chao, et al. Effect of weighting materials on the properties of synthetic-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2023, 40(5):551-555. [17] 高重阳,黄贤斌,白英睿,等. 水基钻井液用抗超高温聚合物刷润滑剂的研制[J]. 钻井液与完井液,2023,40(4):453-461.GAO Chongyang, HUANG Xianbin, BAI Yingrui, et al. Development of ultra-high temperature polymer brush lubricant for water based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2023, 40(4):453-461. -

下载:

下载: