Effects of Thermal Physical Parameters on Circulation Temperature of Cement Slurries

-

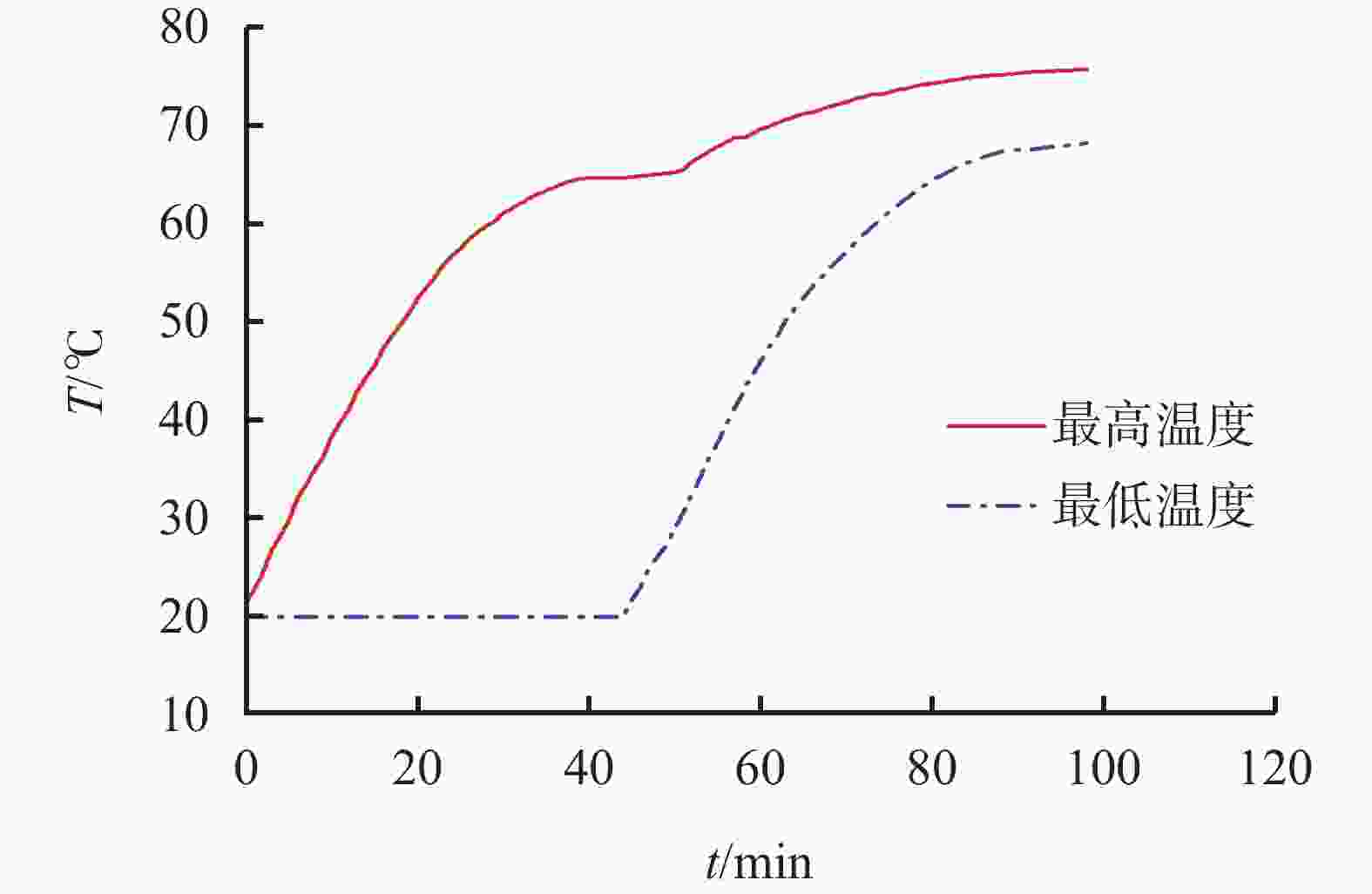

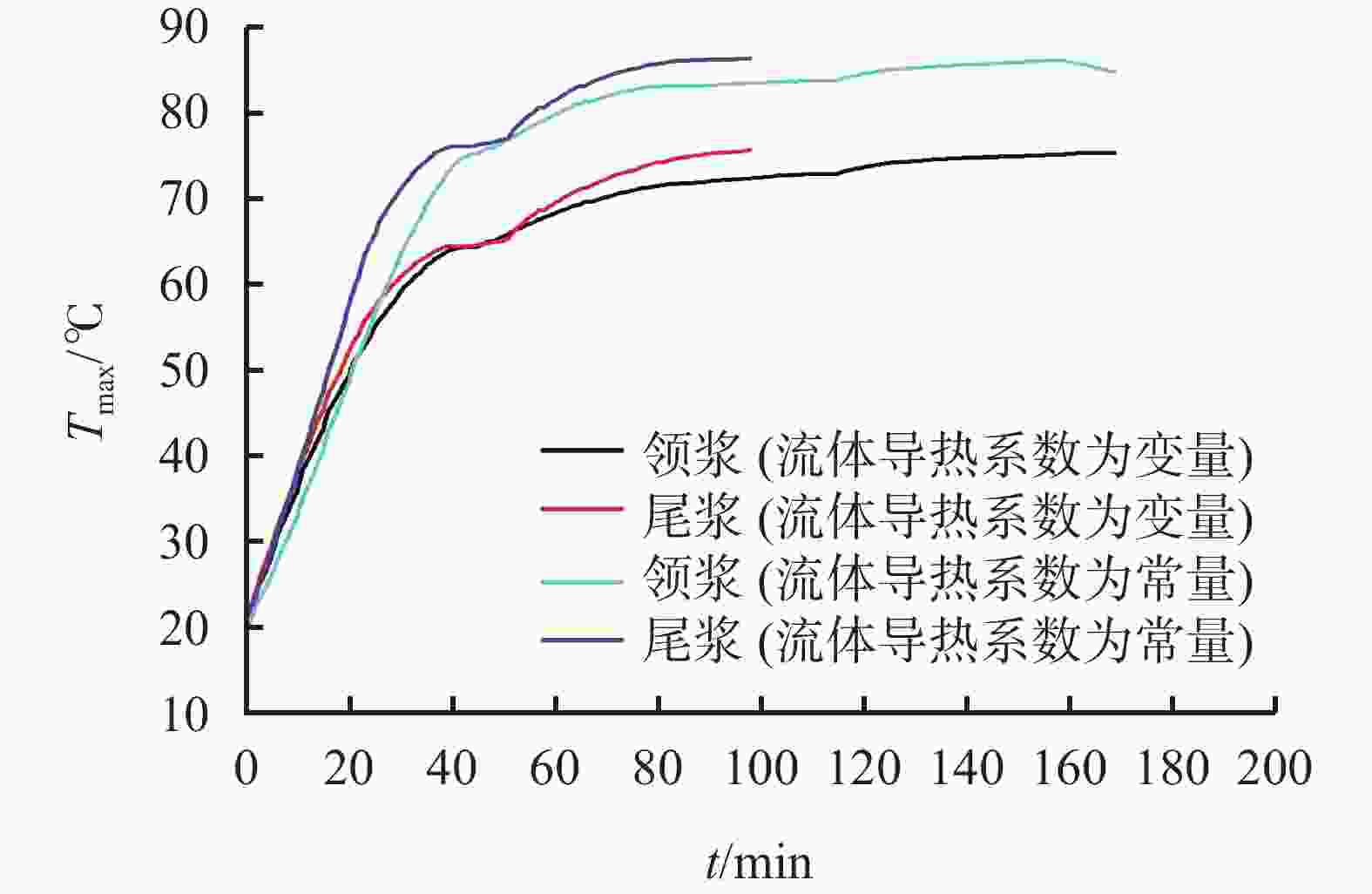

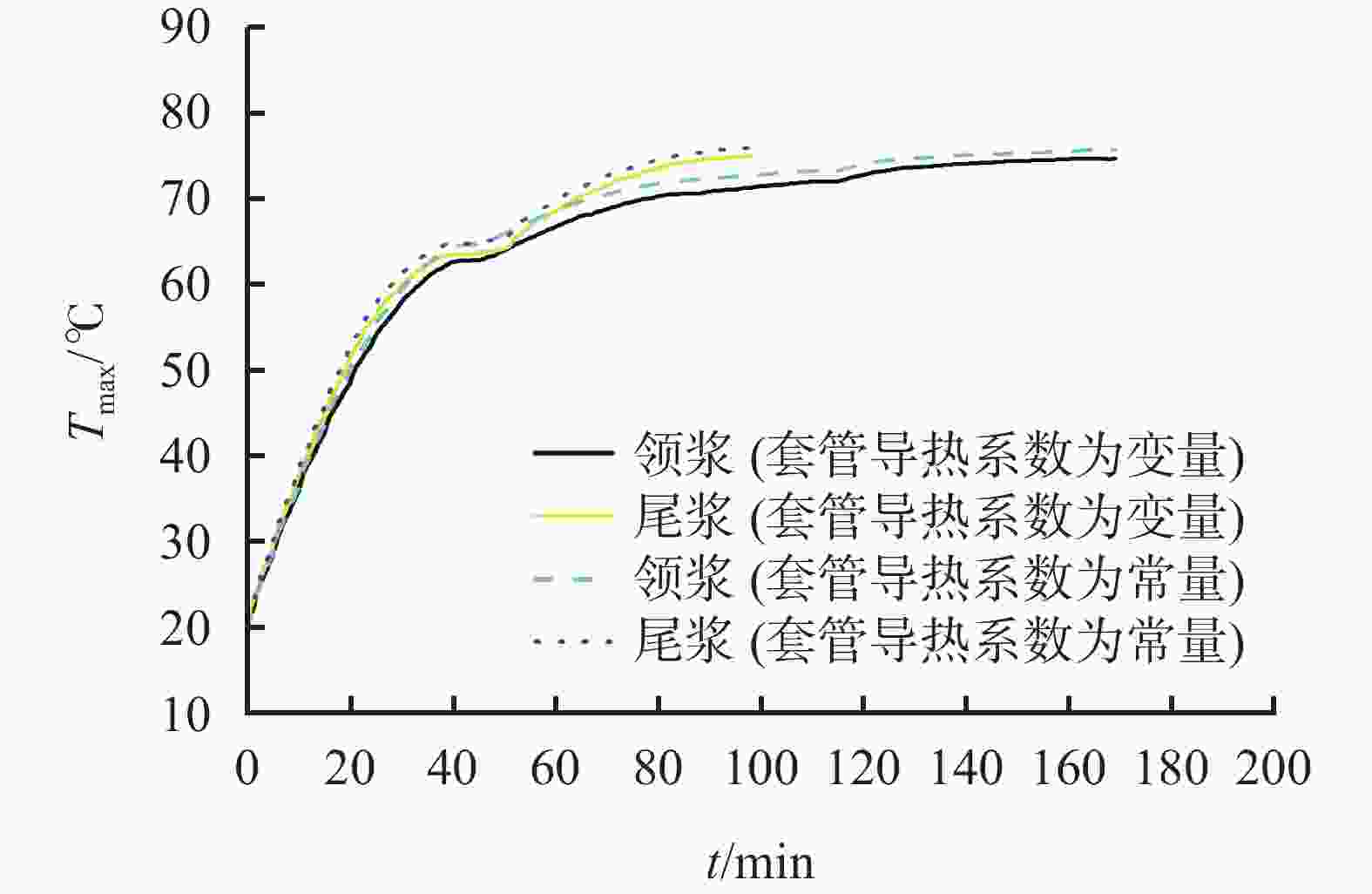

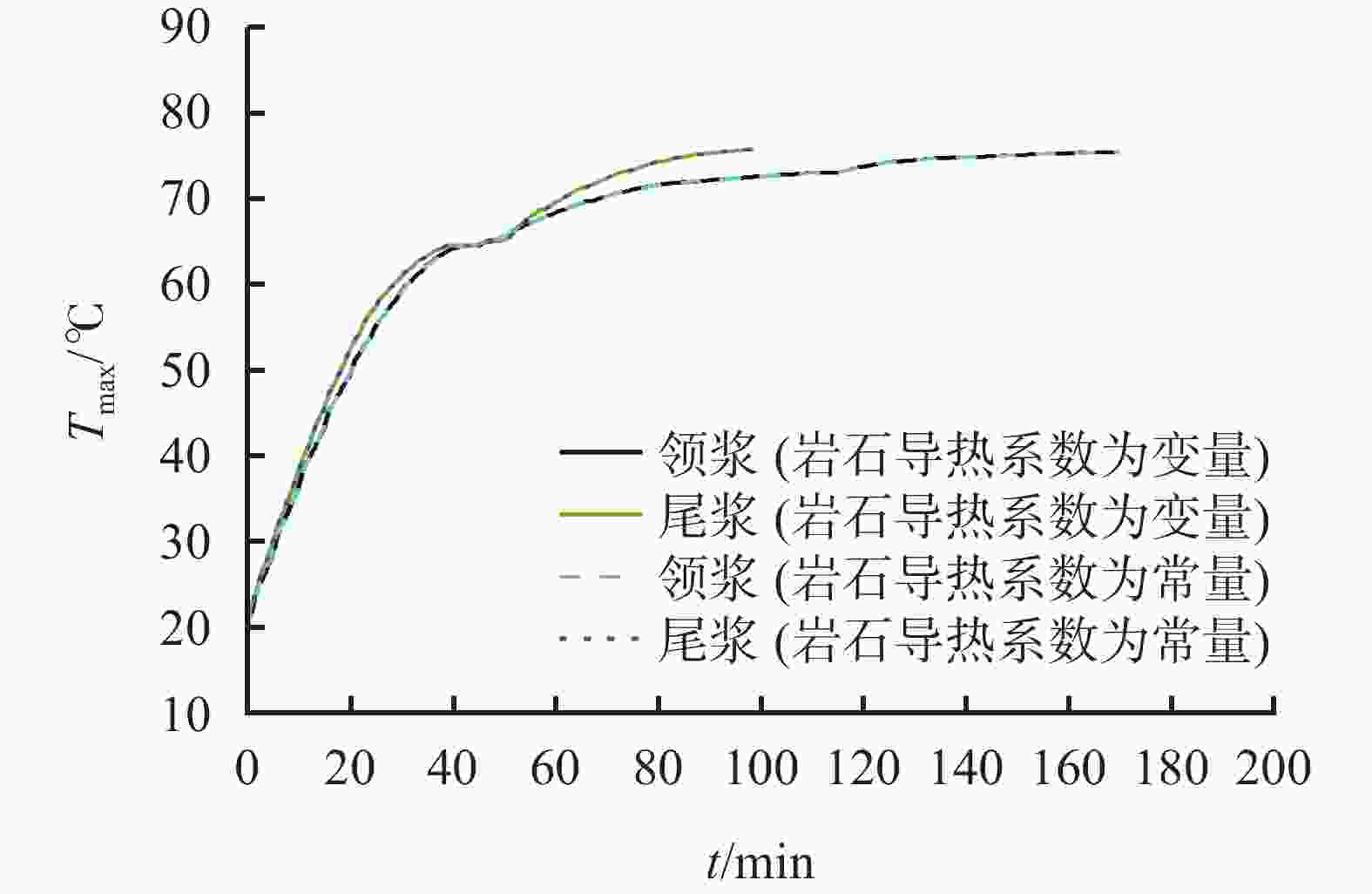

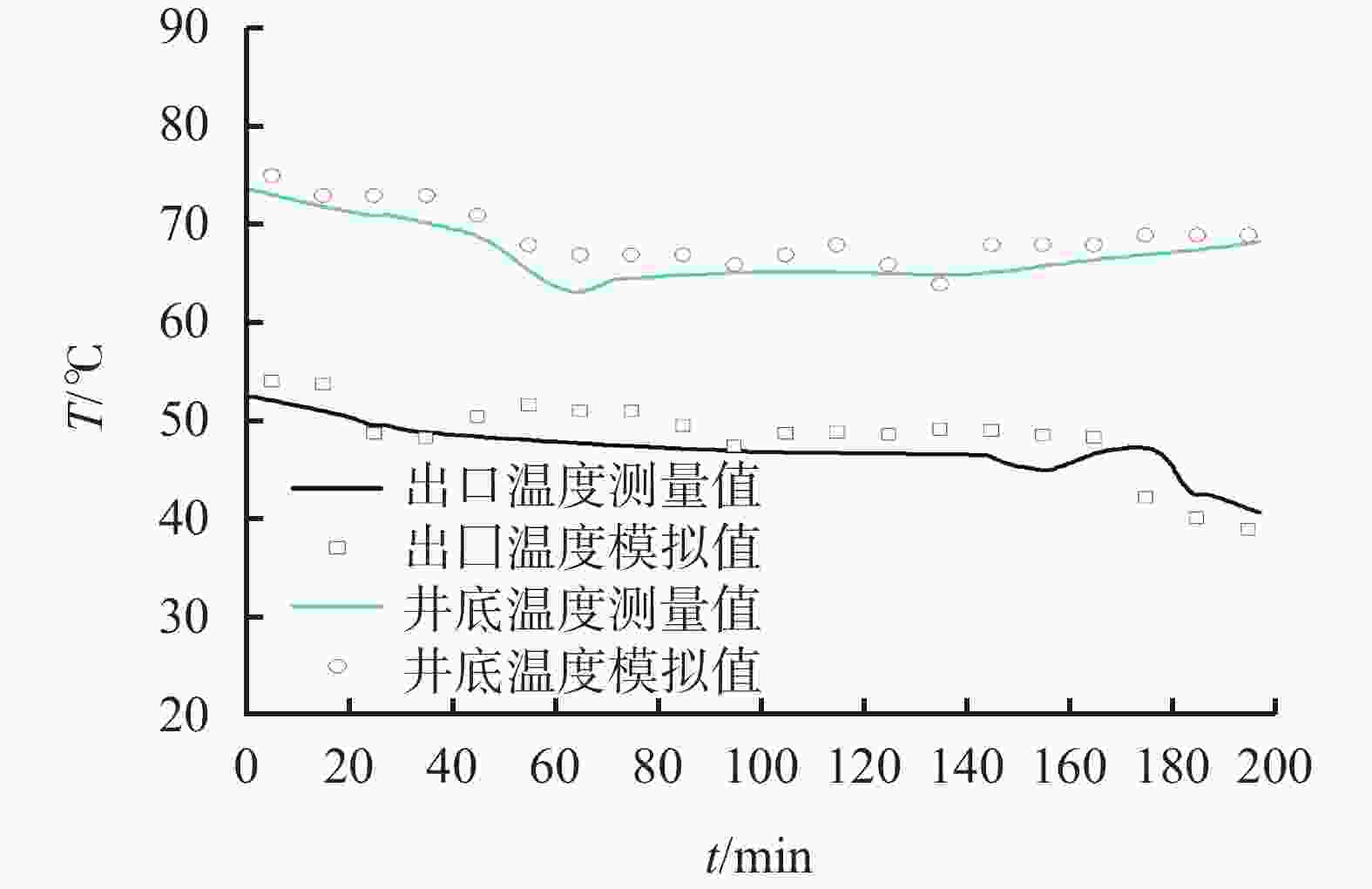

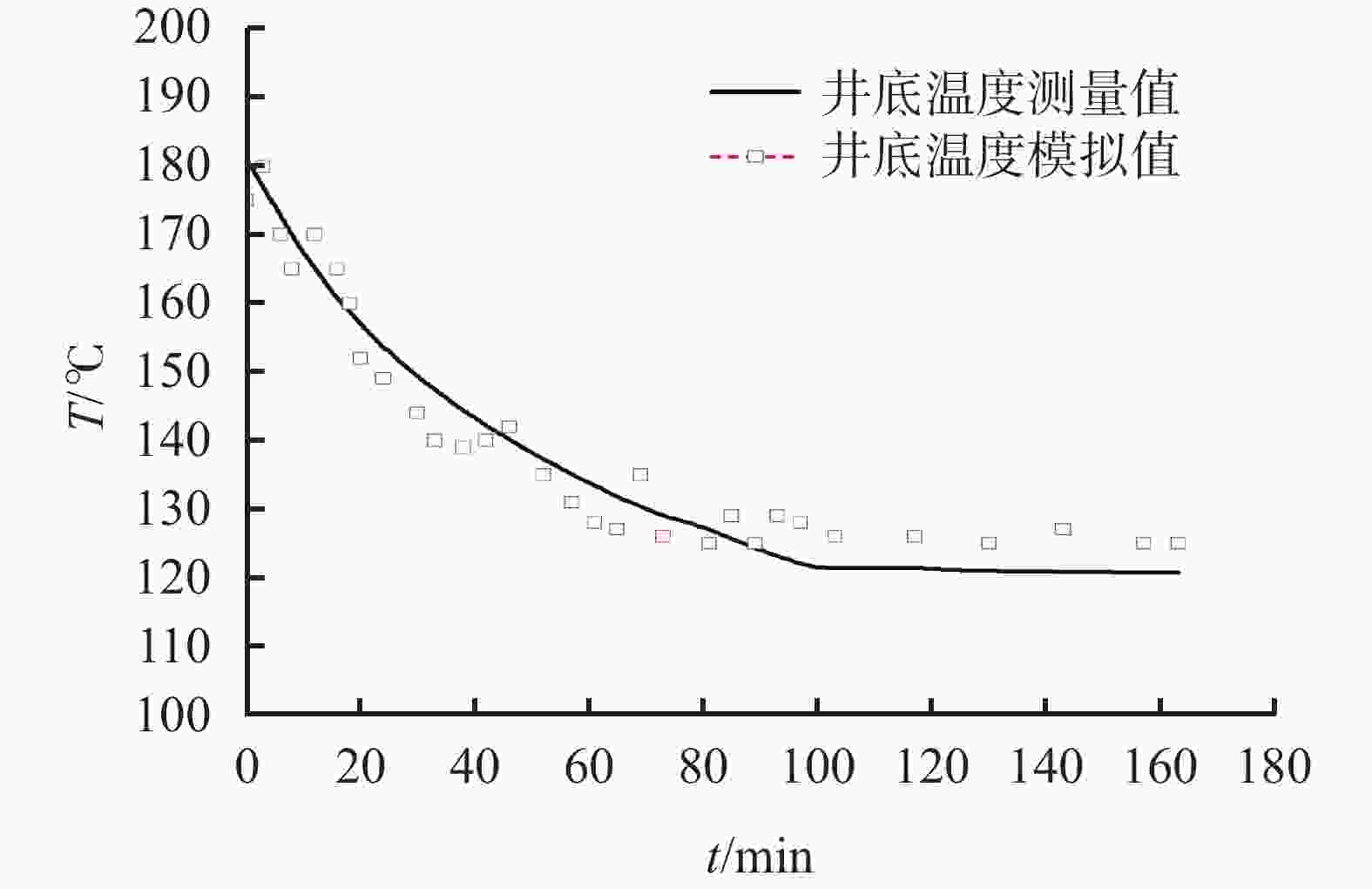

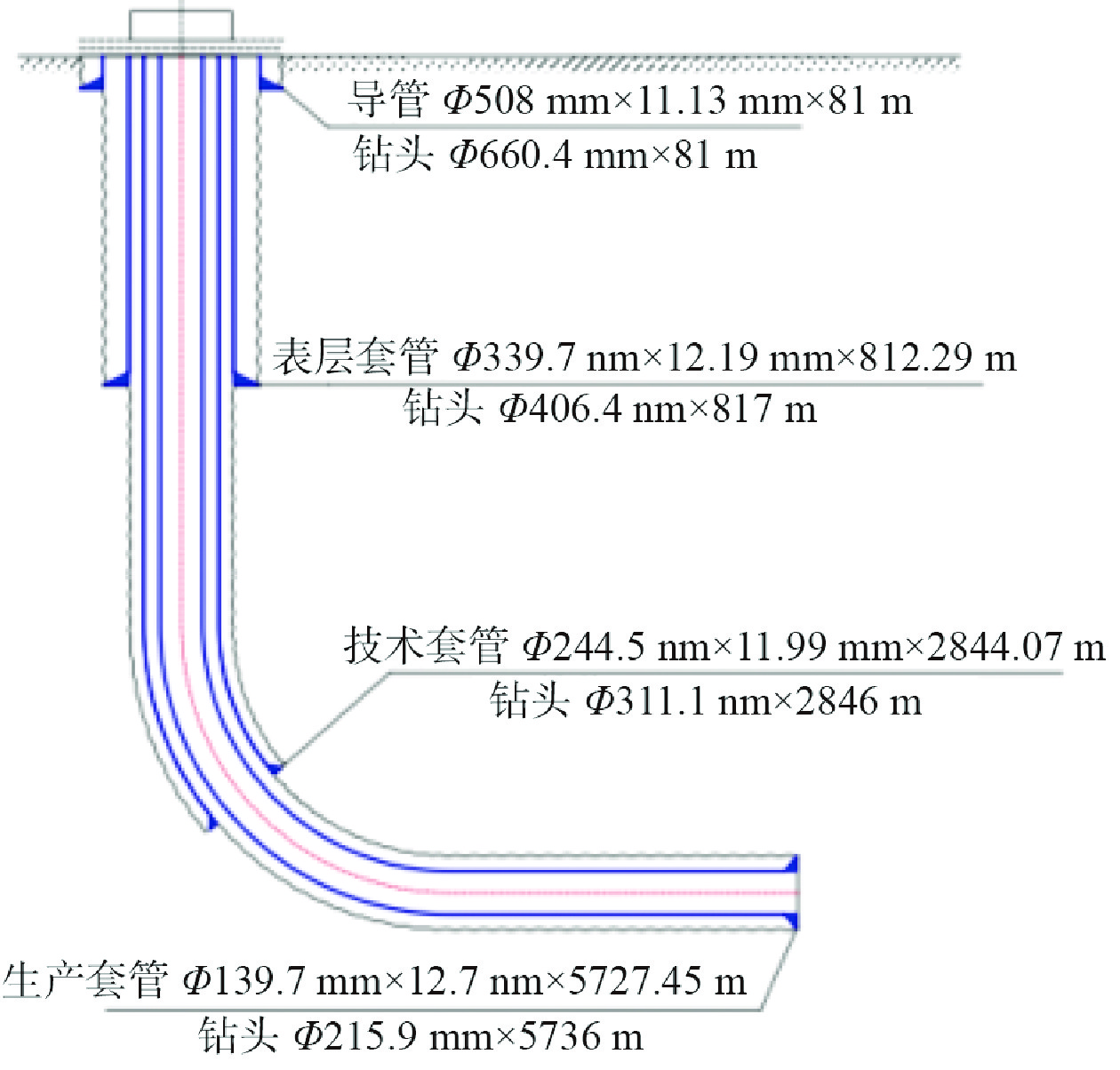

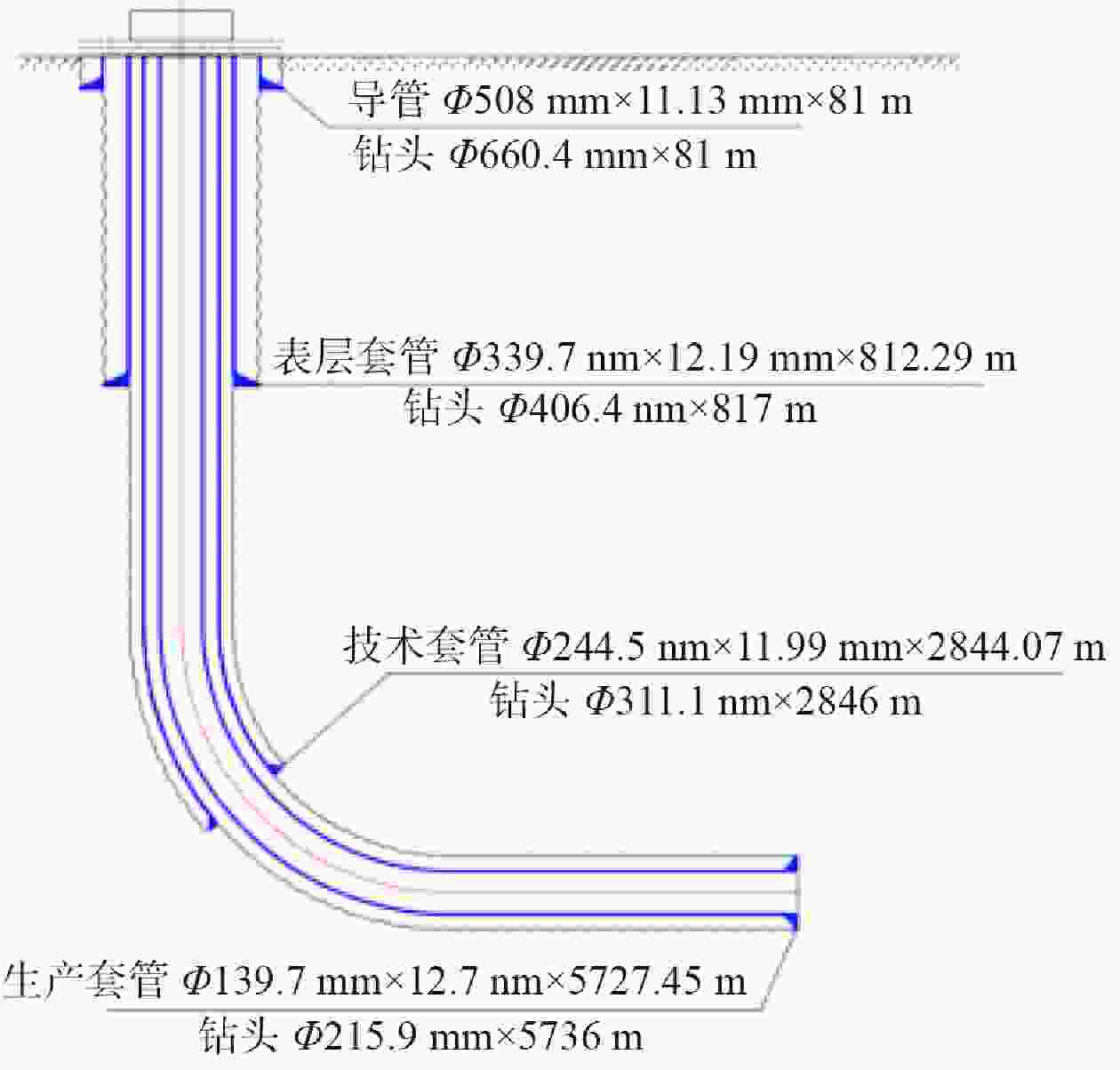

摘要: 在固井施工过程中,为确保水泥浆的安全泵入,需要确定合适的水泥浆稠化时间,水泥浆的循环温度是决定稠化时间的重要因素之一。现有API规范中关于循环温度的计算不能满足不同地区、不同井筒条件的需求。因此,建立了一种非稳态流动传热模型,通过热物性参数测试,确定了钻井液、套管、岩石和水泥浆的导热系数和比热容,实现了对固井注替过程中水泥浆温度场的模拟。模拟结果表明,提高水泥浆与隔离液等流体的导热系数会降低水泥浆的循环温度;降低套管与岩石的导热系数,水泥浆循环温变化范围在1 ℃以内。通过采集浙江油田与塔里木油田的固井温度数据发现,实测数据与模拟数据的差距在5 ℃以内,数据吻合度较高,模型较为准确。通过固井注替过程中水泥浆循环温度影响规律的研究,可为固井水泥浆体系性能设计提供理论支撑,保障固井高效安全施工。Abstract: In well cementing operation, to ensure that the cement slurry is safely pumped int the hole, the cement slurry shall have an appropriate thickening time. The circulating temperature of the cement slurry is one of the important factors affecting the thickening time of the cement slurry. The methods for calculating the circulating temperature of a cement slurry in the API Recommended Practice do not satisfy the need for calculating the circulating temperature in different areas and different borehole conditions. Thus, an unsteady state flow heat transfer model is established. By measuring the thermal physical parameters, the coefficients of heat conductivity and specific heat capacities of the drilling fluid, the casing strings, the rocks and the cement slurry are determined, and the temperature field of the cement slurry during injection and displacement is thus simulated. The simulation results show that increasing the coefficients of heat conductivity of the cement slurry and the spacer fluid reduces the circulating temperature of the cement slurry. Decreasing the coefficients of heat conductivity of the casing string and the rocks, the circulating temperature of the cement slurry changes in less than 1 ℃. Data acquired from the Zhejiang Oilfield and the Tarim Oilfield show that the difference between the measured well cementing temperatures and the simulated well cementing temperatures is less than 5 ℃, indicating that the simulated data is accurate and has good consistency with the measured data. Studies on the factors affecting the circulating temperatures of a cement slurry during injection and displacement in well cementing operations provide theoretical supports to the design of the properties of the cement slurry, thereby ensuring the efficient and safe well cementing operations.

-

表 1 用Hot Disk热常数分析仪测定的热物性参数

介质种类 比热容/(J/(kg·℃)) 导热系数/(W/(m·℃)) 套管 1161 38.31 水泥浆 1783 0.73 钻井液 1420 0.50 隔离液 3229 0.70 顶替液 4182 0.59 页岩 889 1.95 表 2 浙江油田某页岩气井注替计划

流体类型 ρ/

g·cm−3排量/

m3·min−1用量/

m3t/

minPV/

mPa·sYP/

Pa钻井液 2.20 1.20 200 167 73.0 9.0 隔离液 2.23 1.25 30 24 88.5 17.6 下胶塞 3 领浆 2.28 1.30 92 71 244.0 10.4 尾浆 1.90 1.35 54 41 181.0 17.0 下胶塞 5 顶替液 1.00 1.30 58 45 表 3 流体导热系数随温度变化情况

流体种类 不同温度(℃)下的导热系数/(W/(m·℃)) 15 30 45 60 75 90 钻井液 0.47 0.50 0.54 0.55 0.58 0.62 隔离液 0.69 0.70 0.72 0.74 0.76 0.77 水泥浆 0.71 0.73 0.75 0.76 0.78 0.80 顶替液 0.55 0.59 0.60 0.63 0.65 0.68 表 4 流体比热容随温度变化情况

流体种类 不同温度(℃)下的比热容/(J/(kg·℃)) 15 30 45 60 75 90 钻井液 1399 1420 1406 1425 1419 1408 隔离液 3320 3229 3183 3233 3228 3266 水泥浆 1753 1763 1748 1759 1761 1752 顶替液 4191 4182 4181 4179 4204 4199 表 5 套管导热系数和比热容随温度变化情况

T/℃ 导热系数/(W/(m·℃)) 比热容/(J/(kg·℃)) 15 40.43 1172 30 38.31 1161 80 37.43 1158 130 35.87 1226 180 32.13 1184 230 31.26 1186 表 6 岩石导热系数和比热容随温度变化情况

T/℃ 导热系数/(W/(m·℃)) 比热容/(J/(kg·℃)) 15 1.96 998.57 30 1.95 901.92 80 1.92 1.63.09 130 1.89 1003.78 180 1.85 1018.71 230 1.84 1007.24 -

[1] American Petroleum Institute. API RP 10B-2. API recommended practice 10B-2, recommended practice for testing well cements[S]. Washington, DC: American Petroleum Institute, 2013. [2] HONORE R S, TARR B A, HOWARD J A, et al. Cementing temperature predictions based on both downhole measurements and computer predictions: a case history[C]//SPE Production Operations Symposium. Oklahoma City, Oklahoma: SPE, 1993: SPE-25436-MS. [3] DILLENBECK R L, MOMBOURQUETTE I G. Real-time measurement of downhole annular cementing temperature for precise cementing design and application[C]//SPE Annual Technical Conference and Exhibition. New Orleans, Louisiana: SPE, 2001: SPE-71386-MS. [4] GOODMAN M A, MITCHELL R F, WEDELICH H, et al. Improved circulating temperature correlations for cementing[C]//SPE Annual Technical Conference and Exhibition. Houston, Texas: SPE, 1988: SPE-18029-MS. [5] HOLMES C S, SWIFT S C. Calculation of circulating mud temperatures[J]. Journal of Petroleum Technology, 1970, 22(6):670-674. doi: 10.2118/2318-PA [6] RAYMOND L R. Temperature distribution in a circulating drilling fluid[J]. Journal of Petroleum Technology, 1969, 21(3):333-341. doi: 10.2118/2320-PA [7] 夏环宇,翟应虎,安岩,等. 深水钻井隔水管增压排量对井筒温度分布的影响[J]. 石油钻探技术,2012,40(1):32-36.XIA Huanyu, ZHAI Yinghu, AN Yan, et al. The effect of boost flow in riser on the wellbore temperature in deep water drilling[J]. Petroleum Drilling Techniques, 2012, 40(1):32-36. [8] 栾智勇,尚跃强,刘明,等. 稠油热采闭式热流体循环井筒温度场分析[J]. 石油机械,2012,40(6):79-82. doi: 10.16082/j.cnki.issn.1001-4578.2012.06.019LUAN Zhiyong, SHANG Yueqiang, LIU Ming, et al. Analysis of the wellbore temperature field in closed thermal fluid circulation for heavy oil thermal recovery[J]. China Petroleum Machinery, 2012, 40(6):79-82. doi: 10.16082/j.cnki.issn.1001-4578.2012.06.019 [9] 李进,龚宁,张启龙,等. 基于三维温度场的热采井水泥环完整性破坏的研究及对策[J]. 钻井液与完井液,2018,35(5):83-89.LI Jin, GONG Ning, ZHANG Qilong, et al. Study on and countermeasures to the loss of cement sheath integrity in thermal production wells based on 3-D temperature field[J]. Drilling Fluid & Completion Fluid, 2018, 35(5):83-89. [10] 苏雄,杨明合,陈伟峰,等. 顺北一区小井眼超深井井筒温度场特征研究与应用[J]. 石油钻探技术,2021,49(3):67-74. doi: 10.11911/syztjs.2021006SU Xiong, YANG Minghe, CHEN Weifeng, et al. Study and application of wellbore temperature field characteristics in the ultra-deep slim-hole wells in the Shunbei No. 1 area[J]. Petroleum Drilling Techniques, 2021, 49(3):67-74. doi: 10.11911/syztjs.2021006 -

下载:

下载: