Effects of Rock Asphalt with Surface Grafted C—S—H on Mechanical Properties of Set Cement in High Temperature Wells

-

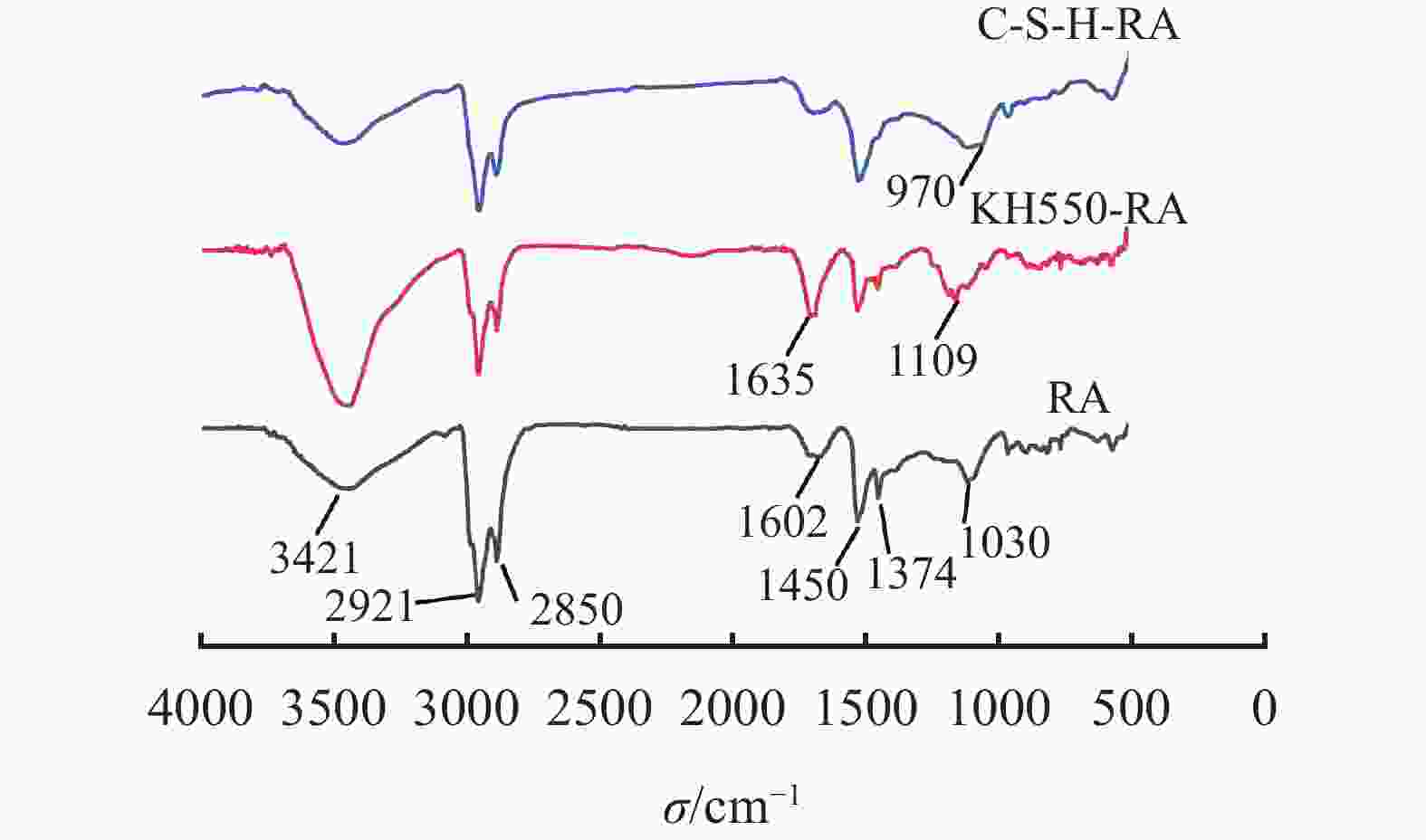

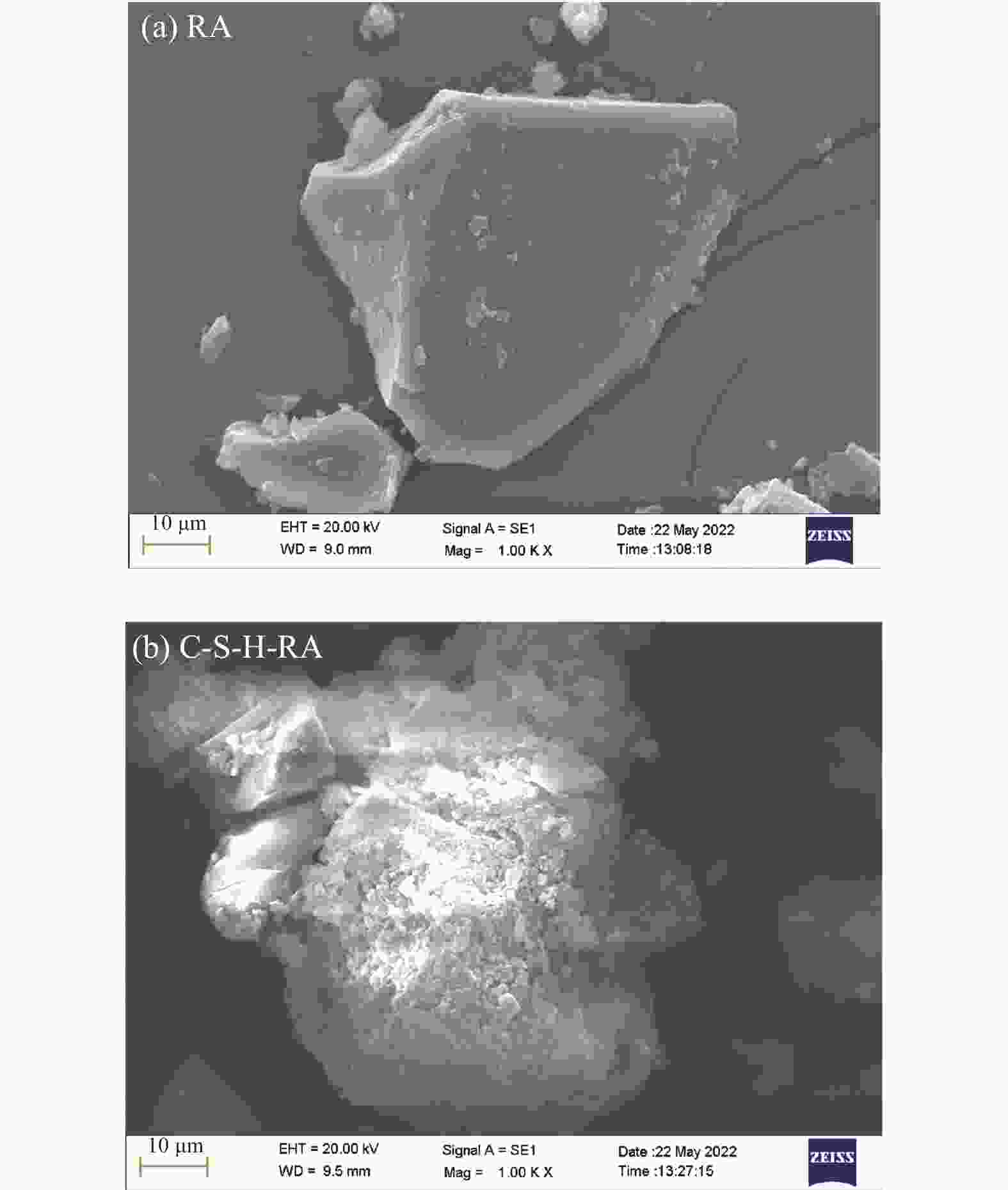

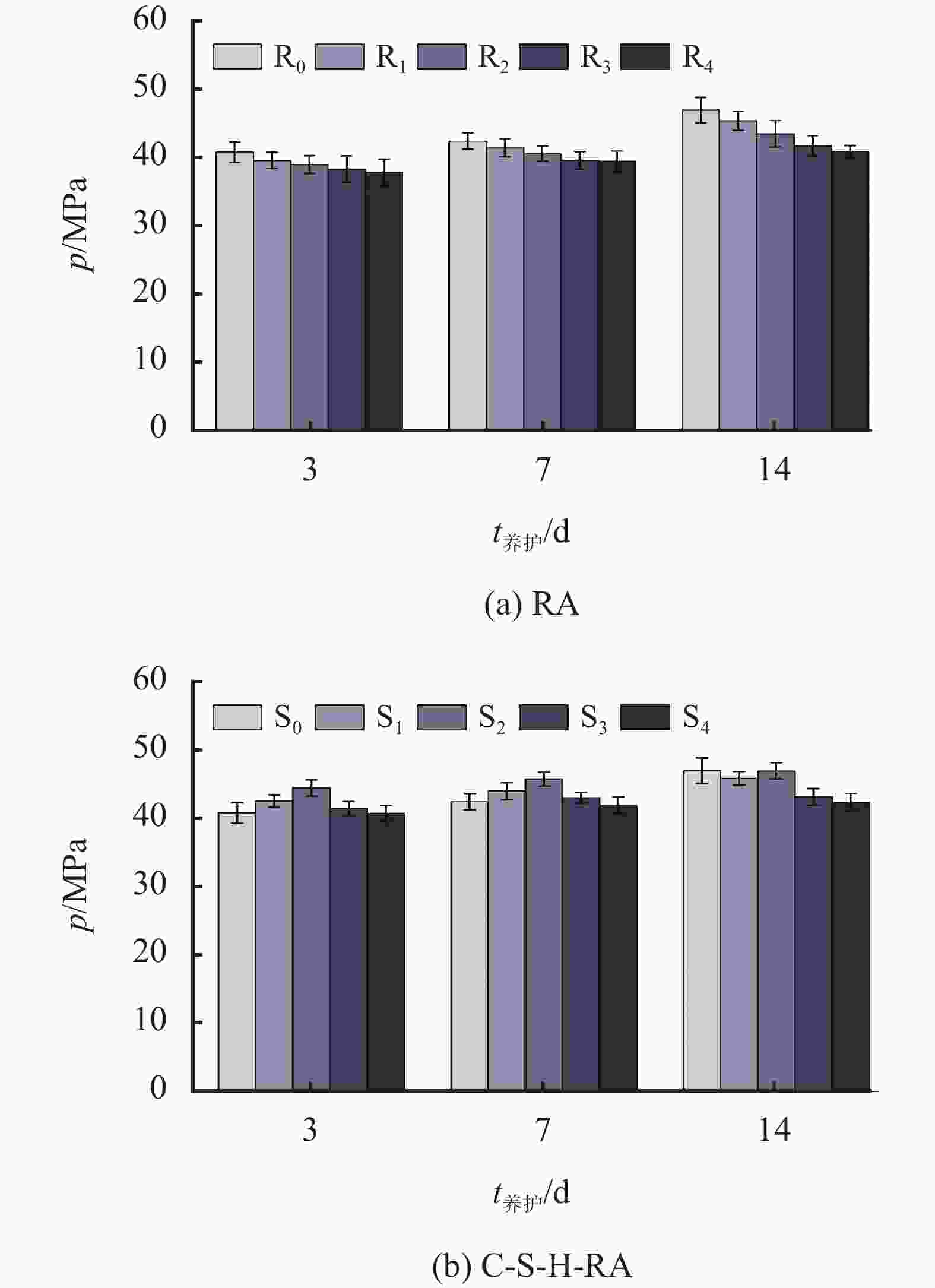

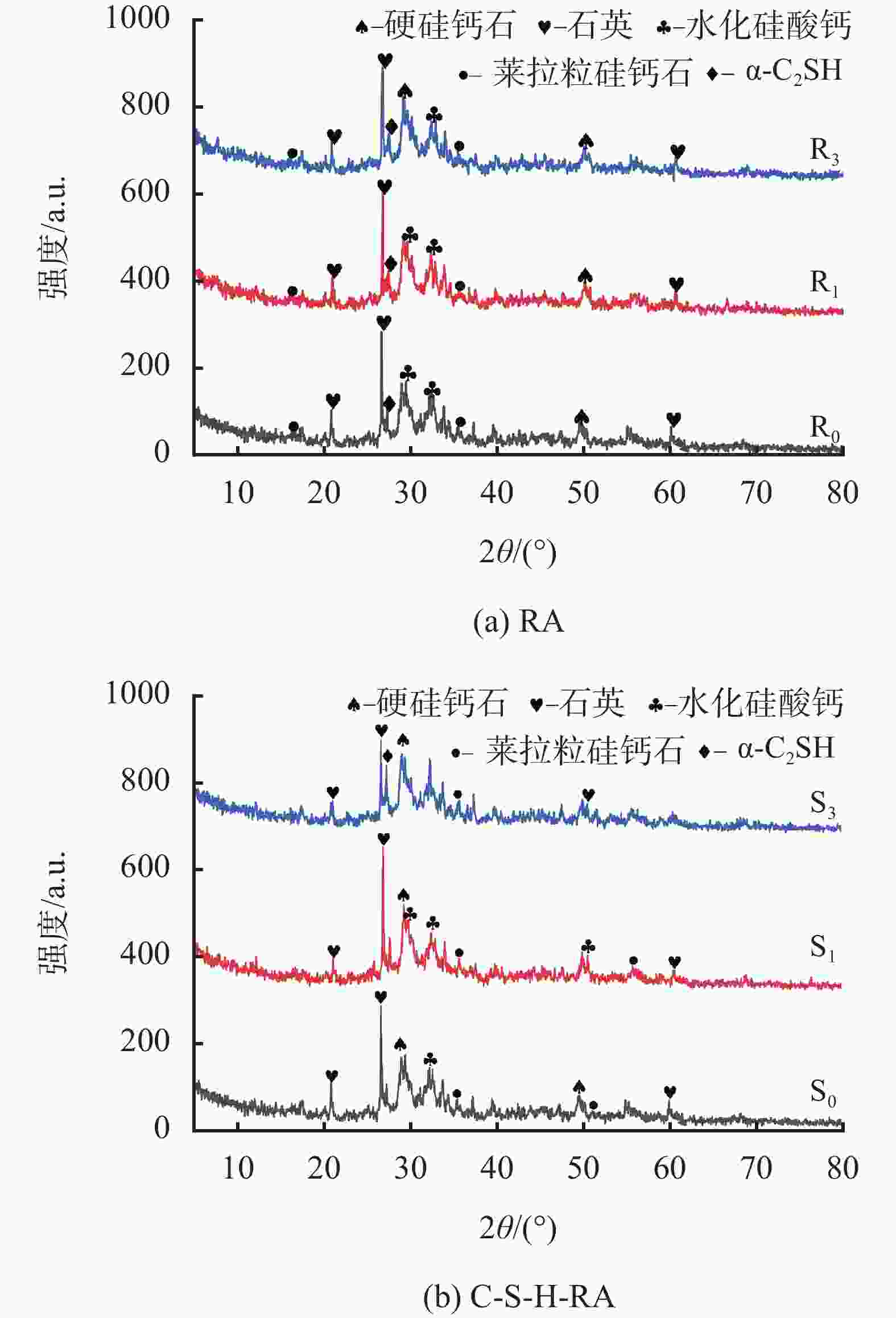

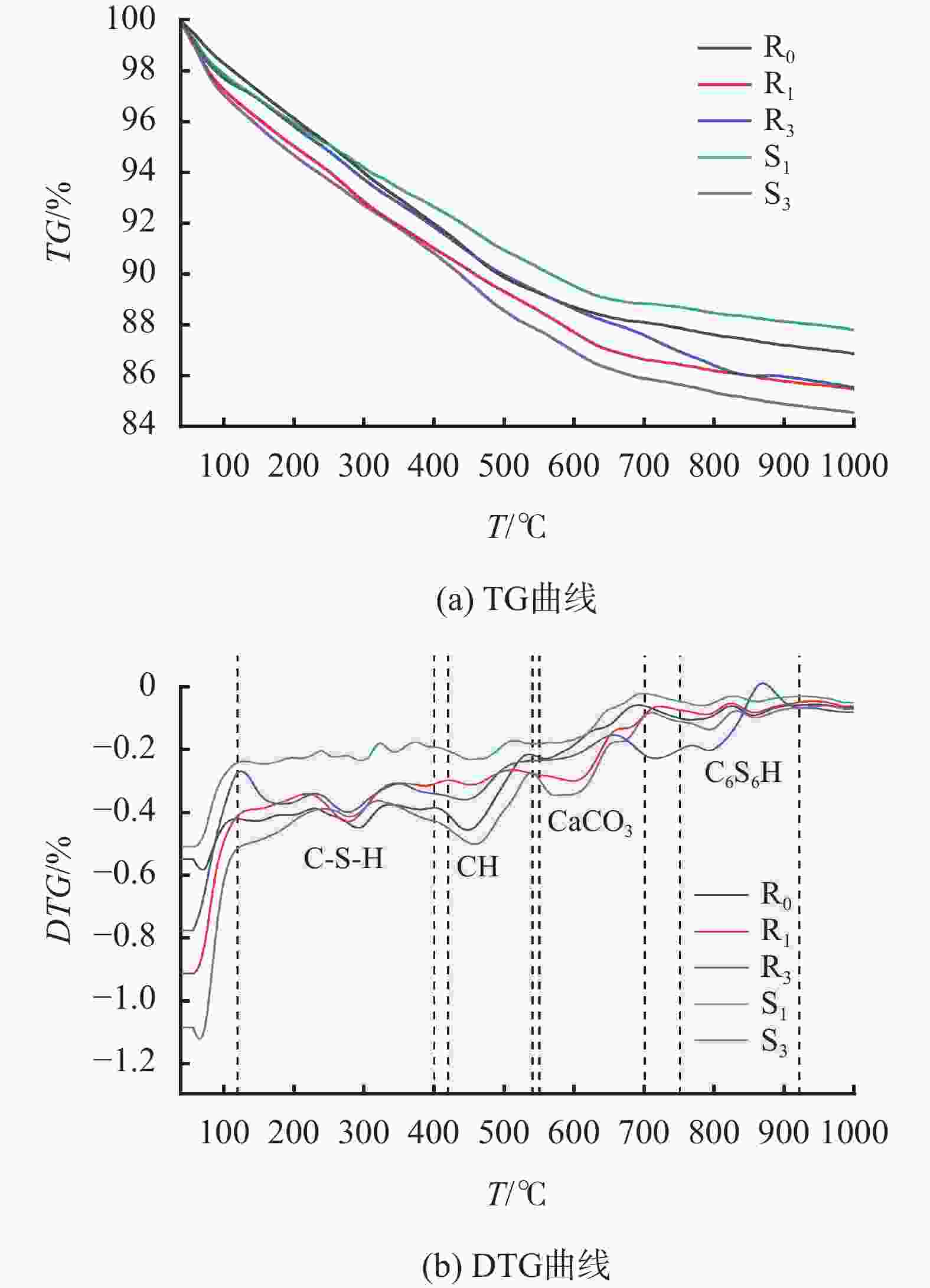

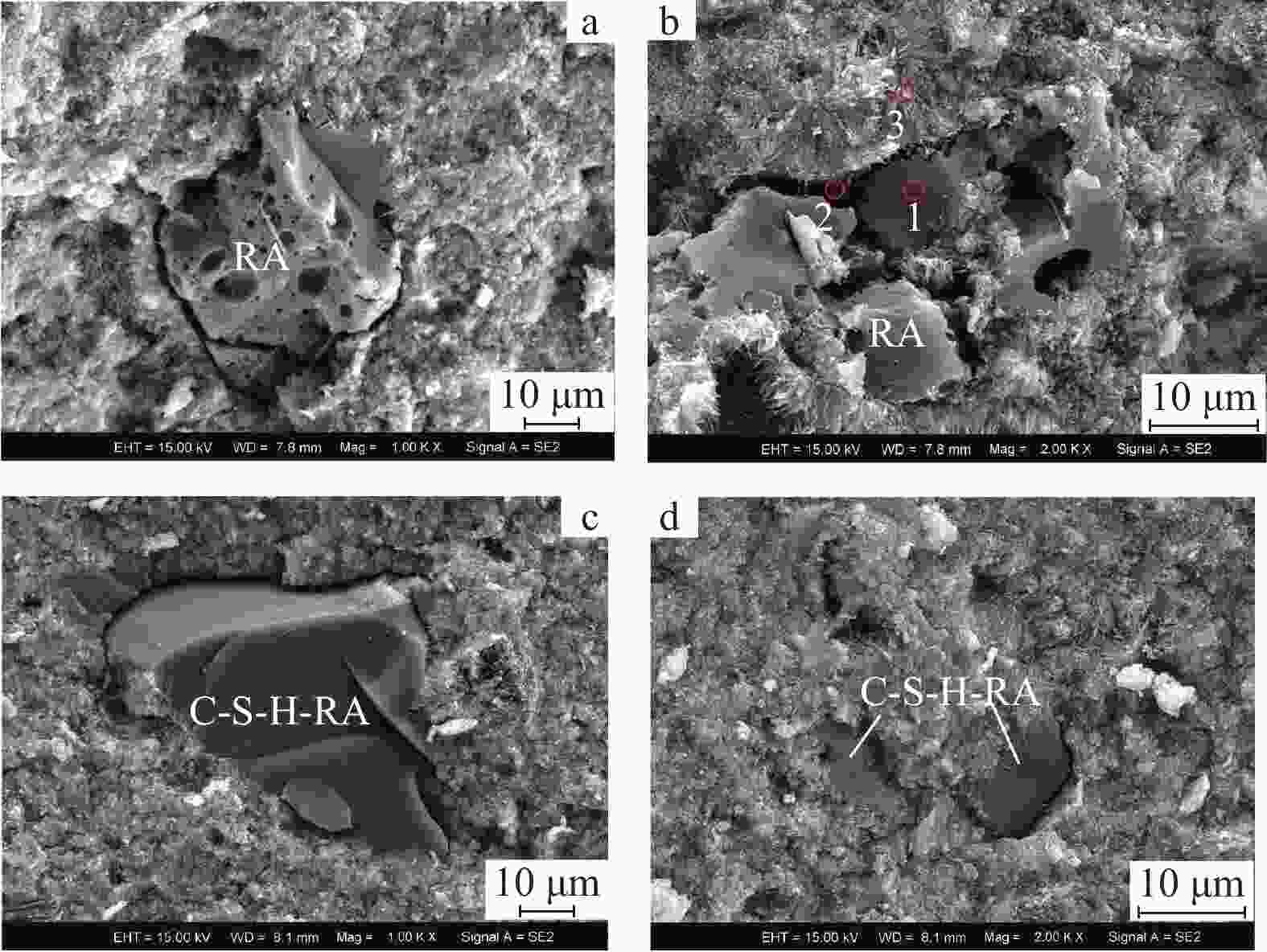

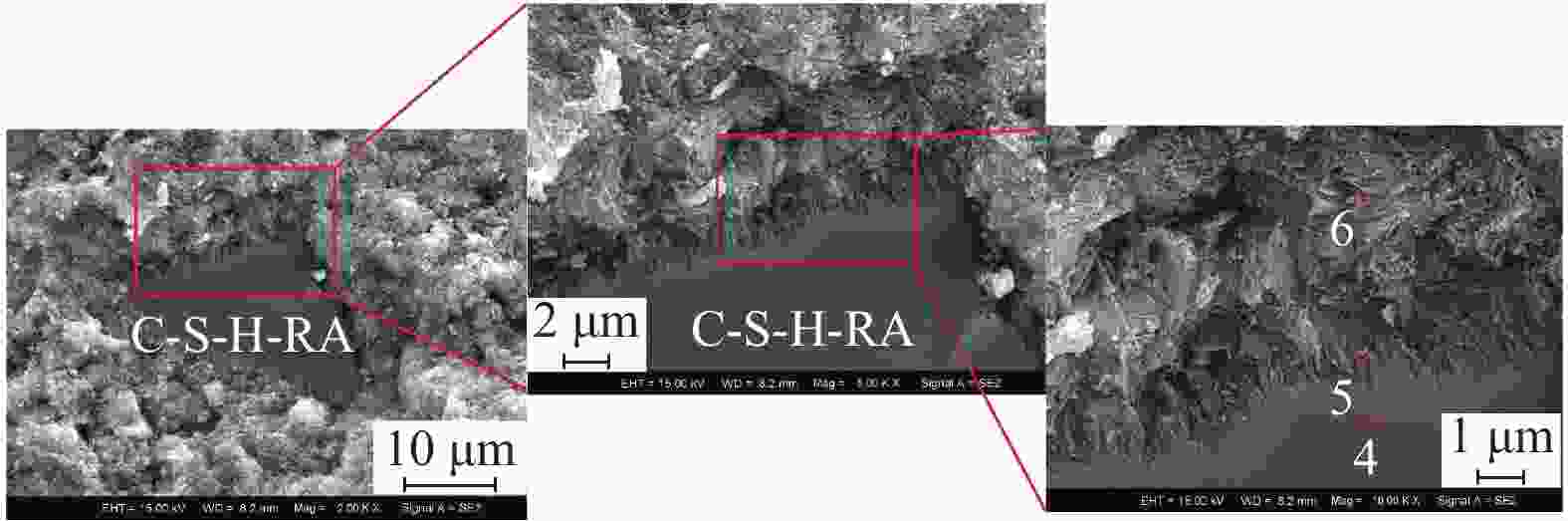

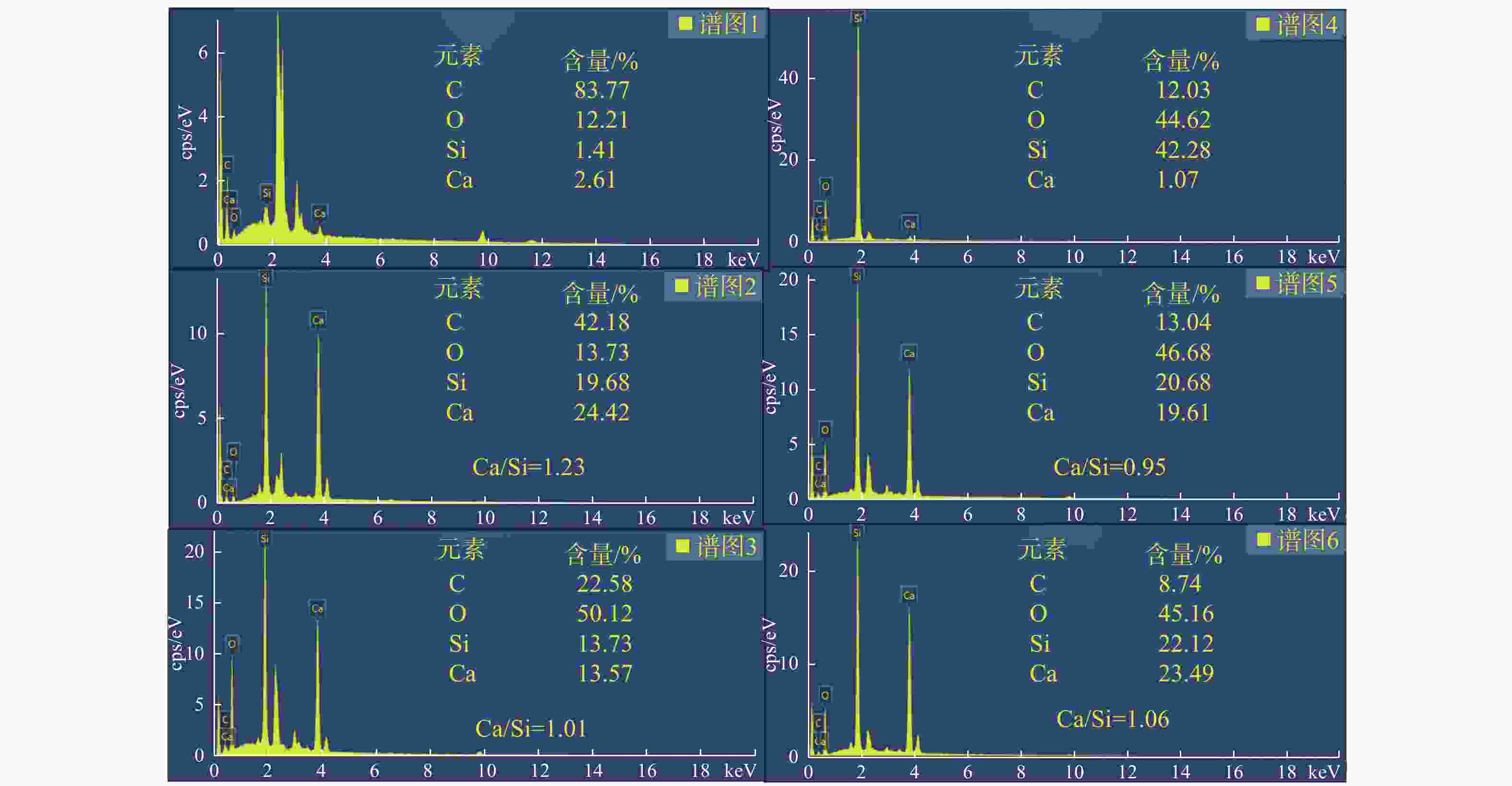

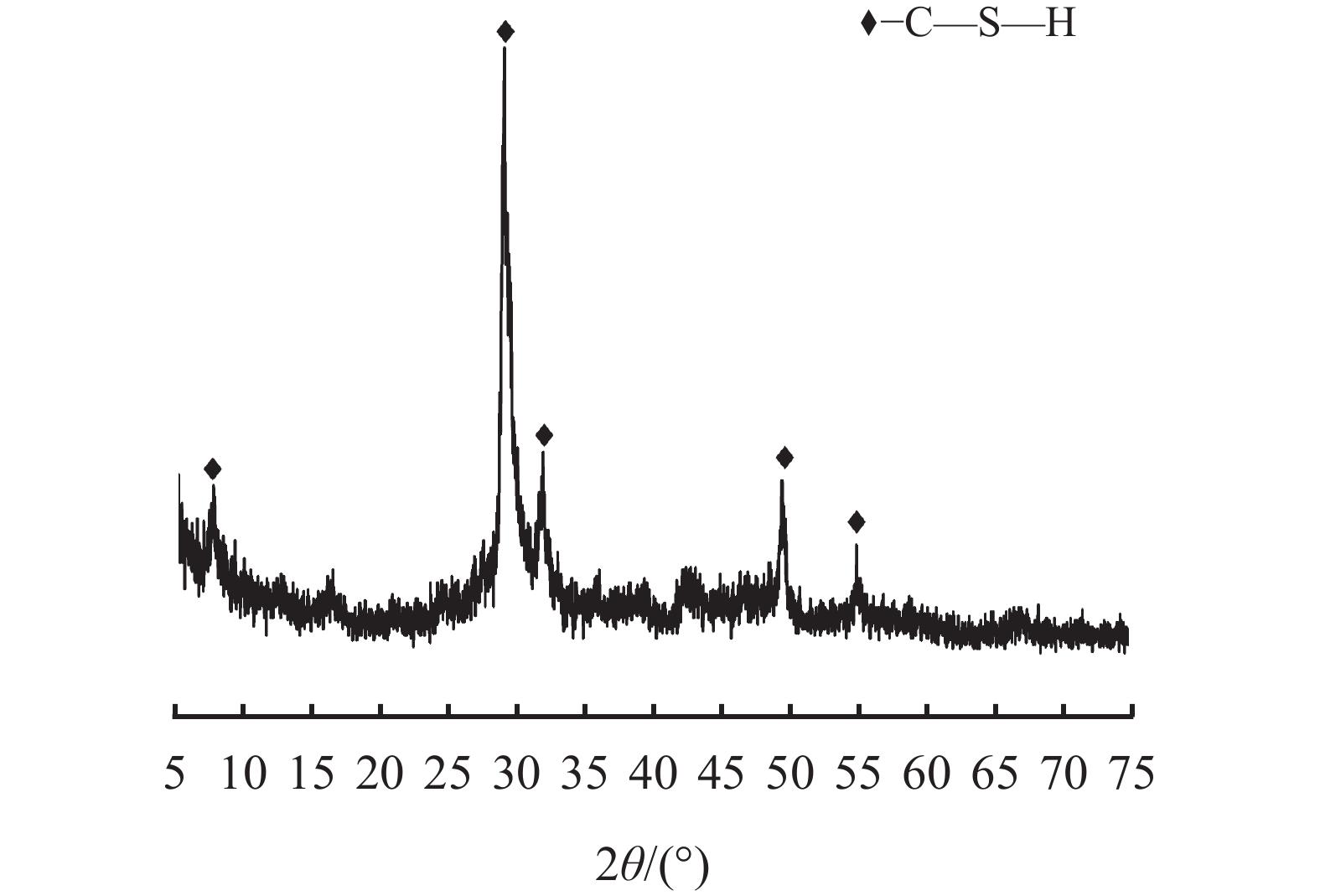

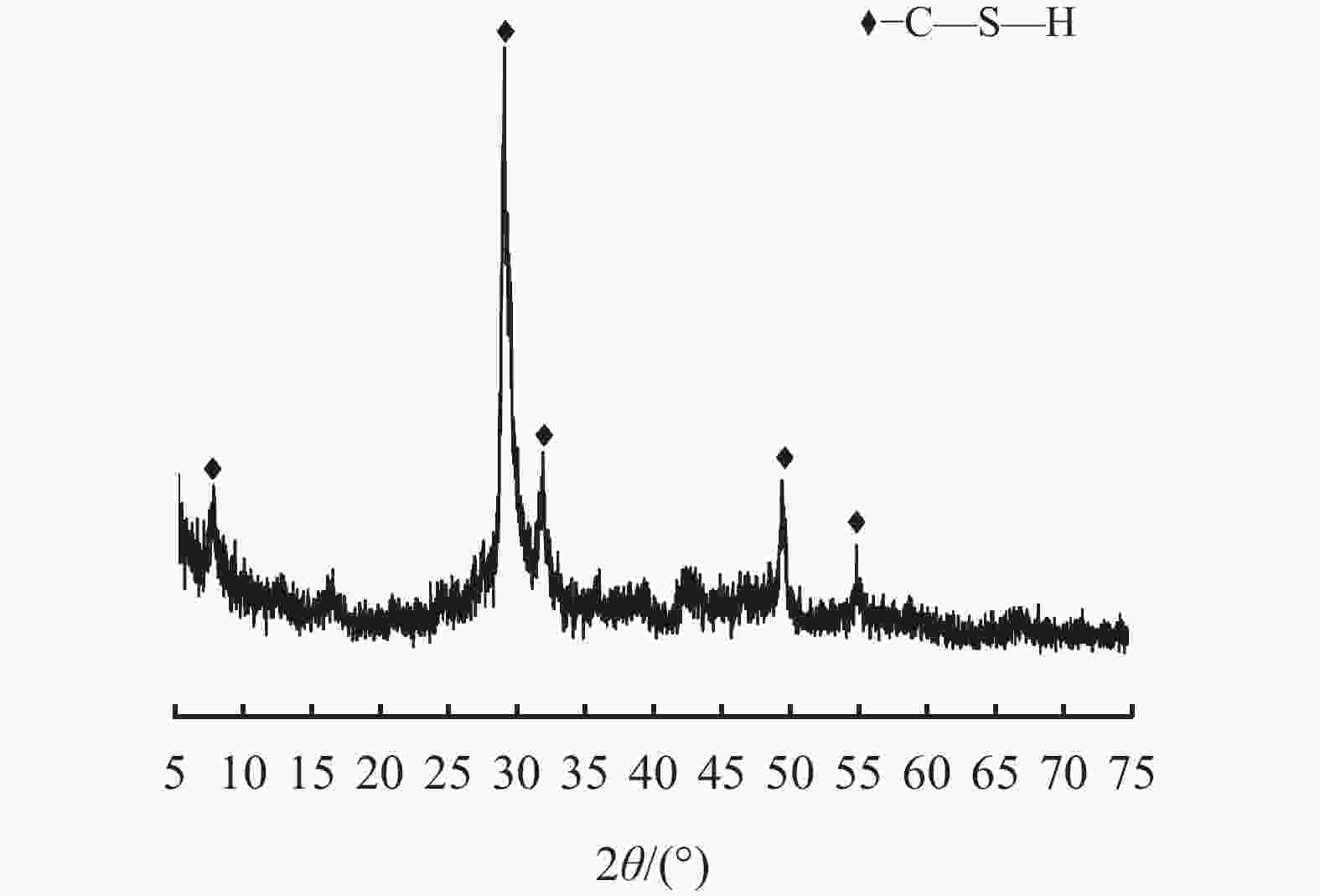

摘要: 研究了表面接枝C—S—H的岩沥青对高温油井水泥石力学性能和微观结构的影响,采用压力试验机及XRD、TG、SEM和EDS对油井水泥石的力学性能和微观结构进行了测试和表征。研究结果表明,与纯水泥石相比,掺入1%未改性岩沥青的水泥石3 d抗压强度下降了2.98%,而掺入1%表面接枝C—S—H岩沥青的水泥石3 d抗压强度提高了4.26%。物相分析和热重实验表明,表面接枝C—S—H岩沥青的加入不会引起水化产物类型的变化,而掺量为3%表面接枝C—S—H的岩沥青水泥石养护3 d的失重量比纯水泥石高1.01%,说明表面接枝C—S—H的岩沥青可以促进水泥的水化。水泥石的微观形貌和元素分析表明,未改性岩沥青在180 ℃下热解导致沥青颗粒破碎,而接枝C—S—H的岩沥青表面形成的富Si层可以避免沥青颗粒因气孔而引起破碎,使得未改性岩沥青水泥石界面处的C元素含量较接枝C—S—H的岩沥青水泥石高29.14%,未改性岩沥青水泥石基体中C元素含量较接枝C—S—H的岩沥青水泥石高13.76%。Abstract: This paper discusses the studies conducted on the effects of rock asphalt with surface grafted C—S—H on the mechanical property and microstructure of set cement used to seal high temperature oil wells. Measurement of the mechanical property and characterization of the microstructure of set cement samples were done with pressure testing machine and XRD, TG, SEM and EDS, respectively. Study results obtained in laboratory experiments show that compared with pure set cement, the set cement containing 1% nonmodified rock asphalt had its 3-day compressive strength reduced by 2.98%, while the set cement containing 1% rock asphalt which surface grafted C—S—H had its 3-day compressive strength increased by 4.26%. Phase analysis and TGA experiment results show that the addition of the rock asphalt with surface grafted C—S—H into the cement slurry does not cause change of the type of the hydrational products. The weight loss of a set cement containing 3% rock asphalt with surface grafted C—S—H is 1.01% higher than the weight loss of the pure set cement after aging for 3 days, indicating that rock asphalt with surface grafted C—S—H has accelerated the hydration process of the cement. Analyses of the micromorphology and element composition of the set cement indicate that the nonmodified rock asphalt thermally disintegrated at 180 ℃ and the particles of the asphalt were broken into pieces, while the rock asphalt with surface grafted C—S—H has formed an Si-rich layer around its surface, protecting the rock asphalt from generating air holes inside it and the asphalt particles are therefore not easy to break down. Furthermore, comparing the set cement containing nonmodified rock asphalt and the set cement containing rock asphalt with surface grafted C—S—H, it is found that the C element content at the interfaces of the former is 29.14% higher than that of the latter, and the C element content in the body of the former is 13.76% higher than that of the latter.

-

表 1 180 ℃/20.7 MPa养护3 d的岩沥青/水泥石对应水化产物的失重量

编号 C—S—H/% CH/% CaCO3/% C6S6H/% 总失重量/% R0 5.90 2.22 1.16 0.74 11.03 R1 5.77 1.98 1.91 0.72 11.34 R3 5.53 2.06 1.70 1.06 11.87 S1 4.83 1.96 1.40 0.62 9.69 S3 5.75 2.48 1.90 0.84 12.04 -

[1] GUO X S, HU D F, LI Y P, et al. Theoretical progress and key technologies of onshore ultra-deep oil/gas exploration[J]. Engineering, 2019, 5(3):458-470. doi: 10.1016/j.eng.2019.01.012 [2] GE Z, YAO X, WANG X J, et al. Thermal performance and microstructure of oil well cement paste containing subsphaeroidal konilite flour in HTHP conditions[J]. Construction and Building Materials, 2018, 172:787-794. doi: 10.1016/j.conbuildmat.2018.03.268 [3] PANG X Y, QIN J K, SUN L J, et al. Long-term strength retrogression of silica-enriched oil well cement: a comprehensive multi-approach analysis[J]. Cement and Concrete Research, 2021, 144:106424. doi: 10.1016/j.cemconres.2021.106424 [4] WEI T C, WEI F Q, ZHOU J H, et al. Formation and strengthening mechanisms of xonotlite in C3S-silica and C2S-silica powder systems under high temperature and pressure[J]. Cement and Concrete Research, 2022, 157:106812. doi: 10.1016/j.cemconres.2022.106812 [5] ZHANG C M, CAI J X, CHENG X W, et al. Interface and crack propagation of cement-based composites with sulfonated asphalt and plasma-treated rock asphalt[J]. Construction and Building Materials, 2020, 242:118161. doi: 10.1016/j.conbuildmat.2020.118161 [6] ZHANG C M, SONG Y L, WANG W, et al. The influence of sulfonated asphalt on the mechanical properties and microstructure of oil well cement paste[J]. Construction and Building Materials, 2017, 132:438-445. doi: 10.1016/j.conbuildmat.2016.12.014 [7] ZHANG C M, XU H, QING L, et al. Interface characteristics of oil-well cement and rock asphalt coated by dicalcium silicate[J]. Journal of Adhesion Science and Technology, 2021, 35(9):973-992. doi: 10.1080/01694243.2020.1829319 [8] NICOLEAU L. Accelerated growth of calcium silicate hydrates: experiments and simulations[J]. Cement and Concrete Research, 2011, 41(12):1339-1348. doi: 10.1016/j.cemconres.2011.04.012 [9] LI J Q, ZHANG W X, XU K, et al. Fibrillar calcium silicate hydrate seeds from hydrated tricalcium silicate lower cement demand[J]. Cement and Concrete Research, 2020, 137:106195. doi: 10.1016/j.cemconres.2020.106195 [10] MOSHIRI A, STEFANIUK D, SMITH S K, et al. Structure and morphology of calcium-silicate-hydrates cross-linked with dipodal organosilanes[J]. Cement and Concrete Research, 2020, 133:106076. doi: 10.1016/j.cemconres.2020.106076 [11] PEDROSA H C, REALES O M, REIS V D, et al. Hydration of Portland cement accelerated by C-S-H seeds at different temperatures[J]. Cement and Concrete Research, 2020, 129:105978. doi: 10.1016/j.cemconres.2020.105978 [12] THEOBALD M, PLANK J. C-S-H-polycondensate nanocomposites as effective seeding materials for Portland composite cements[J]. Cement and Concrete Composites, 2022, 125:104278. doi: 10.1016/j.cemconcomp.2021.104278 [13] ZOU F B, HU C L, WANG F Z, et al. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C-S-H seeds towards a greener binder[J]. Journal of Cleaner Production, 2020, 244:118566. doi: 10.1016/j.jclepro.2019.118566 [14] ZHAO D D, KHOSHNAZAR R. Hydration and microstructural development of calcined clay cement paste in the presence of calcium-silicate-hydrate (C-S-H) seed[J]. Cement and Concrete Composites, 2021, 122:104162. doi: 10.1016/j.cemconcomp.2021.104162 [15] American Petroleum Institute. API RP 10B-2. Recommended practice for testing well cements[S]. Washington, DC: API, 2013. [16] ZHANG Z H, ZHU Y C, ZHU H J, et al. Effect of drying procedures on pore structure and phase evolution of alkali-activated cements[J]. Cement and Concrete Composites, 2019, 96:194-203. doi: 10.1016/j.cemconcomp.2018.12.003 [17] LV S T, HU L, XIA C D, et al. Surface-treated fish scale powder with silane coupling agent in asphalt for performance improvement: conventional properties, rheology, and morphology[J]. Journal of Cleaner Production, 2021, 311:127772. doi: 10.1016/j.jclepro.2021.127772 [18] LI J, ZHANG F L, LIU Y, et al. Preparation and properties of soybean bio-asphalt/SBS modified petroleum asphalt[J]. Construction and Building Materials, 2019, 201:268-277. doi: 10.1016/j.conbuildmat.2018.12.206 [19] LIU J, LV S T, PENG X H, et al. Improvements on performance of bio-asphalt modified by castor oil-based polyurethane: an efficient approach for bio-oil utilization[J]. Construction and Building Materials, 2021, 305:124784. doi: 10.1016/j.conbuildmat.2021.124784 [20] LI J, YANG S, LIU Y, et al. Studies on the properties of modified heavy calcium carbonate and SBS composite modified asphalt[J]. Construction and Building Materials, 2019, 218:413-423. doi: 10.1016/j.conbuildmat.2019.05.139 [21] LIU B Q, LI J, HAN M Z, et al. Properties of polystyrene grafted activated waste rubber powder (PS-ARP) composite SBS modified asphalt[J]. Construction and Building Materials, 2020, 238:117737. doi: 10.1016/j.conbuildmat.2019.117737 [22] LV S T, TAN L, PENG X H, et al. Experimental investigation on the performance of bone glue and crumb rubber compound modified asphalt[J]. Construction and Building Materials, 2021, 305:124734. doi: 10.1016/j.conbuildmat.2021.124734 [23] GARCÍA LODEIRO I, MACPHEE D E, PALOMO A, et al. Effect of alkalis on fresh C-S-H gels. FTIR analysis[J]. Cement and Concrete Research, 2009, 39(3):147-153. doi: 10.1016/j.cemconres.2009.01.003 [24] JOHN E, MATSCHEI T, STEPHAN D. Nucleation seeding with calcium silicate hydrate-a review[J]. Cement and Concrete Research, 2018, 113:74-85. doi: 10.1016/j.cemconres.2018.07.003 [25] WANG C W, CHEN X, ZHOU W, et al. Working mechanism of nano-SiO2 sol to alleviate the strength decline of oil well cement under high temperature[J]. Natural Gas Industry B, 2019, 6(5):517-523. doi: 10.1016/j.ngib.2019.03.008 [26] 张春梅. 沥青-油井水泥基复合材料的性能及改性机理研究[D]. 成都: 西南石油大学, 2018.ZHANG Chunmei. Study on the mechanical properties and modified mechanism of oil well cement-based composites toughened by asphalt[D]. Chengdu: Southwest petroleum university, 2018. [27] PERNITES R B, SANTRA A K. Portland cement solutions for ultra-high temperature wellbore applications[J]. Cement and Concrete Composites, 2016, 72:89-103. doi: 10.1016/j.cemconcomp.2016.05.018 [28] ZHANG W, ZOU X S, WEI F Y, et al. Grafting SiO2 nanoparticles on polyvinyl alcohol fibers to enhance the interfacial bonding strength with cement[J]. Composites Part B:Engineering, 2019, 162:500-507. doi: 10.1016/j.compositesb.2019.01.034 [29] LUAN C Q, ZHOU Y, LIU Y Y, et al. Effects of nano-SiO2, nano-CaCO3 and nano-TiO2 on properties and microstructure of the high content calcium silicate phase cement (HCSC)[J]. Construction and Building Materials, 2022, 314(Part A): 125377. [30] JIANG T, GENG C Z, YAO X, et al. Long-term thermal performance of oil well cement modified by silica flour with different particle sizes in HTHP environment[J]. Construction and Building Materials, 2021, 296:123701. doi: 10.1016/j.conbuildmat.2021.123701 [31] ZHANG Y X, WANG C W, CHEN Z H, et al. Research on the strength retrogression and mechanism of oil well cement at high temperature (240 ℃)[J]. Construction and Building Materials, 2023, 363:129806. doi: 10.1016/j.conbuildmat.2022.129806 [32] WANG C W, CHEN X, WEI X T, et al. Can nanosilica sol prevent oil well cement from strength retrogression under high temperature?[J]. Construction and Building Materials, 2017, 144:574-585. doi: 10.1016/j.conbuildmat.2017.03.221 -

下载:

下载: