Method of Evaluating the Capacity of Gas Channeling Prevention of a Cement Slurry in Gelling Transition-State

-

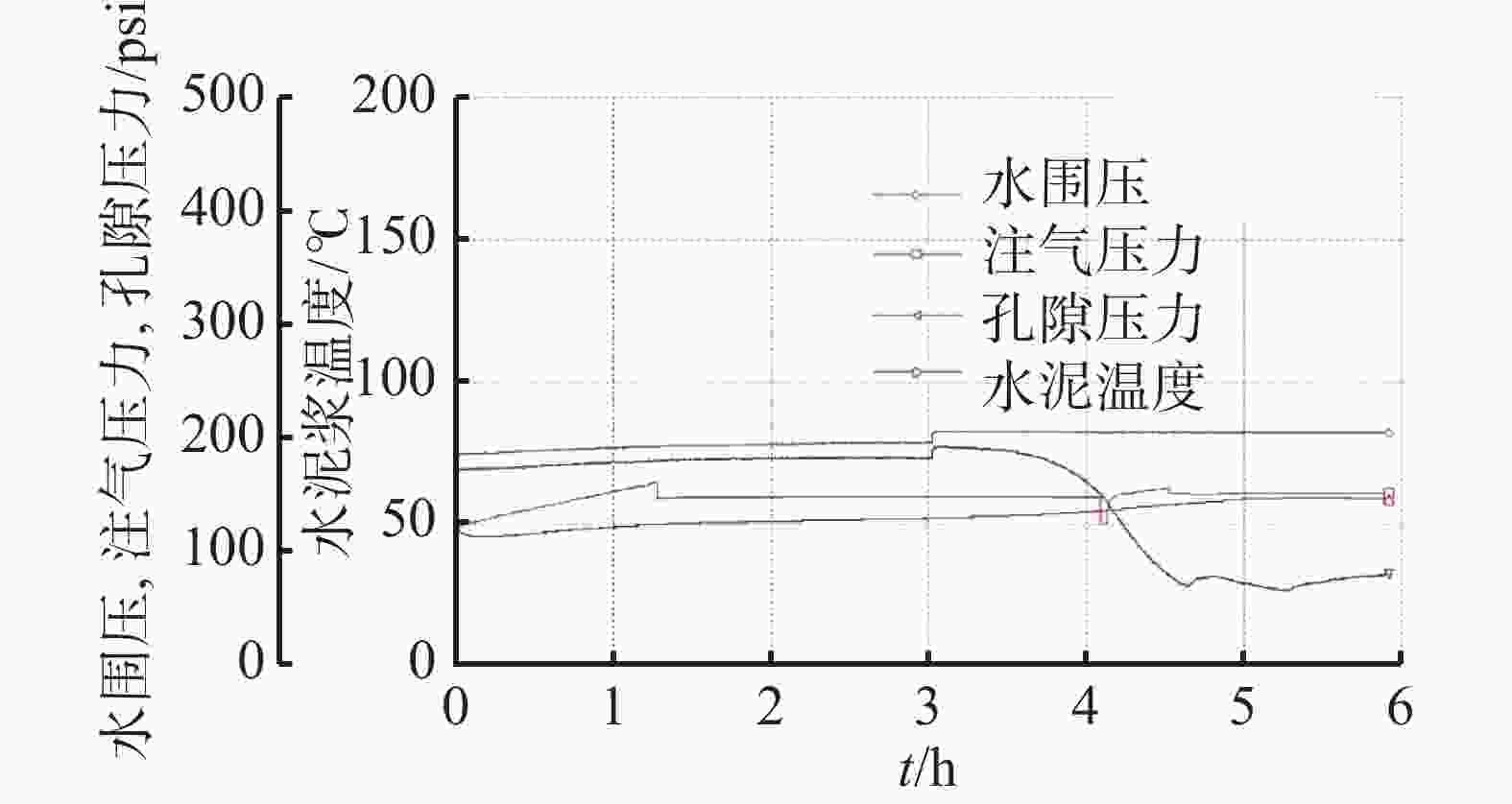

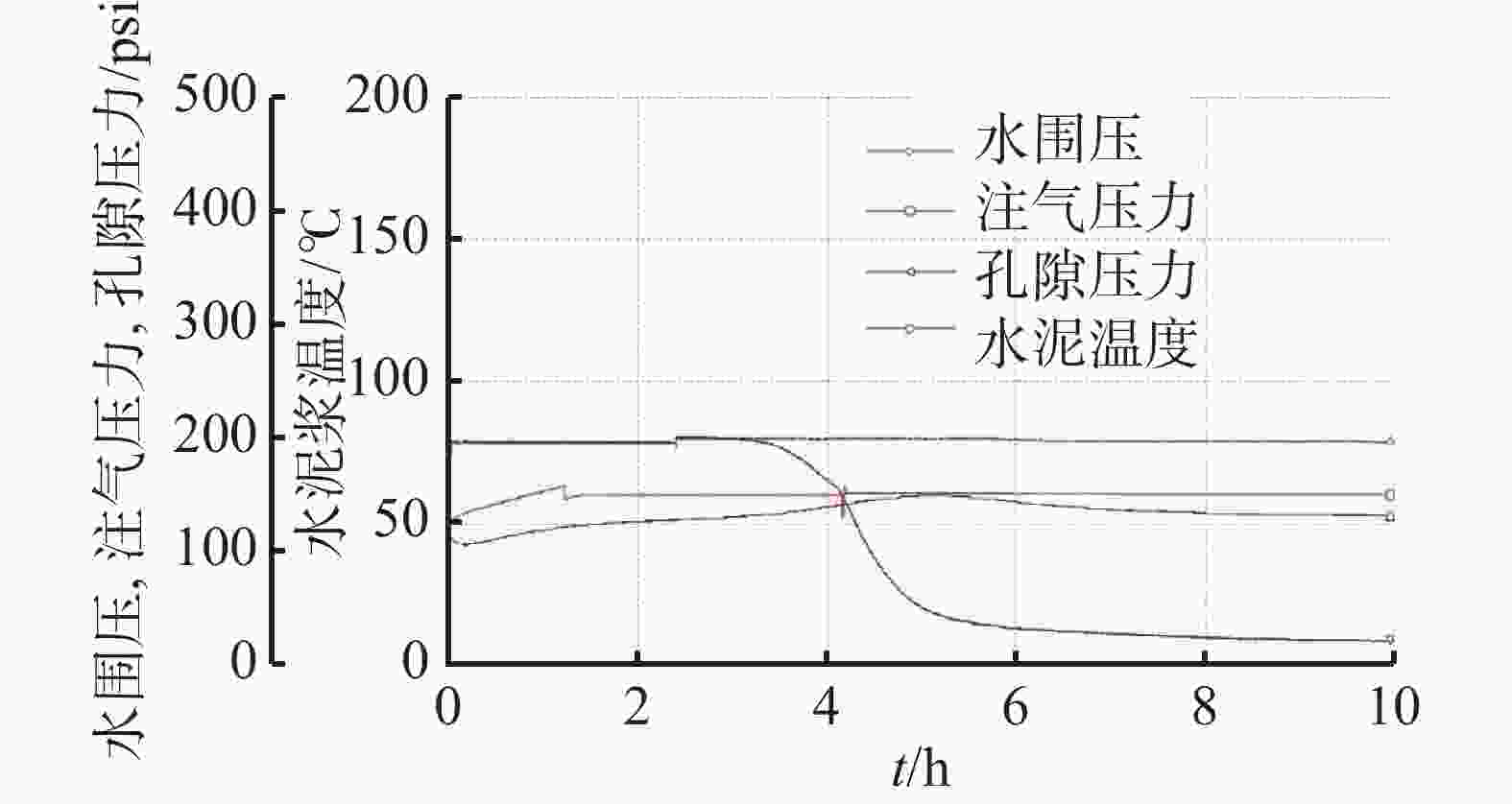

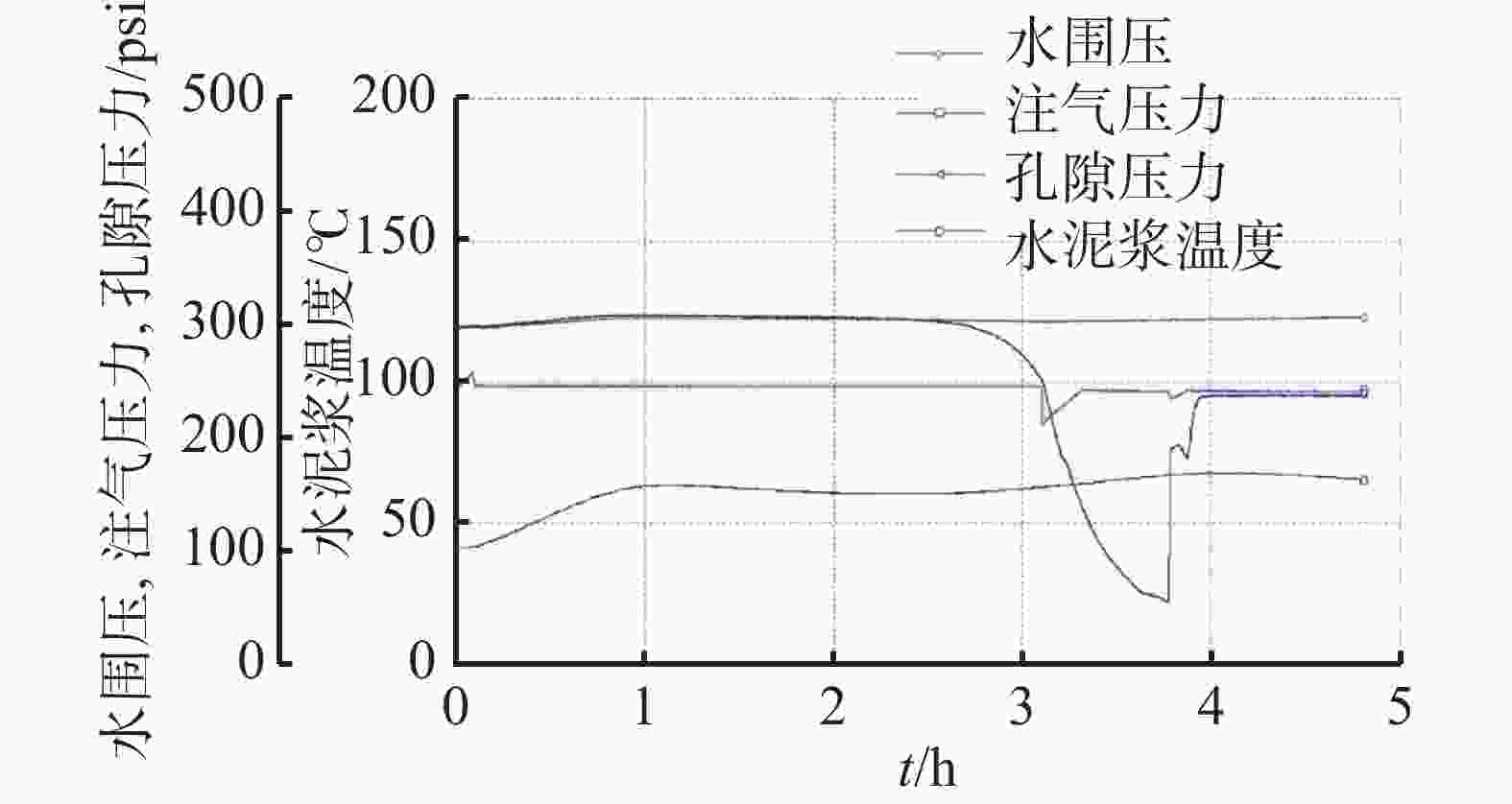

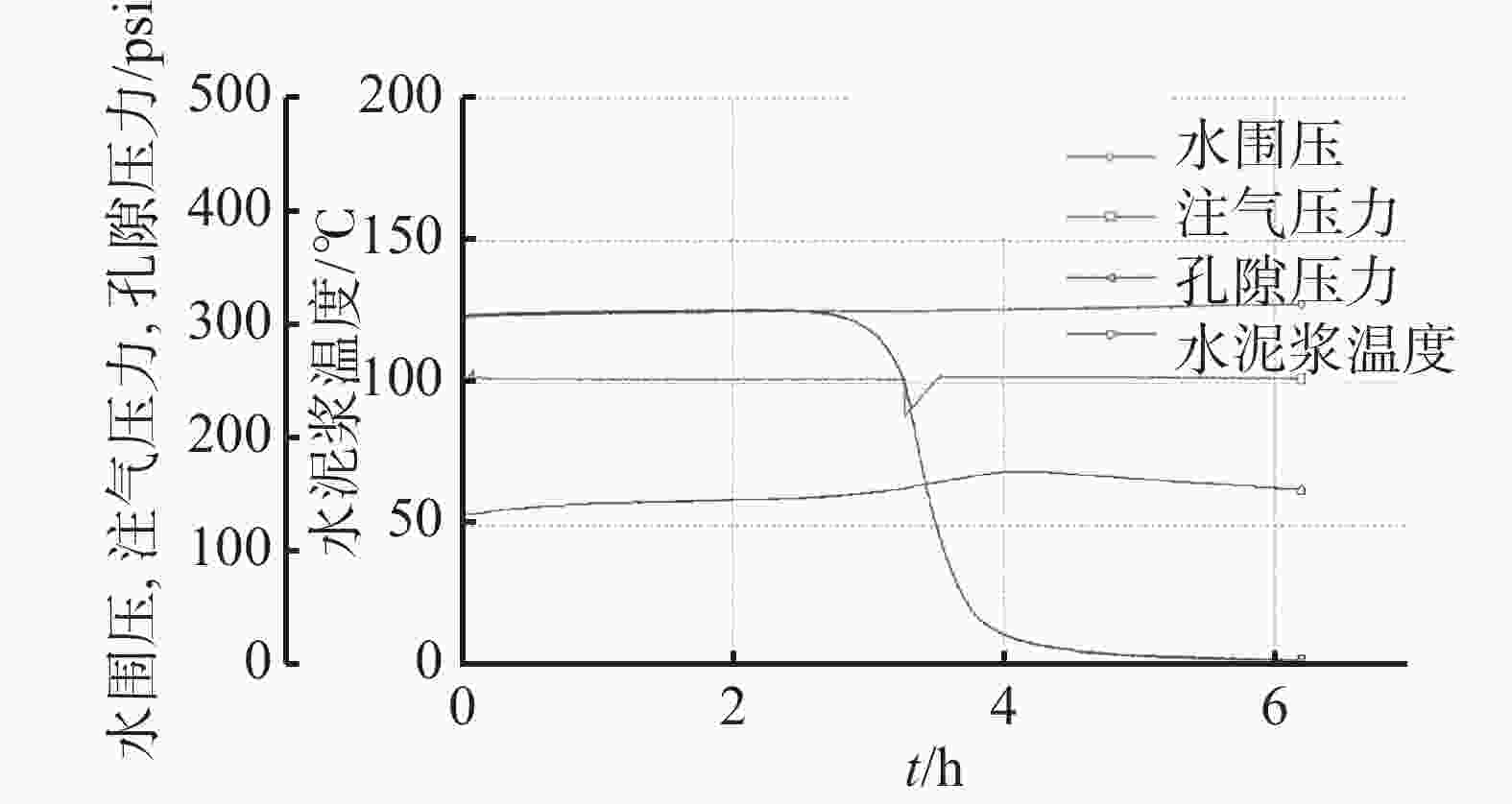

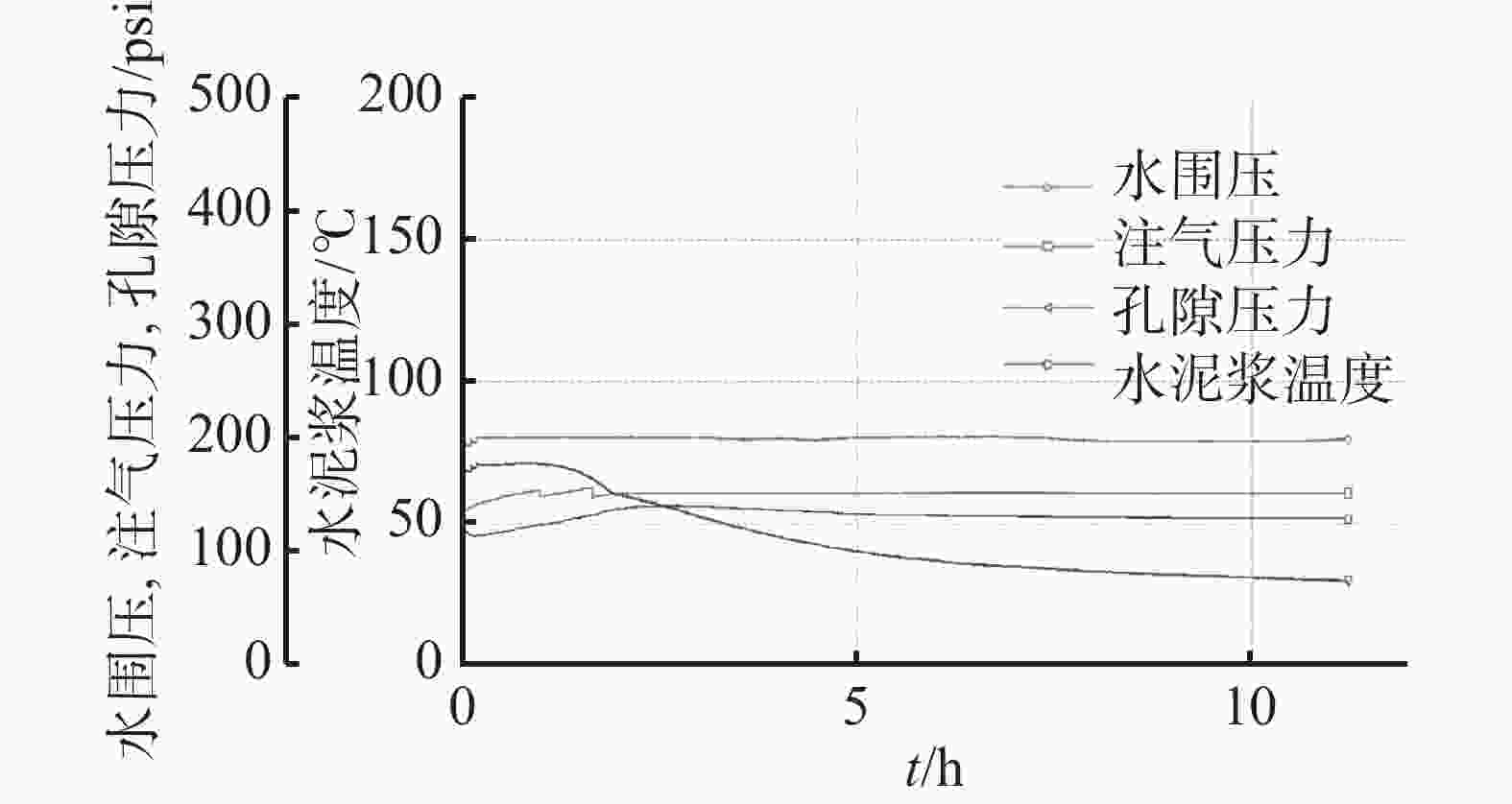

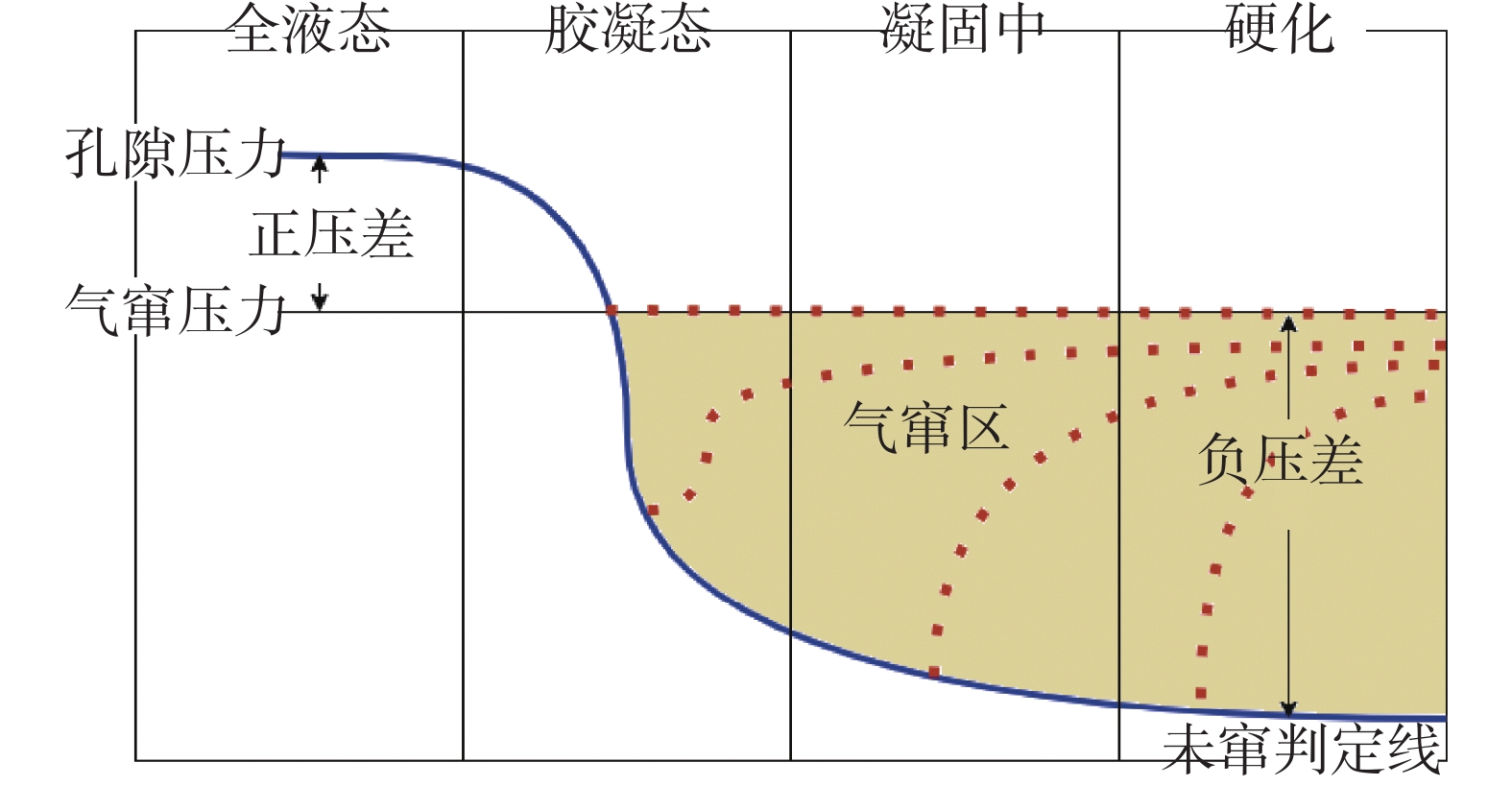

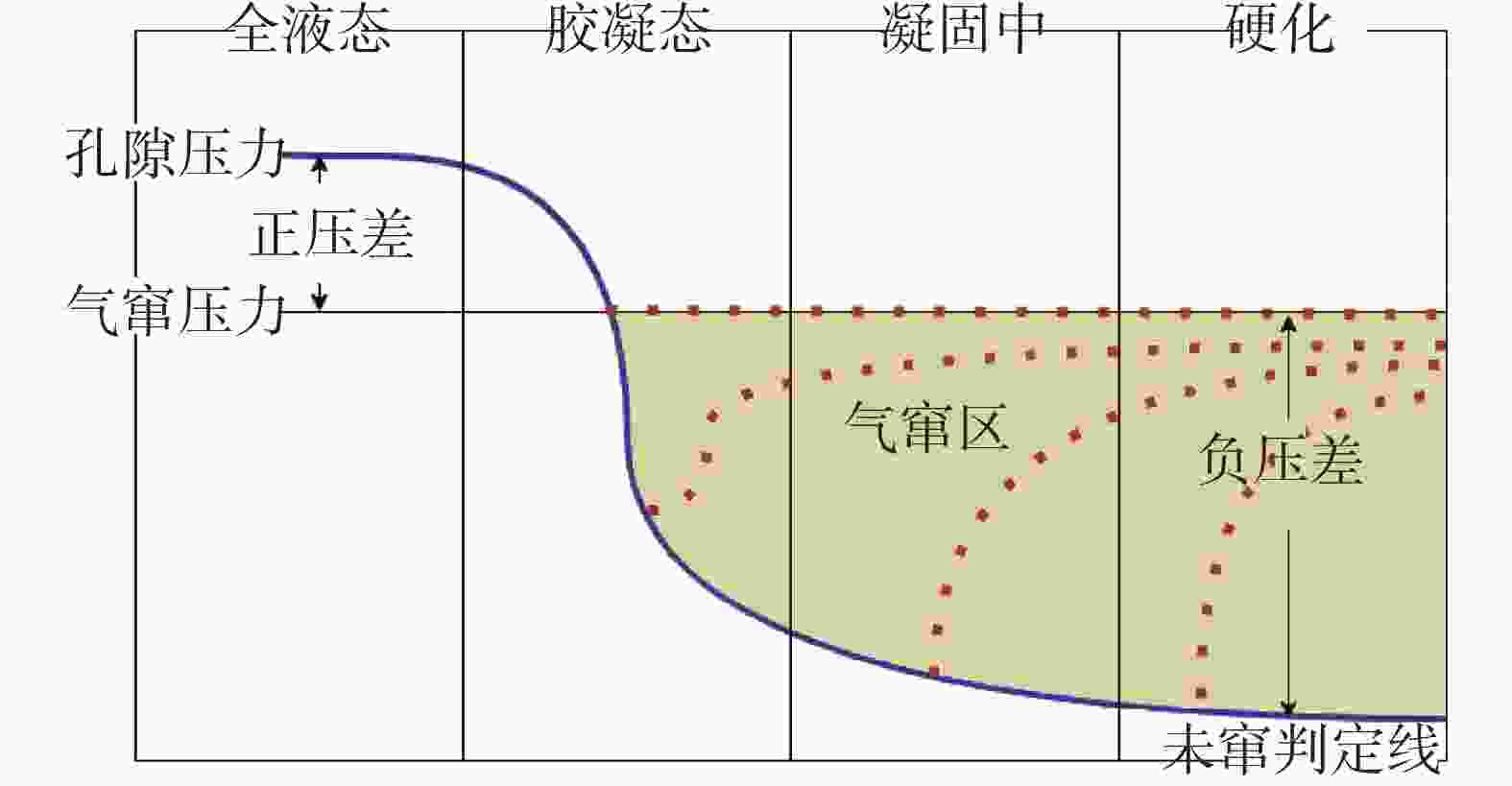

摘要: 环空气窜是多年来困扰固井工程界的技术难题之一。以水泥浆失重理论为基础,通过分析水泥浆有效液柱压力、内部结构阻力和地层流体压力三者间关系以确定验窜时机,结合连续采集水泥浆孔隙压力变化来判别气体是否克服水泥浆内部结构阻力而发生气窜,形成了一种可以直观考察处于胶凝过渡态水泥浆的防气窜能力评价新方法,以此方法研究了不同类型水泥浆的窜流情况,结果表明:① 水泥净浆几乎无法抵抗气体侵入;② 引入适量的降失水剂可轻微提高水泥浆基体的防气窜能力,但效果并不明显,仅能抵抗50 psi(0.344 MPa)的气窜压力;③ 防气窜水泥浆体系因防气窜剂的种类和加量变化,防气窜能力表现各异,通常能够抵御气窜压力范围为100~200 psi(0.689~1.379 MPa),部分防窜材料可以通过增大其加量达到提高防气窜能力的效果,但材料受自身特性影响,存在一定的气窜抵抗能力极限。该方法操作相对简便、实用性强、重复性较好,可横向对比评价不同类型防气窜水泥浆抵抗气体侵入的能力,为防气窜水泥浆体系设计优选提供有效参考。Abstract: Gas channeling in annular space is one of the technical difficulties encountered in oil/gas well cementing. Based on the theory of cement slurry weightlessness, the relationship among the effective fluid column pressure of the cement slurry, the internal structural resistance and the formation fluid pressure is analyzed to determine the timing of channeling detection. By continuously collecting data on the changes of the pore pressure in the cement slurry, it can be determined whether the gas has overcome the internal structural resistance of the cement slurry to cause gas channeling, and this leads to the invention of a new method for evaluating the anti-gas-channeling capacity of a cement slurry in transitional gelling state by direct observation. Using this method, the channeling of several cement slurries is studied. The study results show that: 1) bare cement slurry is almost unable to resist gas channeling; 2) by introducing appropriate amount of filter loss reducers, the anti-channeling capacity of a cement slurry can be slightly improved, with only limited effect; the cement slurry can only resist gas channeling pressure of 50 psi (0.344 MPa); 3) changes in the type and concentration of the anti-gas-channeling agent lead to different anti-channeling capacity of a cement slurry. Generally speaking, cement slurries treated with different anti-channeling agents can stand channeling pressures in a range of 100 – 200 psi (0.689–1.379 MPa). Some anti-channeling agents exhibit higher capacities of anti-channeling by increasing their concentrations in the cement slurries, with limits of performance based on their inherent characteristics. The method described in this paper is easy and simple, and has good practicality and repeatability. It can be used to compare the performances of different anti-channeling agents, and to provide reference to the design of anti-gas channeling cement slurries.

-

Key words:

- Transitional gelling state /

- Cement slurry /

- Weightlessness /

- Anti-gas-channeling /

- Well cementing

-

表 1 基础水泥气窜实验结果

类别 水围压/psi 气窜压力/psi 气窜结果 净浆 100 50 窜 净浆 150 100 窜 净浆 200 150 窜 净浆 250 200 窜 净浆 300 250 窜 3%F 100 50 未窜 3%F 150 100 窜 3%F 200 150 窜 3%F 250 200 窜 3%F 300 250 窜 注:每一实验均重复3次,结果一致,1 psi=0.00689 MPa。 表 2 掺有防气窜剂水泥浆体系气窜实验结果

防气

窜剂水围压/

psi气窜压力/

psi气窜

结果防气

窜剂水围压/

psi气窜压力/

psi气窜

结果3%A 150 100 未窜 5%B 150 100 未窜 3%A 200 150 窜 5%B 200 150 未窜 5%A 200 150 未窜 8%B 200 150 未窜 8%A 200 150 未窜 5%B 250 200 窜 5%A 250 200 窜 8%B 250 200 未窜 8%A 250 200 窜 8%B 300 250 窜 8%A 300 250 窜 11%B 300 250 窜 3%C 150 100 未窜 8%C 250 200 未窜 3%C 200 150 窜 8%C 300 250 未窜 5%C 200 150 未窜 8%C 350 300 窜 5%C 250 200 窜 11%C 350 300 窜 注:1 psi=0.00689 MPa。 -

[1] 刘崇建, 黄柏宗, 徐同台, 等. 油气井注水泥理论与应用[M]. 北京: 石油工业出版社, 2001: 316.LIU Chongjian, HUANG Baizong, XU Tongtai, et al. Theory and application of cement injection in oil and gas wells[M]. Beijing: Petroleum Industry Press, 2001: 316. [2] RAE P, WILKINS D, FREE D. A new approach to the prediction of gas flow after cementing[C]//SPE/IADC Drilling Conference. New Orleans, Louisiana: SPE, 1989: SPE-18622-MS. [3] SABINS F L, SUTTON D L. The relationship of thickening time. Gel strength, and compressive strength of oilwell cements[J]. SPE Production & Operations, 1986, 1(2):143-152. [4] PROHASKA M, OGBE D O, ECONOMIDES M J. Determining wellbore pressures in cement slurry columns[C]//SPE Western Regional Meeting. Anchorage, Alaska: SPE, 1993: SPE-26070-MS. [5] BEIRUTE R M, CHEUNG P R. A method for selection of cement recipes to control fluid invasion after cementing[J]. SPE Production & Operations, 1990, 5(4):433-440. [6] ZHU H J, LV G M, LIU A P, et al. Research on a new method to evaluate the hydrostatic pressure of cement slurries[C]//IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition. Tianjin, China: SPE, 2012: SPE-155923-MS. [7] ZHU H J, QU J S, LIU A P, et al. A new method to evaluate the gas migration for cement slurries [C]//International Oil and Gas Conference and Exhibition in China. Beijing, China: SPE, 2010: SPE-131052-MS. [8] 朱海金,屈建省,刘爱萍,等. 水泥浆防气窜性能评价新方法[J]. 天然气工业,2010,30(8):55-58. doi: 10.3787/j.issn.1000-0976.2010.08.015ZHU Haijin, QU Jiansheng, LIU Aiping, et al. A new method to evaluate gas migration prevention performance of cement slurries[J]. Natural Gas Industry, 2010, 30(8):55-58. doi: 10.3787/j.issn.1000-0976.2010.08.015 [9] 朱海金,王恩合,王学成,等. 水泥浆防窜性能实验评价及其应用[J]. 天然气工业,2013,33(11):79-85. doi: 10.3787/j.issn.1000-0976.2013.11.014ZHU Haijin, WANG Enhe, WANG Xuecheng, et al. Experimental evaluation of gas channeling prevention of cement slurries and its application[J]. Natural Gas Industry, 2013, 33(11):79-85. doi: 10.3787/j.issn.1000-0976.2013.11.014 [10] 韩金良,郭辛阳,宋雨媛,等. 固井水泥浆不同凝固状态时的气体窜流实验[J]. 钻井液与完井液,2021,38(6):760-764. doi: 10.12358/j.issn.1001-5620.2021.06.016HAN Jinliang, GUO Xinyang, SONG Yuyuan, et al. Gas channeling experiment of cement slurry in different solidification state[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):760-764. doi: 10.12358/j.issn.1001-5620.2021.06.016 [11] 刘洋,陈敏,史芳芳,等. 水泥浆失重压力评价技术研究与应用[J]. 钻井液与完井液,2019,36(6):749-753.LIU Yang, CHEN Min, SHI Fangfang, et al. Study and application of a technology for evaluating pressure loss of cement plug[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):749-753. [12] 张兴国. 水泥浆网架结构胶凝悬挂失重机理研究[D]. 成都: 西南石油大学, 2002.ZHANG Xingguo. Research on the weight loss mechanism of cementitious suspension of cement slurry grid structure[D]. Chengdu: Southwest Petroleum University, 2002. [13] 张兴国,郭小阳,杨远光. 用胶凝强度法估计水泥浆防窜能力的室内研究[J]. 天然气工业,2001,21(2):52-55. doi: 10.3321/j.issn:1000-0976.2001.02.012ZHANG Xingguo, GUO Xiaoyang, YANG Yuanguang. A laboratorial research on estimating channeling-preventing ability of cement slurry by use of gel strength method[J]. Natural Gas Industry, 2001, 21(2):52-55. doi: 10.3321/j.issn:1000-0976.2001.02.012 [14] 刘崇建,谢应权,郭小阳,等. 水泥浆凝结过程的气窜问题[J]. 西南石油学院学报,1998,20(4):47-52.LIU Chongjian, XIE Yingquan, GUO Xiaoyang, et al. Breakthrough during cement slurry coagulation[J]. Journal of Southwest Petroleum Institute, 1998, 20(4):47-52. [15] 郭辛阳,宋雨媛,步玉环,等. 固井水泥浆凝固过程中地层水窜流模拟实验[J]. 实验技术与管理,2020,37(11):48-52,57. doi: 10.16791/j.cnki.sjg.2020.11.010GUO Xinyang, SONG Yuyuan, BU Yuhuan, et al. Simulation experiment of formation water channeling during cementing slurry solidification[J]. Experimental Technology and Management, 2020, 37(11):48-52,57. doi: 10.16791/j.cnki.sjg.2020.11.010 [16] POUR M M, MOGHADASI J. New cement formulation that solves gas migration problems in Iranian South Pars field condition[C]//SPE Middle East Oil and Gas Show and Conference. Manama, Bahrain: SPE, 2007: SPE-105663-MS. -

下载:

下载: