A Cement Slurry for Large Temperature Difference in Wells of Ten Thousand Meter Depth

-

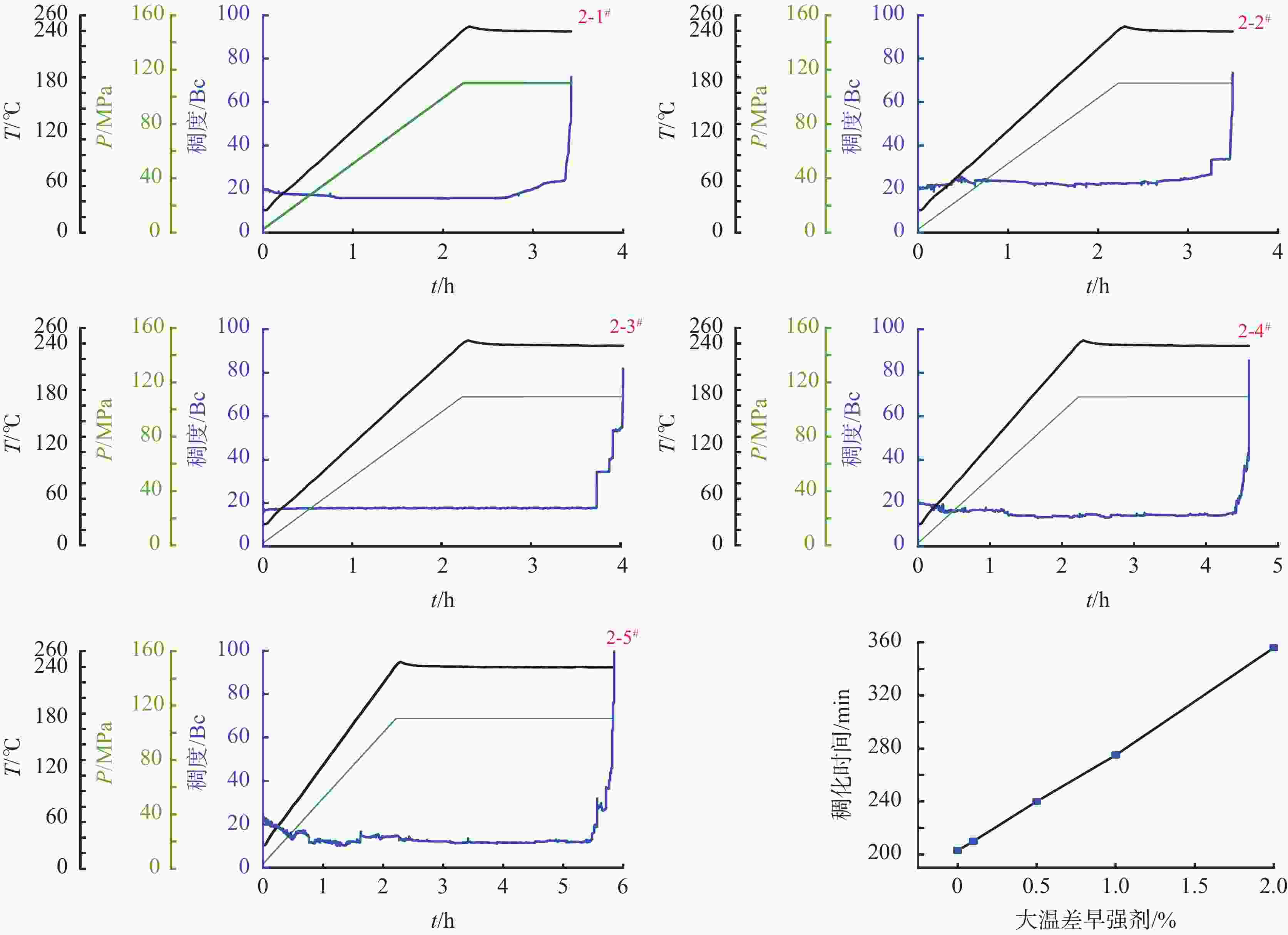

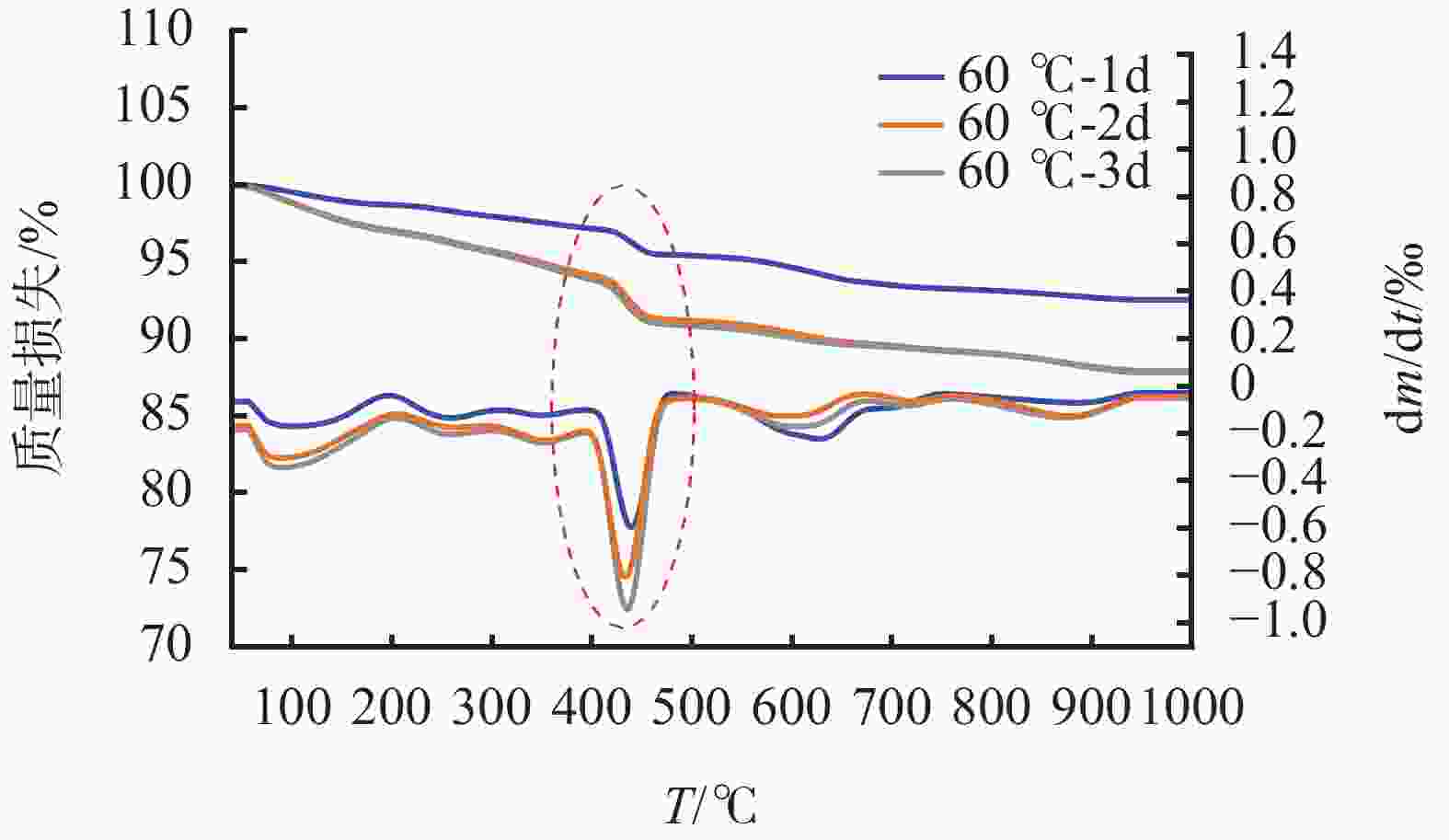

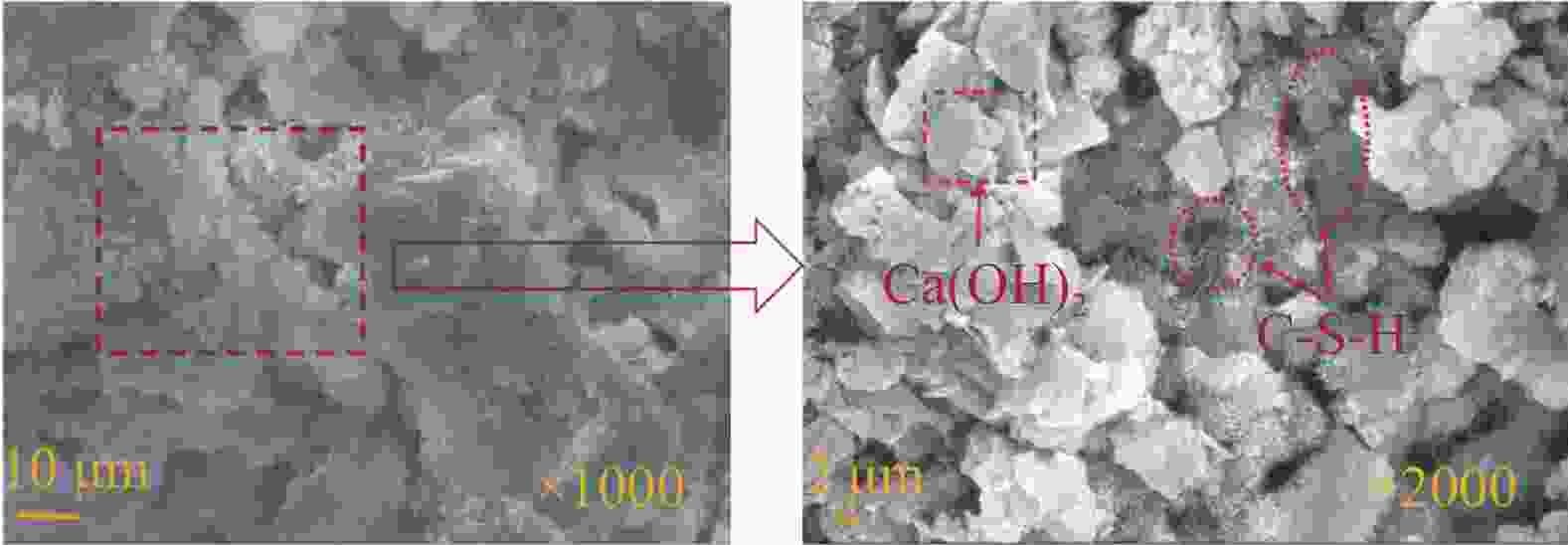

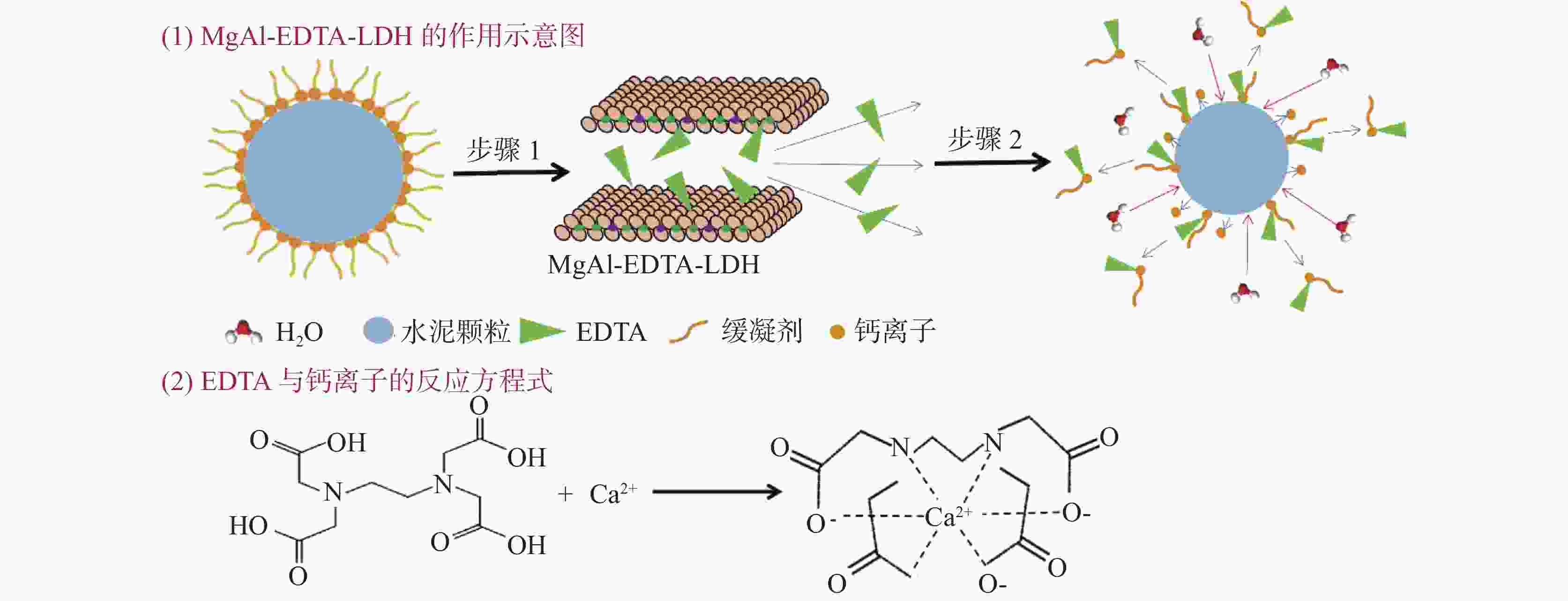

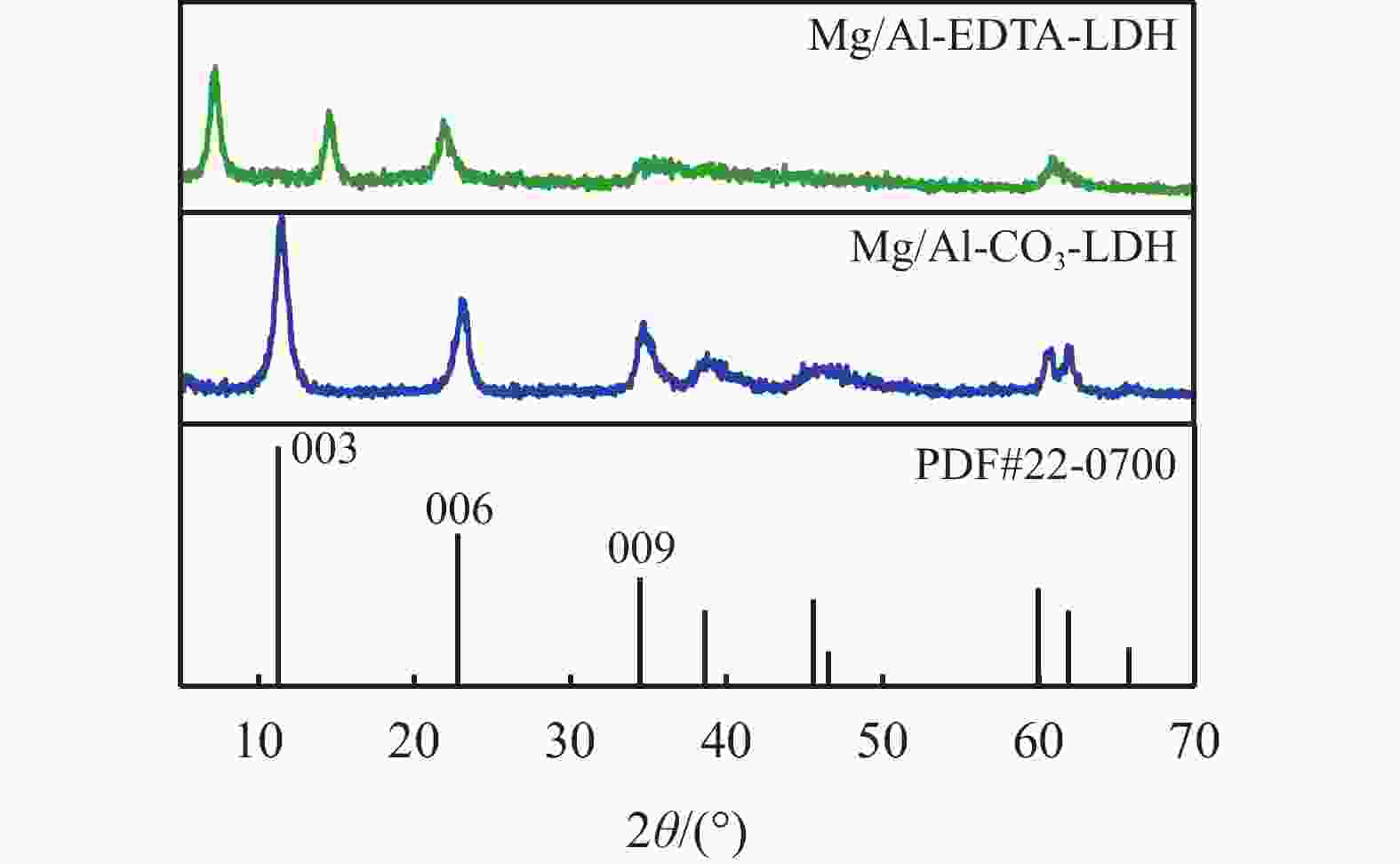

摘要: 针对超深井长封固固井中,顶部底部水泥浆温差大,顶部低温段水泥浆超缓凝、水泥石强度发展缓慢的问题,采用水溶液聚合法制备了一种MgAl-EDTA-LDH(EDTA插层型水滑石)大温差早强剂,并配套形成了一套大温差水泥浆体系。实验结果表明,该大温差早强剂具有一定的缓凝效果,当其加量为2.0%,复配4.0%缓凝剂时,在240 ℃下其稠化时间可达509 min。该水泥浆在60 ℃养护1 d和30 ℃下养护6 d的抗压强度均大于7 MPa,最大温差为210 ℃。大温差早强剂在不影响水泥浆稠化可调性的前提下,有利于低温段水泥浆柱的强度发展,耐热温度达300 ℃以上,适用于大温差固井需求。Abstract: In cementing operation in ultradeep wells with long cementing sections, there is a large difference between the temperature at the top of the cement slurry and that at the bottom of the cement slurry. The low temperature at the top of the cement slurry retards the development of the strength of the set cement. To solve this problem, an early strength additive named EDTA-LDH (EDTA intercalated hydrotalcite) was developed through water solution polymerization. A cement slurry for working at big temperature difference conditions was formulated with EDTA-LDH. Laboratory experimental results show that this early strength additive has retarding effect to some extent; at a concentration of 2.0% EDTA-LDH and 4.0% retarder, a cement slurry has thickening time of 509 min at 240 ℃. After aging at 60 ℃ for 1 d or at 30 ℃ for 6 d, the cement slurry has compressive strengths of both greater than 7 MPa, and experiences maximum temperature difference of 210 ℃. The use of EDTA-LDH is beneficial to the development of the strength of the cement slurry column in low temperature without affecting the adjustability of the thickening time of the cement slurry. This early strength additive can work normally at temperatures above 300 ℃, and is suitable for cementing wells with large temperature differences.

-

表 1 大温差早强剂与外加剂配伍性评价

配方 分散剂 降失水剂 缓凝剂 实验条件 t稠化/min 1-1# DRS-1S G33S GH-9L 140 ℃×70 MPa×70 min 293 1-2# USZ DRF-3L GH-8L 160 ℃×80 MPa×80 min 393 1-3# USZ G33S GH-8L 180 ℃×90 MPa×90 min 275 1-4# DRS-1S DRF-3L GH-9L 205 ℃×130 MPa×70 min 438 1-5# USZ G33S GH-9L 215 ℃×130 MPa×110 min 506 1-6# ZF-1 ZJ-5 ZH-6 240 ℃×110 MPa×130 min 441 注:水泥浆基础配方为100%水泥+30%石英砂+5%微硅+(0~2%)大温差早强剂+(0.4%~0.6%)分散剂+(1.5%~2.0%)降失水剂+(2%~4%)缓凝剂+1.5%高温悬浮稳定剂+H2O(W/S=0.44)。 表 2 大温差水泥浆综合性能评价

配方 缓凝剂

ZH-6/%大温差

早强剂/%流动度/

cmFL/

mLΔρ/

g·cm−3n K/

Pa·sn2-1# 3.0 0 24.0 37 0.01 0.84 0.61 2-2# 3.0 0.1 24.0 39 0.01 0.83 0.67 2-3# 3.0 0.5 24.0 36 0.01 0.86 0.64 2-4# 3.0 1.0 23.5 43 0.01 0.84 0.63 2-5# 3.0 2.0 23.0 40 0.02 0.87 0.67 注:水泥浆基础配方为100%水泥+30%石英砂+5%微硅+0.4%分散剂ZF-1+2%降失水剂ZJ-5 +1.5%高温悬浮稳定剂BH-ZW-1+H2O(W/S=0.44)。 表 3 大温差水泥浆性能评价实验

配方 实验条件 ZH-6/

%大温差

早强剂/%t稠化/

min3-1# 120 ℃×60 MPa×60 min 1.5 0.3 308 3-2# 140 ℃×70 MPa×70 min 1.6 0.6 319 3-3# 160 ℃×80 MPa×80 min 1.8 0.8 364 3-4# 180 ℃×90 MPa×90 min 2.5 1.2 444 3-5# 205 ℃×130 MPa×70 min 3.0 1.5 438 3-6# 215 ℃×130 MPa×110 min 3.5 1.8 442 3-7# 240 ℃×110 MPa×130 min 4.0 2.0 509 注:水泥浆基础配方:100%水泥+30%石英砂+5%微硅+0.4%分散剂ZF-1 +2%降失水剂ZJ-5+1.5%高温悬浮稳定剂BH-ZW-1+H2O(W/S=0.44)。 表 4 大温差水泥浆体系抗压强度测试结果

配方 静止温度下

p24 h /MPa不同温差不同养护时间的水泥石抗压强度/MPa 返高温度90 ℃ 返高温度60 ℃ 返高温度30 ℃ 1 d 2 d 3 d 1 d 2 d 3 d 6 d 3-1# 26.59 19.23 21.98 22.31 18.54 19.66 20.13 15.21 3-2# 25.13 15.62 17.34 19.74 11.03 13.28 15.45 12.65 3-3# 23.87 13.58 15.27 16.88 10.67 11.34 14.86 10.54 3-4# 21.03 12.15 14.07 16.91 9.64 10.91 12.74 8.75 3-5# 19.89 12.37 14.51 14.82 10.89 11.36 13.64 9.01 3-6# 20.46 11.87 13.98 14.75 11.37 13.84 14.21 8.69 3-7# 17.73 9.12 10.12 11.05 7.59 8.97 9.61 7.35 -

[1] 王志刚,王稳石,张立烨,等. 万米科学超深井钻完井现状与展望[J]. 科技导报,2022,40(13):27-35.WANG Zhigang, WANG Wenshi, ZHANG Liye, et al. Present situation and prospect of drilling and completion of 10000 meter scientific ultra deep wells[J]. Science & Technology Review, 2022, 40(13):27-35. [2] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163-177.WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: progress and prospect[J]. Natural Gas Industry, 2021, 41(8):163-177. [3] 李阳,薛兆杰,程喆,等. 中国深层油气勘探开发进展与发展方向[J]. 中国石油勘探,2020,25(1):45-57.LI Yang, XUE Zhaojie, CHENG Zhe, et al. Progress and development directions of deep oil and gas exploration and development in China[J]. China Petroleum Exploration, 2020, 25(1):45-57. [4] 何立成,唐波. 准噶尔盆地超深井钻井技术现状与发展建议[J]. 石油钻探技术,2022,50(5):1-8.HE Licheng, TANG Bo. The up to date technologies of ultra-deep well drilling in Junggar basin and suggestions for further improvements[J]. Petroleum Drilling Techniques, 2022, 50(5):1-8. [5] 陈宗琦,刘湘华,白彬珍,等. 顺北油气田特深井钻井完井技术进展与发展思考[J]. 石油钻探技术,2022,50(4):1-10.CHEN Zongqi, LIU Xianghua, BAI Binzhen, et al. Technical progress and development consideration of drilling and completion engineering for ultra-deep wells in the Shunbei oil & gas field[J]. Petroleum Drilling Techniques, 2022, 50(4):1-10. [6] 杨明清,杨一鹏,卞玮,等. 俄罗斯超深井钻井进展及技术进步[J]. 石油钻采工艺,2021,43(1):15-20.YANG Mingqing, YANG Yipeng, BIAN Wei, et al. Drilling progress and technological improvement of ultra-deep wells in Russia[J]. Oil Drilling & Production Technology, 2021, 43(1):15-20. [7] 王明华,贺立勤,卓云,等. 川渝地区9000 m级超深超高温超高压地层安全钻井技术实践与认识[J]. 天然气勘探与开发,2023,46(2):44-50.WANG Minghua, HE Liqin, ZHUO Yun, et al. Practices and understandings on safe drilling technologies for 9000-m-level super deep and ultra high temperature and pressure strata, Sichuan-Chongqing area[J]. Natural Gas Exploration and Development, 2023, 46(2):44-50. [8] 刘军,沈向存,任丽丹,等. 塔里木盆地顺托果勒低隆区志留系隐蔽性圈闭识别与描述——高分辨率储层预测技术在S1井三维区的应用[J]. 石油实验地质,2012,34(S1):12-16.LIU Jun, SHEN Xiangcun, REN Lidan, et al. Recognition and description of Silurian concealed traps in Shuntuoguole low uplift region of Tarim basin: application of high resolution reservoir prediction technology in well zone S1[J]. Petroleum Geology & Experiment, 2012, 34(S1):12-16. [9] 于永金,夏修建,王治国,等. 深井、超深井固井关键技术进展及实践[J]. 新疆石油天然气,2023,19(2):24-33.YU Yongjin, XIA Xiujian, WANG Zhiguo, et al. Progress and application of the key technologies of deep and ultra-deep well cementing[J]. Xinjiang Oil & Gas, 2023, 19(2):24-33. [10] ZHANG W Y, MA Y, YANG R Y, et al. Effects of ethylene diamine tetraacetic acid and calcium nitrate on high-temperature cementing slurry in a large temperature difference environment[J]. Construction and Building Materials, 2023, 368:130387. doi: 10.1016/j.conbuildmat.2023.130387 [11] WU W C, YU X R, HU A B, et al. Amphoteric retarder for long-standing cementing: preparation, properties and working mechanism[J]. Geoenergy Science and Engineering, 2023, 223:211524. doi: 10.1016/j.geoen.2023.211524 [12] 冯德杰,杨启贞,曹成章. 油井水泥大温差缓凝剂的合成及性能研究[J]. 合成化学,2023,31(2):93-100.FENG Dejie, YANG Qizhen, CAO Chengzhang. Study on synthesis and properties of oil well cement retarder with large temperature difference[J]. Chinese Journal of Synthetic Chemistry, 2023, 31(2):93-100. [13] 张健,彭志刚,黄仁果,等. 一种大温差耐温耐盐缓凝剂的合成及性能评价[J]. 精细化工,2018,35(7):1240-1247.ZHANG Jian, PENG Zhigang, HUANG Renguo, et al. Synthesis and performance evaluation of a temperature resistance and salt tolerance retarder for large temperature difference cementing[J]. Fine Chemicals, 2018, 35(7):1240-1247. [14] 岳家平,徐翔,李早元,等. 高温大温差固井水泥浆体系研究[J]. 钻井液与完井液,2012,29(2):59-62.YUE Jiaping, XU Xiang, LI Zaoyuan, et al. Study on cement slurry system of high temperature and large temperature difference[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):59-62. [15] 岳家平. 高温大温差低密度水泥浆体系研究与应用[D]. 成都: 西南石油大学, 2012.YUE Jiaping. Research and application of high temperature and large temperature difference low density cement slurry system[D]. Chengdu: Southwest Petroleum University, 2012. [16] 赵宝辉,邹建龙,刘爱萍,等. 新型缓凝剂BCR-260L性能评价及现场试验[J]. 石油钻探技术,2012,40(2):55-58.ZHAO Baohui, ZOU Jianlong, LIU Aiping, et al. Performance evaluation and application of novel retarder BCR-260L[J]. Petroleum Drilling Techniques, 2012, 40(2):55-58. [17] 胡晋军,宋海生,孟庆祥,等. 中高温缓凝剂BCR-260L在海上高温深井的应用[J]. 中国石油和化工标准与质量,2016,36(21):116-117.HU Jinjun, SONG Haisheng, MENG Qingxiang, et al. Application of middle and high temperature retarder BCR-260L in offshore high temperature deep wells[J]. China Petroleum and Chemical Standard and Quality, 2016, 36(21):116-117. [18] 张晓兵,李长坤,衡宣亦,等. 塔里木山前构造盐膏层固井难点与技术对策[J]. 西部探矿工程,2021,33(12):48-52.ZHANG Xiaobing, LI Changkun, HENG Xuanyi, et al. Difficulties and technical countermeasures in cementing salt-paste beds in Tarim Piedmont structure[J]. West-China Exploration Engineering, 2021, 33(12):48-52. [19] 费中明,刘鑫,张晔,等. 准噶尔盆地南缘超深井天X井尾管精细控压固井技术[J]. 钻井液与完井液,2023,40(3):391-396.FEI Zhongming, LIU Xin, ZHANG Ye, et al. Liner cementing through precise pressure control in the ultra-deep well Tian-X located at the southern margin of the Junggar basin[J]. Drilling Fluid & Completion Fluid, 2023, 40(3):391-396. [20] 于永金,丁志伟,张弛,等. 抗循环温度210 ℃超高温固井水泥浆[J]. 钻井液与完井液,2019,36(3):349-354.YU Yongjin, DING Zhiwei, ZHANG Chi, et al. A cement slurry used at ultra-high circulation temperature of 210 ℃[J]. Drilling Fluid & Completion Fluid, 2019, 36(3):349-354. [21] 焦少卿,何龙,郭小阳,等. 高温多功能防气窜水泥浆体系在四川盆地海相超深井中的成功应用[J]. 钻井液与完井液,2020,37(4):512-520.JIAO Shaoqing, HE Long, GUO Xiaoyang, et al. Successful application of high temperature multi-functional gas channeling preventing cement slurry in marine ultra deep wells in Sichuan basin[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):512-520. [22] 王敬朋,熊友明,路宗羽,等. 超深井抗盐高密度固井水泥浆技术[J]. 钻井液与完井液,2021,38(5):634-640.WANG Jingpeng, XIONG Youming, LU Zongyu, et al. Study on salt-resistant high density cement slurry technology for ultra-deep wells[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):634-640. [23] 魏浩光,常庆露,刘小刚,等. 水滑石插层降失水剂的制备和性能研究[J]. 化学工业与工程,2022,39(2):84-89.WEI Haoguang, CHANG Qinglu, LIU Xiaogang, et al. Preparation and performance of hydrotalcite intercalation fluid loss agent[J]. Chemical Industry and Engineering, 2022, 39(2):84-89. [24] 左天鹏,程小伟,吴昊,等. 一种长封固段固井用缓凝剂的制备及性能评价[J]. 精细化工,2022,39(3):618-626.ZUO Tianpeng, CHENG Xiaowei, WU Hao, et al. Preparation and performance evaluation of a kind of retarder used in long cementing interval[J]. Fine Chemicals, 2022, 39(3):618-626. [25] 马保国,谭洪波,董荣珍,等. 聚羧酸减水剂缓凝机理的研究[J]. 长江科学院院报,2008,25(6):93-95.MA Baoguo, TAN Hongbo, DONG Rongzhen, et al. Retarding mechanism of polycarboxylic acid type water-reducing agent[J]. Journal of Yangtze River Scientific Research Institute, 2008, 25(6):93-95. [26] 董文博,庄稼,马彦龙,等. 高温油井水泥缓凝剂聚2-丙烯酰胺基-2-甲基丙磺酸/苯乙烯磺酸钠/衣康酸的合成及缓凝效果[J]. 硅酸盐学报,2012,40(5):703-710.DONG Wenbo, ZHUANG Jia, MA Yanlong, et al. Terpolymerization and retardation of a high temperature cement retarder poly 2-acrylamido-2-methyl propane sulfonic acid/sodium styrene sulfonate/itaconic acid for oil well[J]. Journal of the Chinese Ceramic Society, 2012, 40(5):703-710. -

下载:

下载: