A Lost Circulation Control Slurry with Solidifying and Bridging Functions

-

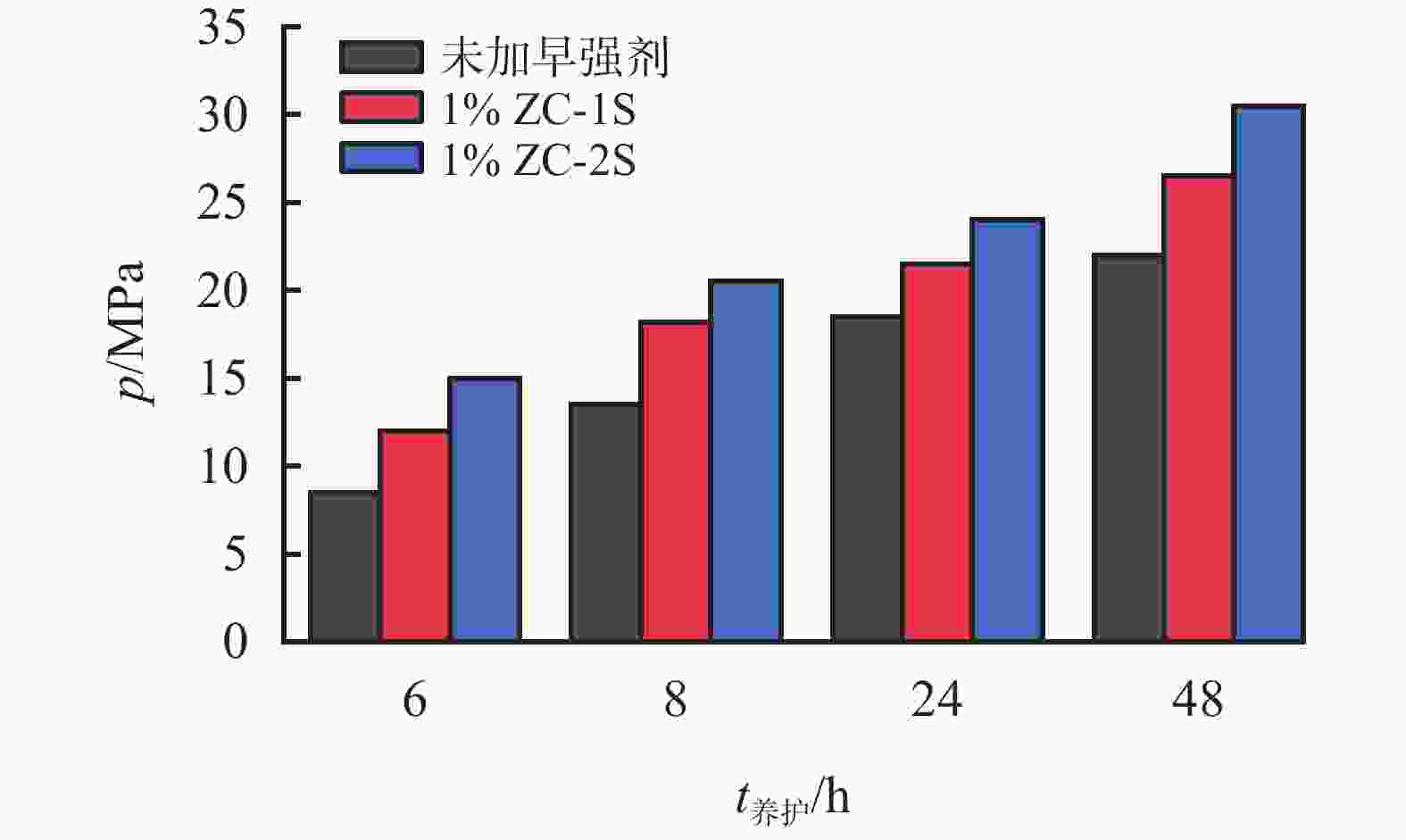

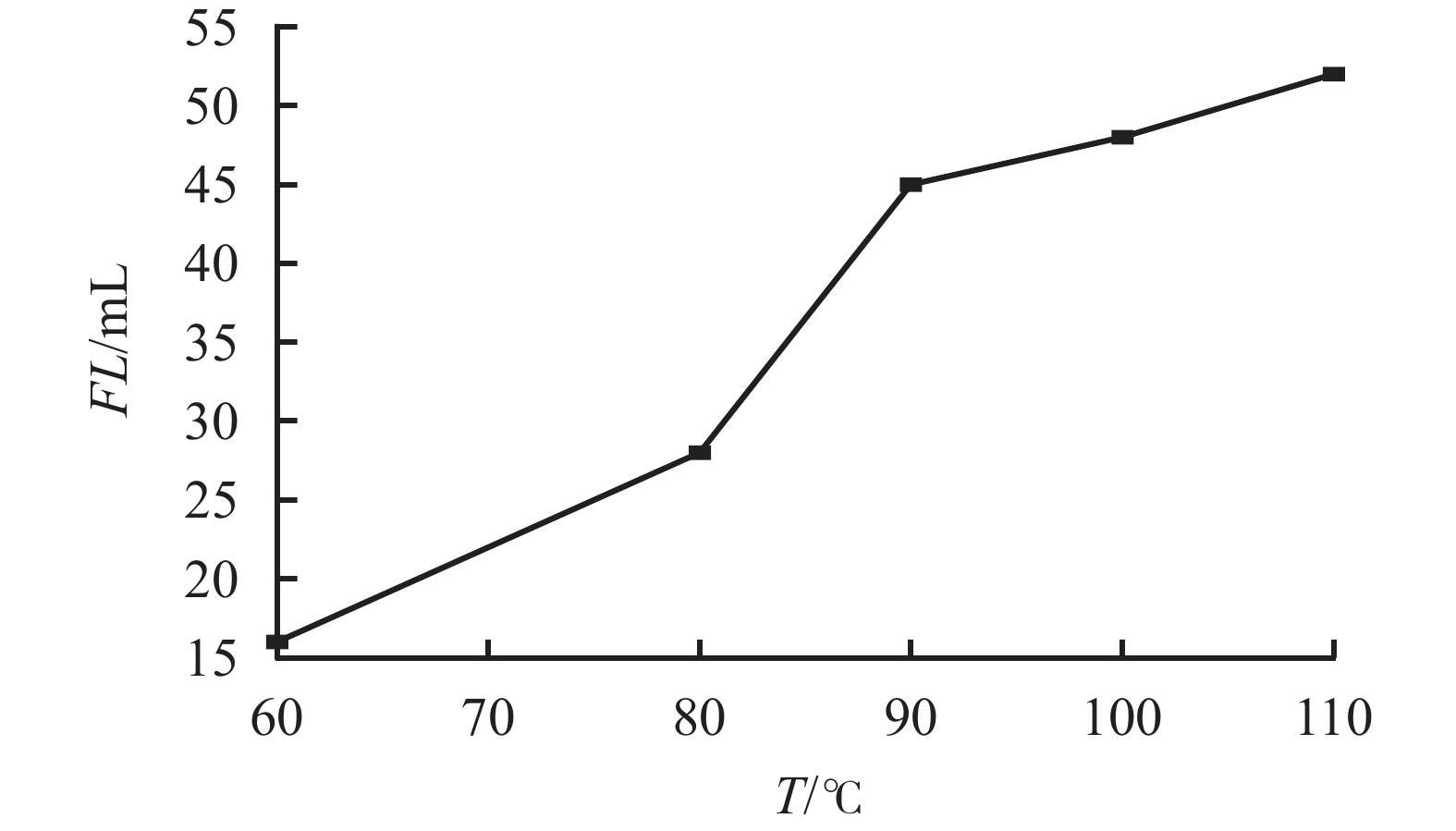

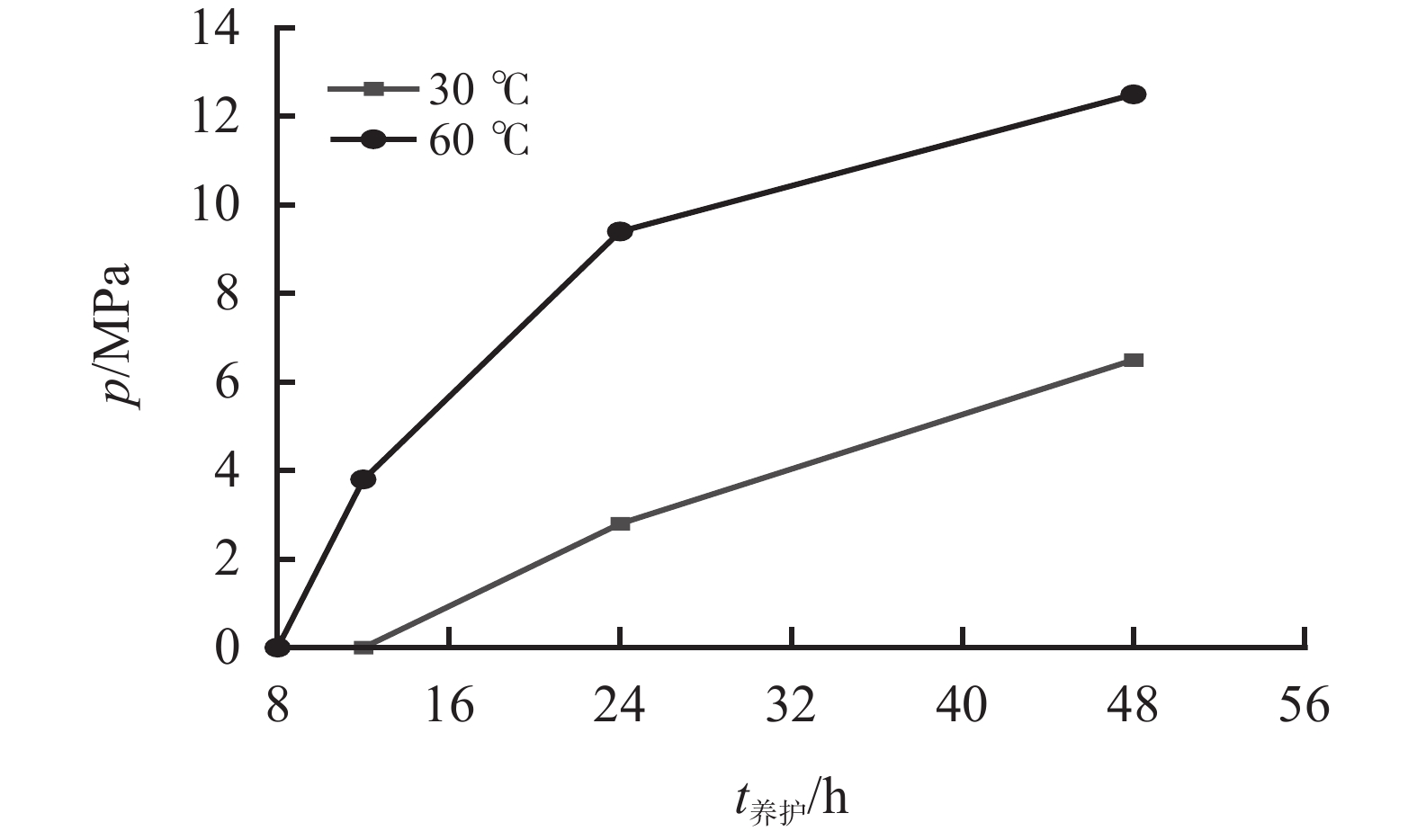

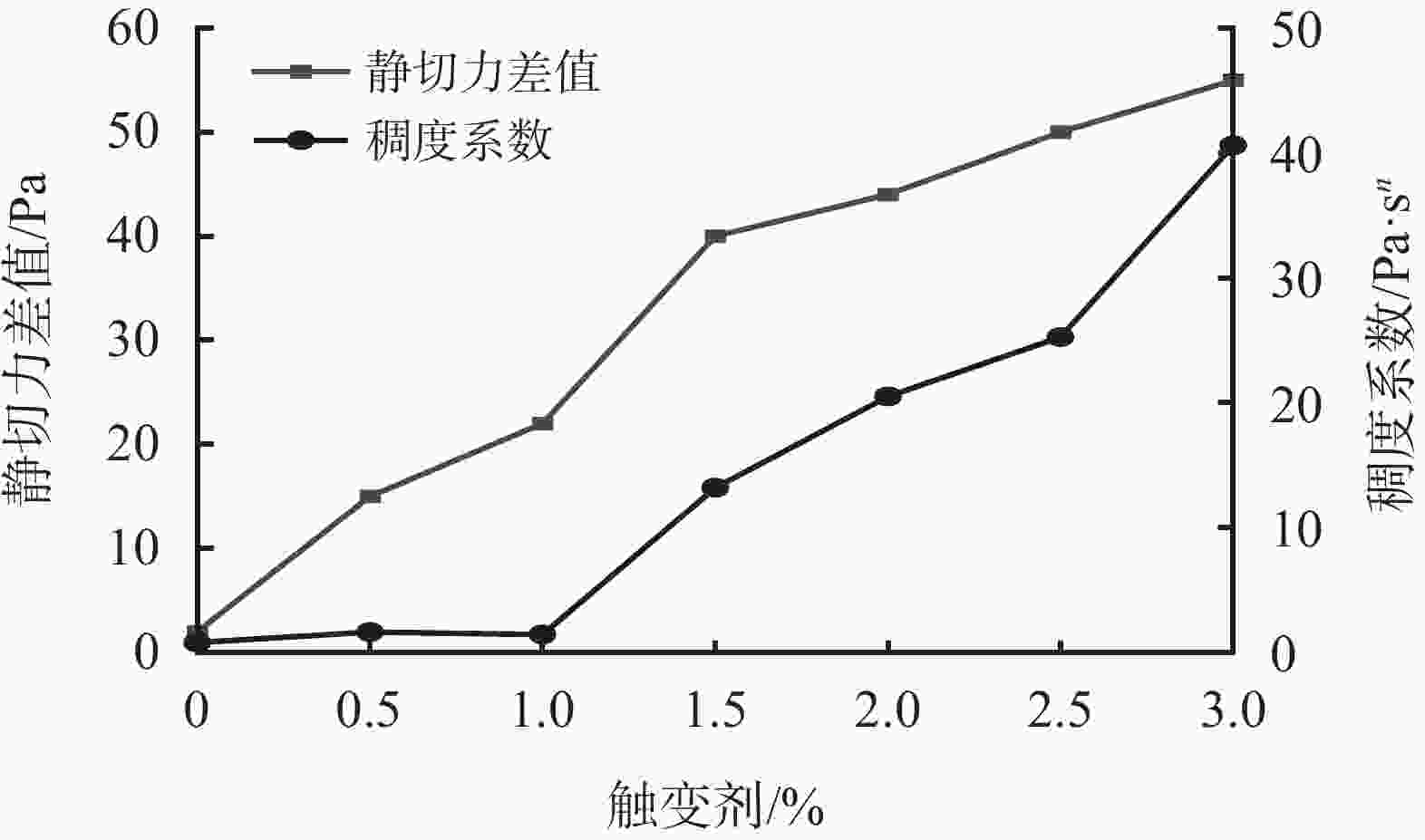

摘要: 针对桥堵浆难以胶结会返吐井筒及触变水泥浆耐漏失压差能力弱,难以有效解决复杂恶性漏失的难题,在对触变水泥浆体系以及桥浆堵漏体系研究的基础上,综合桥浆堵漏和固化堵漏的优点,将二者相结合,研制了一种综合固化和桥接性能的复杂堵漏体系。通过对外加剂的研选,确定了具有良好流变性和触变性的触变水泥浆体系,其中新型触变剂LTA-1的加入对水泥浆稠化时间影响较小,且能增加抗压强度。并通过“狭缝实验”确定桥浆堵漏体系配方。最后根据稠化性能及强度评价,确定该复杂堵漏体系的配方比例为触变水泥浆∶桥浆堵漏体系=2∶1。在满足施工安全的基础上,该堵漏体系能够封堵3~5 mm裂缝块模拟的裂缝性漏失地层和6 mm滚珠模拟的大孔道漏失地层,承压强度大于14 MPa。该体系在满足施工安全的基础上,具有良好的触变性能和堵漏性能,对解决复杂地层的漏失问题起到良好的效果。Abstract: Bridging lost circulation control slurries are difficult to be bonded with the walls of leaking channels during mud loss control, and are therefore generally squeezed back into the borehole. Thixotropic cement slurries as a kind of lost circulation material, have low fracture pressure, and are thus incapable of controlling severe mud losses. Based on the studies performed on the thixotropic cement slurries and bridging lost circulation control materials, the two kinds of lost circulation control materials are compounded together to form a new lost circulation control material with the advantages of both. By carefully selecting other additives, a new thixotropic cement slurry with good rheology and thixotropy is formulated. In the new cement slurry, the addition of a new thixotropic agent LTA-1 has only weak effect on the thickening time of the cement slurry, and LTA-1 can improve the compressive strength of the cement slurry. The composition of the bridging lost circulation control slurry is determined through “experiment on a slit”. Based on the requirement of thickening time and strength, the final composition of the lost circulation control slurry is determined to be thixotropic cement slurry∶bridging slurry = 2∶1. This lost circulation control slurry can be used to control mud losses through 3 – 5 mm artificial fractures simulating fractured formations and control mud losses through large pores simulated with 6 mm roller balls. The lost circulation control slurry can form a layer of barrier on the surface of the simulated formations with a pressure bearing capacity of greater than 14 MPa. The use with of this lost circulation control slurry satisfies the need of safe operations. The good thixotropy and lost circulation control capacity of this lost circulation control slurry are of great help to the control of mud losses in drilling complex formations.

-

表 1 触变水泥浆体系基本性能

序号 配方 ρ/(g·cm−3) 实验条件 t稠化/min 初始稠度/Bc 流动度/cm FL/mL 游离液/mL △ρ/(g·cm−3) 1# 基础配方 1.90 70 ℃×30 MPa 122 20 18 28 0 0.00 2# 基础配方+0.5%GH-9 1.90 90 ℃×50 MPa 265 18 20 44 0 0.00 表 2 25 ℃和80 ℃下水泥浆流变性及触变性

T/℃ φ600 φ300 φ200 φ100 φ6 φ3 静置1 min

后φ3静置10 min

后φ325 280 173 132 81 18 16 35 65 80 220 147 114 73 22 20 43 80 表 3 不同比例堵漏材料堵漏效果评价

堵漏类型 橡胶/

%锯末/

%棉纤维/

%FL/mL 堵漏效果 25 ℃ 80 ℃ 1 mm缝 3 1 1 75 90 堵不住 1 mm缝 4 2 1 60 68 基本堵住 1 mm缝 5 2 1 10 18 完全堵住 2 mm缝 5 2 1 15 22 完全堵住 2 mm孔 5 2 1 16 24 完全堵住 4 mm孔 5 2 1 20 30 完全堵住 注:配方为水+8%膨润土+0.2%Na2CO3。 表 4 该复杂堵漏体系堵漏配方确定实验

1#配方∶

2#配方ρ/

g·cm−3流动度/

cm养护不同时间

的常温强度备注 1∶1 1.52 20 无强度/24 h 流动性好 1∶2 1.54 18 无强度/24 h 流动性好,有触变性 2∶1 1.61 19 6.30 MPa/15 h 流动性好,有触变性 2∶1.5 1.62 14 5.50 MPa/19 h 浆体太稠 表 5 该复杂堵漏体系稠化性能评价

实验条件 t稠化/min 初始稠度/Bc t过渡/min 60 ℃×30 MPa 209 20 9 80 ℃×40 MPa 250 19 14 90 ℃×50 MPa 260 18 12 110 ℃×55 MPa 312 18 10 表 6 该复杂堵漏体系流变性及触变性能评价

T/℃ φ600 φ300 φ200 φ100 φ6 φ3 n K/

Pa·sn静切力

差值/Pa25 270 165 98 45 40 0.947 0.260 56 80 280 142 98 56 15 12 0.870 0.248 40 表 7 模拟裂缝性和大孔道漏失层的实验结果

裂缝 T/

℃挤入压力/

MPa击穿压力/

MPaFL/

mL3~5 mm缝宽 30 3 15 15 80 4 18 18 110 5 22 24 6 mm滚珠 30 2 14 17 80 5 16 20 110 8 20 36 -

[1] 孙金声,白英睿,程荣超,等. 裂缝性恶性井漏地层堵漏技术研究进展与展望[J]. 石油勘探与开发,2021,48(3):630-638.SUN Jinsheng, BAI Yingrui, CHENG Rongchao, et al. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation[J]. Petroleum Exploration and Development, 2021, 48(3):630-638. [2] 赵洪波,单文军,朱迪斯,等. 裂缝性地层漏失机理及堵漏材料新进展[J]. 油田化学,2021,38(4):740-746. doi: 10.19346/j.cnki.1000-4092.2021.04.028ZHAO Hongbo, SHAN Wenjun, ZHU Disi, et al. Advance of fractured formation lost circulation mechanism and lost circulation materials in oil and gas wells[J]. Oilfield Chemistry, 2021, 38(4):740-746. doi: 10.19346/j.cnki.1000-4092.2021.04.028 [3] 王涛,刘锋报,罗威,等. 塔里木油田防漏堵漏技术进展与发展建议[J]. 石油钻探技术,2021,49(1):28-33. doi: 10.11911/syztjs.2020080WANG Tao, LIU Fengbao, LUO Wei, et al. The technical advance and development suggestions for leakage prevention and plugging technologies in the Tarim oilfield[J]. Petroleum Drilling Techniques, 2021, 49(1):28-33. doi: 10.11911/syztjs.2020080 [4] 李伟,白英睿,李雨桐,等. 钻井液堵漏材料研究及应用现状与堵漏技术对策[J]. 科学技术与工程,2021,21(12):4733-4743. doi: 10.3969/j.issn.1671-1815.2021.12.001LI Wei, BAI Yingrui, LI Yutong, et al. Research and application progress of drilling fluid lost circulation materials and technical countermeasures for lost circulation control[J]. Science Technology and Engineering, 2021, 21(12):4733-4743. doi: 10.3969/j.issn.1671-1815.2021.12.001 [5] 卢海川,李洋,宋元洪,等. 新型固井触变水泥浆体系[J]. 钻井液与完井液,2016,33(6):73-78. doi: 10.3969/j.issn.1001-5620.2016.06.013LU Haichuan, LI Yang, SONG Yuanhong, et al. A novel thixotropic well cementing slurry[J]. Drilling Fluid & Completion Fluid, 2016, 33(6):73-78. doi: 10.3969/j.issn.1001-5620.2016.06.013 [6] 赵素丽. 浓度响应型水触变材料及在含水漏层堵漏技术的应用[J]. 钻井液与完井液,2022,39(4):423-429. doi: 10.12358/j.issn.1001-5620.2022.04.004ZHAO Suli. Study on concentration responsive water thixotropic material and plugging technology of water bearing leakage layer[J]. Drilling Fluid & Completion Fluid, 2022, 39(4):423-429. doi: 10.12358/j.issn.1001-5620.2022.04.004 [7] 姜林林,王瑞和,步玉环. 新型触变性水泥浆触变剂的研制[J]. 钻采工艺,2009,32(6):103-106. doi: 10.3969/j.issn.1006-768X.2009.06.032JIANG Linlin, WANG Ruihe, BU Yuhuan. Study on thixotropic agent of new thixotropic cement slurry[J]. Drilling & Production Technology, 2009, 32(6):103-106. doi: 10.3969/j.issn.1006-768X.2009.06.032 [8] GUO S L, BU Y H, ZHOU A N, et al. A three components thixotropic agent to enhance the thixotropic property of natural gas well cement at high temperatures[J]. Journal of Natural Gas Science and Engineering, 2020, 84:103699. doi: 10.1016/j.jngse.2020.103699 [9] 尤军,步玉环,姜林林. 新型油气井固井水泥浆触变剂的优选实验研究[J]. 钻采工艺,2011,34(1):75-77,118. doi: 10.3969/j.issn.1006-768X.2011.01.025YOU Jun, BU Yuhuan, JIANG Linlin. Optimization study on new thixotropic agents of cement slurry[J]. Drilling & Production Technology, 2011, 34(1):75-77,118. doi: 10.3969/j.issn.1006-768X.2011.01.025 [10] 谢承斌,卢海川,李洋,等. 水泥浆触变性评价方法的探索[J]. 钻井液与完井液,2015,32(6):57-60.XIE Chengbin, LU Haichuan, LI Yang, et al. Study on evaluation of thixotropy of cement slurry[J]. Drilling Fluid & Completion Fluid, 2015, 32(6):57-60. [11] 郭子涵,李明,杨燕,等. 近年来油井水泥降失水剂研究现状概述[J]. 现代化工,2015,35(10):49-53. doi: 10.16606/j.cnki.issn0253-4320.2015.10.012GUO Zihan, LI Ming, YANG Yan, et al. Current status of fluid loss reducers for oil well cement in recent years[J]. Modern Chemical Industry, 2015, 35(10):49-53. doi: 10.16606/j.cnki.issn0253-4320.2015.10.012 [12] 邹双,熊钰丹,张天意,等. 盐膏层固井用降失水剂的研究与应用[J]. 钻井液与完井液,2021,38(6):765-770. doi: 10.12358/j.issn.1001-5620.2021.06.017ZOU Shuang, XIONG Yudan, ZHANG Tianyi, et al. Study and application of fluid loss additive used in cement slurries for cementing salt-gypsum stratum[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):765-770. doi: 10.12358/j.issn.1001-5620.2021.06.017 [13] 赵建胜,代清,霍锦华,等. 高温固井水泥浆用降失水剂GT-1的制备及性能[J]. 钻井液与完井液,2022,39(2):234-240. doi: 10.12358/j.issn.1001-5620.2022.02.017ZHAO Jiansheng, DAI Qing, HUO Jinhua, et al. Preparation and application of fluid loss additive GT-1 for high temperature cementing slurry[J]. Drilling Fluid & Completion Fluid, 2022, 39(2):234-240. doi: 10.12358/j.issn.1001-5620.2022.02.017 [14] 刘学鹏,刘仍光. 油井水泥降失水剂的作用机理研究[J]. 化学研究与应用,2017,29(12):1928-1932. doi: 10.3969/j.issn.1004-1656.2017.12.027LIU Xuepeng, LIU Rengguang. Mechanisms involved in fluid loss control of oilwell cement slurries by water-soluble polymer[J]. Chemical Research and Application, 2017, 29(12):1928-1932. doi: 10.3969/j.issn.1004-1656.2017.12.027 [15] 邹建龙,屈建省,吕光明,等. 新型固井降失水剂BXF-200L的研制与应用[J]. 钻井液与完井液,2005,22(2):20-23. doi: 10.3969/j.issn.1001-5620.2005.02.006ZOU Jianlong, QU Jiansheng, LYU Guangming, et al. A novel fluid loss additive BXF-200L for oilfield cement and its application[J]. Drilling Fluid & Completion Fluid, 2005, 22(2):20-23. doi: 10.3969/j.issn.1001-5620.2005.02.006 [16] 杨远光,张继尹,马思平. 油井水泥低温早强剂室内研究[J]. 西南石油大学学报(自然科学版),2009,31(1):141-144.YANG Yuanguang, ZHANG Jiyin, MA Siping. Laboratory study on low temperature early strength agent of oil well cement slurry[J]. Journal of Southwest Petroleum University (Science & Technology Edition) , 2009, 31(1):141-144. [17] 李晓维. 基于复合型膨胀剂的水泥浆体系研究及应用[D]. 青岛: 中国石油大学(华东), 2019.LI Xiaowei. Research and application of cement slurry system based on compound expansive agent[D]. Qingdao: China University of Petroleum (East China), 2019. [18] 刘伟,毛莉君,欧阳伟. 页岩气油基交联固化堵漏技术研究与应用[J]. 钻井液与完井液,2021,38(2):207-211. doi: 10.3969/j.issn.1001-5620.2021.02.013LIU Wei, MAO Lijun, OU YANG Wei. Research on plugging technology of shale gas Oil-Based crosslinking solidification[J]. Drilling Fluid & Completion Fluid, 2021, 38(2):207-211. doi: 10.3969/j.issn.1001-5620.2021.02.013 [19] 周志世,张震,张欢庆,等. 超深井长裸眼井底放空井漏失返桥接堵漏工艺技术[J]. 钻井液与完井液,2020,37(4):456-464. doi: 10.3969/j.issn.1001-5620.2020.04.009ZHOU Zhishi, ZHANG Zhen, ZHANG Huanqing, et al. Controlling mud losses into caves with bridging techniques in ultra-deep long open hole[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):456-464. doi: 10.3969/j.issn.1001-5620.2020.04.009 [20] 王在明,许婧,张艺馨,等. 自固结堵漏剂性能评价及现场应用[J]. 石油钻探技术,2021,49(6):62-66. doi: 10.11911/syztjs.2021044WANG Zaiming, XU Jing, ZHANG Yixin, et al. Performance evaluation and field application of self-consolidating plugging agents[J]. Petroleum Drilling Techniques, 2021, 49(6):62-66. doi: 10.11911/syztjs.2021044 [21] 杨振杰,张玉强,吴伟,等. XAN-D新型堵漏评价试验仪研究与应用[J]. 钻井液与完井液,2010,27(1):44-46. doi: 10.3969/j.issn.1001-5620.2010.01.015YANG Zhenjie, ZHANG Yuqiang, WU Wei, et al. Study and application of the model XAN-D lost circulation tester[J]. Drilling Fluid & Completion Fluid, 2010, 27(1):44-46. doi: 10.3969/j.issn.1001-5620.2010.01.015 -

下载:

下载: