Study on the Imbibition Law and Mechanism of Strong Emulsification System Based on the Experimental and Numerical Assessment

-

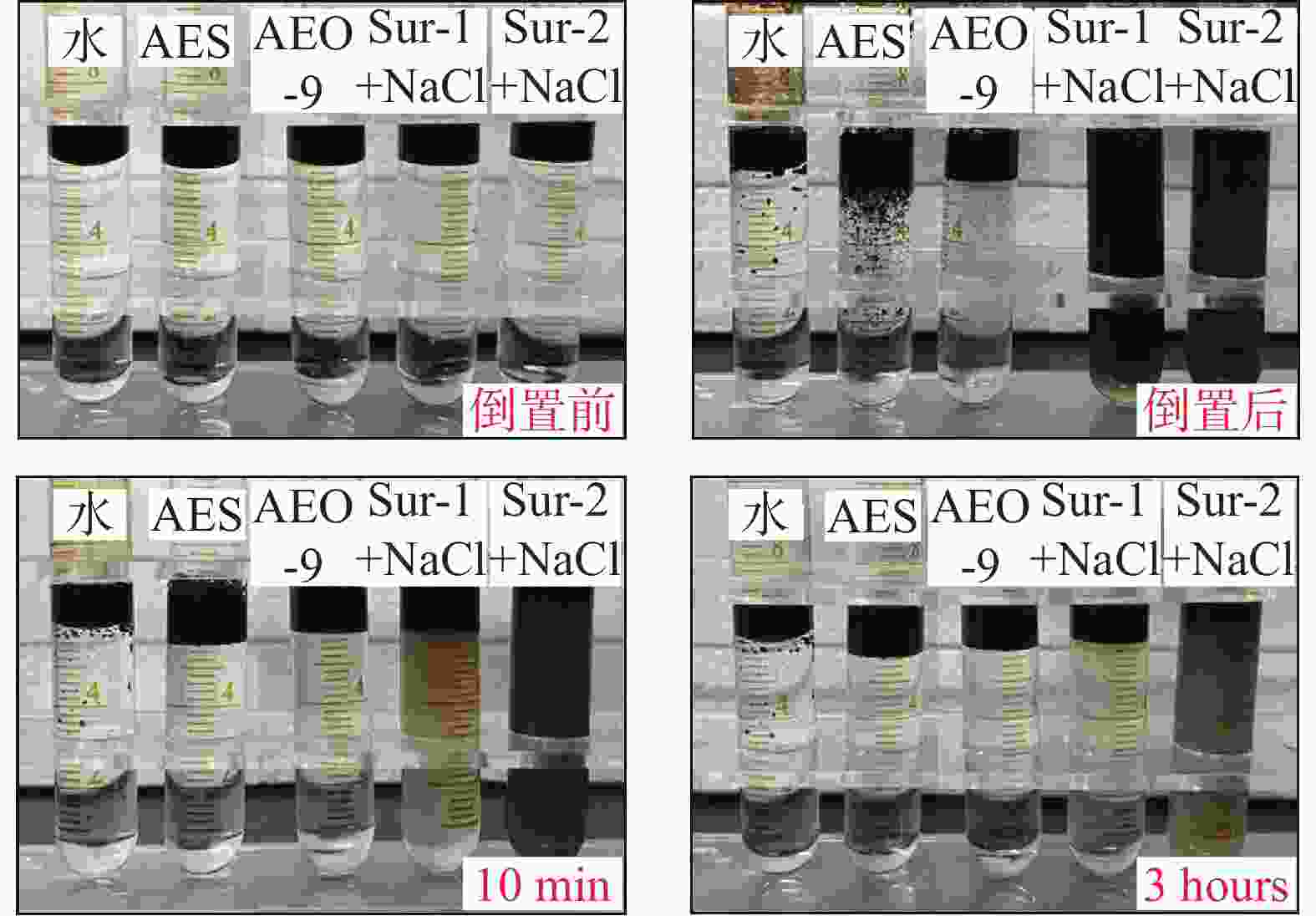

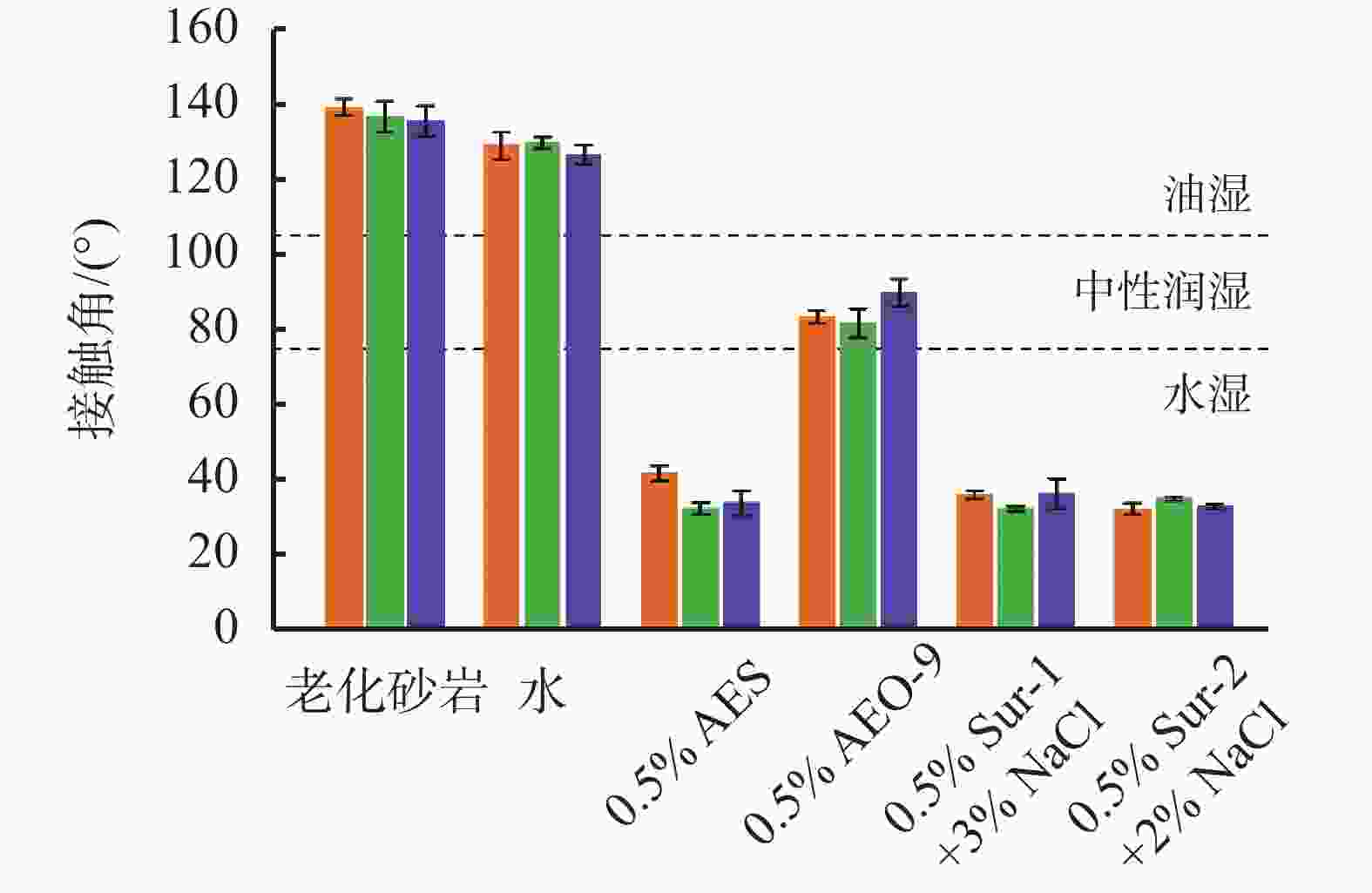

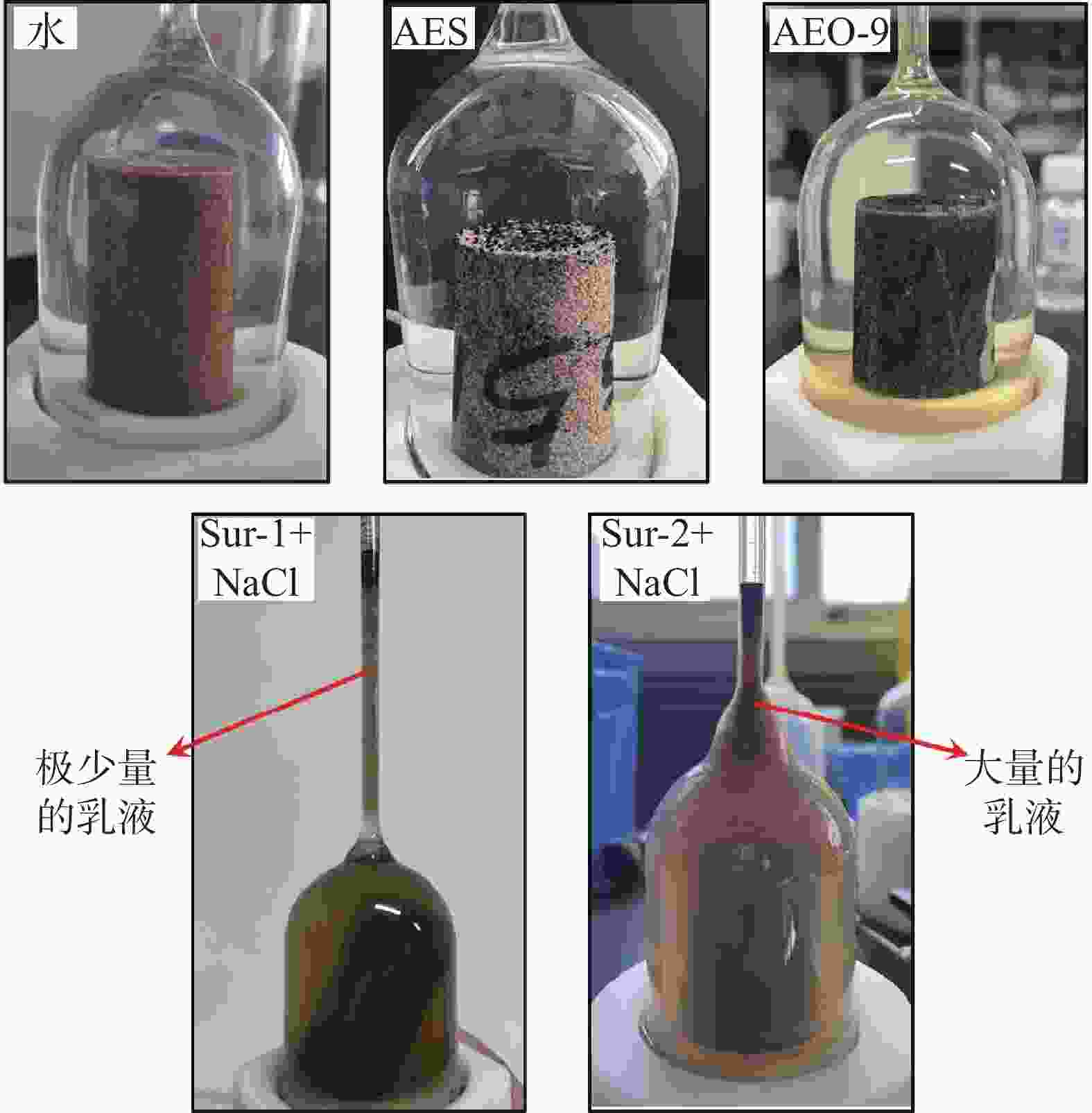

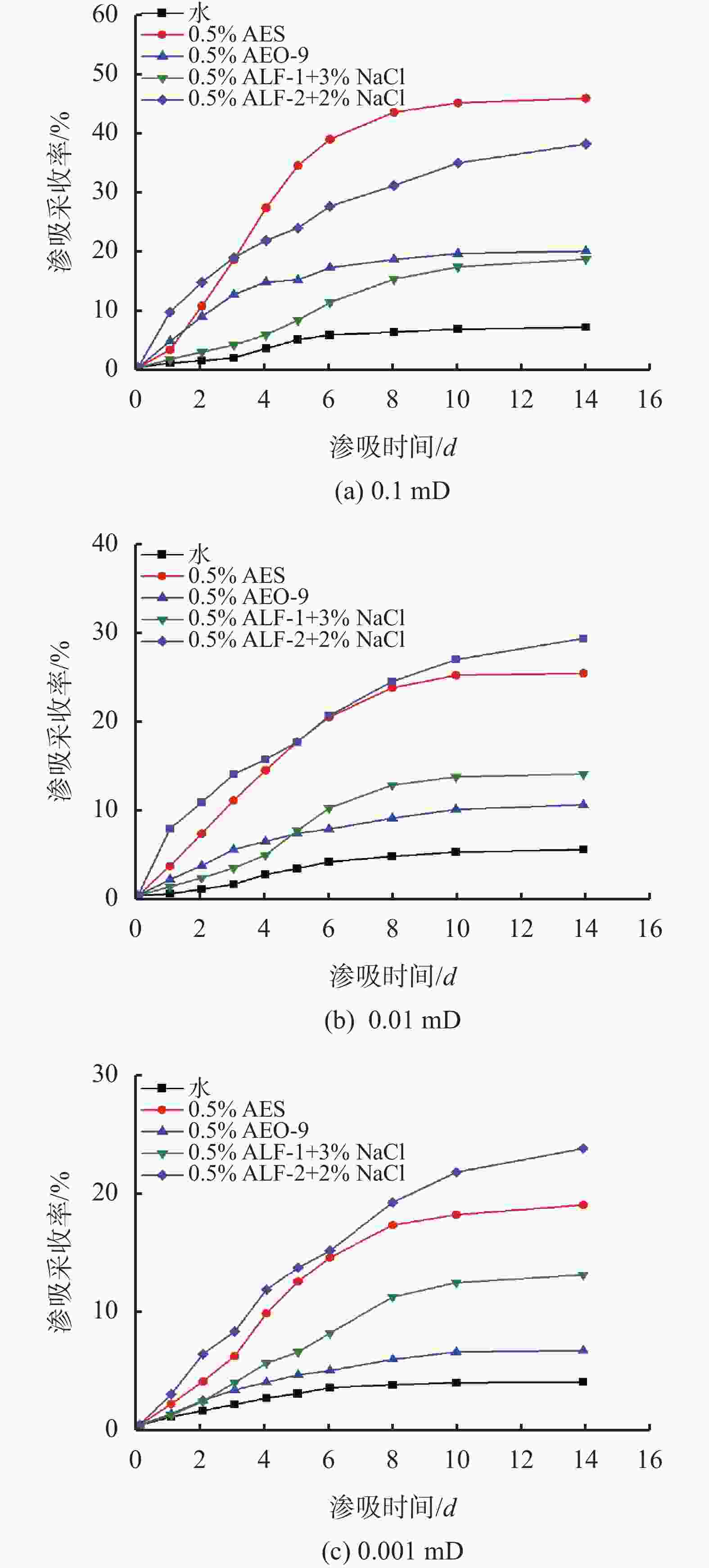

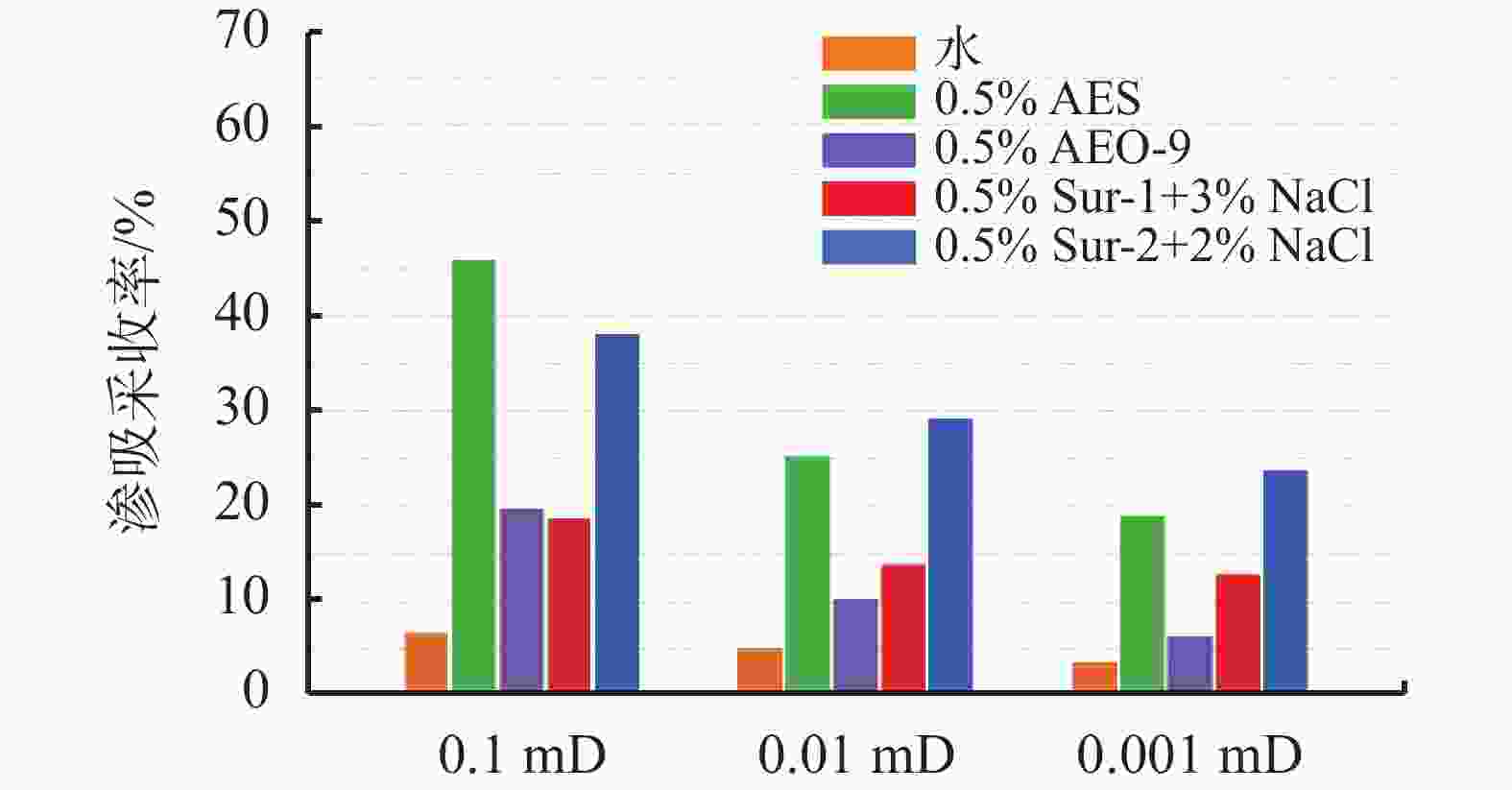

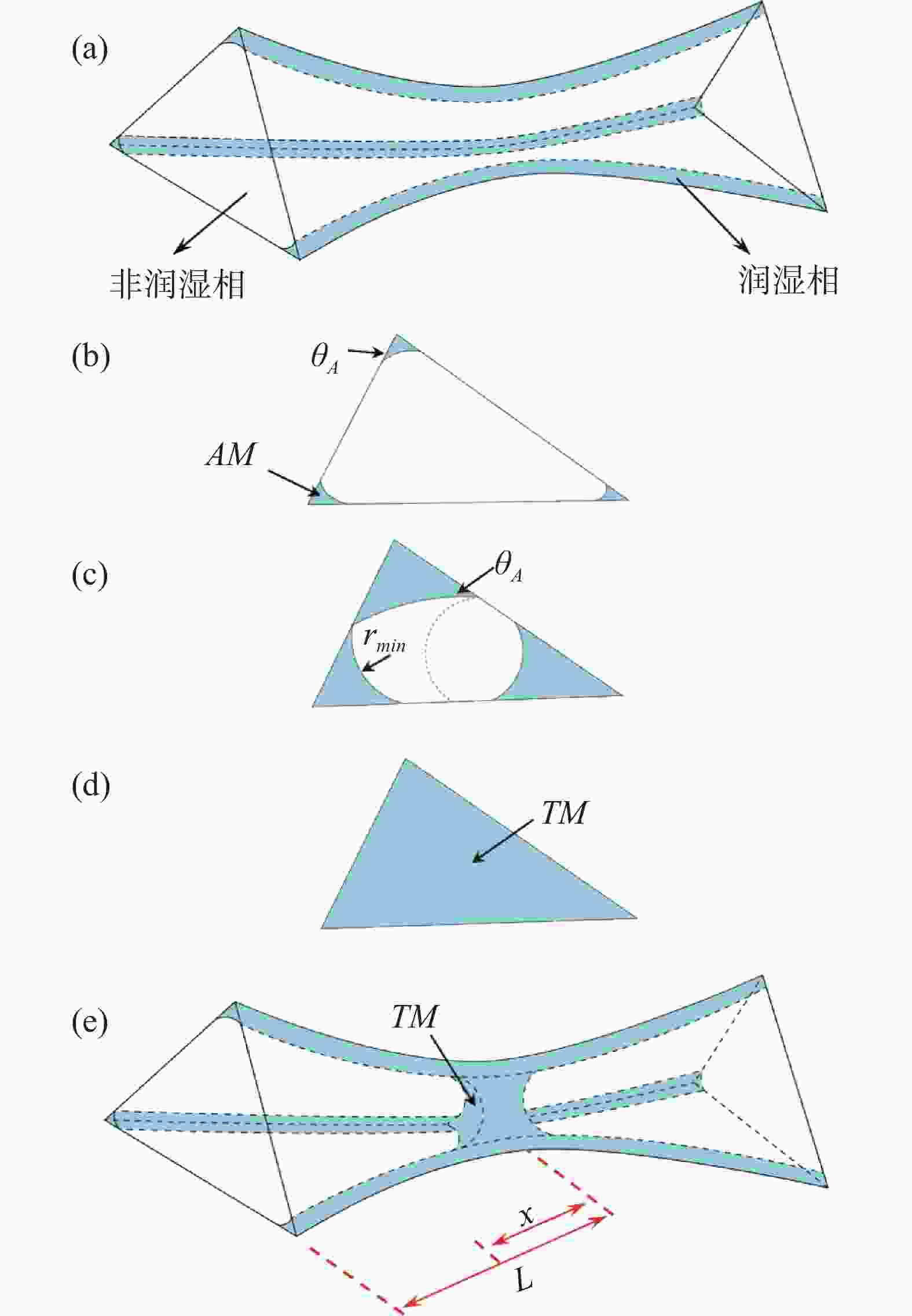

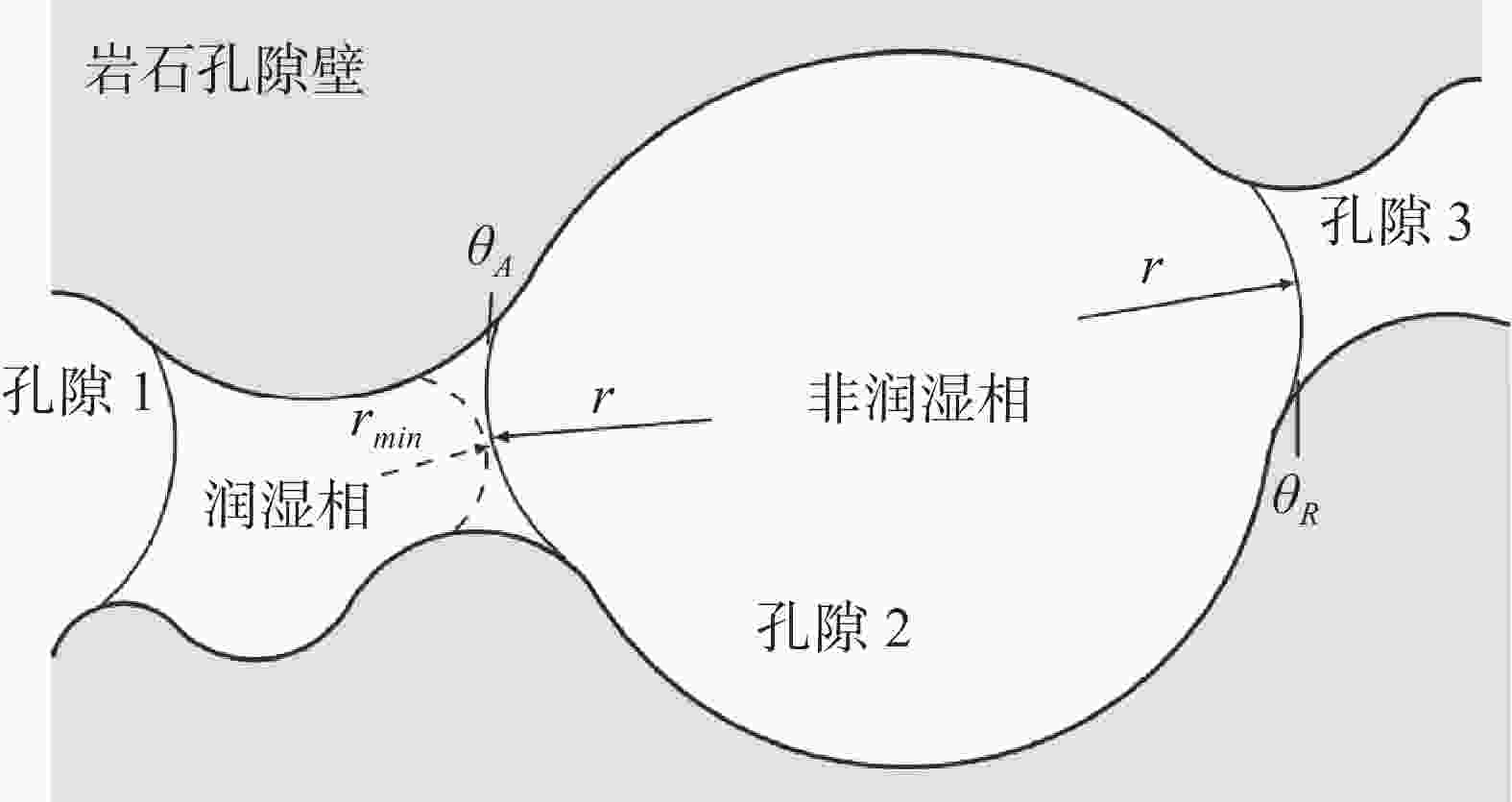

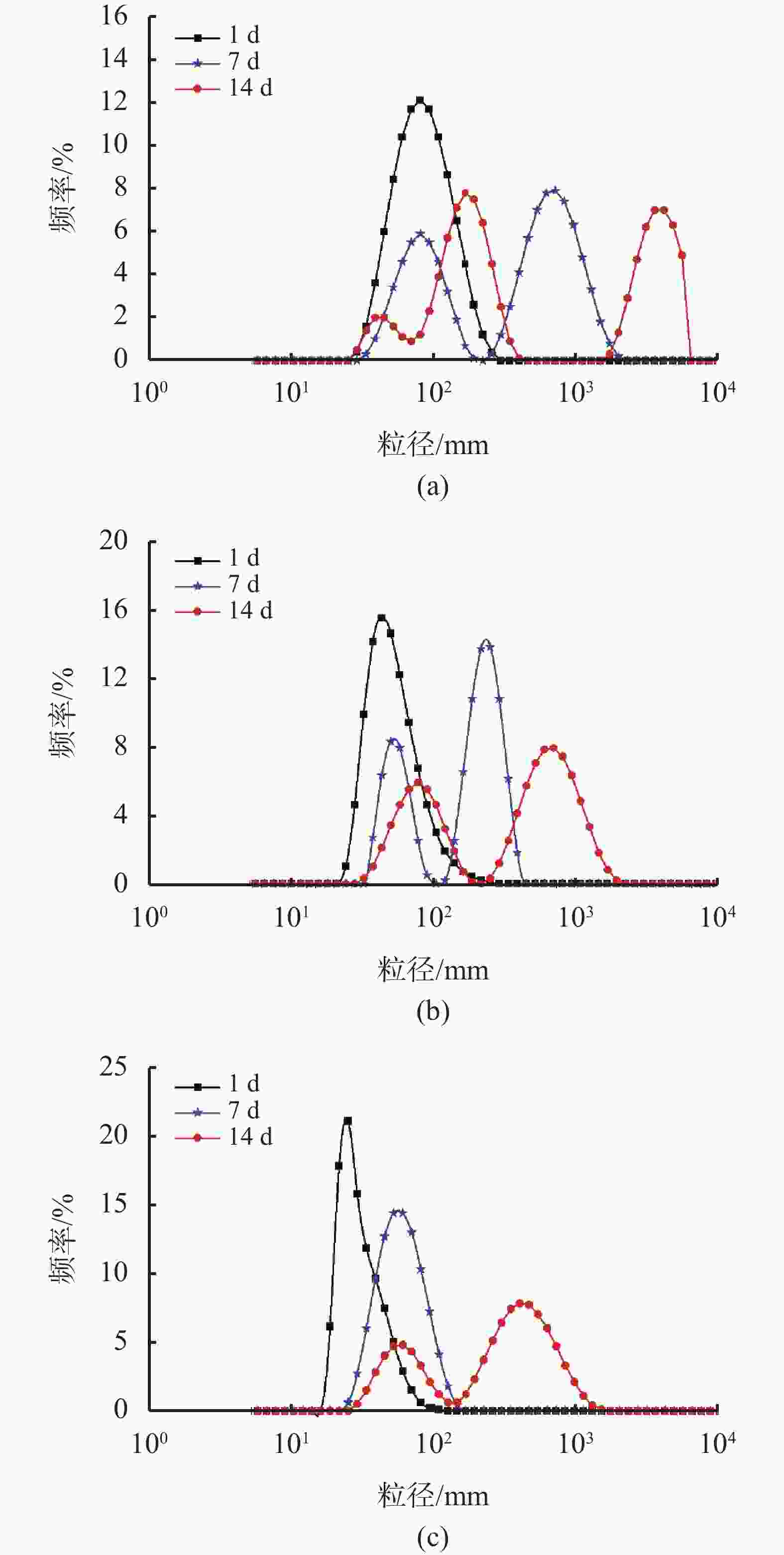

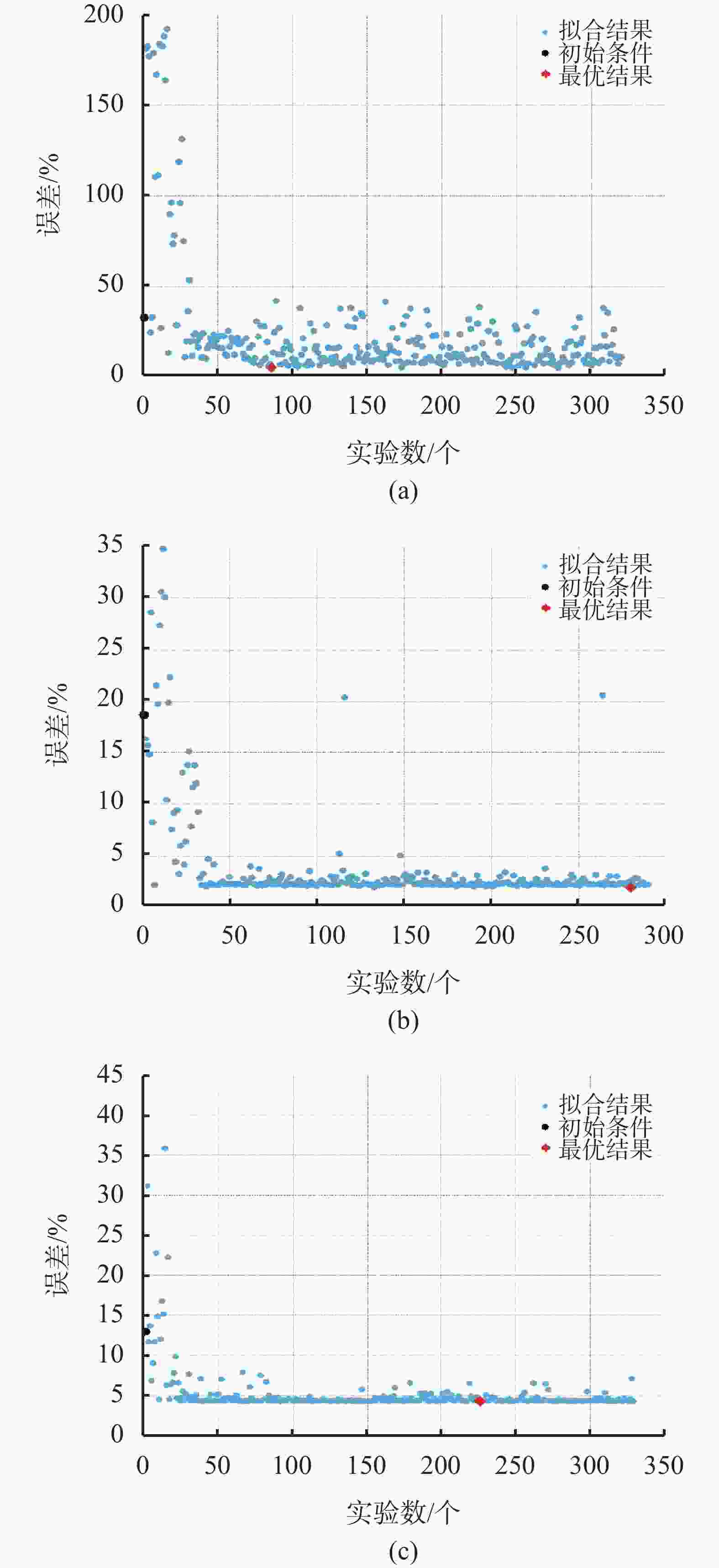

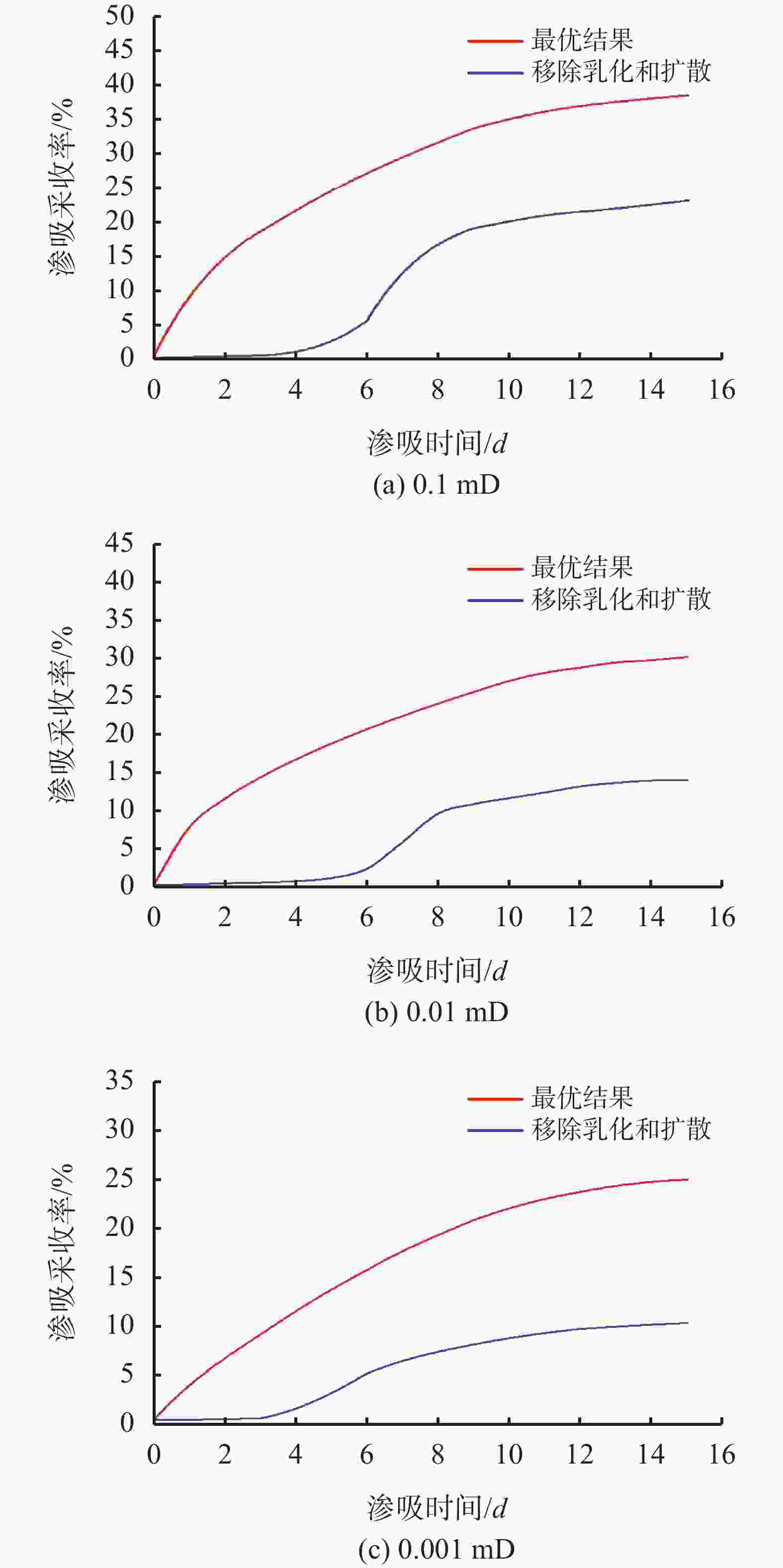

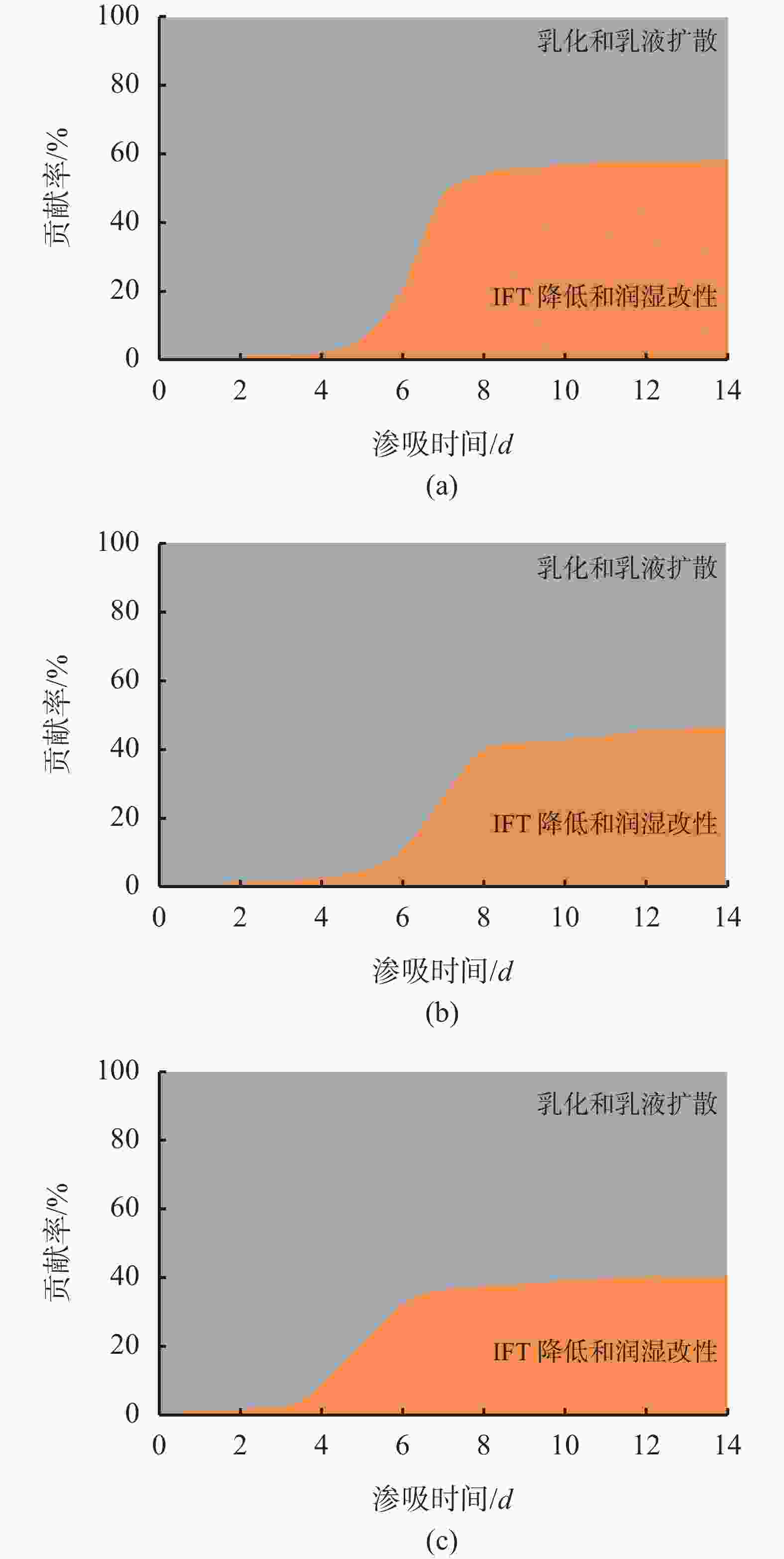

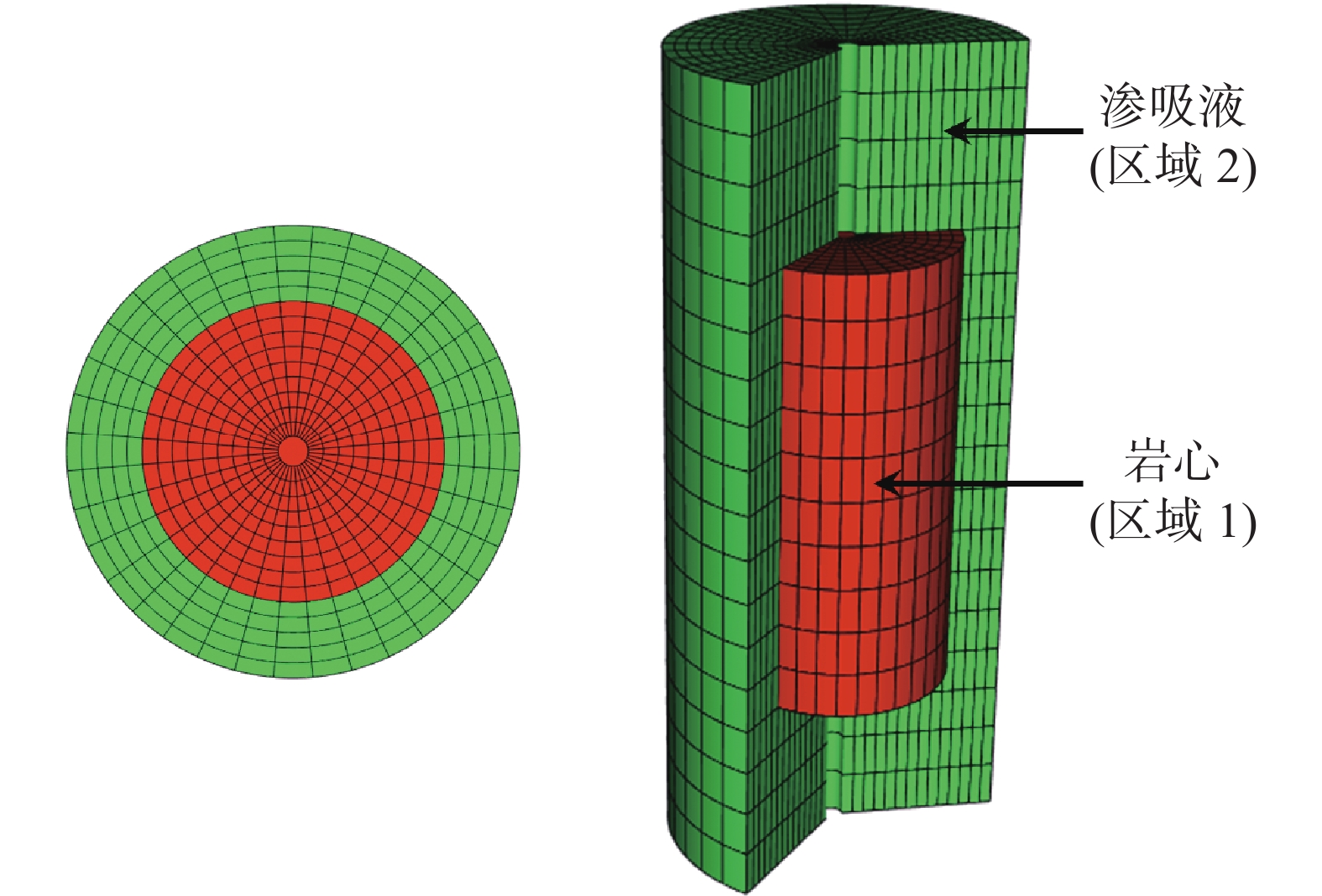

摘要: 向压裂液中加入表面活性剂强化焖井过程中裂缝与基质间的油水置换,是提高致密油采收率的重要措施。普遍的观点认为润湿改性和相对高的界面张力(IFT)是实现渗吸采油的关键。近年来,室内实验和矿场实践均表明,具有超低IFT的表面活性剂体系也能实现渗吸,有效地动用基质中的原油。针对超低IFT体系渗吸机理仍不明确的问题,设计润湿改性和超低IFT乳化体系,明确了致密砂岩中的高效置换体系的特征和渗吸效果,结合数学模型揭示了两种体系渗吸的油水运移模式和主导机制。结果表明,两种体系的适用范围不同,润湿改性体系在0.1 mD的储层中渗吸效果更好,而超低IFT强乳化体系在0.01 mD和0.001 mD储层中的渗吸采收率更高。润湿改性体系的渗吸是以毛管力驱动的层流模式,随着渗透率降低,润湿相填充孔隙的速度快速降低,渗吸采收率从约45%大幅度降低至18%。超低IFT强乳化体系可形成微纳米粒径的乳液,具有特殊的乳化、乳液扩散机制,在渗吸初期,主要通过乳化和扩散效应实现渗吸采油,渗吸后期,IFT降低和润湿改性的层流模式逐渐发挥作用,采收率从约38%降低至23%。超低IFT强乳化体系的乳化、扩散机制适合用于更致密油藏的油水置换过程,在致密储层的压裂增产方面具有广阔的应用前景。Abstract: Surfactants are usually added to the fracturing fluids to enhance the imbibition between fractures and matrix, which is an important measure to improve oil recovery. The popular perspective believes that altering water-wet conditions and keeping a relatively high IFT value are the keys to achieving the imbibition process. Recently, both indoor experiments and oilfield practice have shown that the surfactant systems with ultra-low IFT can also achieve imbibition and effectively recover oil from the matrix. For the problem that the imbibition mechanism of ultra-low IFT system is still unclear, the wettability alteration system, ultra-low IFT system, and emulsification system are constructed, the characteristics of imbibition systems and imbibition recovery are clarified, the oil-water transport patterns and dominant mechanisms of wettability alteration system and ultra-low IFT system with excellent emulsification are revealed by using mathematical models. The results show that the applicability range of the wettability alteration system and ultra-low IFT system with excellent emulsification is different. The wettability alteration system has better imbibition effects under 0.1 mD, but the ultra-low IFT system with excellent emulsification performs better under 0.01 mD and 0.001 mD. The imbibition process of the wettability alteration system is a layer flow pattern dominated by capillary force, the rate at which the wetted phase fills the pores decreases rapidly with the decrease of permeability, and the imbibition recovery decreases significantly from about 45% to 18%. The micro-nano emulsions can be formed by the ultra-low IFT system with excellent emulsification, which has a special emulsification and diffusion mechanism. In the early stage, oil is mainly recovered by emulsification and diffusion, in the late stage, the layer flow pattern of IFT reduction and wettability alteration gradually works, and the imbibition recovery decreases from about 38% to 23%. The emulsification and diffusion mechanism of the ultra-low IFT system with excellent emulsification is suitable for the imbibition of tighter reservoirs, and has a broad application in fracturing and stimulation of tight reservoirs.

-

Key words:

- Spontaneous imbibition /

- Ultra-low IFT /

- Emulsification /

- NMR /

- Tight reservoirs

-

表 1 岩心样品参数

岩心 直径/mm 长度/mm 孔隙度/% 渗透率/mD H1 2.53 24.96 13.71 0.1631 H2 2.50 25.17 13.35 0.0951 H3 2.52 24.87 13.49 0.0995 H4 2.49 24.92 13.96 0.2236 H5 2.51 24.86 14.38 0.2321 M1 2.53 25.29 8.26 1.45×10-2 M2 2.53 24.80 8.04 1.21×10-2 M3 2.50 25.07 9.05 1.08×10-2 M4 2.48 24.84 7.27 2.10×10-2 M5 2.53 24.88 7.69 2.31×10-2 L1 2.51 25.01 5.74 2.05×10-3 L2 2.50 24.98 4.15 3.21×10-3 L3 2.49 25.11 4.64 1.96×10-3 L4 2.55 25.06 4.10 1.64×10-3 L5 2.48 24.97 4.76 1.14×10-3 表 2 表面活性剂与原油之间的IFT

溶液 IFT/(mN/m) 水 16.1320 0.5% AES 3.2790 0.5% AEO-9 3.1270 0.5% Sur-1 + 3% NaCl 0.0042 0.5% Sur-2 + 2% NaCl 0.0048 表 3 核磁共振(NMR)仪器参数

功能 脉冲

序列磁场强度/

MHz扫描

次数回波

个数等待时间/

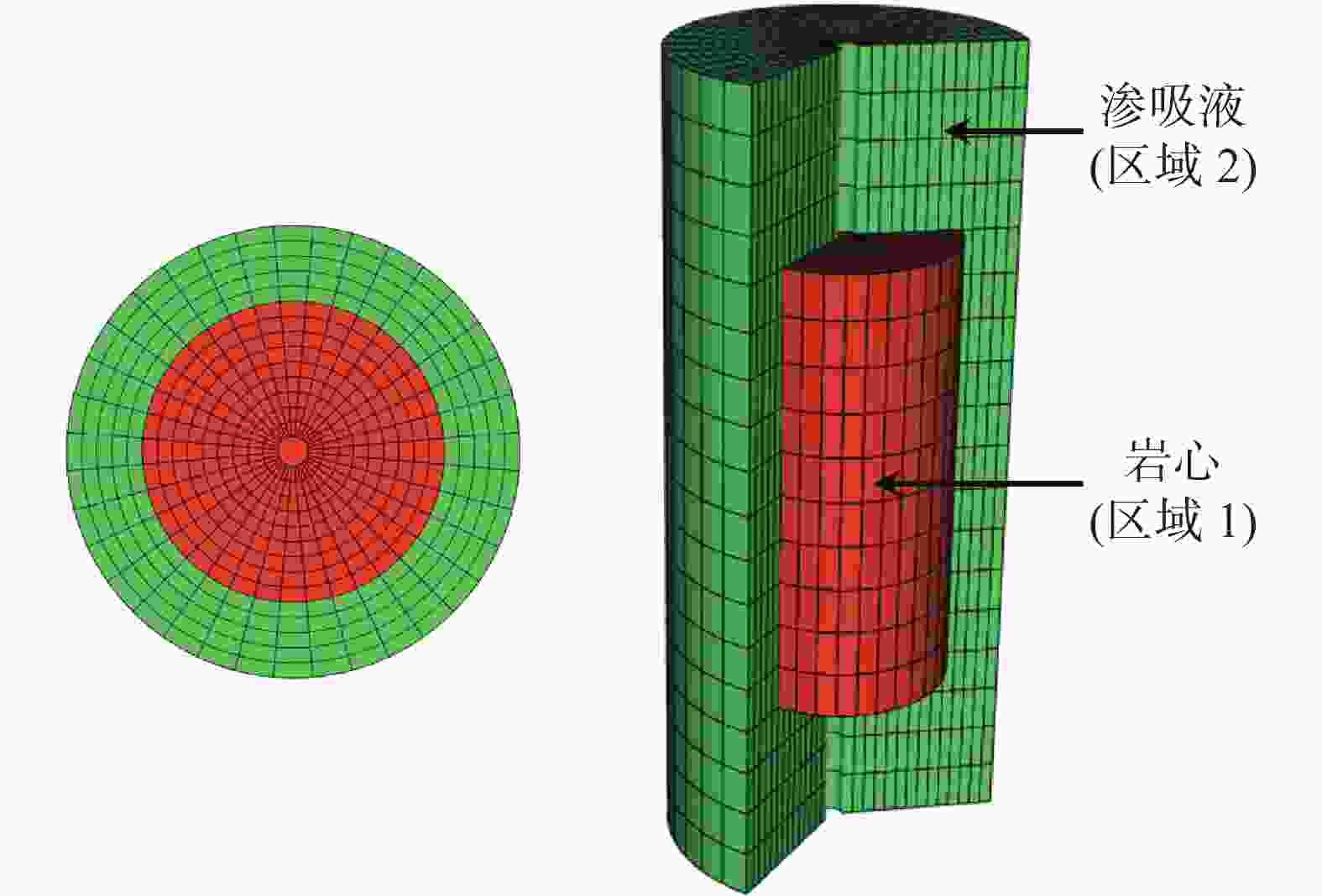

msT/℃ T2 CPMG 12 8 12 000 3000 25 表 4 岩心模型的初始参数

参数 数值 模型参数(r×θ×z) 1.875 cm×360°×9 cm 网格数(r×θ×z) 15×10×18 岩心区域参数(区域1) Φ2.5 cm×5 cm 孔隙度(区域1) 13%、8%、4% 渗透率(区域1) 0.1 mD、0.01 mD、0.001 mD 含油饱和度(区域1) 90% 孔隙度(区域2) 99.9% 渗透率(区域2) 999 mD 含水饱和度(区域2) 99.9% -

[1] HOU X Y, SHENG J J. Properties, preparation, stability of nanoemulsions, their improving oil recovery mechanisms, and challenges for oil field applications—A critical review[J]. Geoenergy Science and Engineering, 2023, 221:211360. doi: 10.1016/j.geoen.2022.211360 [2] 贾承造,郑民,张永峰. 中国非常规油气资源与勘探开发前景[J]. 石油勘探与开发,2012,39(2):129-136.JIA Chengzao, ZHENG Min, ZHANG Yongfeng. Unconventional hydrocarbon resources in China and the prospect of exploration and development[J]. Petroleum Exploration and Development, 2012, 39(2):129-136. [3] 贾承造,邹才能,李建忠,等. 中国致密油评价标准、主要类型、基本特征及资源前景[J]. 石油学报,2012,33(3):343-350.JIA Chengzao, ZOU Caineng, LI Jianzhong, et al. Assessment criteria, main types, basic features and resource prospects of the tight oil in China[J]. Acta Petrolei Sinica, 2012, 33(3):343-350. [4] SHENG J J. What type of surfactants should be used to enhance spontaneous imbibition in shale and tight reservoirs?[J]. Journal of Petroleum Science and Engineering, 2017, 159:635-643. doi: 10.1016/j.petrol.2017.09.071 [5] 申金伟,袁文奎,赵健,等. 用返排液作基液的压裂液配方研究[J]. 钻井液与完井液,2022,39(2):241-247.SHEN Jinwei, YUAN Wenkui, ZHAO Jian, et al. Study on formulating fracturing fluids with used fracturing fluids for tight gas reservoirs[J]. Drilling Fluid & Completion Fluid, 2022, 39(2):241-247. [6] 张大年,程兴生,李永平,等. 大规模体积压裂过程中压裂液性能表征方法研究[J]. 钻井液与完井液,2021,38(4):517-524.ZHANG Danian, CHENG Xingsheng, LI Yongping, et al. Study on characterization of the performance of fracturing fluids in large scale volumetric fracturing[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):517-524. [7] 刘汉斌,柏浩,唐梅荣,等. 纳米变黏滑溜水黏弹携砂机理与渗吸性能[J]. 钻井液与完井液,2022,39(5):638-645. doi: 10.12358/j.issn.1001-5620.2022.05.016LIU Hanbin, BAI Hao, TANG Meirong, et al. Study on viscoelastic sand-carrying mechanism and imbibition performance of Nano variable-viscosity slickwater[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):638-645. doi: 10.12358/j.issn.1001-5620.2022.05.016 [8] HOU X Y, SHENG J J. Experimental study on the imbibition mechanism of the Winsor type Ⅰ surfactant system with ultra-low IFT in oil-wet shale oil reservoirs by NMR[J]. Journal of Petroleum Science and Engineering, 2022, 216:110785. doi: 10.1016/j.petrol.2022.110785 [9] WANG X K, WANG S, WU W S, et al. Coupled pressure-driven flow and spontaneous imbibition in shale oil reservoirs[J]. Physics of Fluids, 2023, 35(4):042104. doi: 10.1063/5.0146836 [10] TU J W, SHENG J J. Effect of pressure on imbibition in shale oil reservoirs with wettability considered[J]. Energy & Fuels, 2020, 34(4):4260-4272. [11] 王红科,刘音,何武,等. 高温水配制压裂液技术研究与现场应用[J]. 钻井液与完井液,2020,37(3):384-388.WANG Hongke, LIU Yin, HE Wu, et al. Preparation of fracturing fluids with hot water[J]. Drilling Fluid & Completion Fluid, 2020, 37(3):384-388. [12] 于馥玮,高振东,朱文浩,等. 基于微流控模型的裂缝性储集层渗吸机理实验[J]. 石油勘探与开发,2021,48(5):1004-1013. doi: 10.11698/PED.2021.05.12YU Fuwei, GAO Zhendong, ZHU Wenhao, et al. Experimental research on imbibition mechanisms of fractured reservoirs by microfluidic chips[J]. Petroleum Exploration and Development, 2021, 48(5):1004-1013. doi: 10.11698/PED.2021.05.12 [13] HE K, XU L, GAO Y F, et al. Evaluation of surfactant performance in fracturing fluids for enhanced well productivity in unconventional reservoirs using Rock-on-a-Chip approach[J]. Journal of Petroleum Science and Engineering, 2015, 135:531-541. doi: 10.1016/j.petrol.2015.10.008 [14] HOU X Y, SHENG J J. Experimental study on the effects of IFT reduction and Shut-In on water blockage after hydraulic fracturing in tight sandstone reservoirs based on the NMR method[J]. Energy & Fuels, 2023, 37(9):6569-6584. [15] TU J W, SHENG J J. Experimental and numerical study of surfactant solution spontaneous imbibition in shale oil reservoirs[J]. Journal of the Taiwan Institute of Chemical Engineers, 2020, 106:169-182. doi: 10.1016/j.jtice.2019.11.003 [16] WEI B, WANG L L, MAO R X, et al. Understanding imbibition mechanisms of catanionic surfactant–stabilized nanoemulsion for enhanced oil recovery in tight sandstone reservoirs: experimental and numerical assessment[J]. SPE Journal, 2023, 28(3):1437-1452. doi: 10.2118/204336-PA [17] LANGMUIR I. The adsorption of gases on plane surfaces of glass, mica and Platinum[J]. Journal of the American Chemical Society, 1918, 40(9):1361-1403. doi: 10.1021/ja02242a004 [18] WIJAYA N, SHENG J J. Mitigating near-fracture blockage and enhancing oil recovery in tight reservoirs by adding surfactants in hydraulic fracturing fluid[J]. Journal of Petroleum Science and Engineering, 2020, 185:106611. doi: 10.1016/j.petrol.2019.106611 [19] BLUNT M J. Multiphase flow in permeable media[M]. Cambridge: Cambridge University Press, 2017. [20] BERGENSTÅHL B. Emulsion formation and instability[M]//RAYNER M, DEJMEK P. Engineering Aspects of Food Emulsification and Homogenization, Boca Raton: CRC Press/Taylor & Francis Group, 2015: 33-50. [21] Particle Sciences. Emulsion stability and testing[R]. 3894 Courtney St. Bethlehem, PA 18017-8920, USA, 2011. [22] LI Z, JIANG A A, LIU H N, et al. Evaluation of hydrophilic and hydrophobic silica particles on the release kinetics of essential oil pickering emulsions[J]. ACS Omega, 2022, 7(10):8651-8664. doi: 10.1021/acsomega.1c06666 [23] APPELO C A J, POSTMA D. Geochemistry, groundwater and pollution[M]. London: CRC press, 2005. [24] EMCH G G. Diffusion, einstein formula and mechanics[J]. Journal of Mathematical Physics, 1973, 14(12):1775-1783. doi: 10.1063/1.1666250 [25] KALE S N, DEORE S L. Emulsion micro emulsion and nano emulsion: a review[J]. Systematic Reviews in Pharmacy, 2017, 8(1):39-47. -

下载:

下载: