Challenges, Developments, and Suggestions for Drilling Fluid Technology in China

-

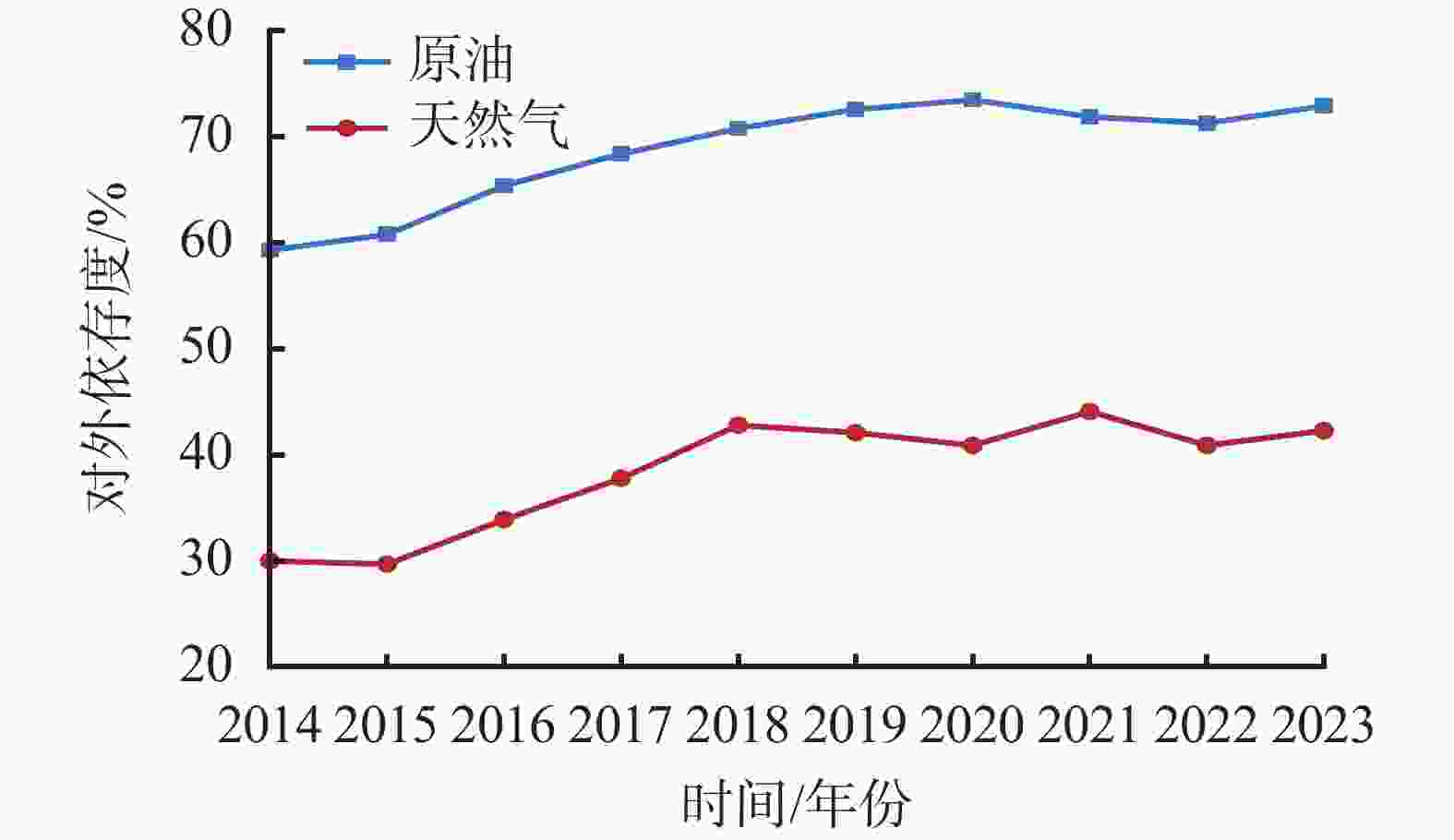

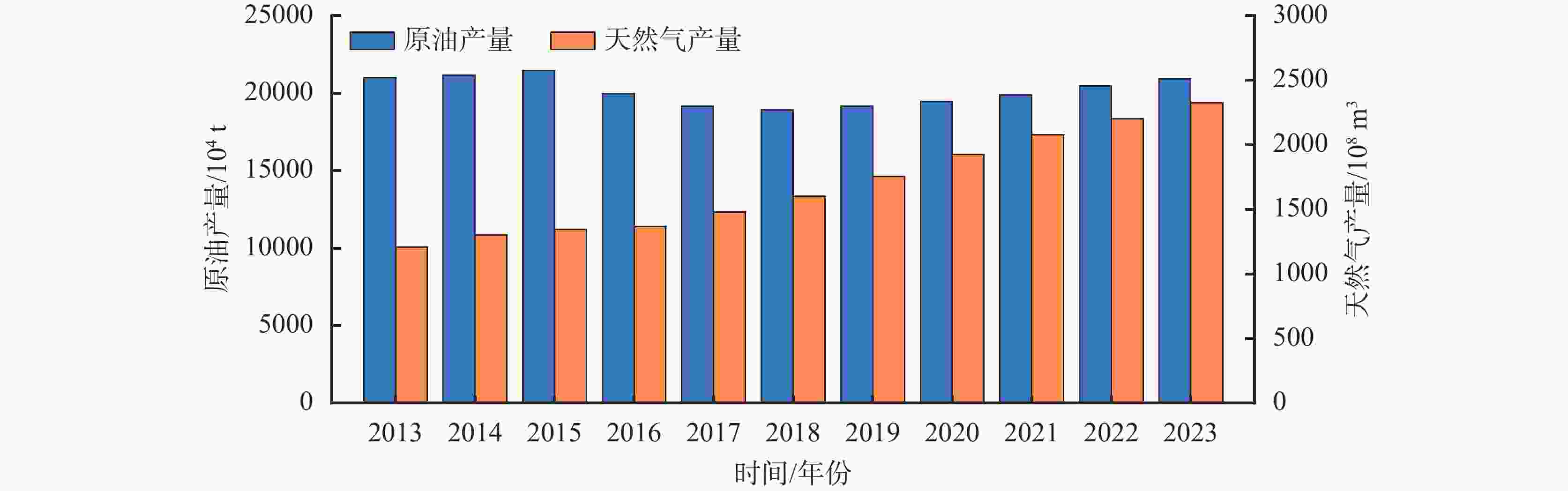

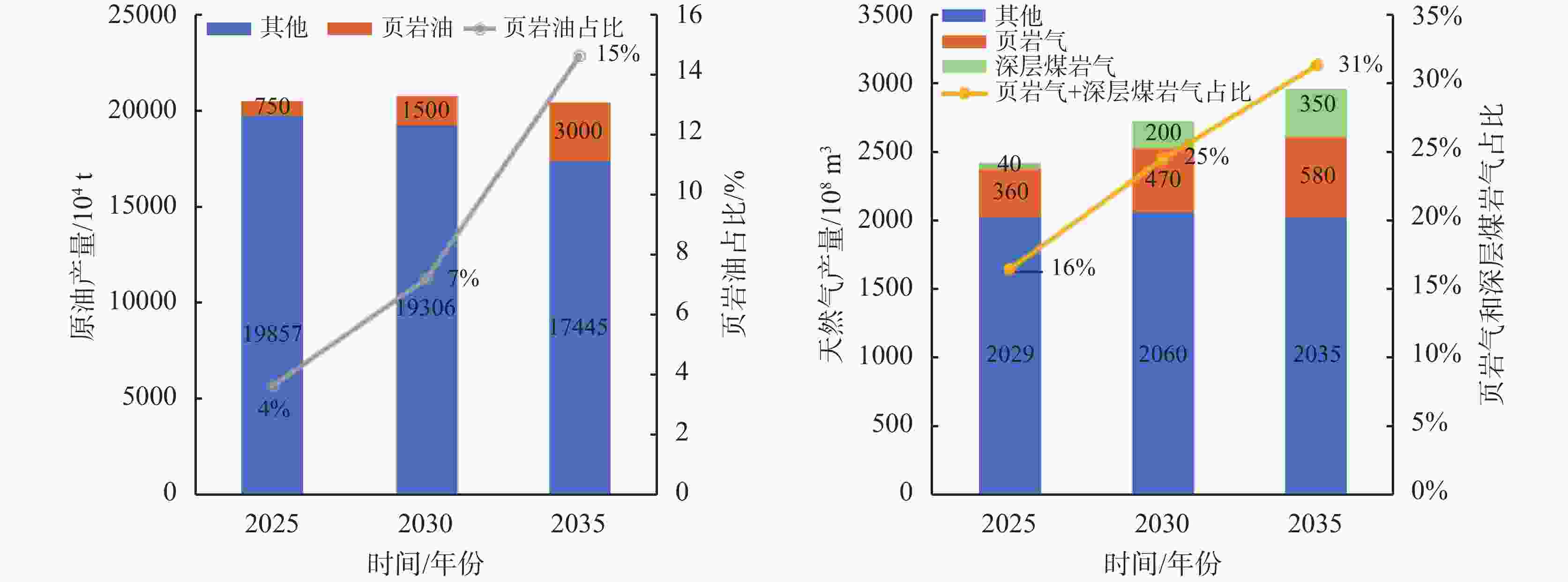

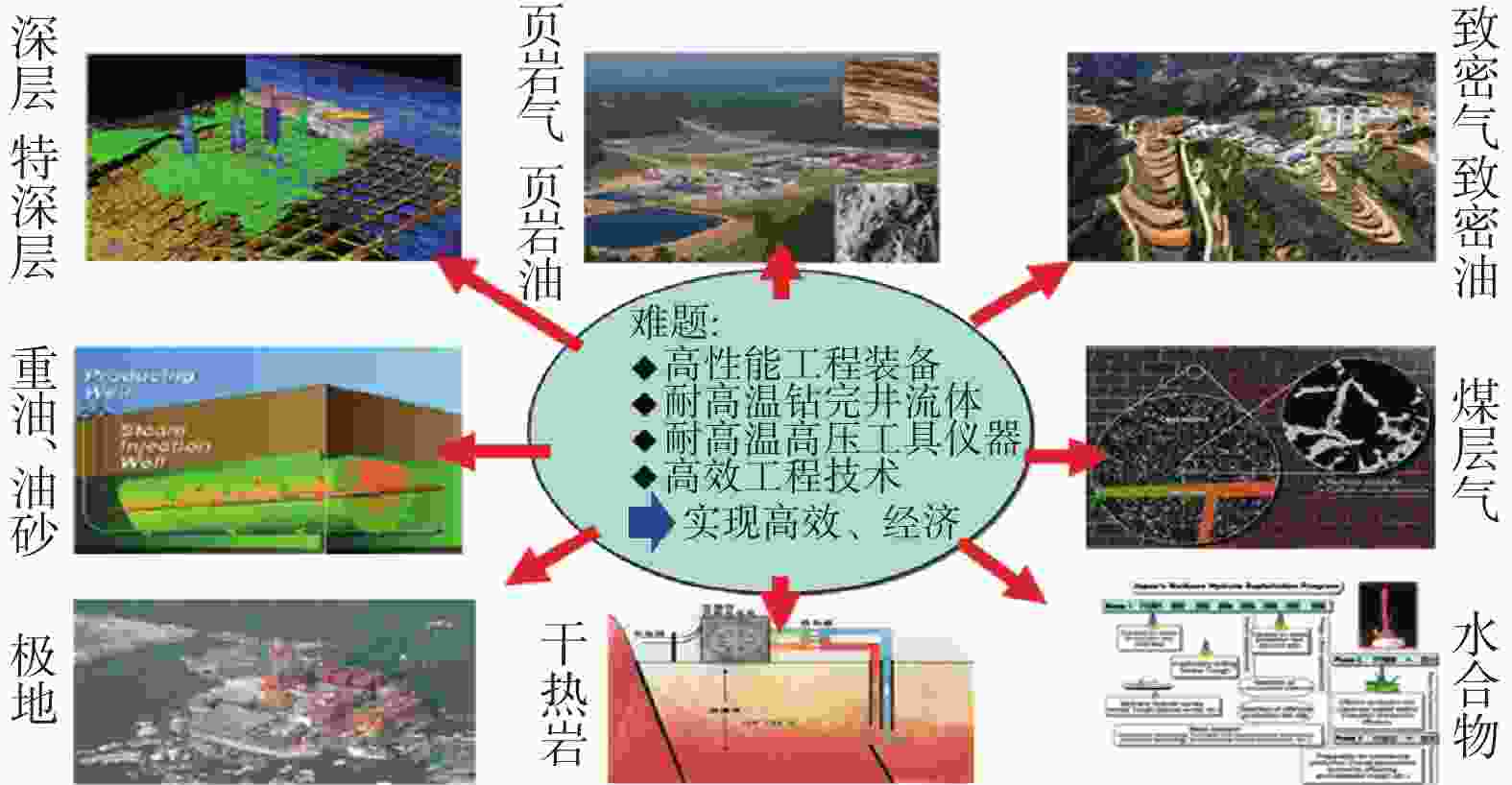

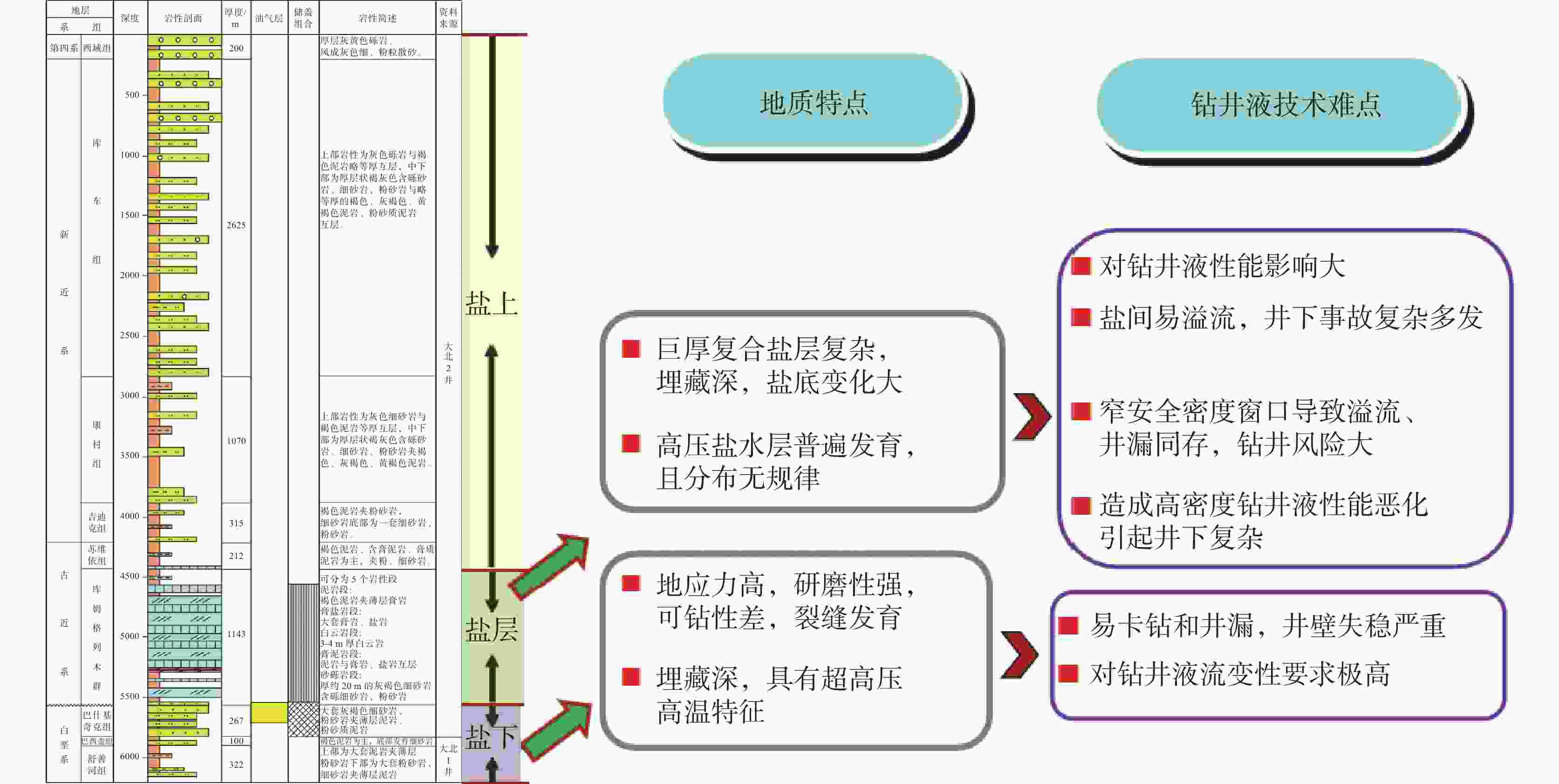

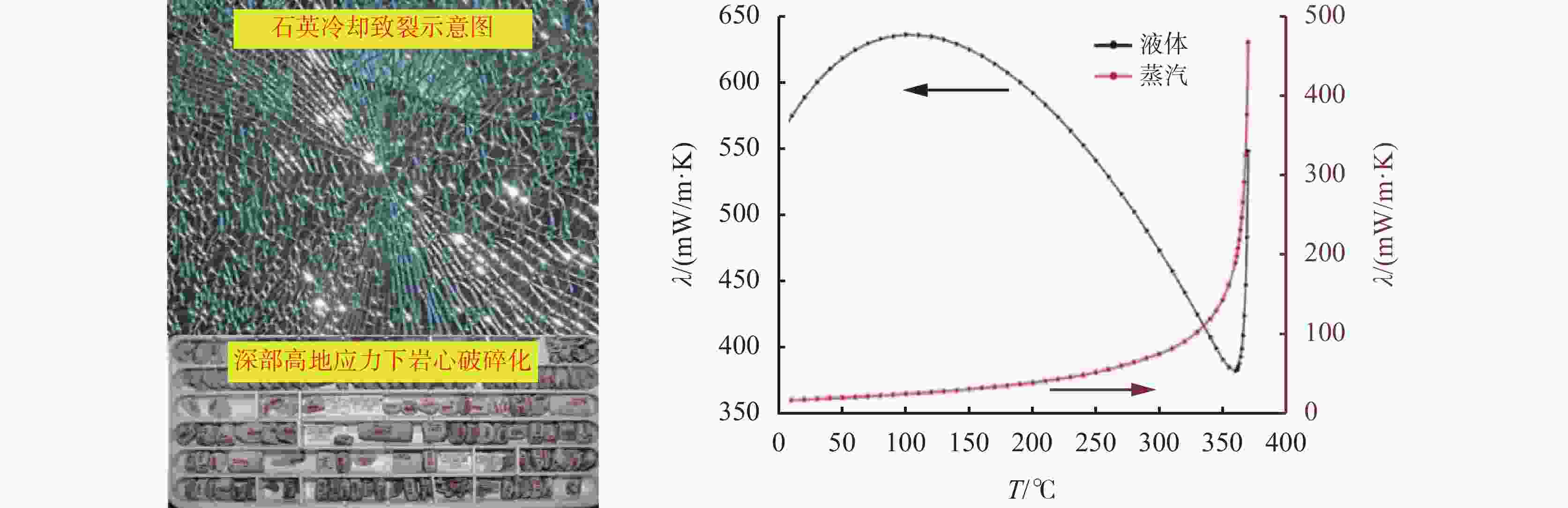

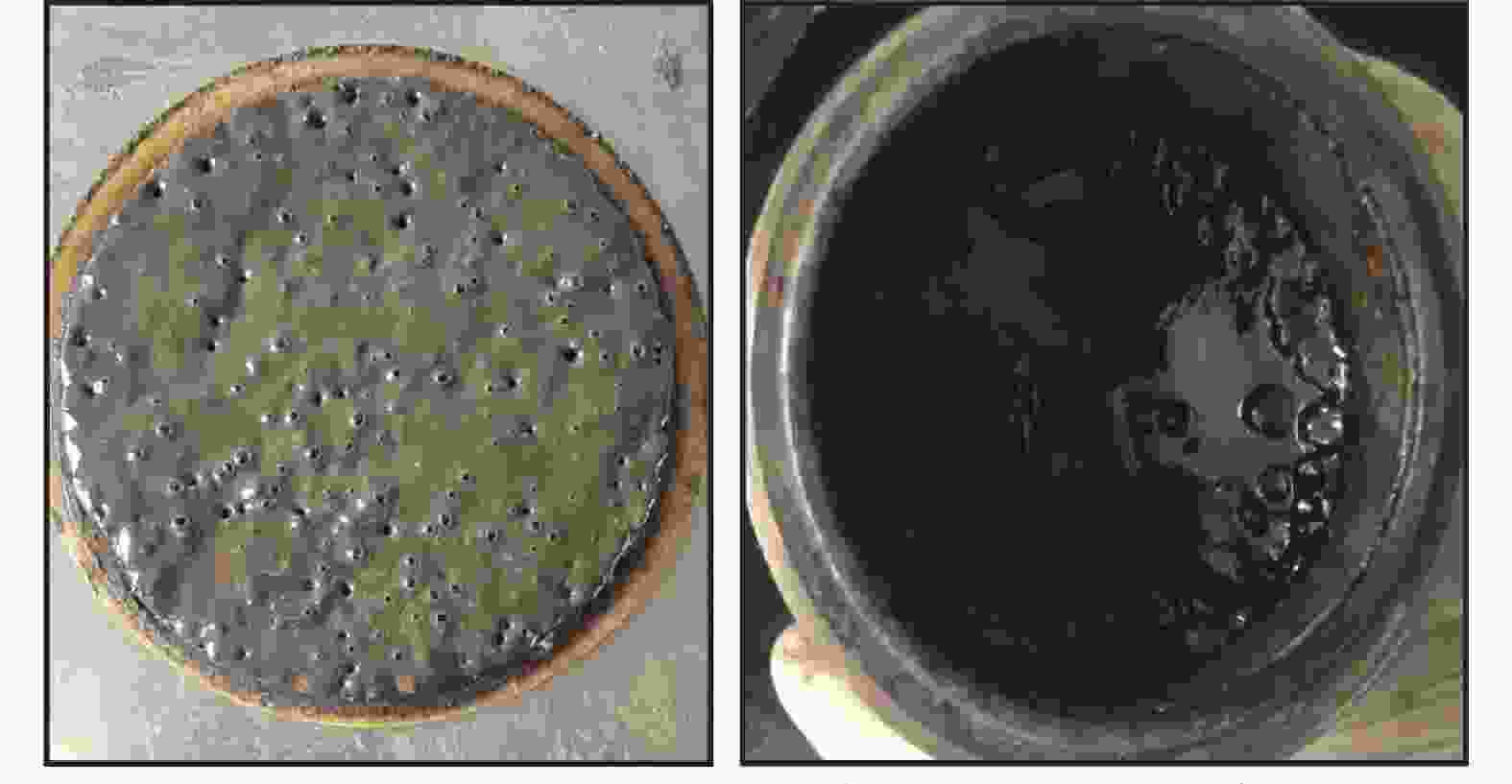

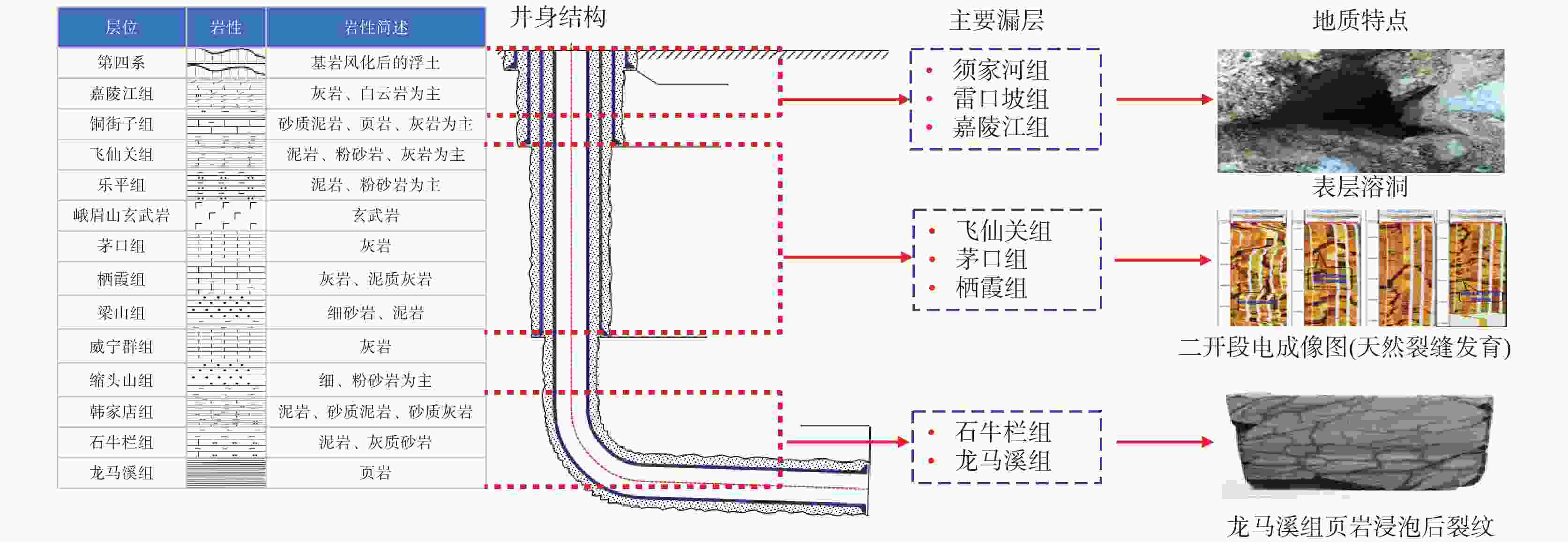

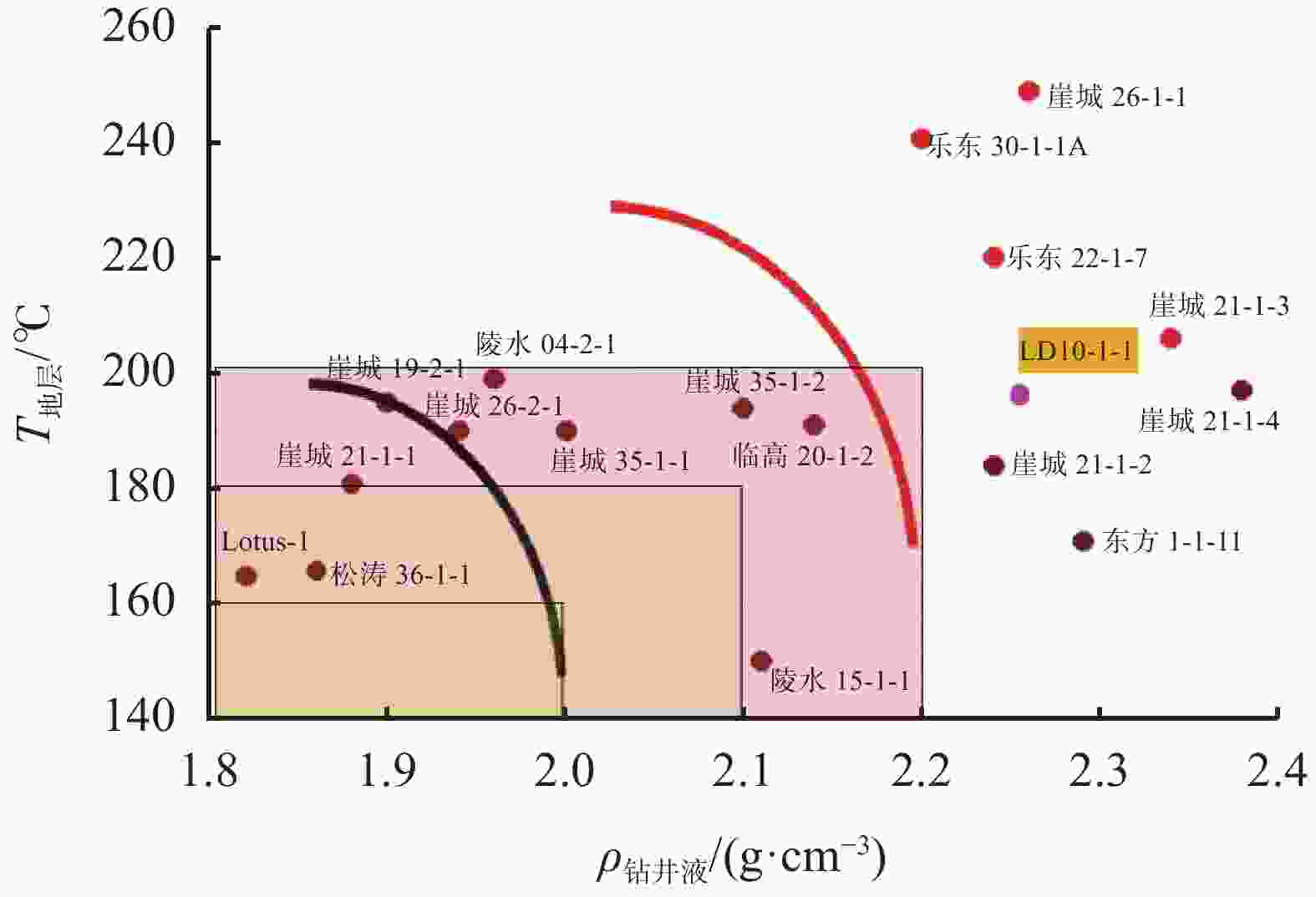

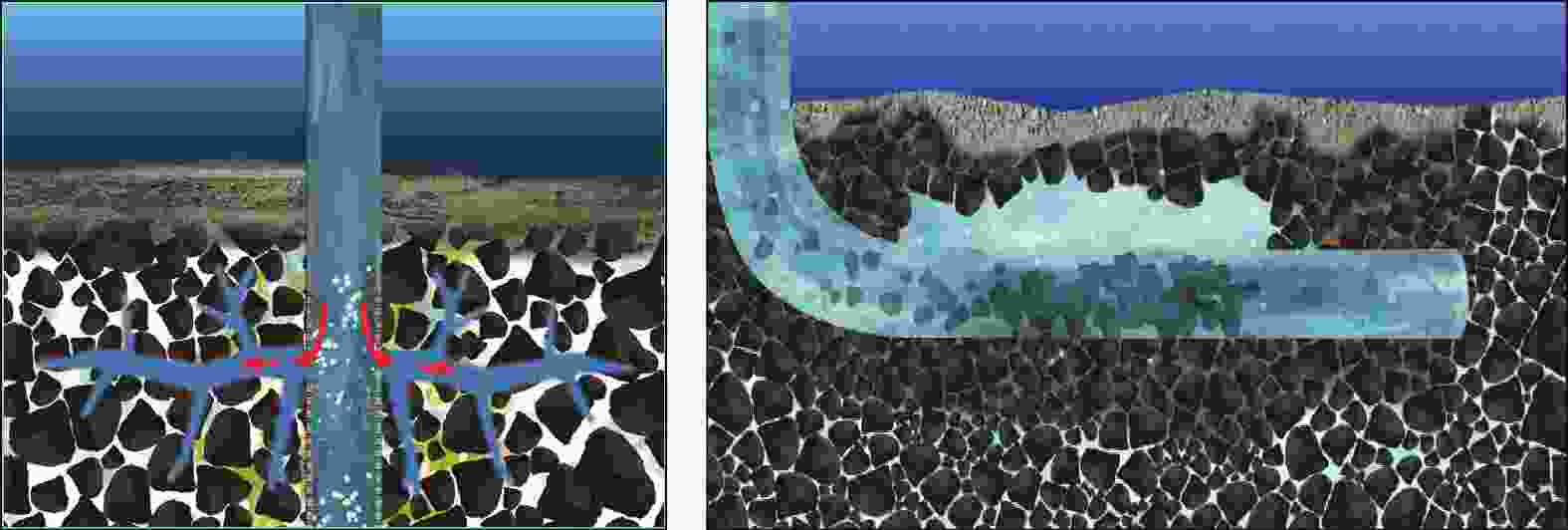

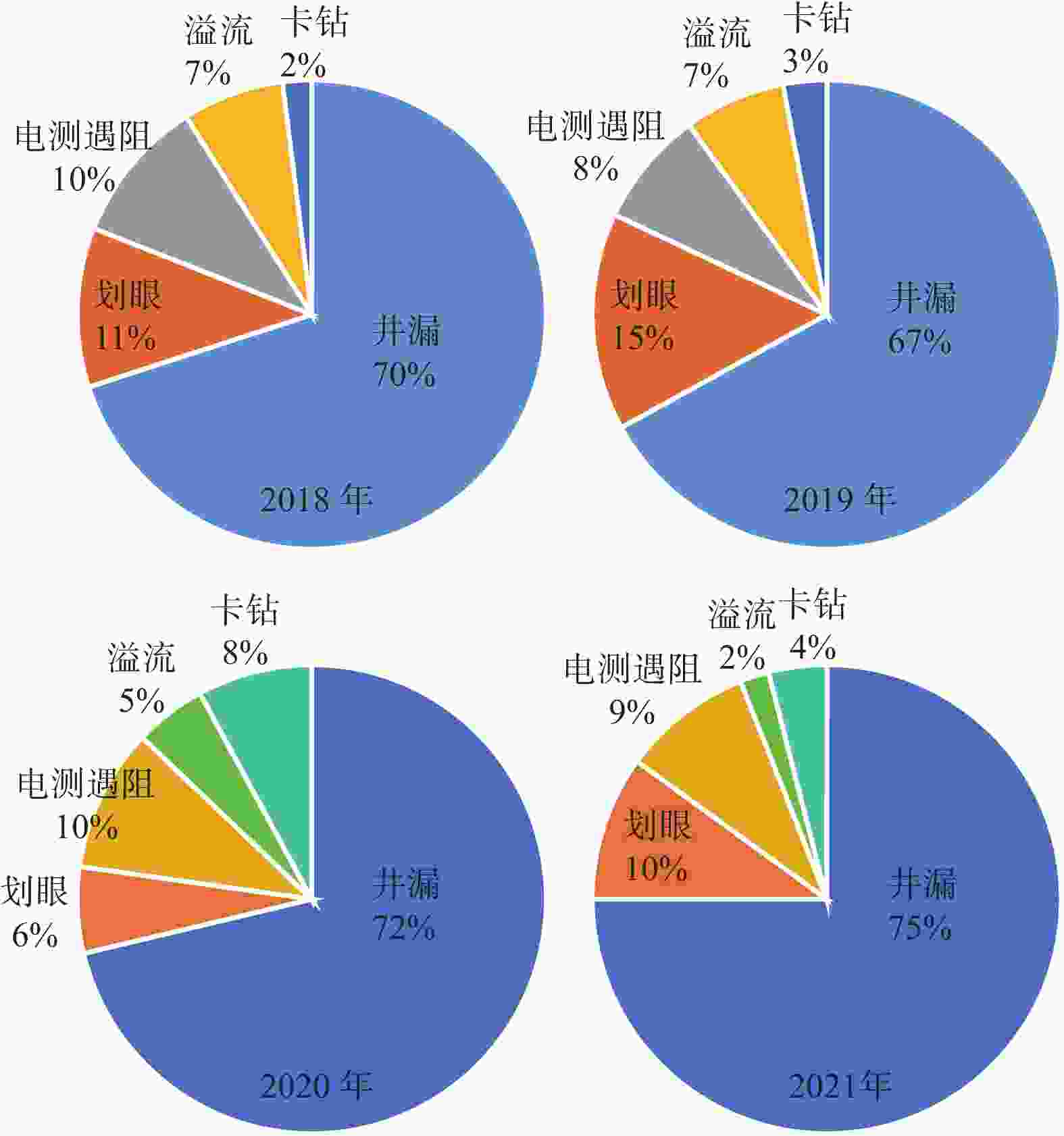

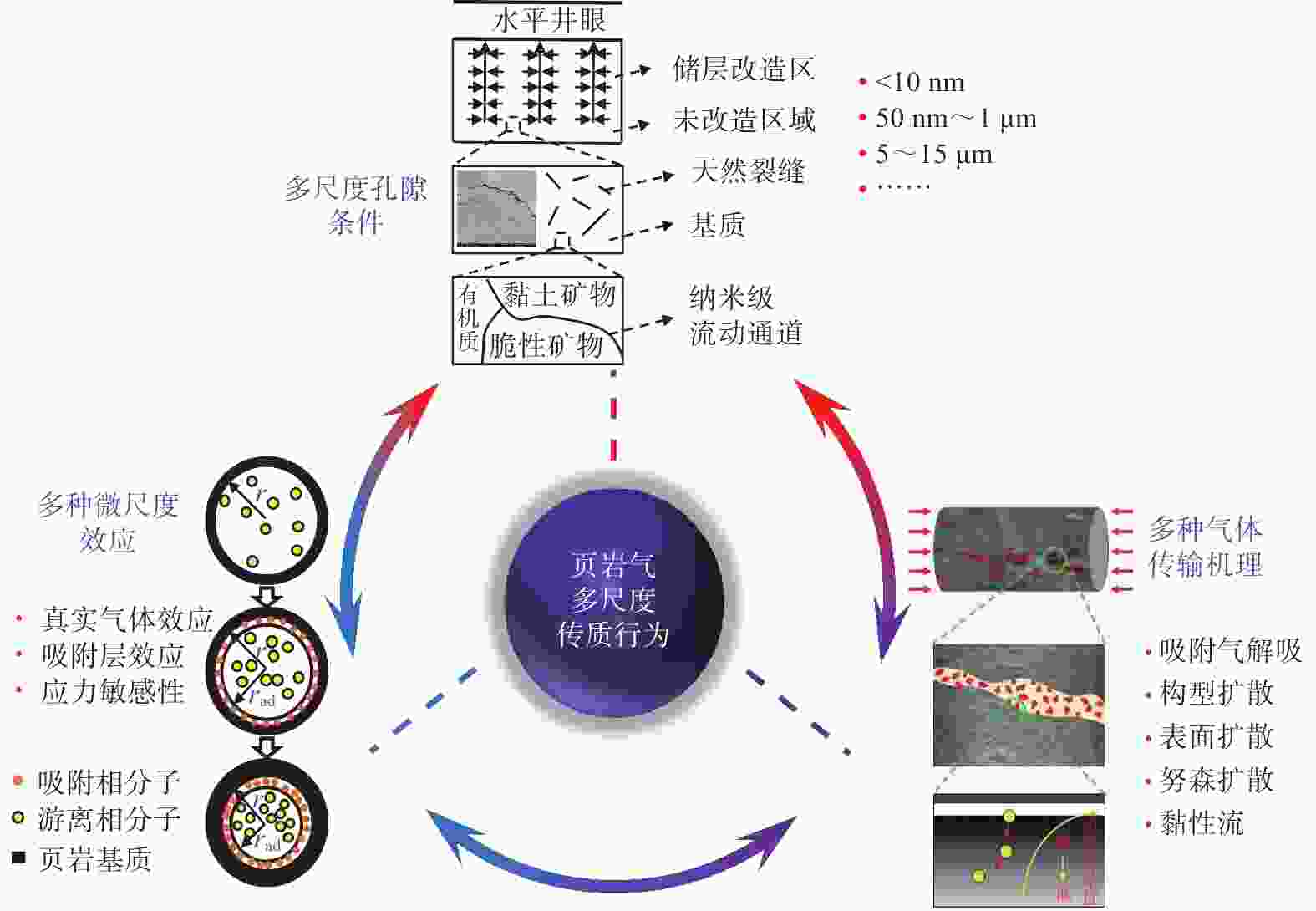

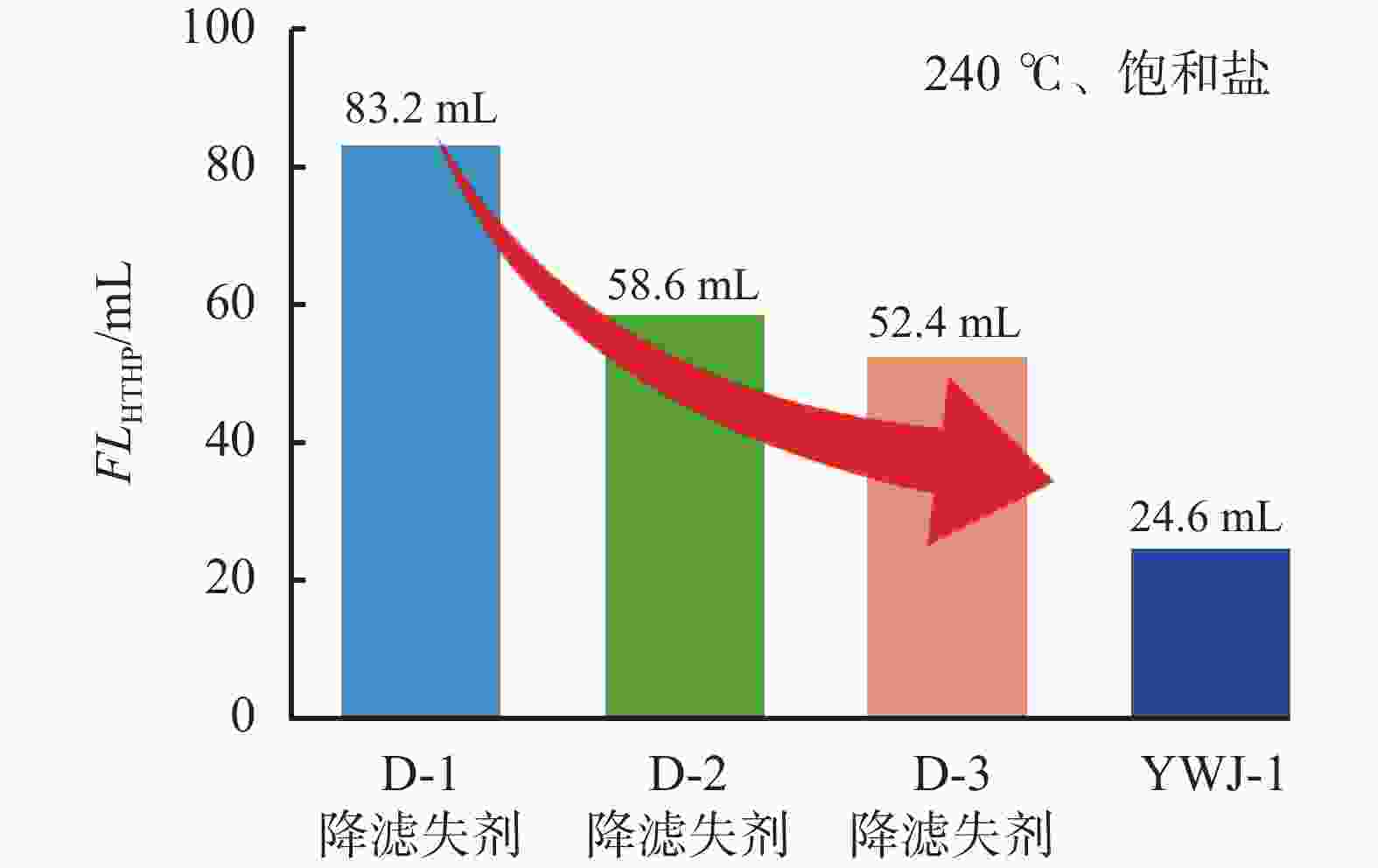

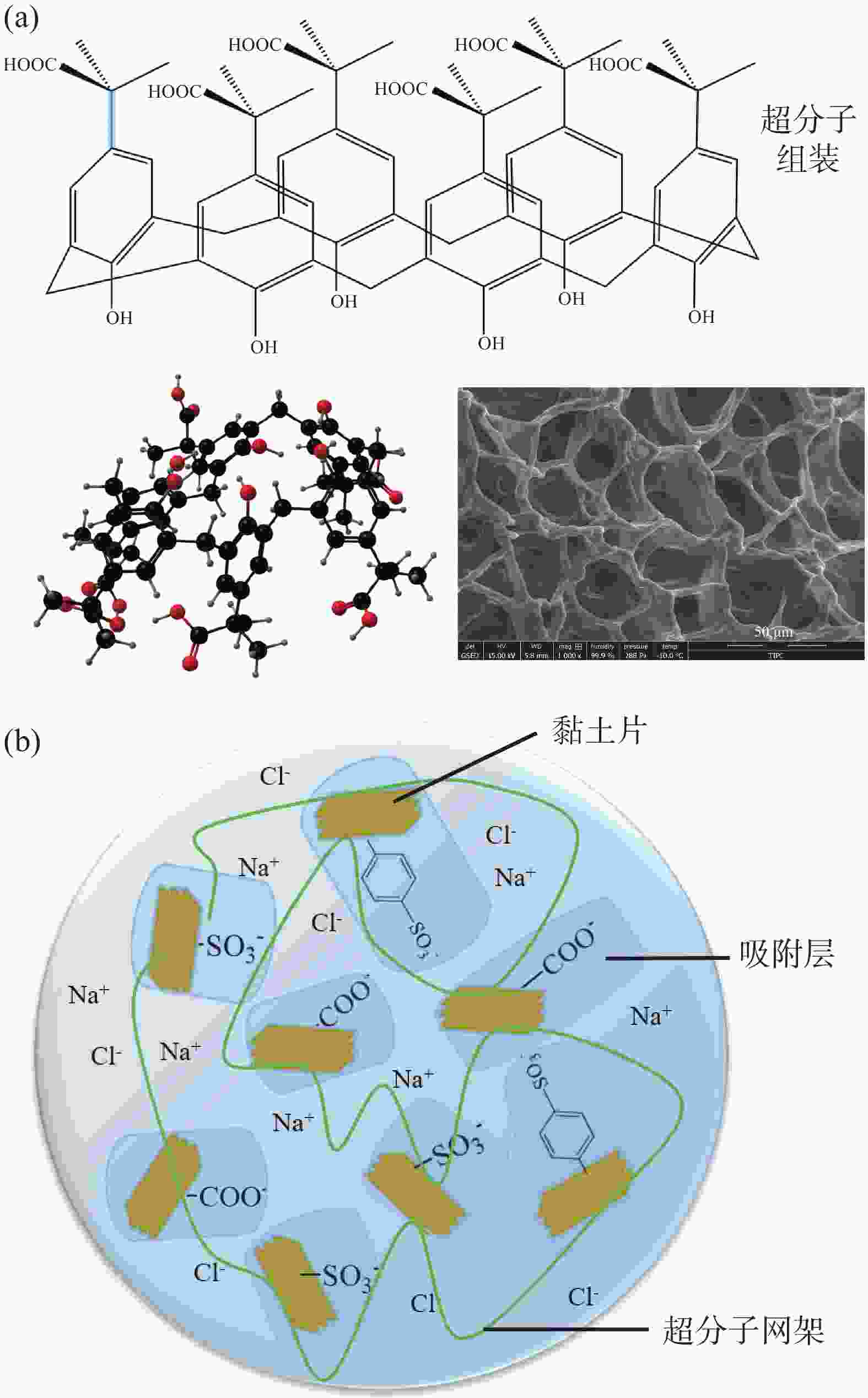

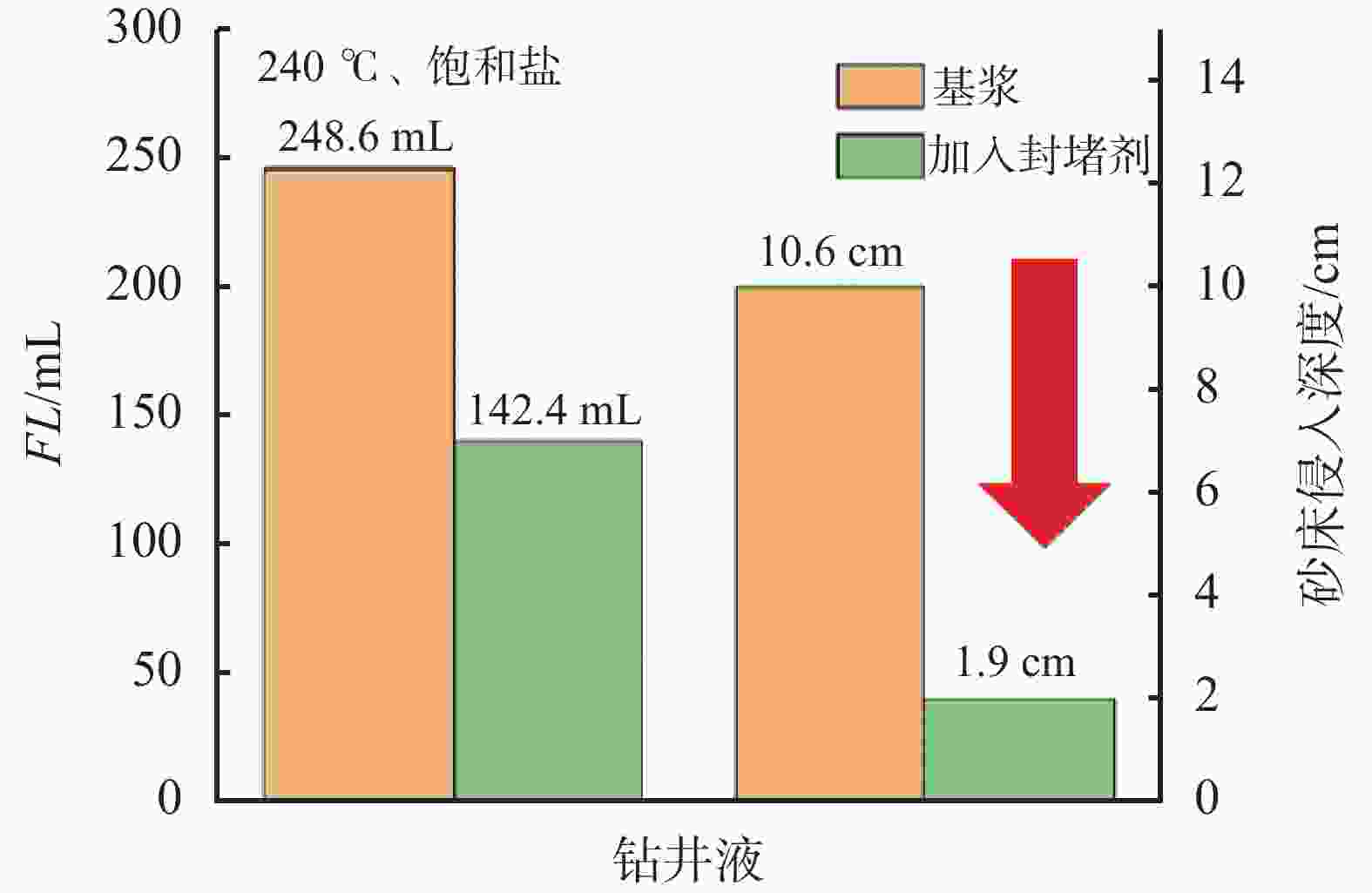

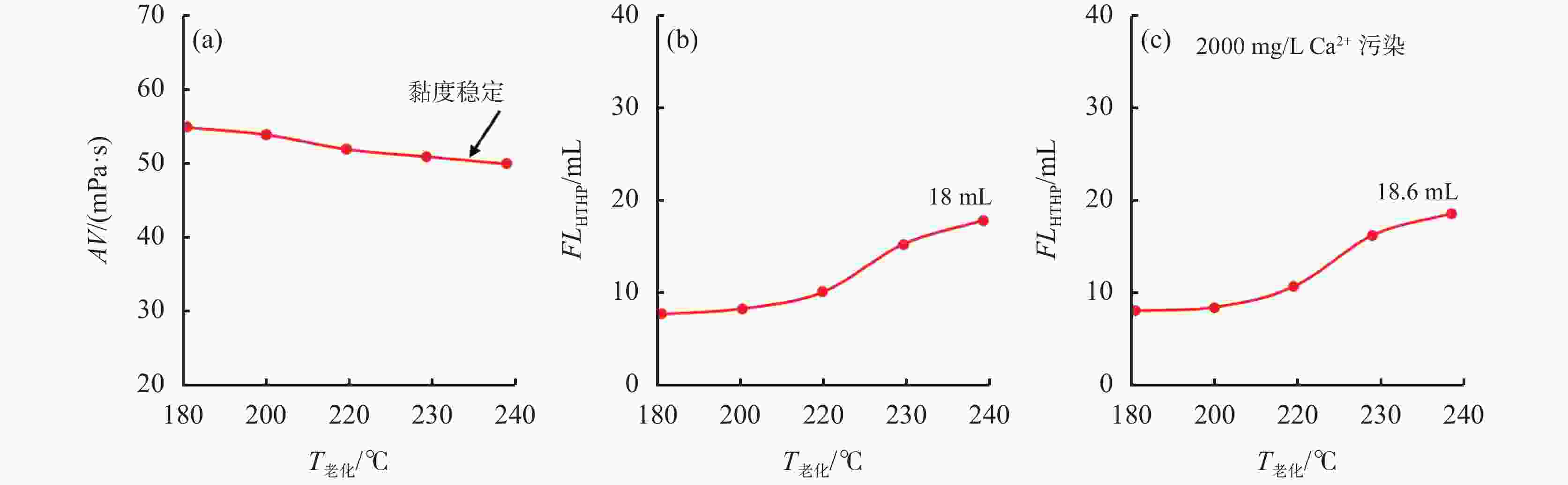

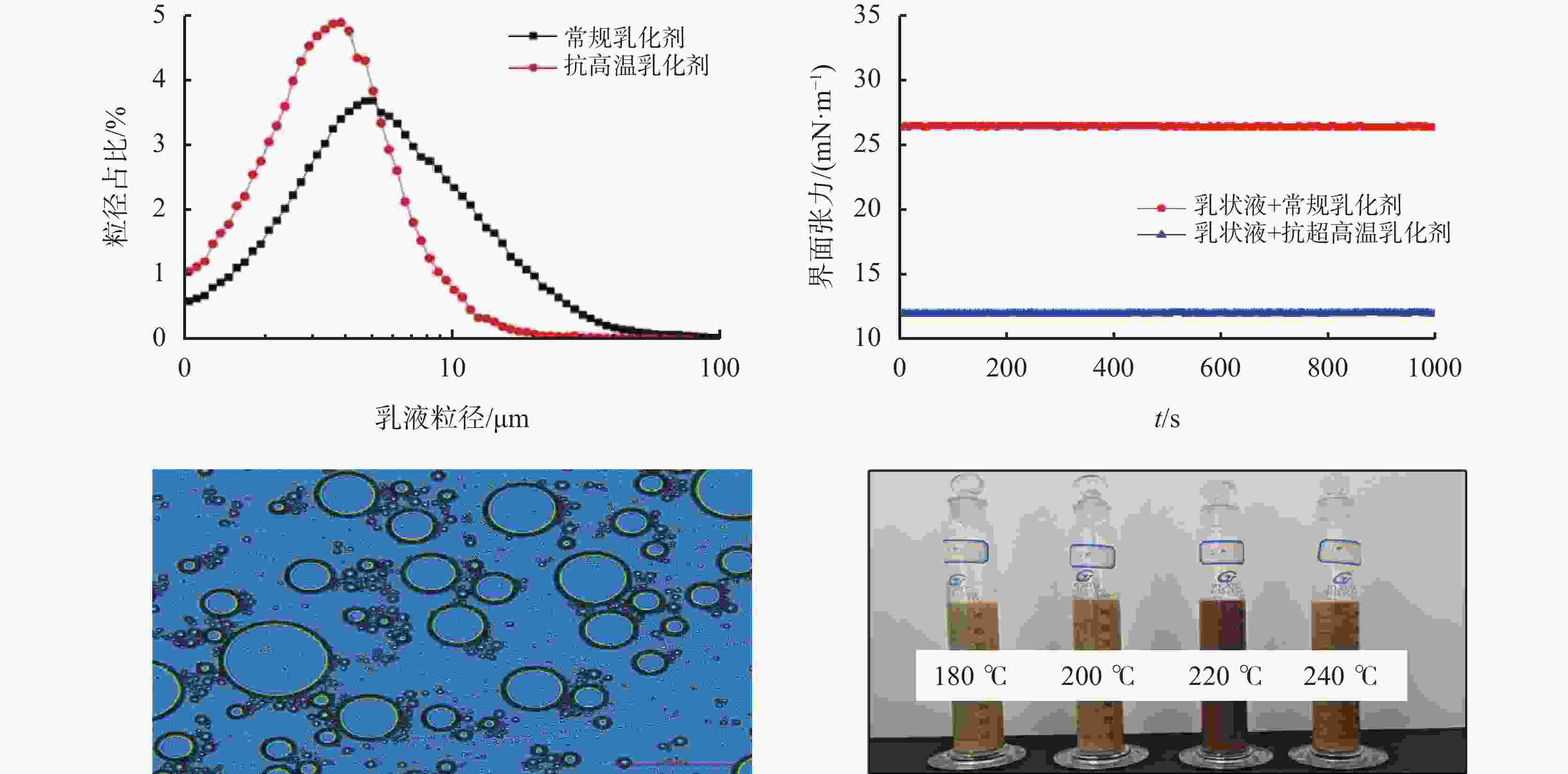

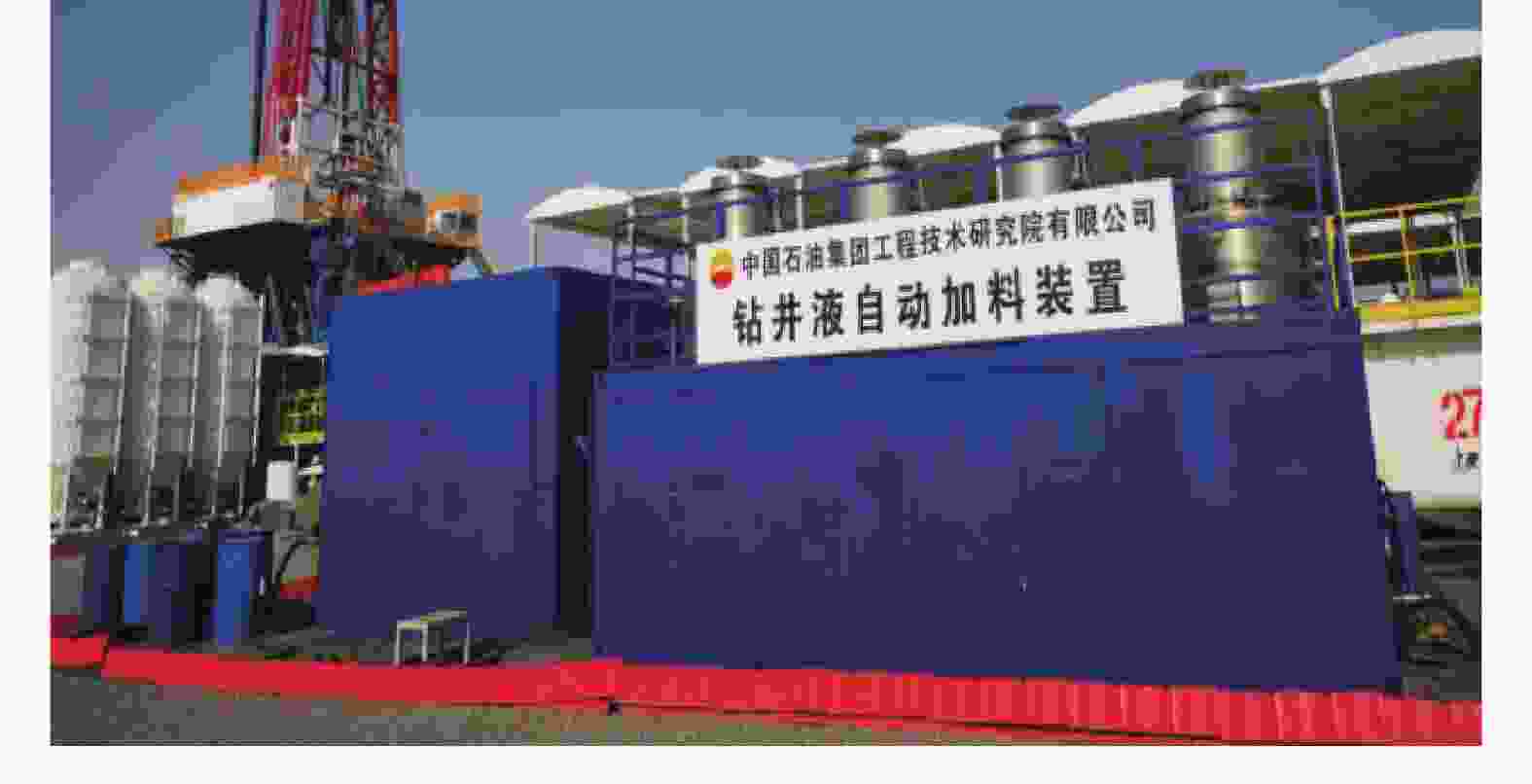

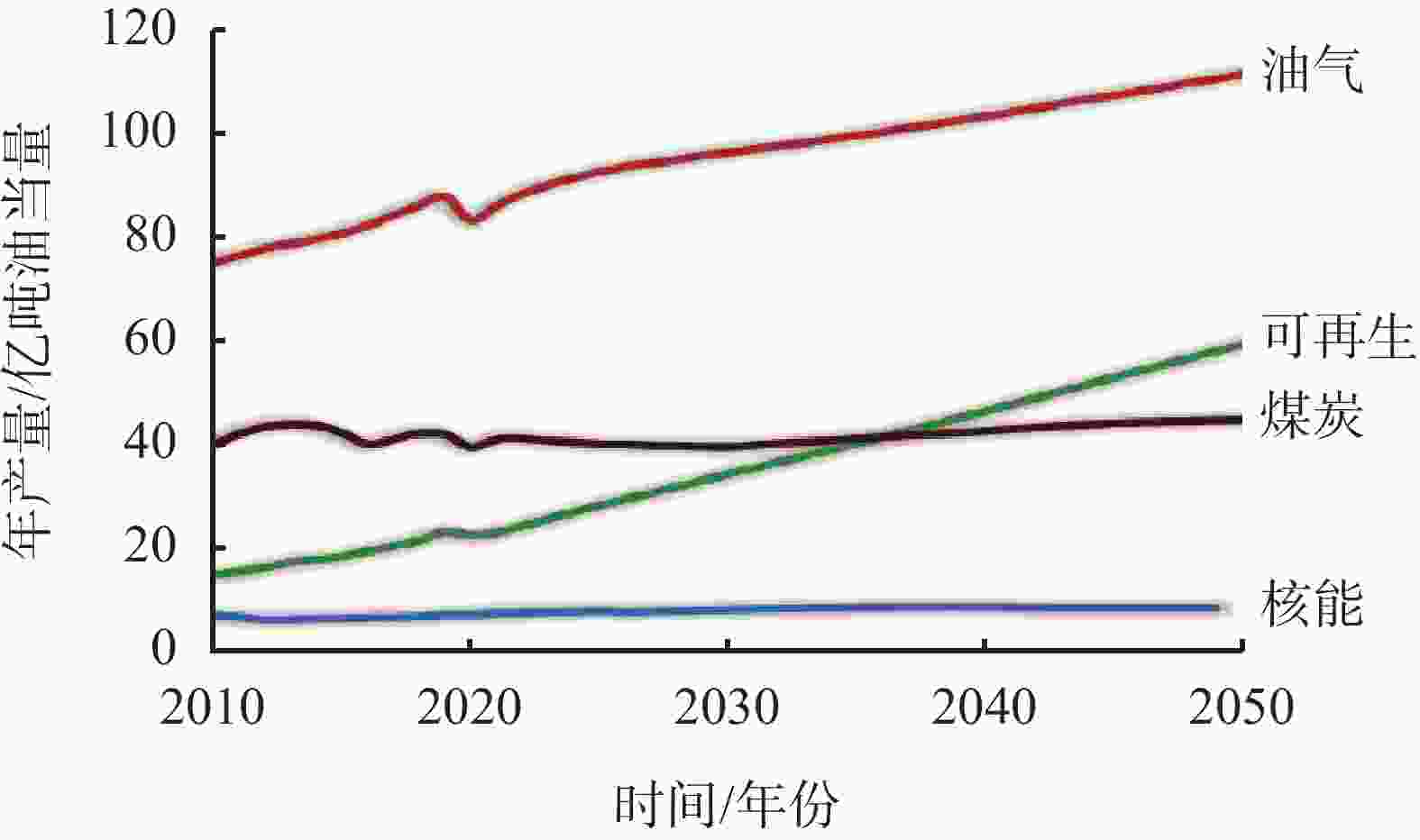

摘要: 系统地梳理了超深/特深层、非常规、深水、干热岩、极地、天然气水合物等复杂地层钻探过程中面临的钻井液技术难题,探讨了关键科学问题与核心工程难题,结合近年来的钻井液技术进展,介绍了钻井液技术最新进展。针对复杂地层钻井过程中遇到的高温高压高盐、泥页岩水化严重、井壁失稳、大温差、井漏、储层损害,以及钻井液维护自动化程度低等问题,国内外学者研发了抗高温高盐水基/油基钻井液、恒流变钻井液、抗超高温泡沫钻井液、环境友好型超低温钻井液、智能温压响应承压堵漏材料、可降解储层保护材料、钻井液在线监测与自动加料系统等关键材料、体系与装备。但随着地质、工程环境愈加复杂 ,钻井液材料仍面临抗超高温高盐、超长时间稳定、防塌固壁、恶性漏失以及钻井液性能自动化调控等重大技术瓶颈。为满足复杂地层钻探过程中钻井液性能需求 ,未来还需深入研究钻井液处理剂在极端条件下的起效/失效机理 ,钻井液处理剂在微观-介观-宏观等不同尺度下的构效关系变化及作用机制,建立安全高效的钻井液多功能一体化调控方法,构建智能钻井液理论与技术,为实现复杂地层安全高效经济环保钻井提供关键技术支撑。Abstract: The technical problems of drilling fluid in ultra-deep, unconventional oil/gas, deep water, hot dry rock, polar, natural gas hydrate and other complex formations are systematically sorted out. The key scientific problems and core engineering problems are discussed. Combined with the research progress of drilling fluid technology in recent years, the development of drilling fluid technology for ultra-deep, unconventional oil/gas, deep water, hot dry rock, polar, natural gas hydrate and other complex oil and gas is provided.The problems in the drilling of complex formations, such as hightemperature, high-pressure and high- salinity, serious shale hydration, wellbore instability, large temperature difference, loss circulation, formation damage, and low degree of automation of drilling fluid maintenance, domestic and foreign researchers have developed key material, systems and equipments such as high-temperature and high-salinity water-based/oil-based drilling fluid, constant rheological drilling fluid, anti-ultra-high temperature foam drilling fluid, environmentally friendly ultra-lowtemperature drilling fluid, intelligent temperature and pressure response plugging material, degradable reservoirprotection material, drilling fluid online monitoring and automatic feeding system. However, with the increasingly complex formationconditions of drilling, there are still deficiencies in drilling fluid materials in terms of ultra-high temperature resistance, ultra-long-term stability, clay swelling inhibition, and environmental protection performance. Severe/total loss circulation, reservoirprotection, and drilling fluid automation control still face severe challenges. In order to meet the performance requirements of drillingfluid in the process of drilling in complex formations, it is necessary to further study the working/failure mechanism of drilling fluidadditives under complex formation conditions, the structure-activity relationship changes and action mechanism of drilling fluidadditives at different scales such as micro-meso-macro scales, establish a safe and efficient multi-functional integrated controlmethod of drilling fluid, construct intelligent drilling fluid theory and technology, and provide technical support for the development of complex underground resources.

-

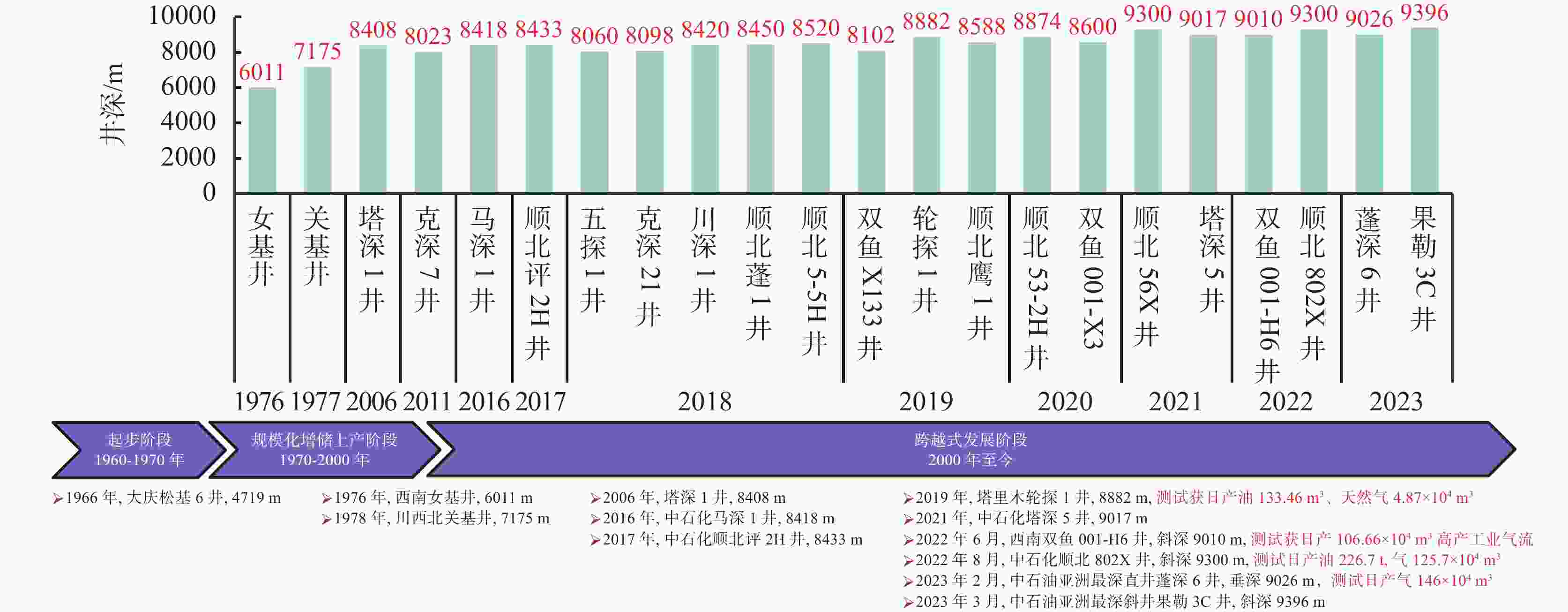

表 1 全球主要深层油气藏实钻相关数据统计

地区 储层深度/

m储层温度/℃ 储层压力/MPa 砾石层

最大厚度/m最大地层倾角/

(°)盐层最大厚度/m 盐层

特征最多盐层套数 盐水最高压力系数 最高硫化氢浓度/(mg·L−1) 最高CO2物质的量浓度/% 最大孔隙度/% 最大渗透率/

mD塔里木盆地 6000~

8882130~

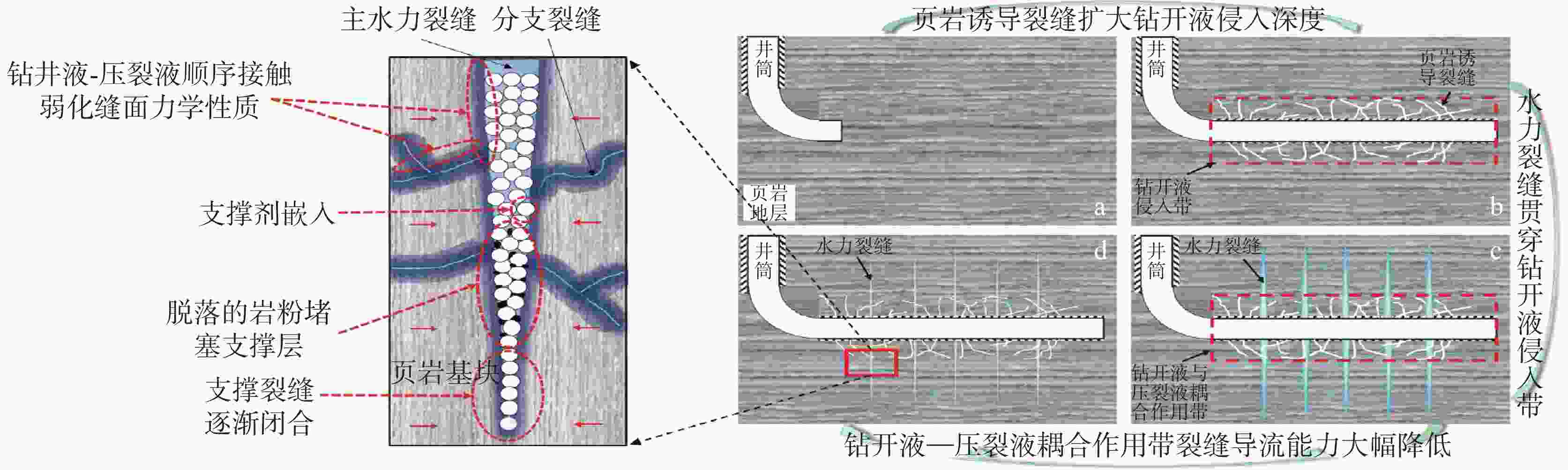

19070~

1435833 87 5969 复合

盐层3 2.64 45.7×104 16 8.0 0.1 四川

盆地6000~

8500130~

20360~

147200 70 800 复合

盐层1 2.20 62.1×104 32 6.0 1 墨西

哥湾6000~

12 000240~

26570~

2065500 纯盐 2 2.27 46×104 40 34.1 1200 英国

北海5000~

6500180~

20560~

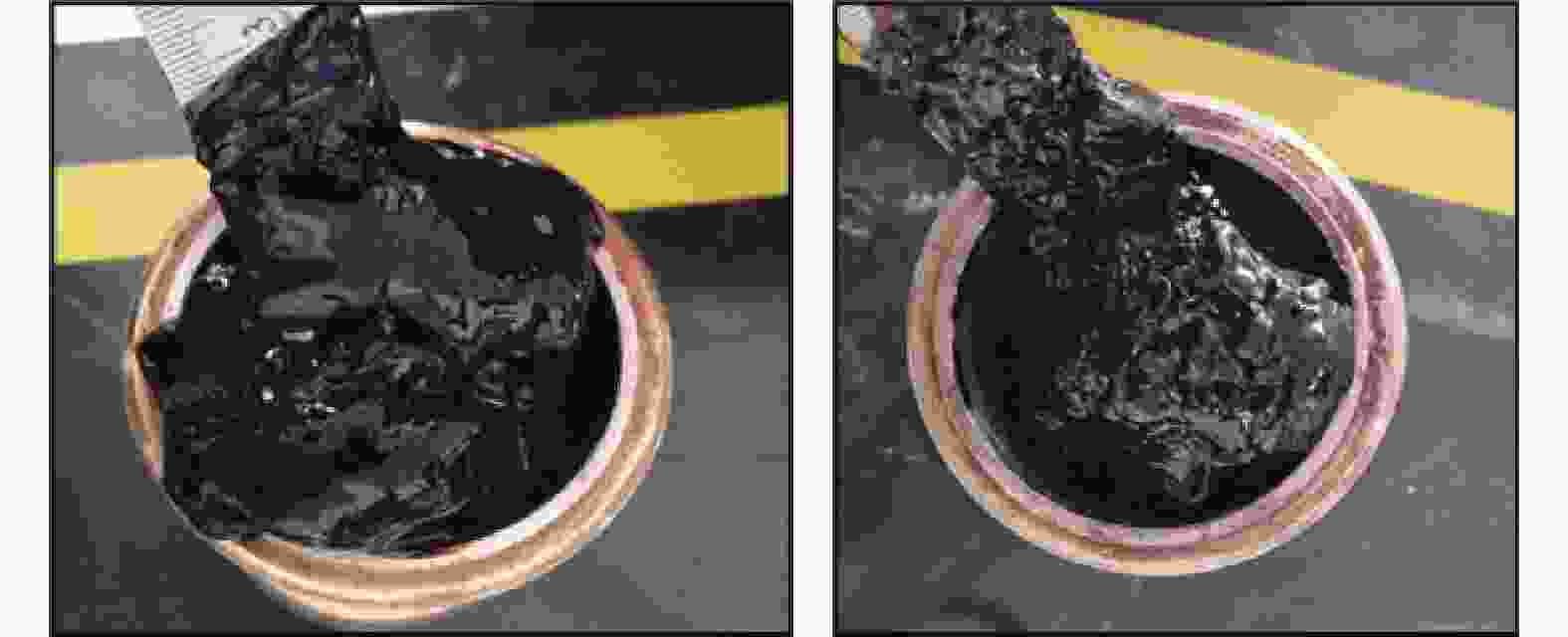

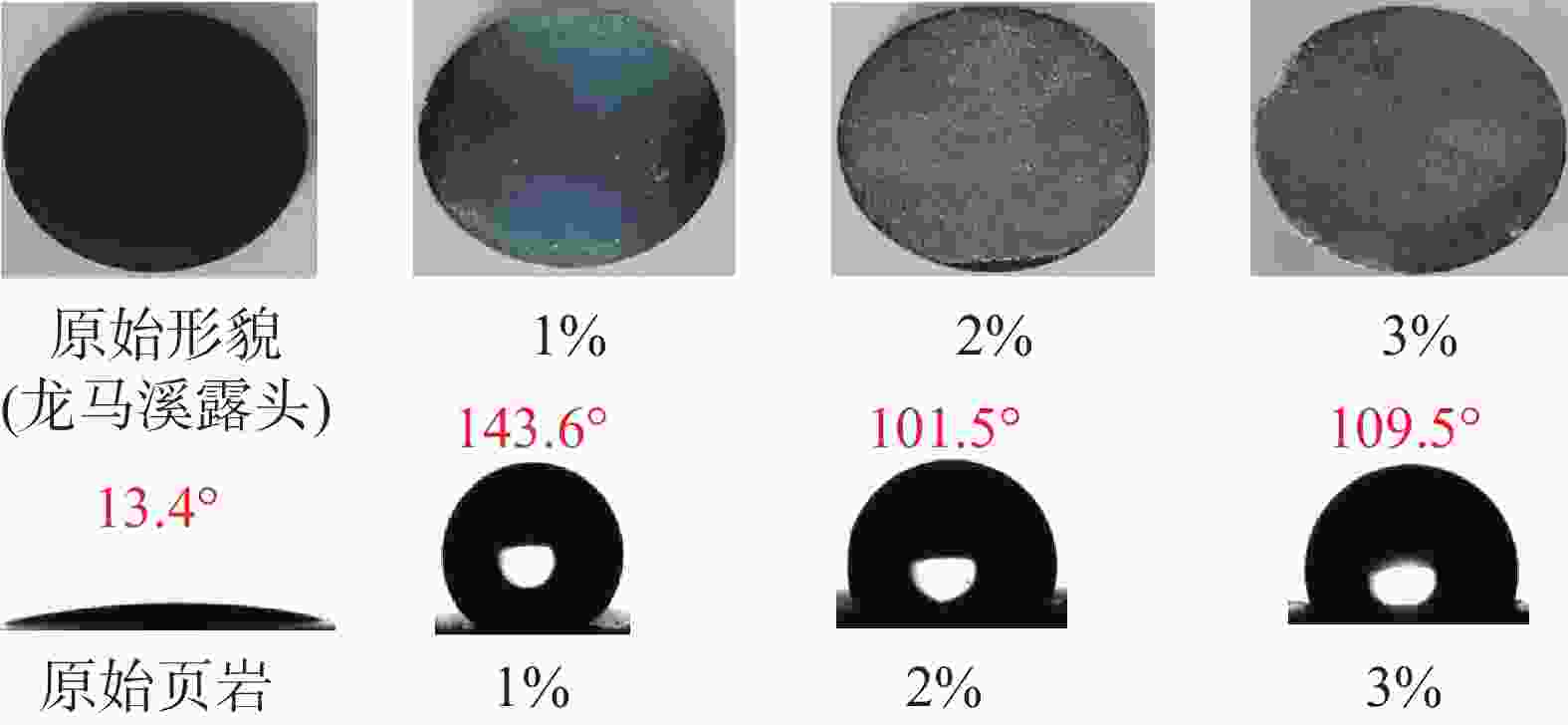

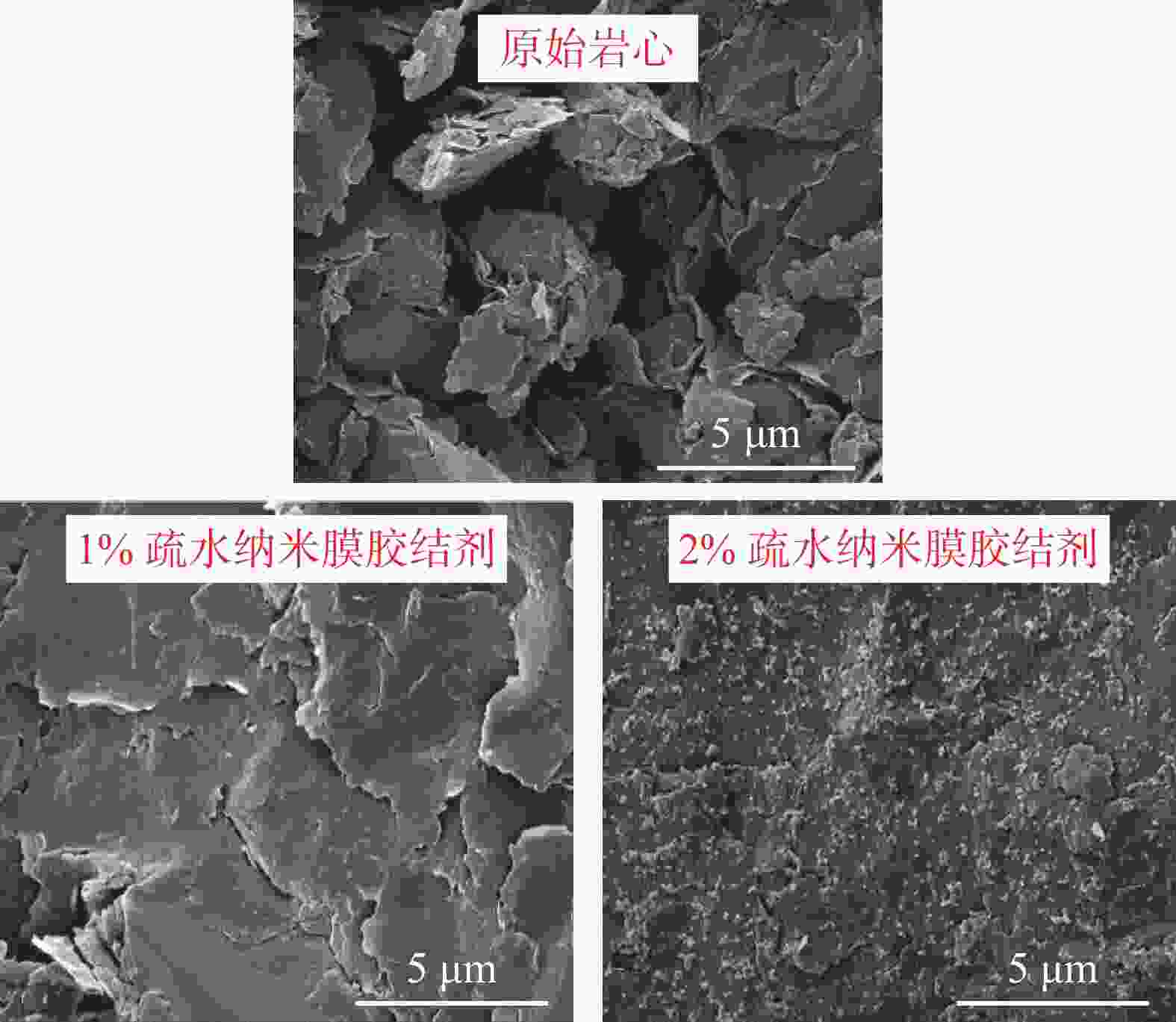

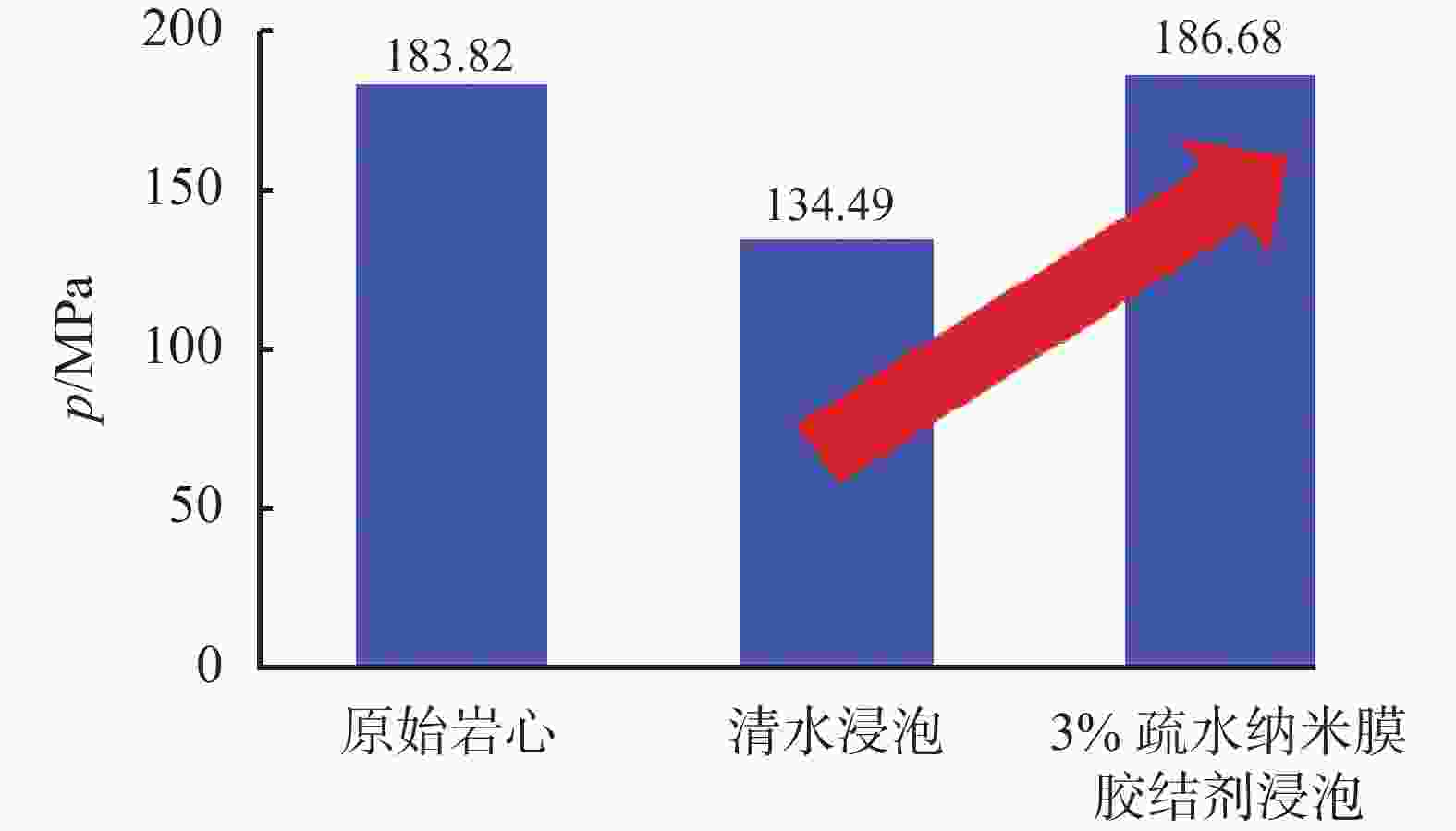

179700 30 2396 复合

盐层1 2.34 50 7 32.0 1000 巴西

近海3000~

610090~

16050~

10580 3727 多种盐

夹层1 1.95 78 36.0 2400 中东

地区3000~

6700100~

20560~

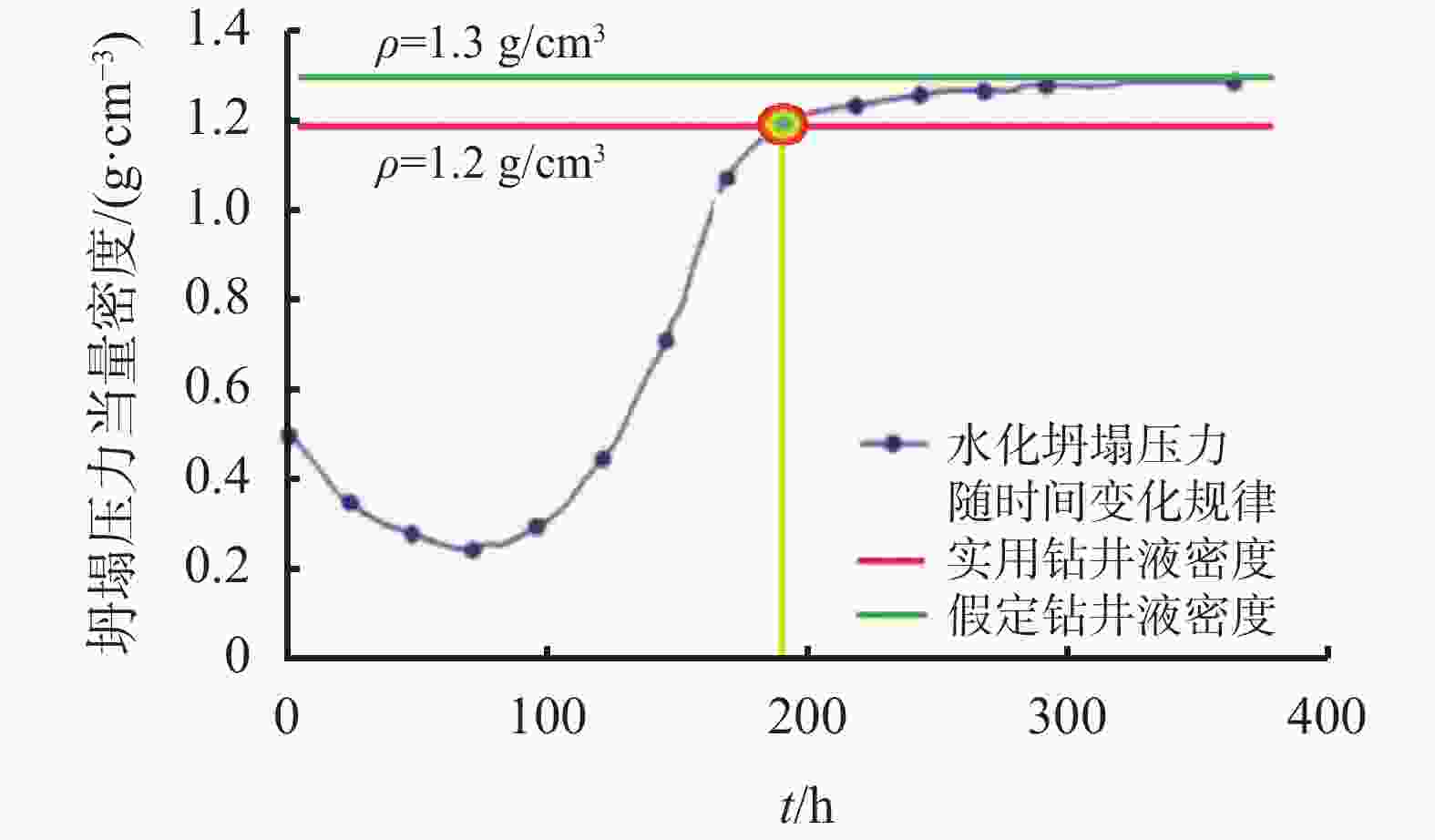

152900 60 3800 复合

盐层1 1.84 35×104 14 27.0 100 中国

南海3000~

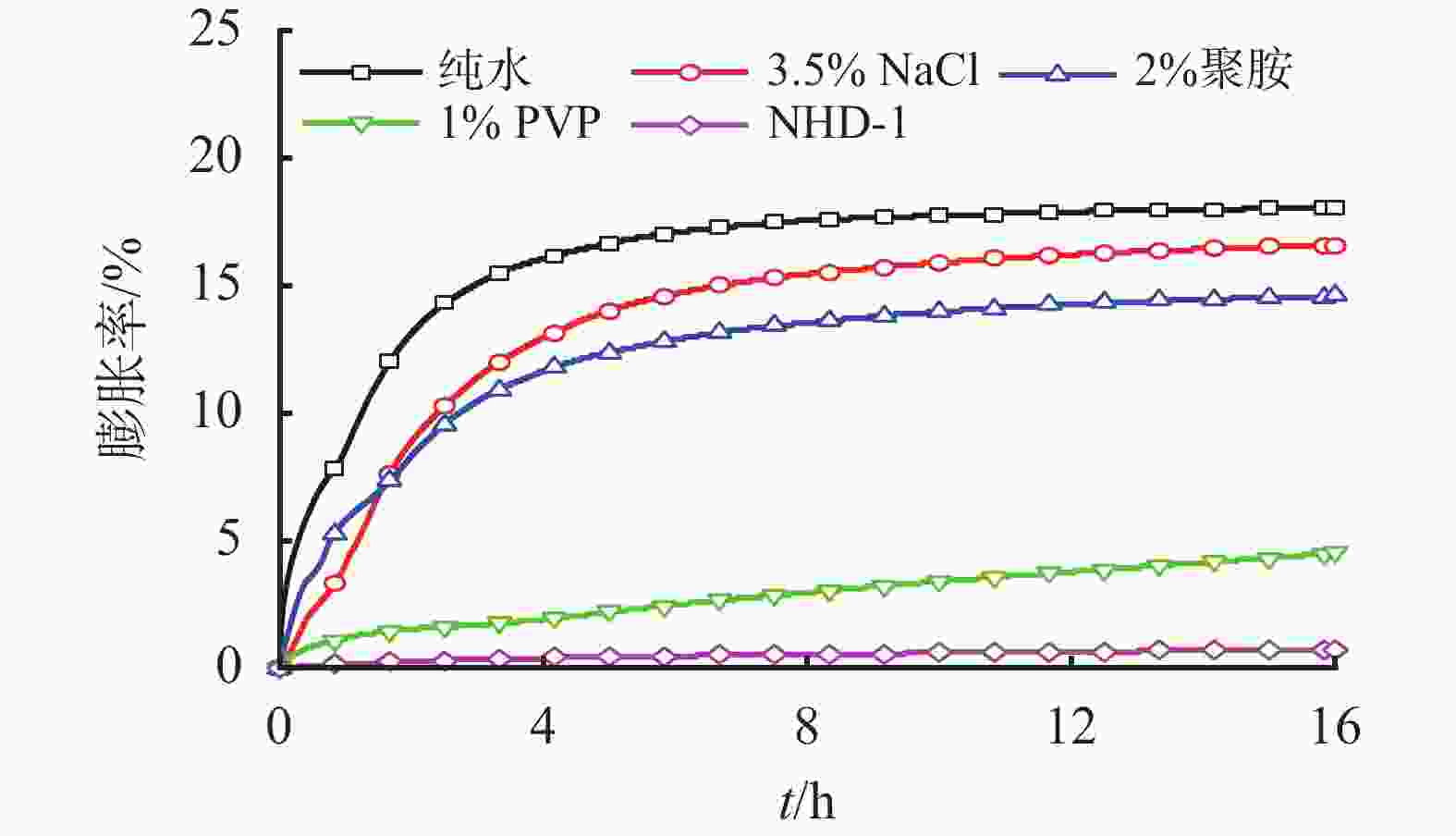

6000150~

24970~

1429 2.30 47 70 20.0 40 表 2 柴达木盆地主要钻井液技术难题

区带名称 油田/含油构造 钻探目的层位 地质难点 钻井液面临挑战 英雄岭 英西南带 E32 浅部井漏

E32顶部盐层易缩颈

E32中下部异常高压,溢漏同层

局部含H2S

水平井建井周期长限制效益开发浅部地层恶性井漏严重

压力系统复杂,对钻井液密度和流变性要求高

膏盐层蠕变缩径和污染钻井液,钻井复杂频繁

含硫地层井控风险高英中 E32 英西南斜坡 E32 英西中、北带 E32 阿尔金

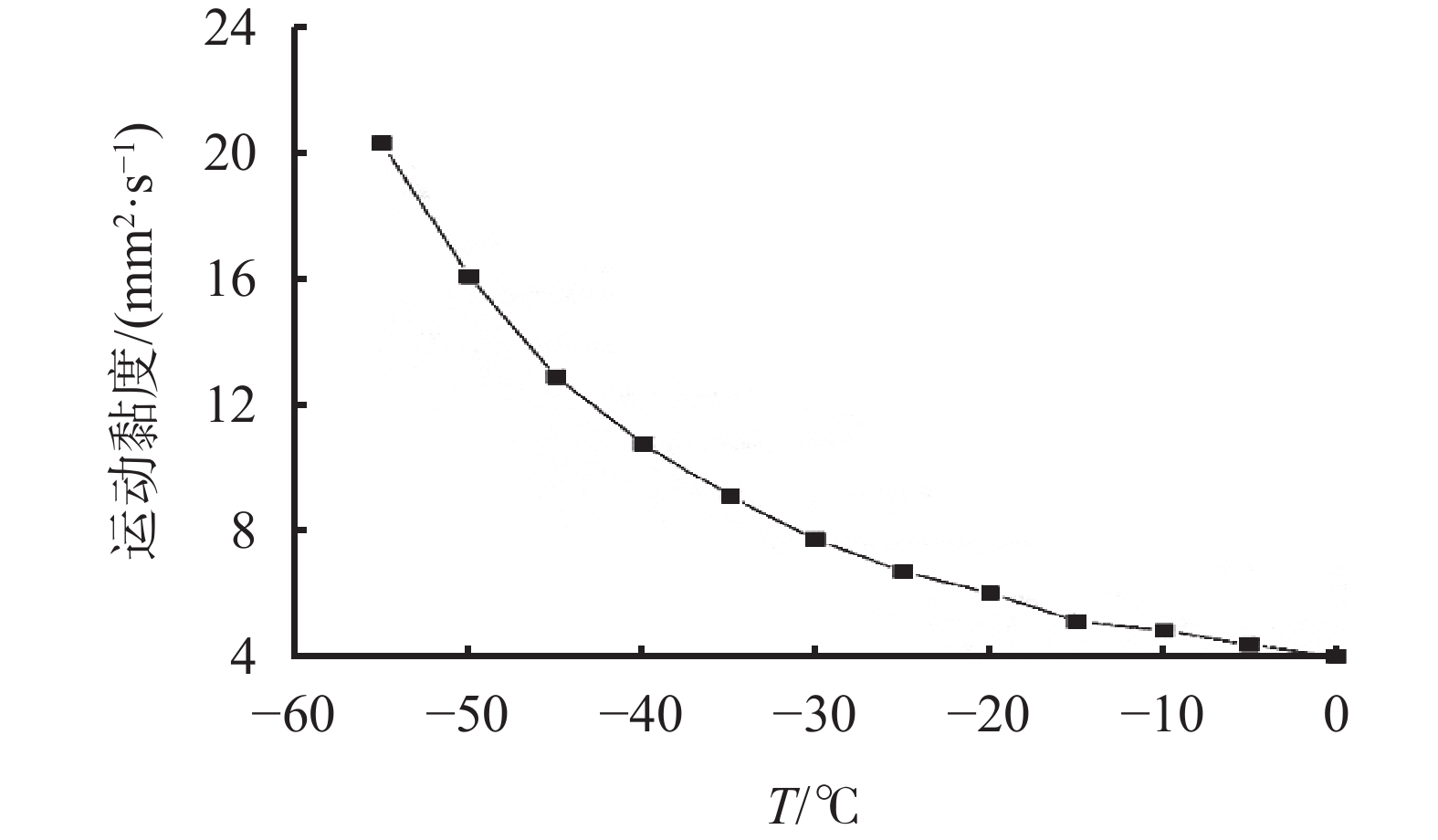

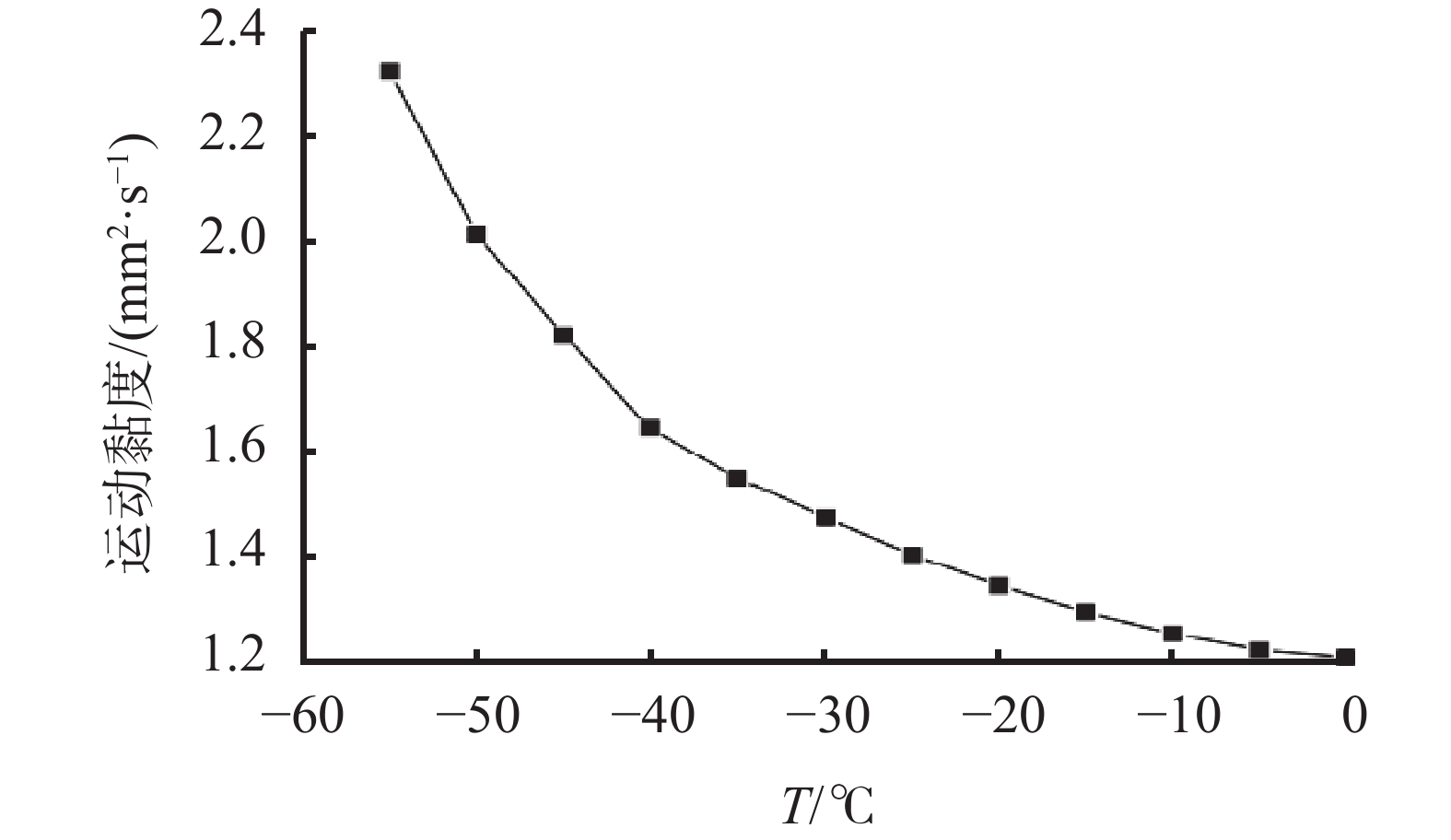

山前尖北 基岩 目的层埋藏深

地层倾角大

存在异常高温地层破碎、断层多,易诱发井漏、卡钻

钻井液面临高温稳定性牛中 基岩 碱山 基岩 盆地腹部 冷湖七号 基岩、J 高压气水层发育

高低压系统交互出现溢漏共存、安全钻井难度大

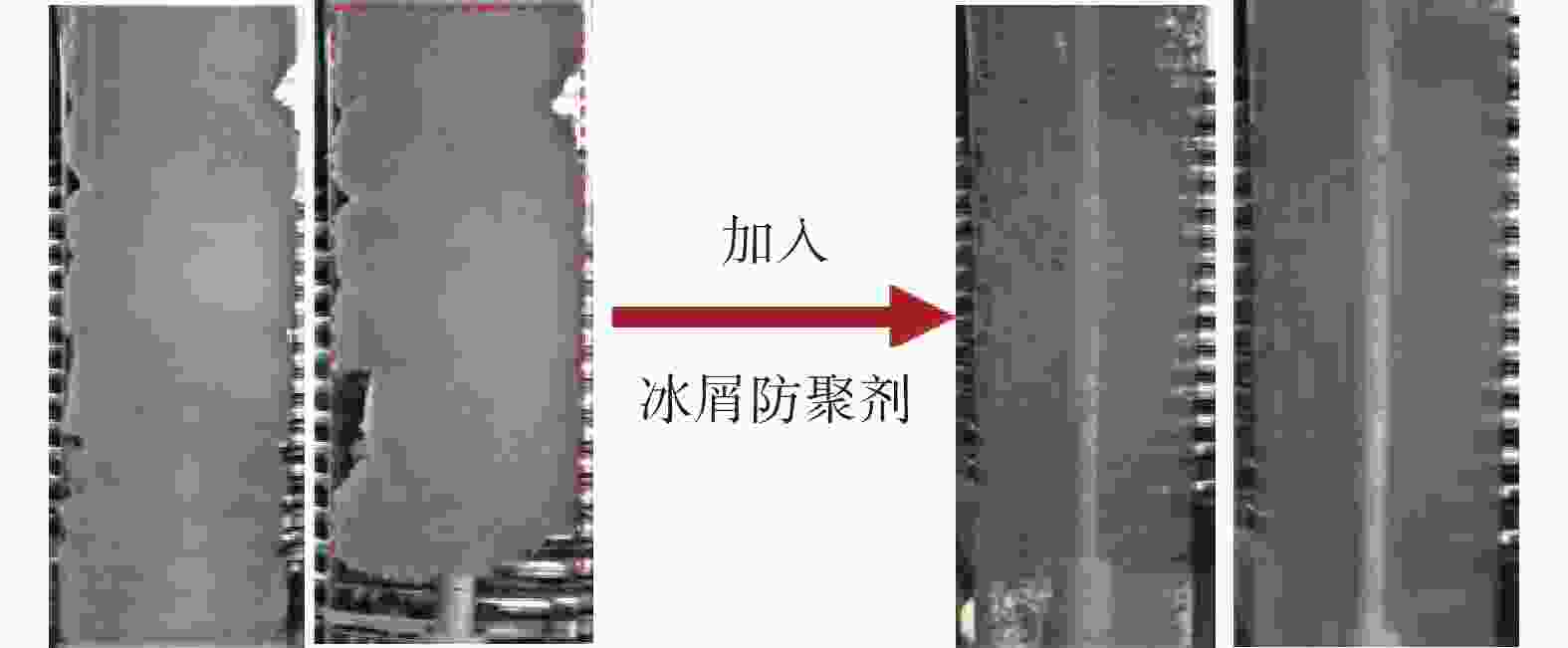

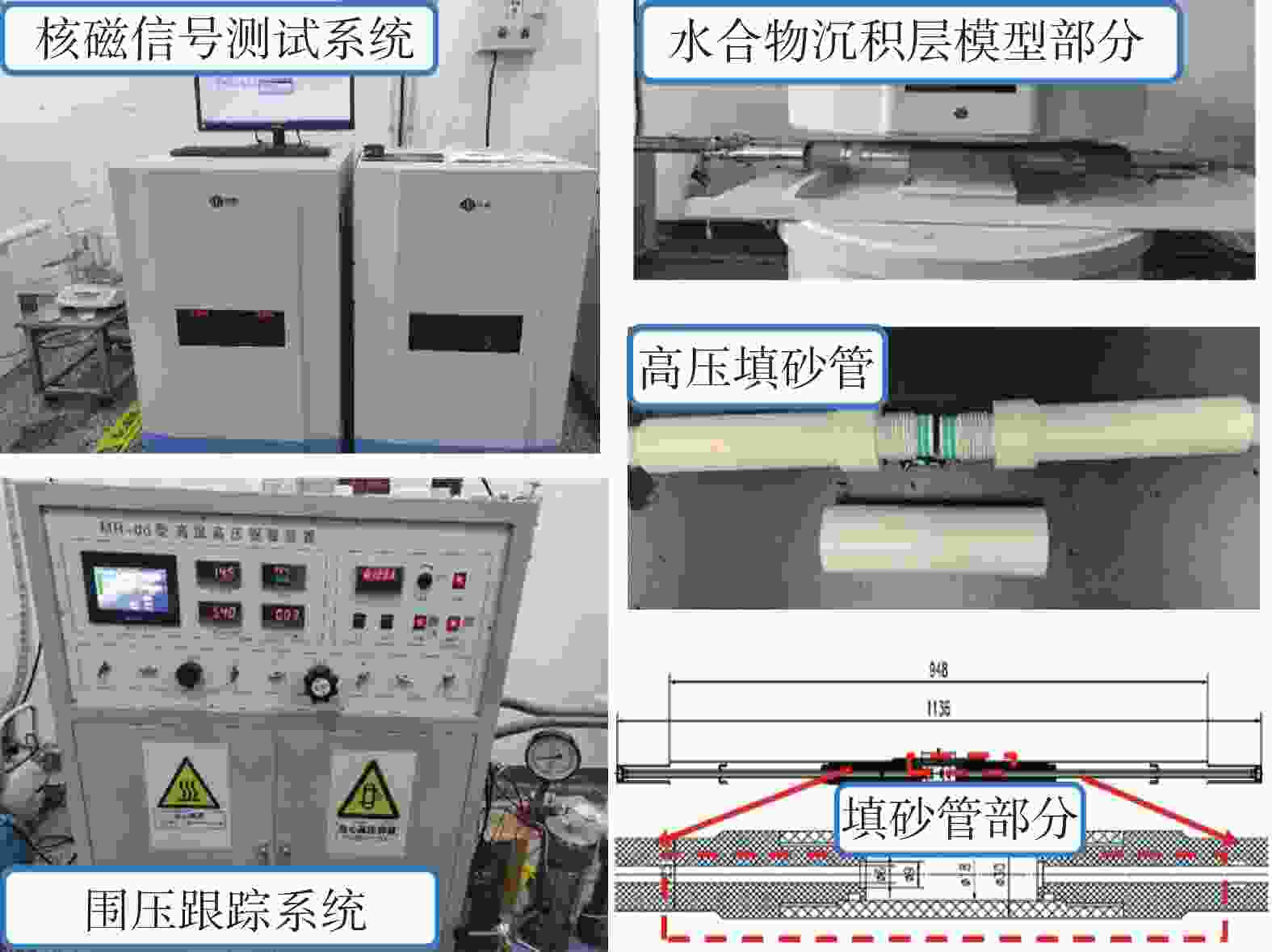

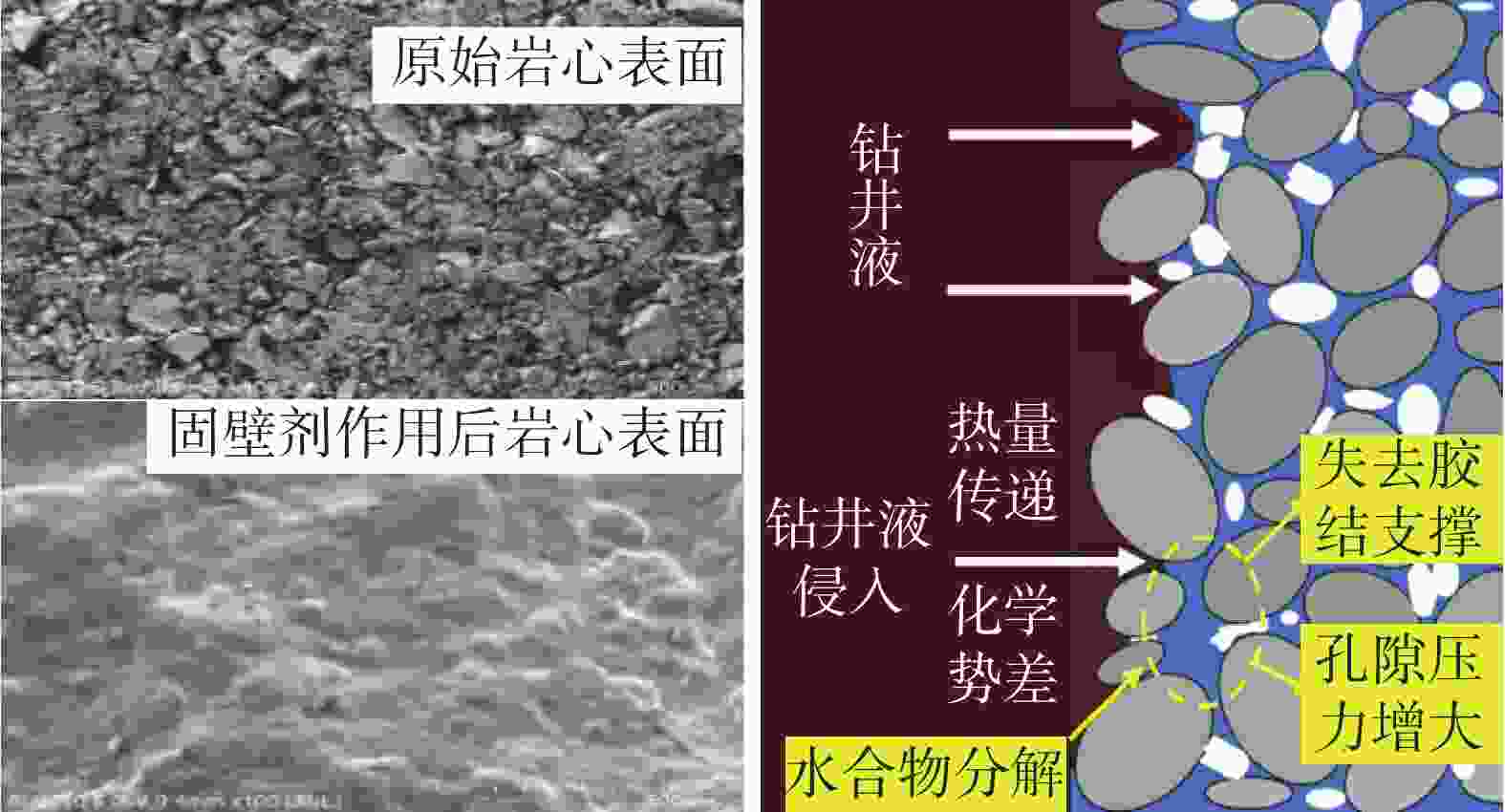

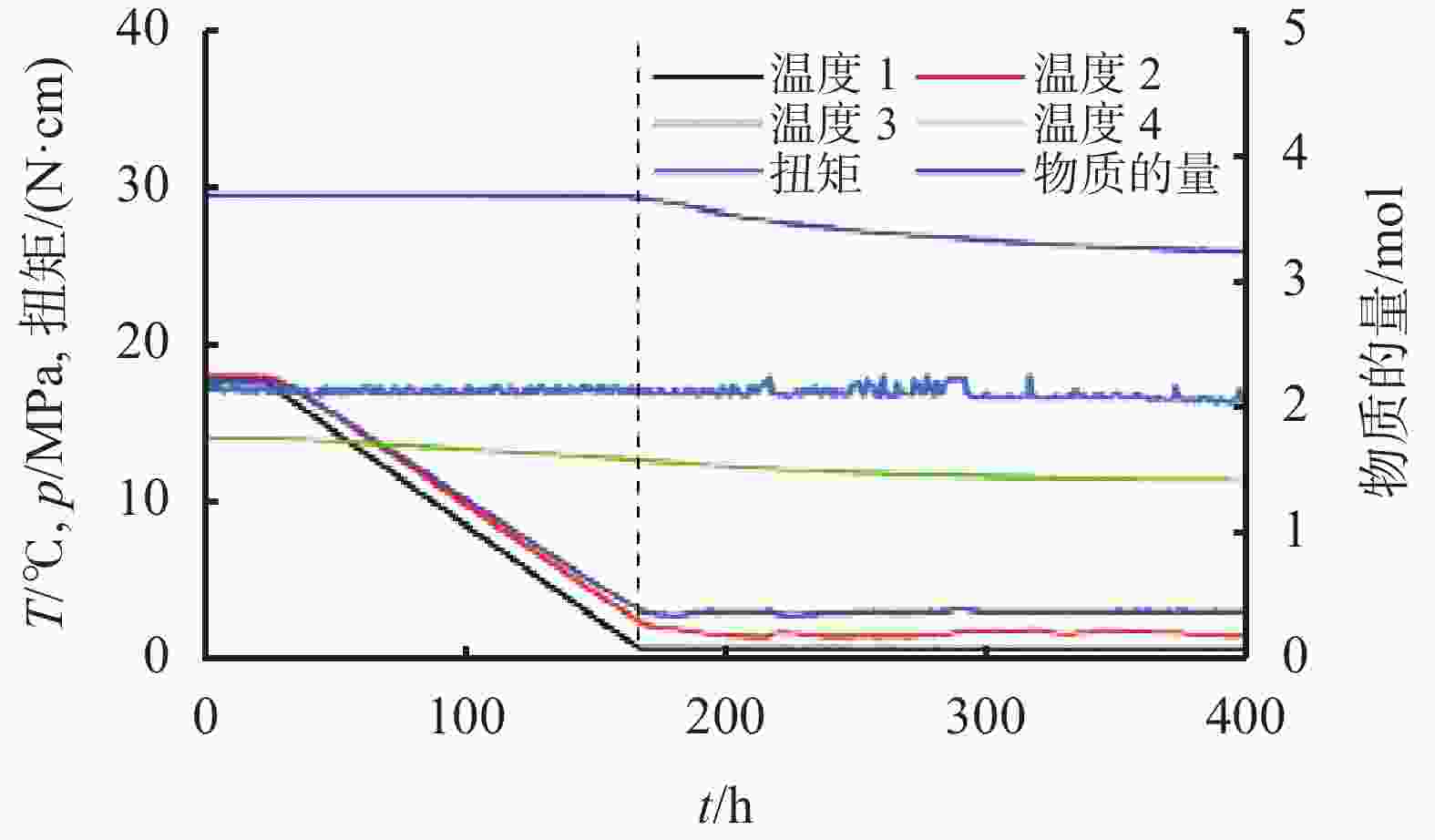

水侵对钻井液性能影响较大冷湖五号 基岩、J 潜伏构造 基岩 柴西北 风西 N22 井底温度高 高温下钻井液面临挑战 南翼山 E32 柴西南 切克里克 N1 井壁稳定性差

发育高压盐水层易发生掉块

压差卡钻风险高表 3 国内外的页岩油气钻井技术指标统计

技术名称 国内现状 国外现状 差距 发展趋势 高效PDC

钻头中石油休斯敦技术研究中心形成选择性超深靶向脱钴工艺,研制出多种PDC钻头,取得积极进展页岩水平段单趟进尺普遍不超过1500 m 材料、设计和制造工艺发展迅速,技术不断推陈出新,耐磨性、攻击性强,占领大部分高端市场全面实现二开造斜段+水平段(>3000 m)一趟钻,单趟最高进尺达6215 m 高端复合片依赖进口,设计与制造能力不足钻头攻击性、耐磨性、可导向性存在差距 高耐磨性、高抗冲击性、三维复合片、从被动破岩向自适应破岩 旋转地质

导向突破旋导导向模块结构设计等核心技术,研制出推靠式旋转导向系统,耐温150 ℃,稳定造斜率10°/30 m,指向式旋导尚处于样机试验阶段 推靠式、指向式和复合式导向工具较为成熟,如Archer、AutoTrak Curve、iCruise、NeoSteer 等七类工具,尺寸规格齐全,耐温175 ℃以上,最高造斜率18°/30 m 可靠性、抗高温能力、系列化等方面存在一定差距造斜率12°/30 m以上的高造斜率旋转导向缺乏 耐高温高造斜率智能化 井筒工作液 抗温160 ℃,密度1.2~2.5 g/cm3,弹性模量4~8 GPa,强度20~40 MPa体系单一,以常规柴油/白油基基钻井液为主,水平段最长达3583 m形成低固相防塌、反渗透高性能水基钻井液,水平段突破5060 m 抗温240 ℃,密度1.1~2.6 g/cm3,弹性模量3~8 GPa,强度14~35 MPa无土相油基、合成基应用广泛哈里伯顿、斯伦贝谢、Newpark等公司个性化钻井液设计,区块不同,设计不同,水平段超过5000 m 抗温性、高密度加重材料、水泥石力学性能水平段长度、体系少长水平段井壁稳定 高温、高强、低弹性模量无土相油基钻井液、有害固相清除长水平井稳、定井眼清洁及降摩阻技术 自动化智能化钻井 研发了“一键式”7000 m自动化钻机,实现了起下钻等工况流程化作业,自动送钻,地面、二层台无人化 研发了钻台机器人、起下钻自动控制、自动送钻系统、自动控压钻井等规模化应用 在全流程自动化、连续管智能作业等革新方面与国外存在一定差距 向电驱、高精度、自主感知发展,推动钻台面无人化进程 表 4 北美主要油气盆地的钻井液应用情况

页岩油气田 钻井液种类 海因斯维尔 INTEGRADE、Master Clear等油基钻井液;

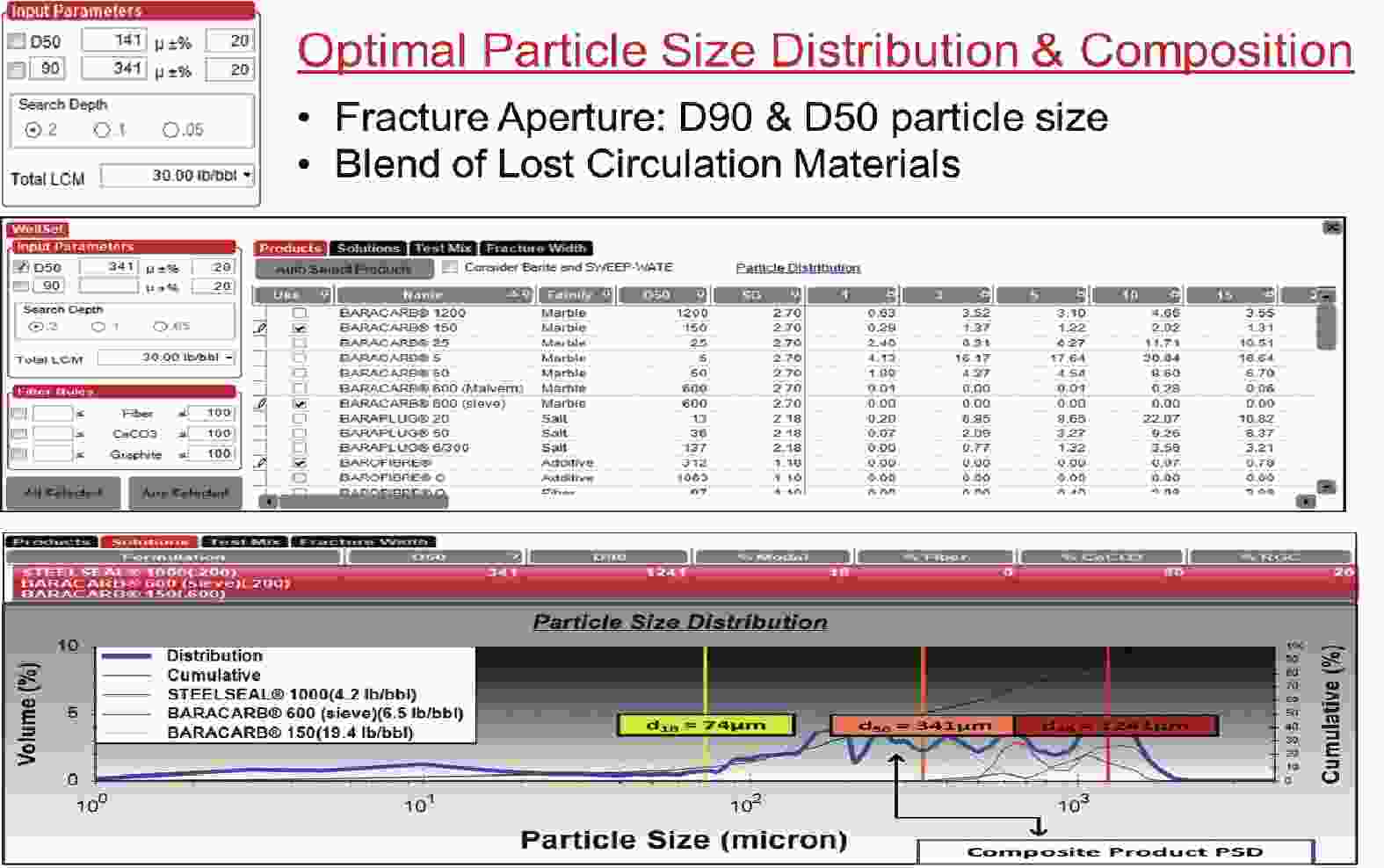

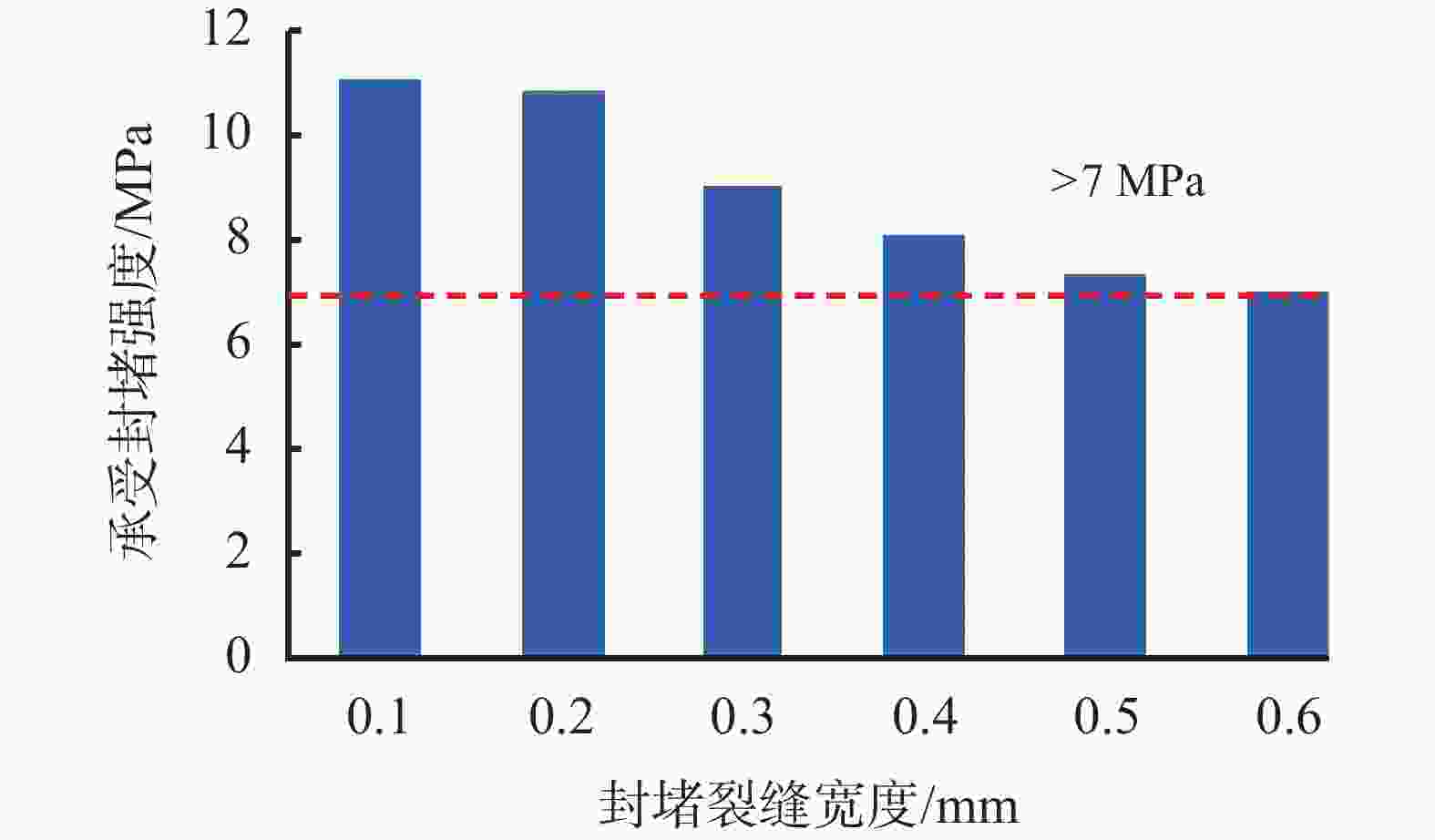

硅酸盐/铝酸盐或者磺化沥青等水基钻井液鹰滩 INTEGRADE、INVERMUL、Terra-Max等

油基钻井液;新型水基钻井液马塞勒斯 超过1500 m水平段多采用INNOVERT, INTEGRADE等油基、合成基钻井液;

1500 m以内多采用新型水基钻井液二叠纪 3000 m水平段以下多使用水基钻井液;

3000 m以上水平段多使用油基钻井液表 5 北美超长水平井应用油基钻井液的典型案例

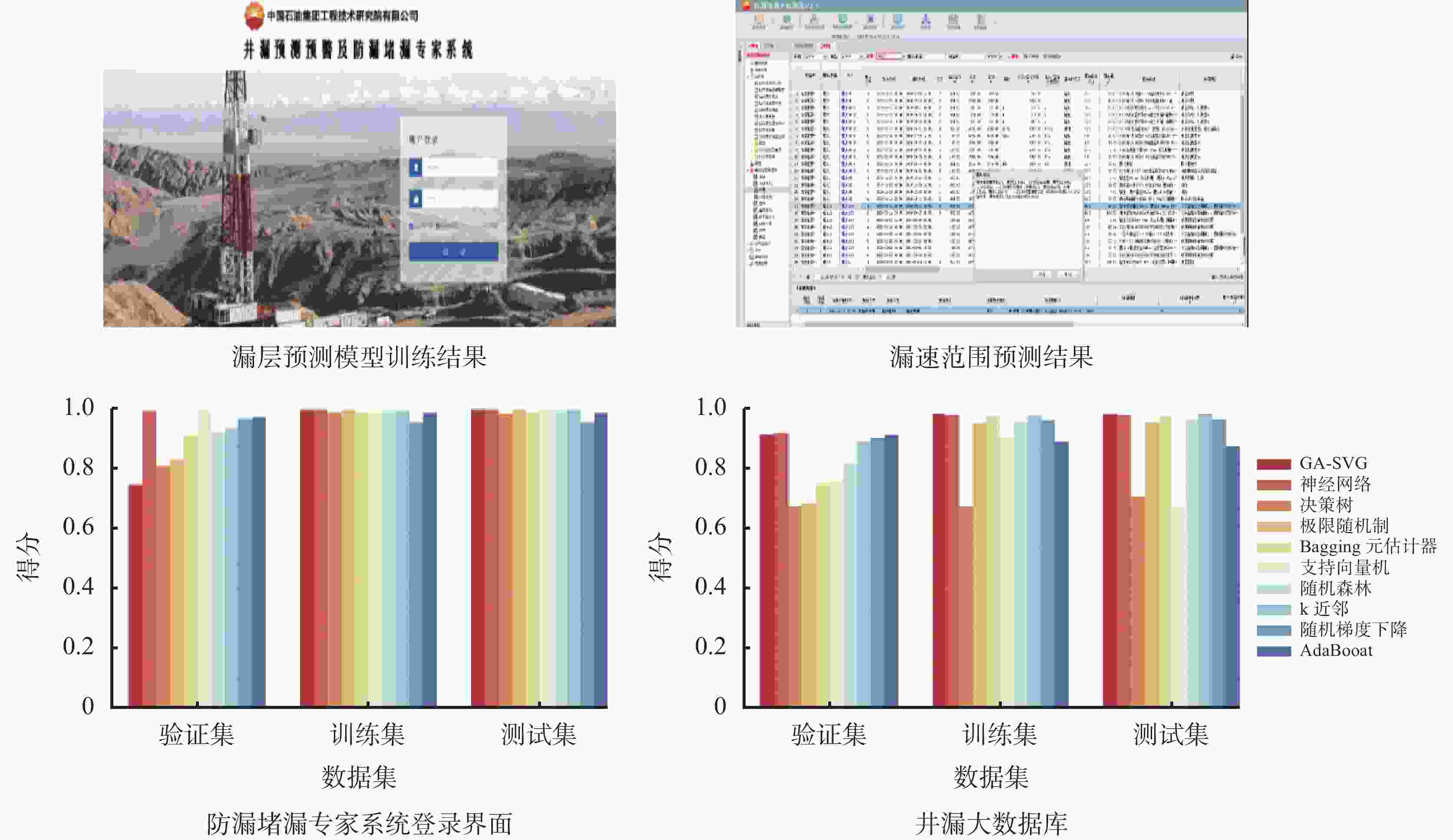

井号 水平段长度/m 井深/m Purple Hayes 1H 5638 8244 Great Scott 3H 5882 8351 Outlaw C 11H 5974 8332 Mercury B 5H 6339 8770 表 6 絮凝剂添加前后钻井液性能对比

井浆 PV/

mPa•sYP/

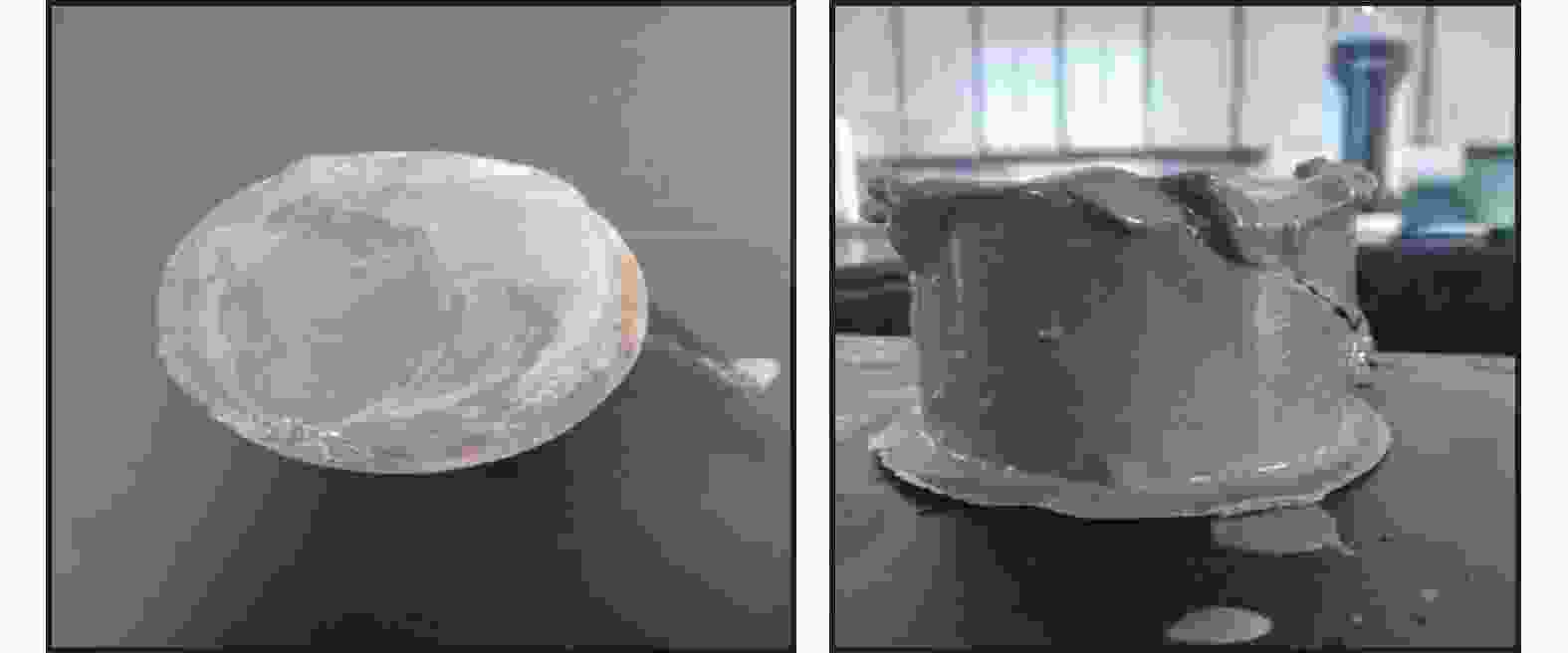

PaGel10 s/

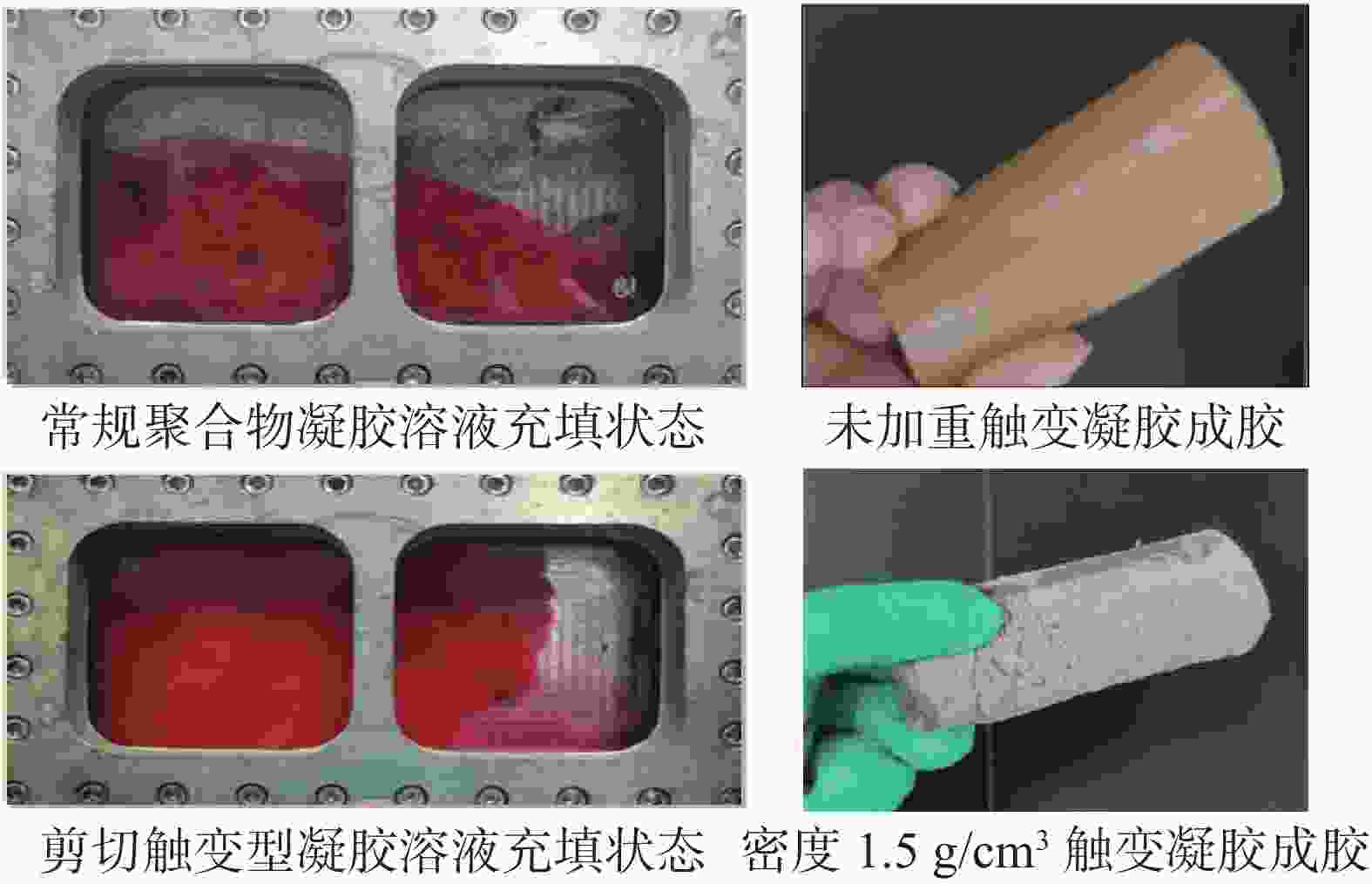

PaGel10 min/

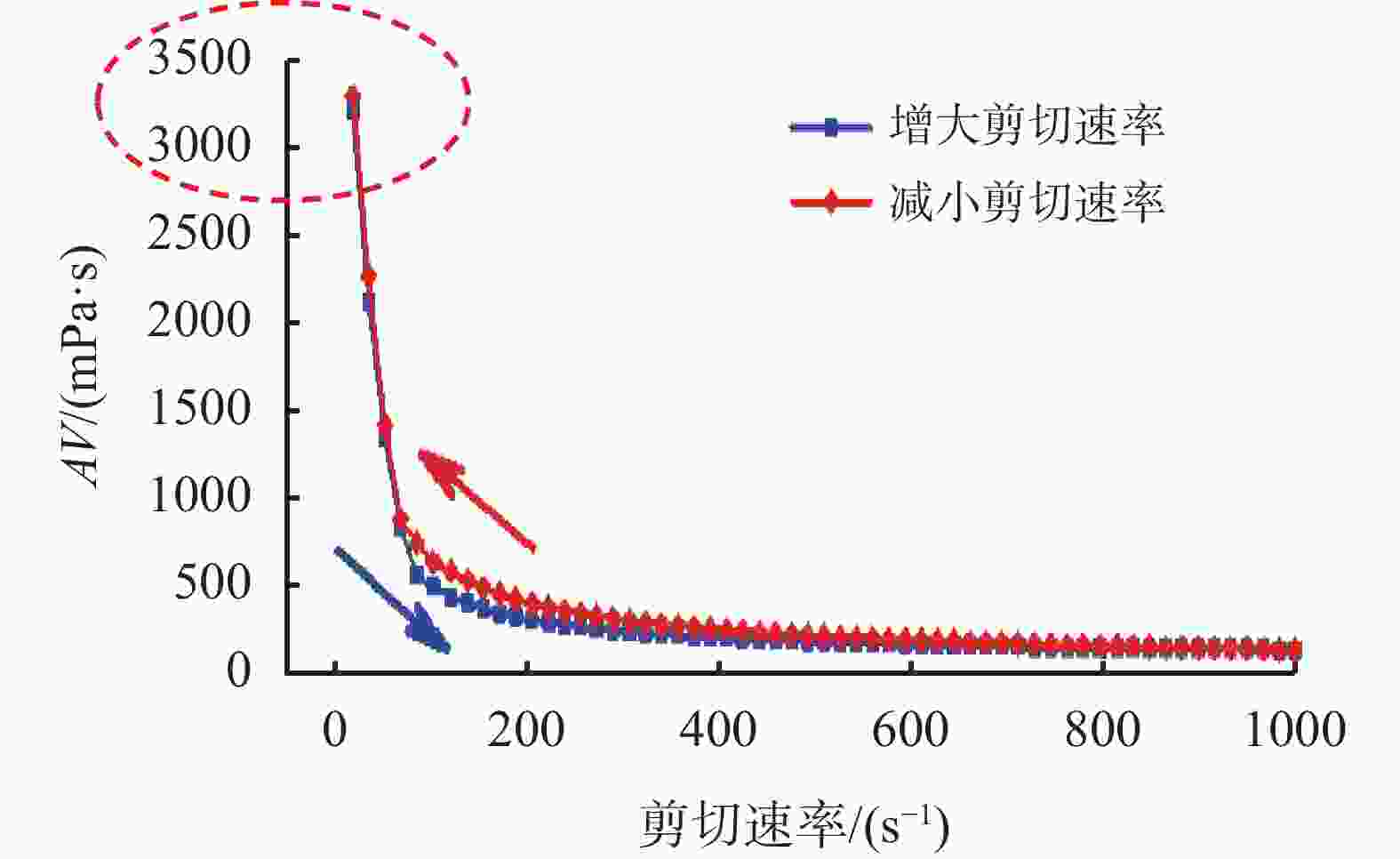

Pa原始井浆(1745 m) 29 7.0 4.00 20.0 添加0.5%井浆(1870 m) 21 5.0 3.00 14.5 添加1%絮凝剂(1930 m) 22 4.5 3.00 13.0 表 7 絮凝后离心液重新配浆性能与新浆、原始老浆对比

钻井液 PV/

mPa•sYP/

PaGel10 s/

PaGel10 min/

Pa絮凝后离心液配制 77 15.0 6.00 20.00 未絮凝离心液配制 86 16.0 7.50 33.00 新配制 71 10.0 4.00 5.00 原始老浆 98 18.5 6.50 33.00 表 8 国外油服公司典型页岩油气水基钻井液体系

公司名称 麦克巴 哈里伯顿 贝克休斯 NewPark 页岩气水基钻

井液体系名称ULTRADRIL体系

针对环境敏感性地区HYDRO-GUADR

高性能水基钻井液

针对活性泥页岩地层PERFORMAX

水基钻井液

针对环保要求高的

页岩区块FlexDrill体系

适用于北美和加拿大页

岩区块SHALEDRIL H

高性能水基钻井液

针对北美Haynesville页岩区块KLA-SHIELD体系

针对北美Alaska页

岩区块SHALEDRIL F

高性能水基钻井液

针对北美Fayetteville页岩区块LATIDRILL

水基钻井液

针对沙特的非常规

水平井Evolution体系

环保型高性能

水基钻井液HydraGlyde体系

针对德克萨斯的Wolfcamp页岩区SHALEDRIL B

高性能水基钻井液

针对北美Barnett页岩区块表 9 国外油服公司推出的交联固化类堵漏新材料

国外公司 名称 核心材料 技术特点 斯伦贝谢 CACP化学交联

堵漏剂交联聚合物、生物大分子、交联剂、

缓凝剂、纤维适合水基、油基钻井液

泵送前加入交联剂,井下快速成胶

凝胶结构强,隔水效果好贝克休斯 可降解交联堵漏剂 交联聚合物、酸溶性架桥粒子、

有机交联剂、缓凝剂抗温150 ℃,长期高温可自降解,

也可辅助破胶,适合储层MAX-LOCK循环堵漏材料 镁氧基水泥、黏弹性表活剂、缓凝剂 最高抗温121 ℃

剪切触变性高、密度低

90%酸溶,适合储层及压力衰竭地层哈里伯顿 CS-LCM化学封堵剂 油相、增黏剂、黏土、反应物,

激活剂为水基钻井液具备直角成胶特点

可封堵31 mm圆孔,承压6.8 MPa

泵送性能好,100%酸溶RAS-Co交联堵漏剂 热固性树脂 黏度低(18~30 mPa•s),易泵送

成胶后材料抗压75 MPa

水基抗温204 ℃,油基抗温130 ℃表 10 自适应防漏钻井液技术典型应用

井号 二开(二叠系) 三开(志留系) 应用井SHB53-4H 自适应随钻防漏钻井液,密度1.30~1.35 g/cm3,井下无漏失 自适应随钻防漏钻井液,密度1.37~1.38 g/cm3,井下无漏失 邻井SHB53-7H 常规钻井液,

密度1.25~1.28 g/cm3,

井下漏失179 m3常规钻井液,

密度1.30~1.38 g/cm3,

井下漏失1060 m3表 11 四川盆地中部磨溪区块储层保护技术现场试验效果

区块 区块 有效储层段

长度/m测试产量/

104 m3/d测试效果 磨溪022 试验井 474.50 105.56 测试产量是平均

数的1.78倍邻井 599.55 59.81 磨溪019 试验井 567.30 82.89 测试产量是邻井

平均数的1.46倍邻井 684.50 56.70 -

[1] 孙金声,杨杰,戎克生,等. 水基钻井液用流型调节剂研究进展[J]. 新疆石油天然气,2023,19(2):1-16.SUN Jinsheng, YANG Jie, RONG Kesheng, et al. Advances in study on rheology modifier for Water-Based drilling fluids[J]. Xinjiang Oil & Gas, 2023, 19(2):1-16. [2] 刘锋报,孙金声,王建华. 国内外深井超深井钻井液技术现状及发展趋势[J]. 新疆石油天然气,2023,19(2):34-39.LIU Fengbao, SUN Jinsheng, WANG Jianhua. A global review of technical status and development trend of drilling fluids for deep and Ultra-Deep wells[J]. Xinjiang Oil & Gas, 2023, 19(2):34-39. [3] 袁玥辉,屈沅治,高世峰,等. 抗温抗盐水基钻井液降滤失剂研究进展[J]. 新疆石油天然气,2023,19(2):62-68.YUAN Yuehui, QU Yuanzhi, GAO Shifeng, et al. Advances in study on temperature-resistant and salt-tolerant fluid loss reducers for water-based drilling fluids[J]. Xinjiang Oil & Gas, 2023, 19(2):62-68. [4] 屈沅治,林凌,黄宏军,等. 两性离子聚合物老化对蒙脱土性质的影响[J]. 石油化工,2022,51(8):931-938.QU Yuanzhi, LIN Ling, HUANG Hongjun, et al. Influence of zwitterionic polymer aging on the properties of montmorillonite[J]. Petrochemical Technology, 2022, 51(8):931-938. [5] 张雁,屈沅治,张志磊,等. 超高温水基钻井液技术研究现状及发展方向[J]. 油田化学,2022,39(3):540-547.ZHANG Yan, QU Yuanzhi, ZHANG Zhilei, et al. Research progress and development direction of technologies for water-based drilling fluid in ultra-high temperature[J]. Oilfield Chemistry, 2022, 39(3):540-547. [6] 邓虎,贾利春. 四川盆地深井超深井钻井关键技术与展望[J]. 天然气工业,2022,42(12):82-94.DENG Hu, JIA Lichun. Key technologies for drilling deep and ultra-deep wells in the Sichuan Basin: current status, challenges and prospects[J]. Natural Gas Industry, 2022, 42(12):82-94. [7] 伍贤柱,万夫磊,陈作,等. 四川盆地深层碳酸盐岩钻完井技术实践与展望[J]. 天然气工业,2020,40(2):97-105.WU Xianzhu, WAN Fulei, CHEN Zuo, et al. Drilling and completion technologies for deep carbonate rocks in the Sichuan Basin: practices and prospects[J]. Natural Gas Industry, 2020, 40(2):97-105. [8] 王明华,贺立勤,卓云,等. 川渝地区9000m级超深超高温超高压地层安全钻井技术实践与认识[J]. 天然气勘探与开发,2023,46(2):44-50.WANG Minghua, HE Liqin, ZHUO Yun, et al. Practices and understandings on safe drilling technologies for 9000-m-level super deep and ultra high temperature and pressure strata, Sichuan-Chongqing area[J]. Natural Gas Exploration and Development, 2023, 46(2):44-50. [9] 张民立,庄伟,徐成金,等. 抗240 ℃高密度复合有机盐钻井液在翼探1井的应用[J]. 钻井液与完井液,2020,37(4):431-437.ZHANG Minli, ZHUANG Wei, XU Chengjin, et al. Application of ultra-high temperature high density compound organic salt drilling fluid in well Jitan-1[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):431-437. [10] 邢星,刘凤和,程长坤,等. 柴达木盆地复杂深井安全钻井技术[J]. 石油科技论坛,2022,41(2):69-73. doi: 10.7202/1086925arXING Xing, LIU Fenghe, CHENG Changkun, et al. Drilling safety technology for complicated deep wells in Qaidam basin[J]. Oil Forum, 2022, 41(2):69-73. doi: 10.7202/1086925ar [11] 王学成,乔东宇,刘灵,等. 柴达木盆地西北地区井壁失稳要因分析[J]. 世界石油工业,2022,29(6):63-71.WANG Xuecheng, QIAO Dongyu, LIU Ling, et al. Analysis on the main factors of wellbore instability in northwest Qaidam Basin[J]. World Petroleum Industry, 2022, 29(6):63-71. [12] 孙金声,许成元,康毅力,等. 致密/页岩油气储层损害机理与保护技术研究进展及发展建议[J]. 石油钻探技术,2020,48(4):1-10.SUN Jinsheng, XU Chengyuan, KANG Yili, et al. Research progress and development recommendations covering damage mechanisms and protection technologies for tight/shale oil and gas reservoirs[J]. Petroleum Drilling Techniques, 2020, 48(4):1-10. [13] 孙金声,黄贤斌,吕开河,等. 提高水基钻井液高温稳定性的方法、技术现状与研究进展[J]. 中国石油大学学报(自然科学版),2019,43(5):73-81.SUN Jinsheng, HUANG Xianbin, LYU Kaihe, et al. Methods, technical progress and research advance of improving high-temperature stability of water based drilling fluids[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2019, 43(5):73-81. [14] 黄贤斌,孙金声,吕开河,等. 抗超高温高密度聚合物饱和盐水钻井液体系[J]. 石油勘探与开发,2023,50(5):1056-1064.HUANG Xianbin, SUN Jinsheng, LYU Kaihe, et al. A high-temperature resistant and high-density polymeric saturated brine-based drilling fluid[J]. Petroleum Exploration and Development, 2023, 50(5):1056-1064. [15] 王宗轮,孙金声,刘敬平,等. 耐高温高盐钻井液润滑剂的研制与性能评价[J]. 钻井液与完井液,2022,39(5):538-544.WANG Zonglun, SUN Jinsheng, LIU Jingping, et al. Development and performance evaluation of high temperature salt resistant drilling lubricant[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):538-544. [16] YANG J, WANG R, SUN J S, et al. Comb polymer/layered double hydroxide (LDH) composite as an ultrahigh temperature filtration reducer for water-based drilling fluids[J]. Applied Surface Science, 2024, 645:158884. doi: 10.1016/j.apsusc.2023.158884 [17] YANG J, WANG R, SUN J S, et al. Nanolaponite/comb polymer composite as a rheological modifier for water-based drilling fluids[J]. ACS Applied Nano Materials, 2023, 6(14):13453-13465. doi: 10.1021/acsanm.3c02079 [18] 王岩,孙金声,黄贤斌,等. 抗高温耐盐钙五元共聚物降滤失剂的合成与性能[J]. 钻井液与完井液,2018,35(2):23-28.WANG Yan, SUN Jinsheng, HUANG Xianbin, et al. Synthesis and properties of a high temperature calcium and salt resistant quinary copolymer filter loss reducer[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):23-28. [19] 卢震,黄贤斌,孙金声,等. 水基钻井液用耐高温纳米聚合物封堵剂的研制[J]. 石油钻采工艺,2020,42(5):587-591.LU Zhen, HUANG Xianbin, SUN Jinsheng, et al. Development of the nano-polymer plugging agent with high temperature tolerance for water-based drilling fluid[J]. Oil Drilling & Production Technology, 2020, 42(5):587-591. [20] 张东悦,周劲辉,史浩明,等. 油基钻井液用有机土研究进展[J]. 当代化工研究,2022(11):168-170.ZHANG Dongyue, ZHOU Jinhui, SHI Haoming, et al. Research progress of organoclays for Oil-Based drilling fluids[J]. Modern Chemical Research, 2022(11):168-170. [21] 黄津松,张家旗,王建华,等. 国内油基钻井液研发现状与思考[J]. 化工管理,2020(33):130-133.HUANG Jinsong, ZHANG Jiaqi, WANG Jianhua, et al. Current situation and suggestion of domestic oil-based drilling fluid[J]. Chemical Enterprise Management, 2020(33):130-133. [22] 黄贤斌,孙金声,蒋官澄,等. 改性脂肪酸提切剂的研制及其应用[J]. 中国石油大学学报(自然科学版),2019,43(3):107-112.HUANG Xianbin, SUN Jinsheng, JIANG Guancheng, et al. Synthesis of a modified fatty acid as rheology modifier and its application[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2019, 43(3):107-112. [23] 王建华,王立辉,杨海军,等. 抗高温高密度油基钻井液体系DR-OBM[J]. 石油科技论坛,2015,34(S1):56-58.WANG Jianhua, WANG Lihui, YANG Haijun, et al. High temperature resistant and high density oil-based drilling fluid system—RD-ROM[J]. Petroleum Science and Technology Forum, 2015, 34(S1):56-58. [24] 王建华,张家旗,谢盛,等. 页岩气油基钻井液体系性能评估及对策[J]. 钻井液与完井液,2019,36(5):555-559.WANG Jianhua, ZHANG Jiaqi, XIE Sheng, et al. Evaluation and improvement of the performance of oil base drilling fluids for shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):555-559. [25] 王建华,闫丽丽,谢盛,等. 塔里木油田库车山前高压盐水层油基钻井液技术[J]. 石油钻探技术,2020,48(2):29-33.WANG Jianhua, YAN Lili, XIE Sheng, et al. Oil-Based drilling fluid technology for high pressure brine layer in Kuqa piedmont of the Tarim oilfield[J]. Petroleum Drilling Techniques, 2020, 48(2):29-33. [26] 程荣超,王建华,闫丽丽,等. 油基钻井液用抗高温树脂类封堵剂的研制[J]. 当代化工研究,2021(5):160-162. doi: 10.3969/j.issn.1672-8114.2021.05.077CHENG Rongchao, WANG Jianhua, YAN Lili, et al. Development of high temperature resistant resin plugging agent for oil-based drilling fluid[J]. Modern Chemical Research, 2021(5):160-162. doi: 10.3969/j.issn.1672-8114.2021.05.077 [27] 罗平亚,李文哲,代锋,等. 四川盆地南部龙马溪组页岩气藏井壁强化钻井液技术[J]. 天然气工业,2023,43(4):1-10.LUO Pingya, LI Wenzhe, DAI Feng, et al. Strengthening drilling fluid technology for shale gas reservoirs in the Longmaxi Formation, southern Sichuan Basin[J]. Natural Gas Industry, 2023, 43(4):1-10. [28] 白杨,李道雄,李文哲,等. 长宁区块龙马溪组水平段井壁稳定钻井液技术[J]. 西南石油大学学报(自然科学版),2022,44(2):79-88.BAI Yang, LI Daoxiong, LI Wenzhe, et al. Borehole wall stabilization drilling fluid technology of Longmaxi formation horizontal section in Changning block[J]. Journal of Southwest Petroleum University(Science & Technology Edition) , 2022, 44(2):79-88. [29] 李文哲,傅栋,王翔,等. 龙马溪页岩微米防漏堵漏剂研究与应用[J]. 钻采工艺,2021,44(6):111-114.LI Wenzhe, FU Dong, WANG Xiang, et al. Research and application of micron anti-leak and plugging technology in Changning-weiyuan Longmaxi formation[J]. Drilling & Production Technology, 2021, 44(6):111-114. [30] GENG Y, SUN J, WANG J H, et al. Modified nanopolystyrene as a plugging agent for Oil-Based drilling fluids applied in shale formation[J]. Energy & Fuels, 2021, 35(20):16543-16552. [31] 王建华,耿愿,黄贤斌,等. 选择性絮凝剂在页岩气废弃油基钻井液中的应用[J]. 当代化工研究,2022(10):68-70.WANG Jianhua, GENG Yuan, HUANG Xianbin, et al. Application of selective flocculant in shale gas waste oil-based drilling fluid[J]. Modern Chemical Research, 2022(10):68-70. [32] 司西强,王中华,吴柏志. 中国页岩油气水平井水基钻井液技术现状及发展趋势[J]. 精细石油化工进展,2022,23(1):42-50.SI Xiqiang, WANG Zhonghua, WU Baizhi. Current situation and development trend of water-based drilling fluids technology for shale oil and gas horizontal wells in China[J]. Advances in Fine Petrochemicals, 2022, 23(1):42-50. [33] 李东平,赵贤正,王子毓,等. 新型有机硅聚合物抑制封堵剂性能及作用机制[J]. 中国石油大学学报(自然科学版),2020,44(4):135-141.LI Dongping, ZHAO Xianzheng, WANG ZI Yu, et al. Performance and mechanism of new silicone polymer for inhibitor and plugging agent[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2020, 44(4):135-141. [34] SHEN H K, LYU K H, HUANG X B, et al. Hydrophobic-associated polymer-based laponite nanolayered silicate composite as filtrate reducer for water-based drilling fluid at high temperature[J]. Journal of Applied Polymer Science, 2020, 137(18):48608. doi: 10.1002/app.48608 [35] LEI M, HUANG W A, SUN J S, et al. Synthesis of hydrophobically modified polyampholyte based on epoxidized soybean oil as shale inhibitor in water-based drilling fluid[J]. Colloids and Surfaces. a, Physicochemical and Engineering Aspects, 2021, 622:126664. doi: 10.1016/j.colsurfa.2021.126664 [36] 康圆,孙金声,吕开河,等. 一种页岩气疏水强封堵水基钻井液[J]. 钻井液与完井液,2021,38(4):442-448.KANG Yuan, SUN Jinsheng, LYU Kaihe, et al. Research on a water-based drilling fluid for shale gas drainage and strong blocking[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):442-448. [37] 刘敬平,孙金声. 页岩气藏地层井壁水化失稳机理与抑制方法[J]. 钻井液与完井液,2016,33(3):25-29.LIU Jingping, SUN Jinsheng. Borehole wall collapse and control in shale gas well drilling[J]. Drilling Fluid & Completion Fluid, 2016, 33(3):25-29. [38] 张帆,都伟超,孙金声,等. 抗温强抑制有机硅酸盐聚合物的合成与性能评价[J]. 钻井液与完井液,2022,39(3):265-272.ZHANG Fan, DU Weichao, SUN Jinsheng, et al. The synthesis and evaluation of a high temperature organosilicate polymer with high inhibitive capacity[J]. Drilling Fluid & Completion Fluid, 2022, 39(3):265-272. [39] 刘敬平,孙金声. 川滇页岩气水平井水基钻井液技术[J]. 钻井液与完井液,2017,34(2):9-14.LIU Jingping, SUN Jinsheng. Water base drilling fluid technology for horizontal shale gas drilling in Sichuan and Yunnan[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):9-14. [40] 刘敬平,孙金声. 钻井液活度对川滇页岩气地层水化膨胀与分散的影响[J]. 钻井液与完井液,2016,33(2):31-35.LIU Jingping, SUN Jinsheng. Effects of drilling fluid activity on hydration and dispersion of formation rocks in shale gas drilling in Chuan-Dian area[J]. Drilling Fluid & Completion Fluid, 2016, 33(2):31-35. [41] 罗健生,刘刚,李超,等. 深水FLAT-PRO合成基钻井液体系研究及应用[J]. 中国海上油气,2017,29(3):61-66.LUO Jiansheng, LIU Gang, LI Chao, et al. Research and application of FLAT-PRO synthetic based drilling fluid system in deep water[J]. China Offshore Oil and Gas, 2017, 29(3):61-66. [42] 狄明利,赵远远,邱文发. FLAT-PRO合成基钻井液在南海东部超深水井的应用[J]. 广东化工,2019,46(20):38-40.DI Mingli, ZHAO Yuanyuan, QIU Wenfa. Application of FLAT-PRO synthetic base drilling fluid in ultra-deepwater well in the eastern South China sea[J]. Guangdong Chemical Industry, 2019, 46(20):38-40. [43] 耿铁. 深水恒流变合成基钻井液技术研究[D]. 青岛: 中国石油大学(华东), 2019.GENG Tie. Study on flat-rheology synthetic-based drilling fluid for deepwater drilling[D]. Qingdao: China University Of Petroleum(East China), 2019. [44] 李超,罗健生,刘刚,等. FLAT-PRO深水合成基钻井液恒流变作用机理研究[J]. 广东化工,2021,48(4):242-243,241.LI Chao, LUO Jiansheng, LIU Gang, et al. Study on the flat-rheological mechanism of FLAT-PRO flat-rheology synthetic-based drilling fluid system in deepwater[J]. Guangdong Chemical Industry, 2021, 48(4):242-243,241. [45] 沈炎,刘俊,程晓年,等. 泡沫流体钻井技术在肯尼亚OW904超高温地热井的应用[J]. 重庆科技学院学报(自然科学版),2009,11(4):16-18,32.SHEN Yan, LIU Jun, CHENG Xiaonian, et al. Application of foam fluid drilling technology at OW904 UHT geothermal well in Kenya[J]. Journal of Chongqing University of Science And Technology(Natural Sciences Edition) , 2009, 11(4):16-18,32. [46] 鲁立强,单正明,邓发兵,等. 肯尼亚OLKARIA地热井空气泡沫流体定向钻井综合技术研究[J]. 科学技术与工程,2009,9(14):4137-4139.LU Liqiang, SHAN Zhengming, DENG Fabing, et al. Stduy on geothermal well directional drilling with air foam in Kenya OLKARIA[J]. Science Technology and Engineering, 2009, 9(14):4137-4139. [47] 赖晓晴,楼一珊,屈沅治,等. 超高温地热井泡沫钻井流体技术[J]. 钻井液与完井液,2009,26(2):37-38.LAI Xiaoqing, LOU Yishan, QU Yuanzhi, et al. Foam drilling fluid technology for ultra-high temperature geothermal wells[J]. Drilling Fluid & Completion Fluid, 2009, 26(2):37-38. [48] 谈心,孙金声,徐显广,等. 油基泡沫钻井流体技术研究[J]. 石油学报,2010,31(5):829-833.TAN Xin, SUN Jinsheng, XU Xianguang, et al. A study on the oil-based foam drilling fluid technique[J]. Acta Petrolei Sinica, 2010, 31(5):829-833. [49] 王龙,张子桥,张华伟,等. 肯尼亚OLKARIA高温地热井钻井技术应用[J]. 国外油田工程,2010,26(10):32-33,51.WANG Long, ZHANG Ziqiao, ZHANG Huawei, et al. Application of drilling technology for high temperature geothermal wells of OLKARIA block in Kenya[J]. Foreign Oil Field Engineering, 2010, 26(10):32-33,51. [50] SUN J S, WANG Z L, LIU J P, et al. Research progress and development direction of low-temperature drilling fluid for Antarctic region[J]. Petroleum Exploration and Development, 2022, 49(5):1161-1168. doi: 10.1016/S1876-3804(22)60340-9 [51] 孙金声,王宗轮,刘敬平,等. 南极地区低温钻井液研究进展与发展方向[J]. 石油勘探与开发,2022,49(5):1005-1011.SUN Jinsheng, WANG Zonglun, LIU Jingping, et al. Research progress and development direction of low-temperature drilling fluid for Antarctic region[J]. Petroleum Exploration and Development, 2022, 49(5):1005-1011. [52] 韩丽丽, 徐会文, 于达慧, 等. 南极冰钻超低温钻井液试验研究[C]//第十六届全国探矿工程(岩土钻掘工程)技术学术交流年会论文集. 南宁, 2011: 255-259.HAN Lili, XU Huiwen, YU Dahui, et al. Experimental study on ultra low temperature fluids for Antarctic deep ice core drilling[C]//Proceedings of the 16th National Academic Exchange Conference on Exploration Engineering (Rock and Soil Drilling Engineering) Technology. Nanning, 2011: 255-259. [53] 刘宁,徐会文,韩丽丽,等. 南极冰钻钻井液应用性试验研究[J]. 探矿工程(岩土钻掘工程),2016,43(8):11-14,43.LIU Ning, XU Huiwen, HAN Lili, et al. Physicochemical properties of potential ultralow-temperature drilling fluids for Antarctic deep ice core drilling[J]. Exploration Engineering(Rock & Soil Drilling and Tunneling) , 2016, 43(8):11-14,43. [54] 刘宁. 深冰心钻探潜在低温钻井液理化特性试验研究[D]. 长春: 吉林大学, 2017.LIU Ning. Experimental study on physicochemical properties of potential low-temperature drilling fluids for deep ice coring[D]. Changchun: Jilin University, 2017. [55] 王金堂,徐嘉崎,廖波,等. 海域天然气水合物钻井液用多功能处理剂制备与性能评价[J]. 钻探工程,2023,50(6):11-17.WANG Jintang, XU Jiaqi, LIAO Bo, et al. Preparation and properties evaluation of multifunctional drilling fluid additive for marine natural gas hydrate[J]. Drilling Engineering, 2023, 50(6):11-17. [56] 李轩,黄维安,孙金声,等. 核磁共振法研究钻井液侵入对甲烷水合物沉积层分解及渗透率的影响[J]. 中国石油大学学报(自然科学版),2022,46(6):11-20.LI Xuan, HUANG Weian, SUN Jinsheng, et al. Effect of fluid invasion on methane hydrate dissociation and sediment damage using low-field NMR[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2022, 46(6):11-20. [57] 孙金声,程远方,秦绪文,等. 南海天然气水合物钻采机理与调控研究进展[J]. 中国科学基金,2021,35(6):940-951.SUN Jinsheng, CHENG Yuanfang, QIN Xuwen, et al. Research progress on natural gas hydrate drilling & production in the South China sea[J]. Bulletin of National Natural Science Foundation of China, 2021, 35(6):940-951. [58] 王韧,孙金声,孙慧翠,等. 不同驱动力条件下改性淀粉、羧甲基纤维素钠和黄原胶对水合物形成的影响[J]. 中国石油大学学报(自然科学版),2021,45(1):127-136.WANG Ren, SUN Jinsheng, SUN Huicui, et al. Effects of modified starch, CMC and XC on hydrate formation under different driving forces[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2021, 45(1):127-136. [59] 王韧,李锐,张凌,等. 亲水性氨基酸抑制四氢呋喃水合物形成的动力学机理[J]. 天然气工业,2019,39(9):82-88. doi: 10.3787/j.issn.1000-0976.2019.09.010WANG Ren, LI Rui, ZHANG Ling, et al. Kinetic mechanism of hydrophilic amino acid inhibiting the formation of tetrahydrofuran (THF) hydrate[J]. Natural Gas Industry, 2019, 39(9):82-88. doi: 10.3787/j.issn.1000-0976.2019.09.010 [60] 王韧,宁伏龙,刘天乐,等. 游离甲烷气在井筒内形成水合物的动态模拟[J]. 石油学报,2017,38(8):963-972.WANG Ren, NING Fulong, LIU Tianle, et al. Dynamic simulation of hydrate formed from free methane gas in borehole[J]. Acta Petrolei Sinica, 2017, 38(8):963-972. [61] 孙慧翠,王韧,王建华,等. 不同分子量聚乙烯吡咯烷酮对四氢呋喃水合物形成及生长的影响[J]. 天然气工业,2018,38(5):125-132.SUN Huicui, WANG Ren, WANG Jianhua, et al. Effects of polyvinylpyrrolidone with different molecular weights on the formation and growth of tetrahydrofuran hydrate[J]. Natural Gas Industry, 2018, 38(5):125-132. [62] 吕开河,王中义,黄贤斌,等. 适用于深水水基钻井液的温敏聚合物流型调节剂[J]. 钻井液与完井液,2021,38(1):14-20.LYU Kaihe, WANG Zhongyi, HUANG Xianbin, et al. A temperature sensitive polymer flow pattern modifier for water base drilling fluids for deep water drilling[J]. Drilling Fluid & Completion Fluid, 2021, 38(1):14-20. [63] SUN J S, BAI Y R, CHENG R C, et al. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation[J]. Petroleum Exploration and Development, 2021, 48(3):732-743. doi: 10.1016/S1876-3804(21)60059-9 [64] YANG J B, SUN J S, BAI Y R, et al. Status and prospect of drilling fluid loss and lost circulation control technology in fractured formation[J]. Gels, 2022, 8(5):260. doi: 10.3390/gels8050260 [65] 吕开河,王晨烨,雷少飞,等. 裂缝性地层钻井液漏失规律及堵漏对策[J]. 中国石油大学学报(自然科学版),2022,46(2):85-93.LYU Kaihe, WANG Chenye, LEI Shaofei, et al. Dynamic behavior and mitigation methods for drilling fluid loss in fractured formations[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2022, 46(2):85-93. [66] 孙金声,白英睿,程荣超,等. 裂缝性恶性井漏地层堵漏技术研究进展与展望[J]. 石油勘探与开发,2021,48(3):630-638. doi: 10.11698/PED.2021.03.18SUN Jinsheng, BAI Yingrui, CHENG Rongchao, et al. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation[J]. Petroleum Exploration and Development, 2021, 48(3):630-638. doi: 10.11698/PED.2021.03.18 [67] 孙金声,刘凡,程荣超,等. 机器学习在防漏堵漏中研究进展与展望[J]. 石油学报,2022,43(1):91-100.SUN Jinsheng, LIU Fan, CHENG Rongchao, et al. Research progress and prospects of machine learning in lost circulation control[J]. Acta Petrolei Sinica, 2022, 43(1):91-100. [68] 刘凡,程荣超,郝惠军,等. 裂缝性地层固化类堵漏材料井下运移仿真模拟研究[J]. 钻井液与完井液,2021,38(5):560-567.LIU Fan, CHENG Rongchao, HAO Huijun, et al. Simulation study on movement of solidifying LCMs for controlling mud losses into fracturing formations[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):560-567. [69] 刘凡,刘钦政,郝惠军,等. 高强度可固化树脂堵漏剂PMMM研制与评价[J]. 钻井液与完井液,2021,38(6):671-676,683.LIU Fan, LIU Qinzheng, HAO Huijun, et al. Synthesis and evaluation of a high strength curable resin LCM PMMM[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):671-676,683. [70] BAI Y, LIU Y, YANG K Q, et al. Application and research prospect of functional polymer Gels in oil and gas drilling and development engineering[J]. Gels, 2023, 9(5):413. doi: 10.3390/gels9050413 [71] BAI Y R, YANG J B, SUN J S, et al. Self-filling and plugging performance of a thixotropic polymer gel for lost circulation control in fractured formation[J]. Geoenergy Science and Engineering, 2023, 225:211717. doi: 10.1016/j.geoen.2023.211717 [72] YANG J B, BAI Y R, SUN J S, et al. Experimental study on physicochemical properties of a shear thixotropic polymer gel for lost circulation control[J]. Gels, 2022, 8(4):229. doi: 10.3390/gels8040229 [73] 张全立, 徐丙贵, 贾涛, 等. 高性能膨胀管技术[Z]. 北京: 中国石油集团工程技术研究院有限公司, 2020.ZHANG Quanli, XU Binggui, JIA Tao, et al. High performance expansion pipe technology[Z]. Beijing: China Petroleum Engineering Technology Research Institute Co. , Ltd, 2020. [74] 王建利,郭启军,朱英杰,等. 高钢级膨胀管封堵技术的应用[J]. 中国石油和化工标准与质量,2020,40(11):197-198. doi: 10.3969/j.issn.1673-4076.2020.11.097WANG Jianli, GUO Qijun, ZHU Yingjie, et al. The application of sealing technology for high-grade expansion pipes[J]. China Petroleum and Chemical Standard and Quality, 2020, 40(11):197-198. doi: 10.3969/j.issn.1673-4076.2020.11.097 [75] 郑有成,郭建华. 长裸眼恶性漏失井膨胀管堵漏适用技术[J]. 天然气工业,2023,43(8):98-107.ZHENG Youcheng, GUO Jianhua. Application of expandable tubular plugging technology in long open hole wells with severe lost circulation[J]. Natural Gas Industry, 2023, 43(8):98-107. [76] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163-177.WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: progress and prospect[J]. Natural Gas Industry, 2021, 41(8):163-177. [77] 张志敏,邹博,蔡莹莹,等. 膨胀管技术在塔里木油田超深侧钻井LN8C井成功应用[J]. 化学工程与装备,2018(6):49-50.ZHANG Zhimin, ZOU Bo, CAI Yingying, et al. The successful application of expansion tube technology in ultra deep lateral drilling of LN8C well in Tarim Oilfield[J]. Chemical Engineering & Equipment, 2018(6):49-50. [78] 唐洪明,徐诗雨,王茜,等. 克拉苏气田超致密砂岩气储层水锁损害[J]. 断块油气田,2017,24(4):541-545.TANG Hongming, XU Shiyu, WANG Qian, et al. Water blocking damage of hyper-tight sandstone gas reservoir in Kelasu gas field[J]. Fault-Block Oil and Gas Field, 2017, 24(4):541-545. [79] 唐洪明,朱柏宇,王茜,等. 致密砂岩气层水锁机理及控制因素研究[J]. 中国科学(技术科学),2018,48(5):537-547. doi: 10.1360/N092017-00200TANG Hongming, ZHU Baiyu, WANG Qian, et al. Mechanism and control factors of water blocking in tight sandstone gas reservoir[J]. SCIENTIA SINICA Technologica, 2018, 48(5):537-547. doi: 10.1360/N092017-00200 [80] 李宁,康毅力,郭斌,等. 塔里木迪北区块深层致密碎屑岩气藏损害机理与钻开方式选择[J]. 钻采工艺,2019,42(1):108-110. doi: 10.3969/J.ISSN.1006-768X.2019.01.34LI Ning, KANG Yili, GUO Bin, et al. Damage mechanism and drilling method selection of deep dense clastic gas reservoirs in the Dibei Block of Tarim Basin[J]. Drilling & Production Technology, 2019, 42(1):108-110. doi: 10.3969/J.ISSN.1006-768X.2019.01.34 [81] 蒋官澄,程荣超,谭宾,等. 钻井过程中保护低渗特低渗油气层的必要性、 重要性与发展趋势[J]. 钻井液与完井液,2020,37(4):405-411.JIANG Guancheng, CHENG Rongchao, TAN Bin, et al. Protecting the low permeability and ultra-low permeability pay zones during drilling: necessity, importance and developing tendency[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):405-411. [82] 王双威,张闯,张洁,等. 狮子沟构造带裂缝储层保护钻井液配方[J]. 科学技术与工程,2021,21(19):7991-7996.WANG Shuangwei, ZHANG Chuang, ZHANG Jie, et al. The formulation of drilling fluid to protect the fracture reservoir of the Shizigou structural belt[J]. Science Technology and Engineering, 2021, 21(19):7991-7996. [83] 张浩,佘继平,杨洋,等. 可酸溶固化堵漏材料的封堵及储层保护性能[J]. 油田化学,2020,37(4):581-586,592.ZHANG Hao, SHE Jiping, YANG Yang, et al. Plugging and formation damage control performance of a lost circulation material[J]. Oilfield Chemistry, 2020, 37(4):581-586,592. [84] 张志财,刘保双,王忠杰,等. 钻井液性能在线监测系统的研制与现场应用[J]. 钻井液与完井液,2020,37(5):597-601,607.ZHANG Zhicai, LIU Baoshuang, WANG Zhongjie, et al. Development and field application of an online drilling fluid property monitoring system[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):597-601,607. -

下载:

下载: