Identifying Types and Analyzing Main Controlling Factors of Mud Losses Using a Method Integrating LightGBM Algorithm and SHAP

-

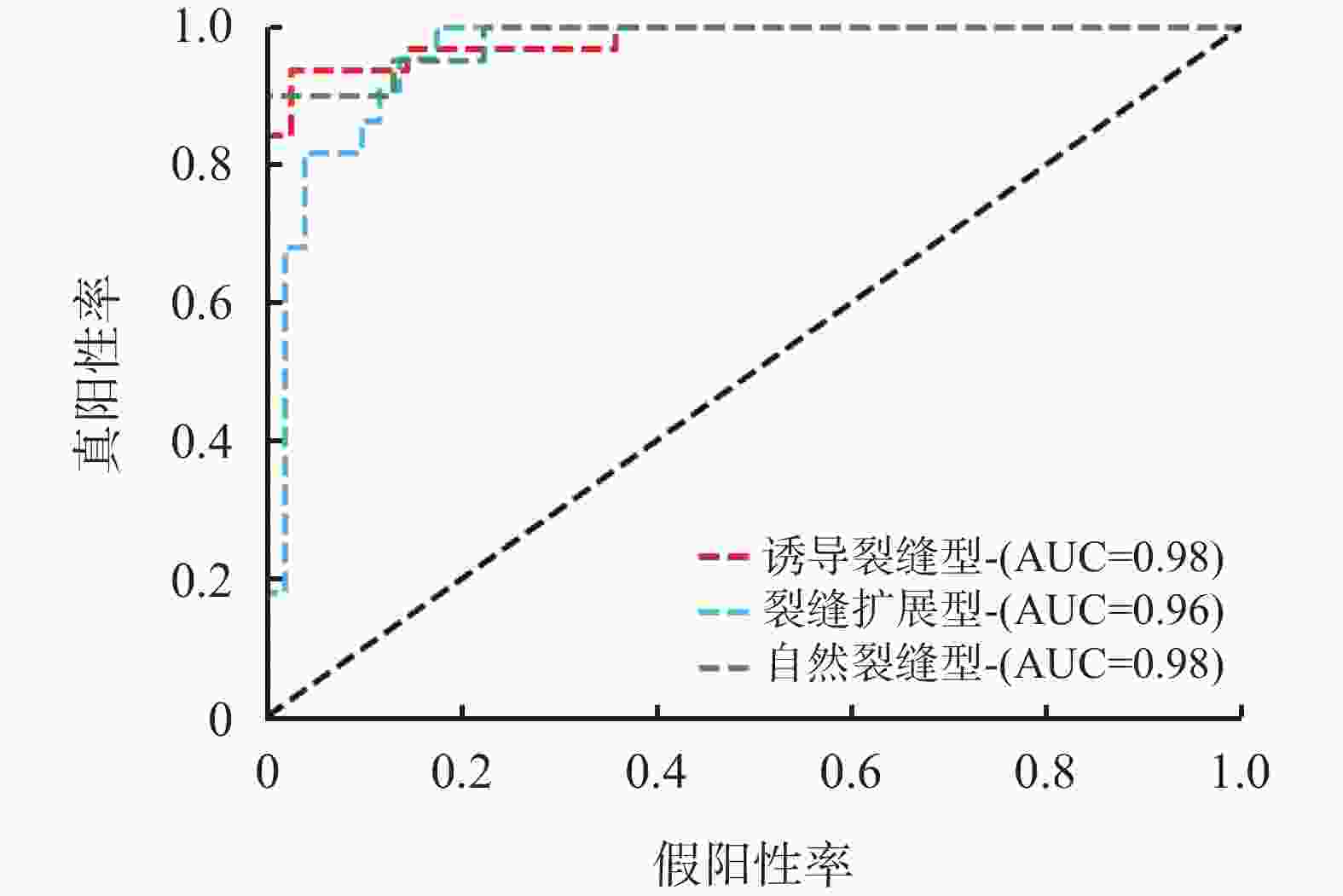

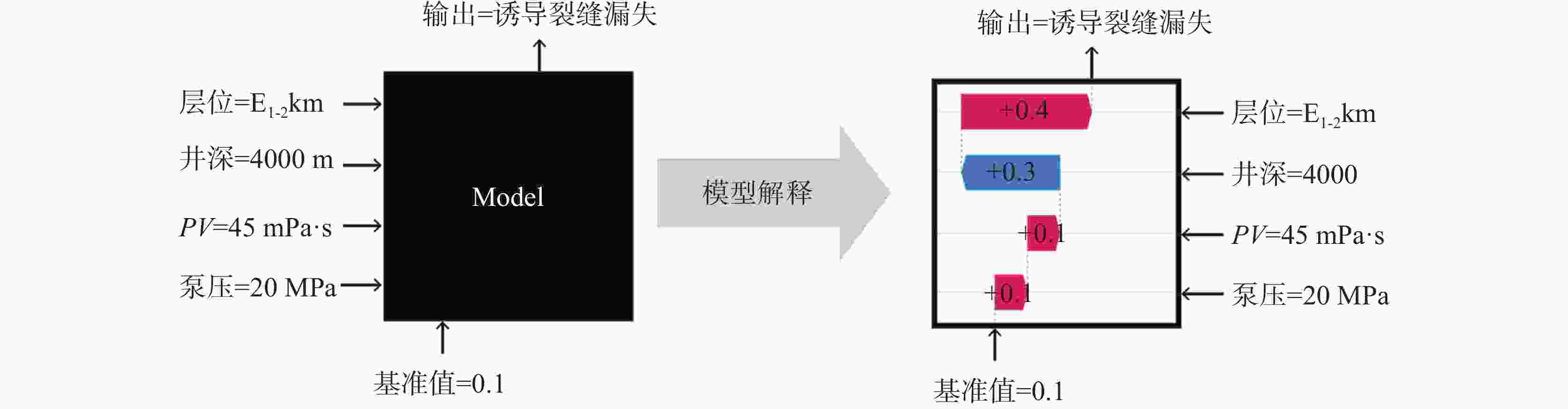

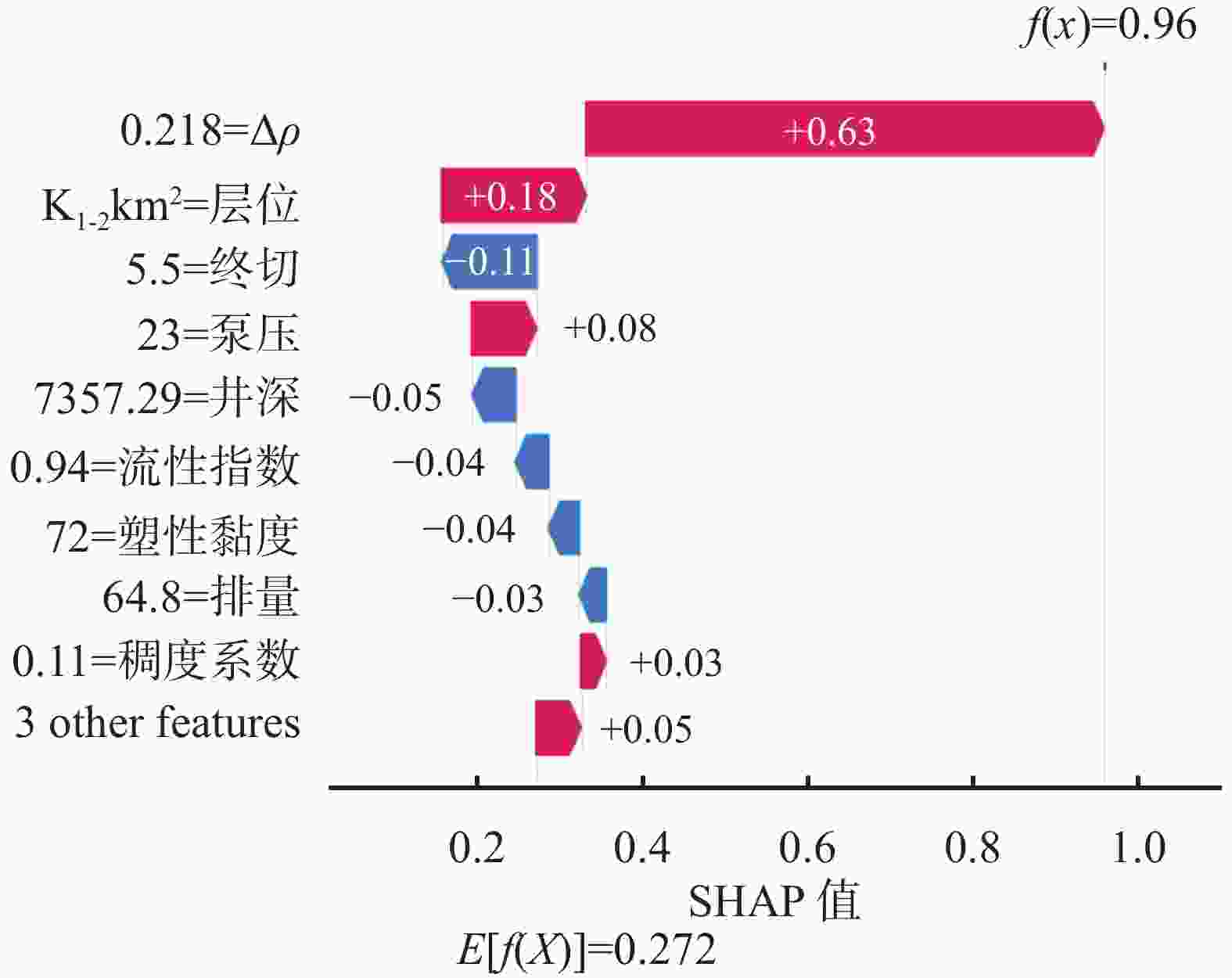

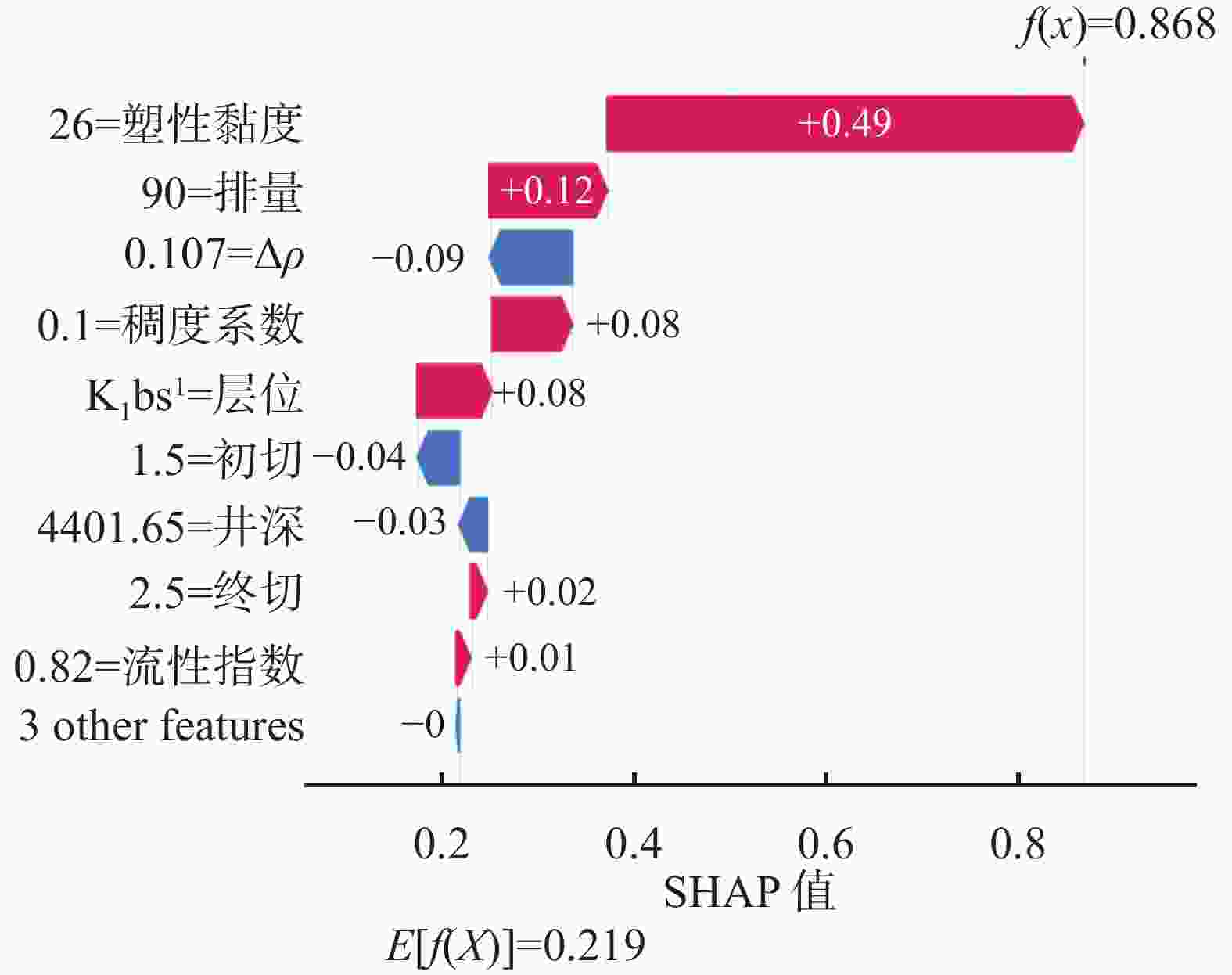

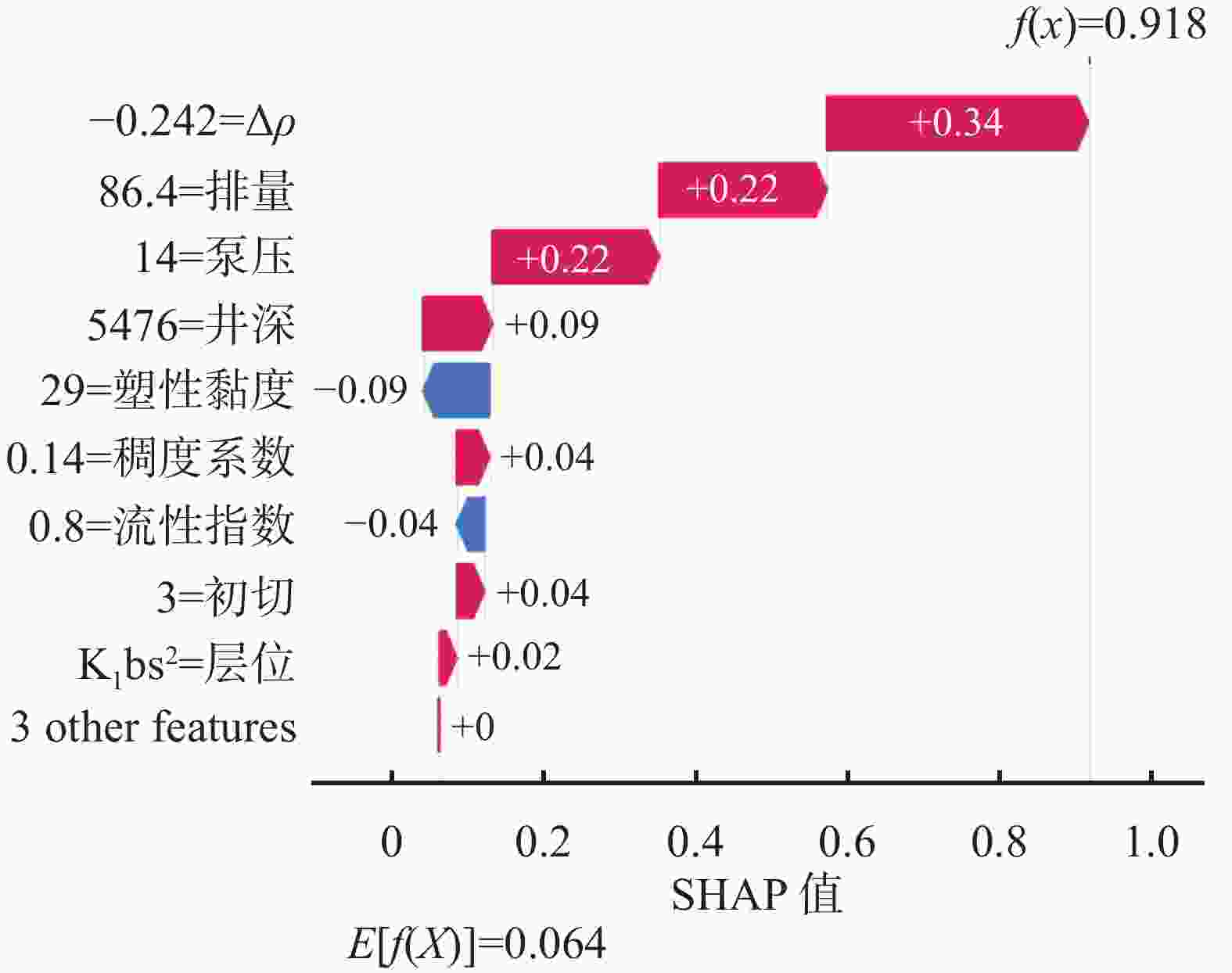

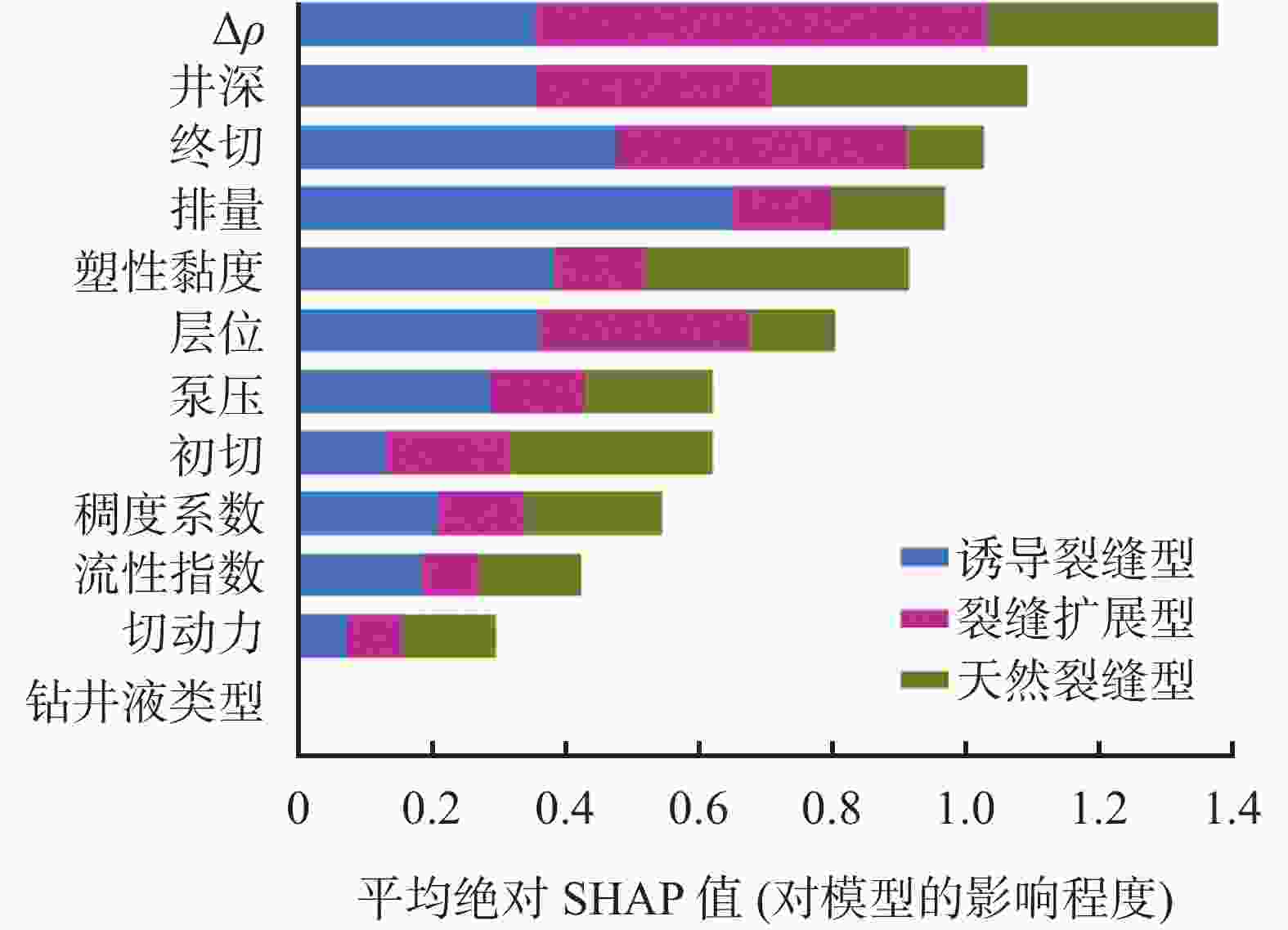

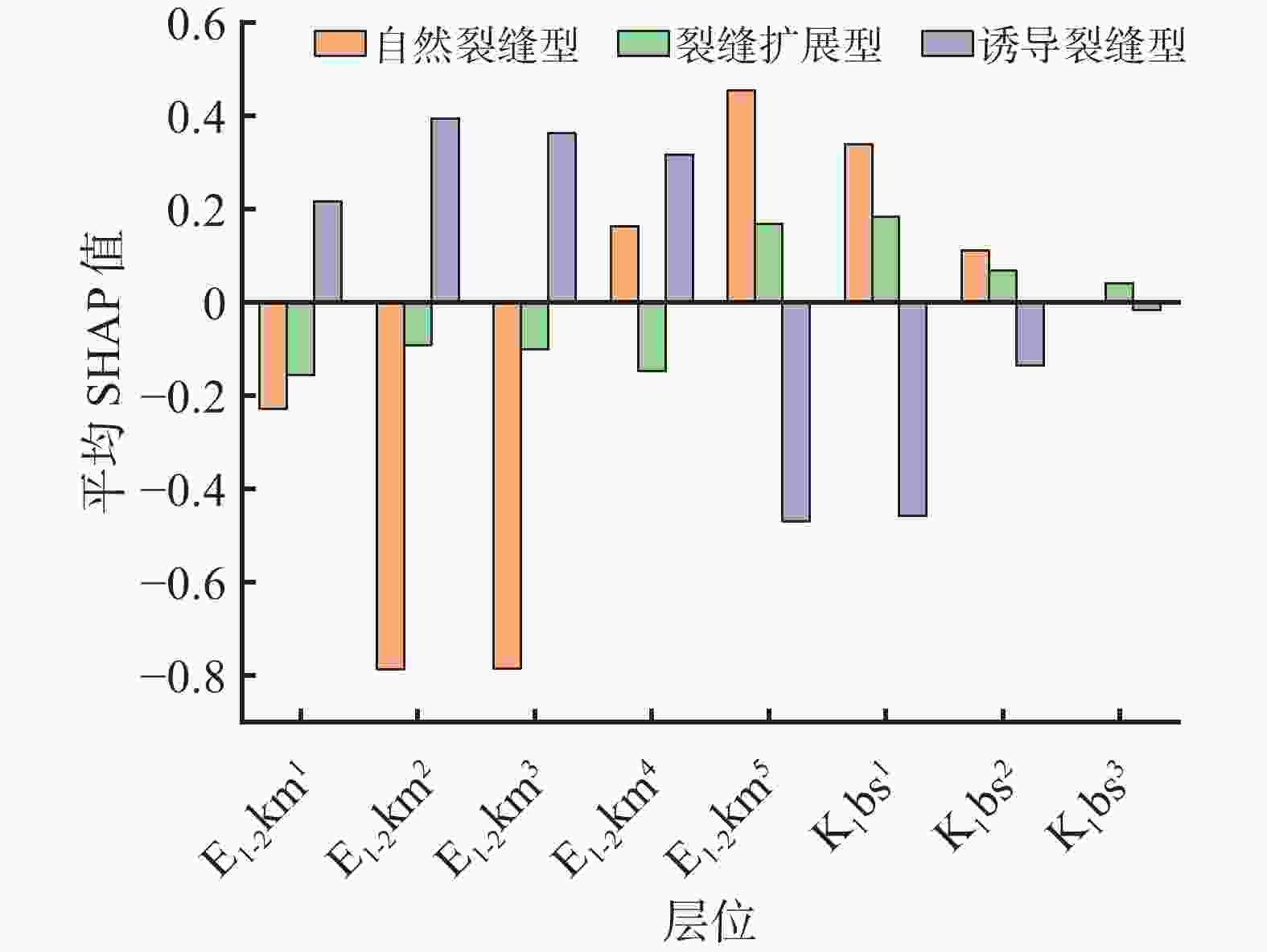

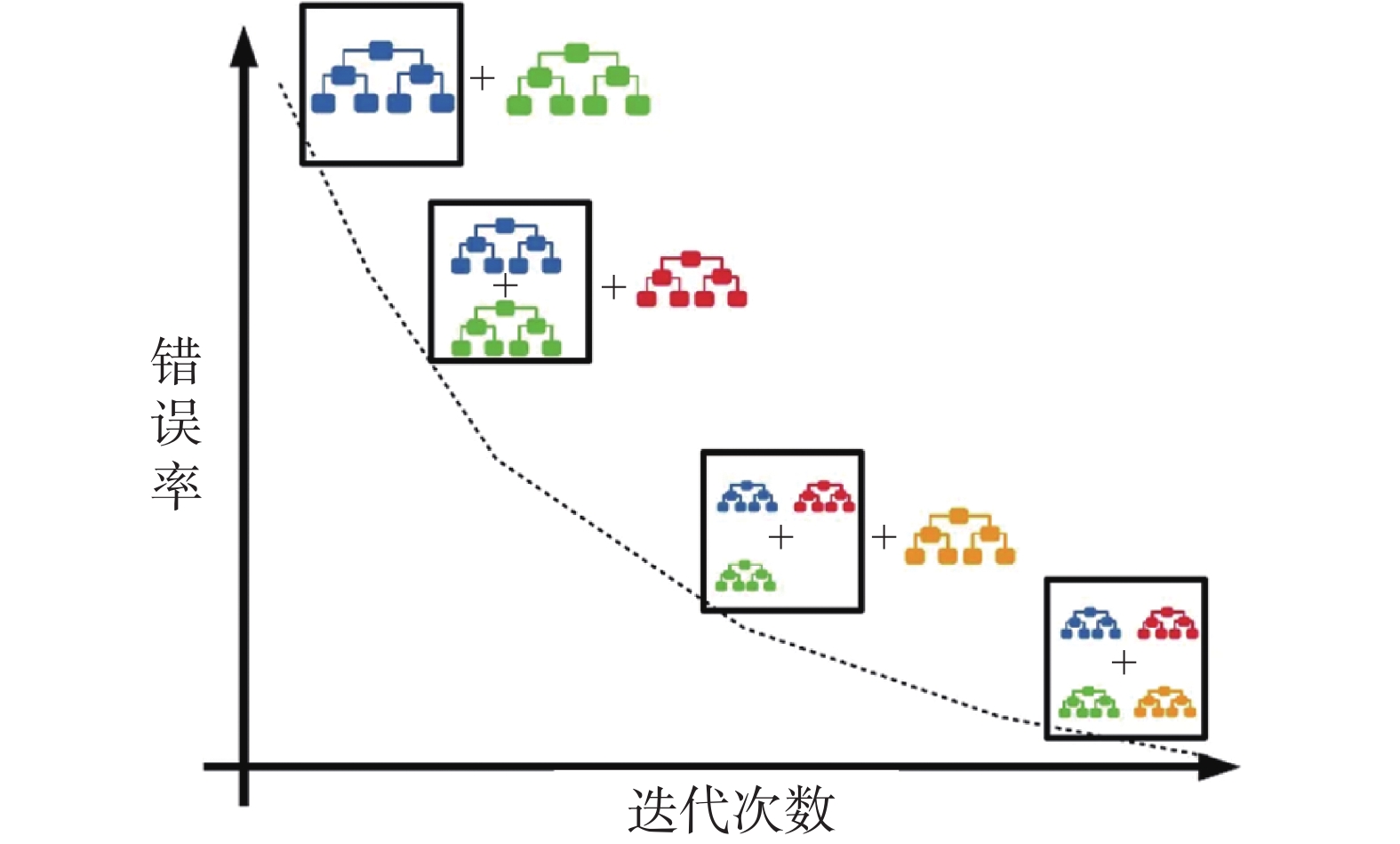

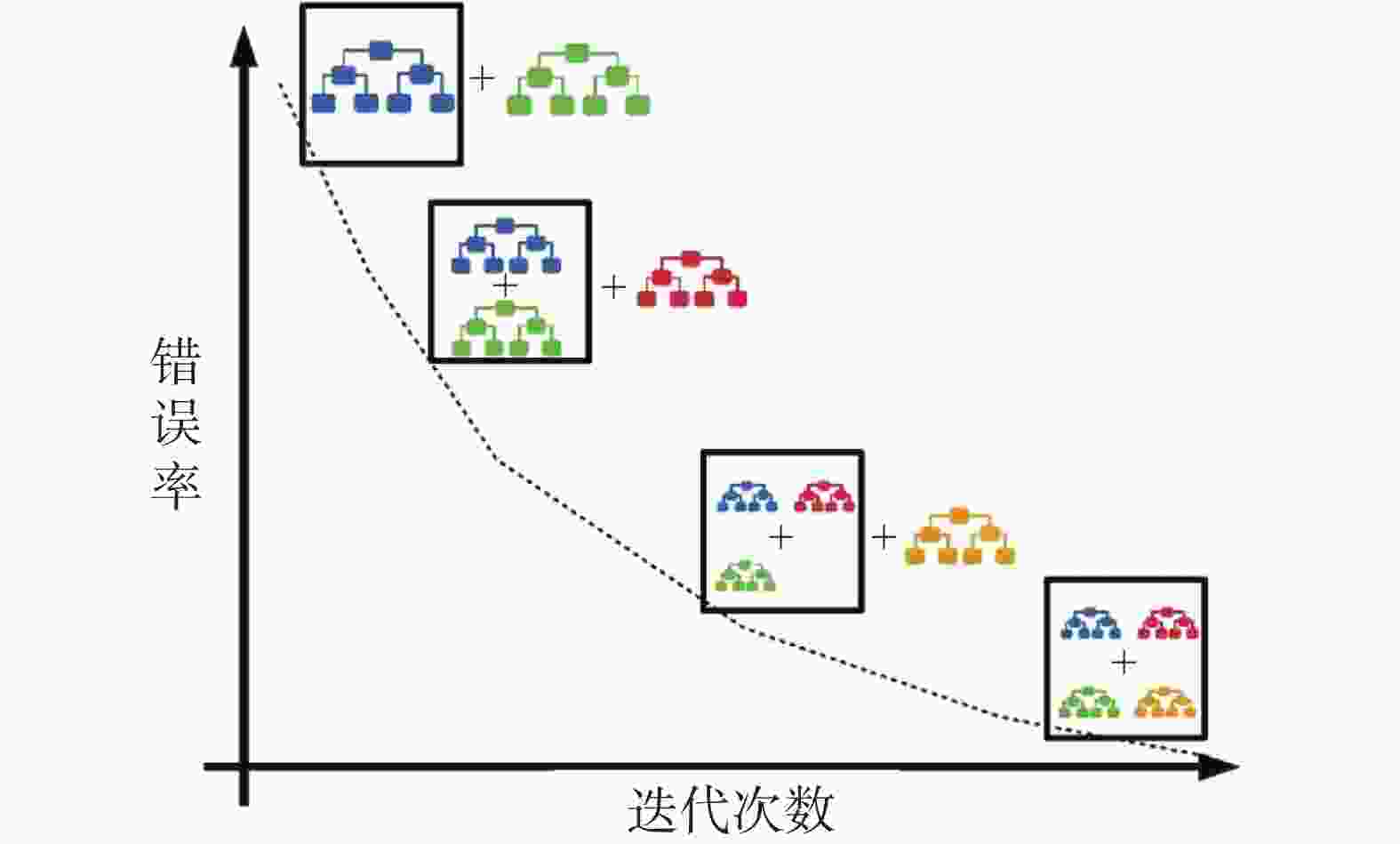

摘要: 在塔里木盆地库车山前地区,盐膏层和目的层的地质条件复杂,钻井过程中面临许多挑战。这种复杂性导致井漏在钻井过程中频繁发生,带来巨大的经济损失。研究采用LightGBM算法建立了井漏判断模型,LightGBM模型判别性能较好,平均召回率为85%,精确率为91%,F1-Socre为86.7%。同时利用了基于SHAP值的可解释性机器学习技术分别针对单次井漏事件和所有井漏事件进行分析。SHAP值方法基于合作博弈理论,它将井漏事件的发生分解为不同特征的贡献值,以解释每个特征对于井漏事件的影响。研究发现,Δρ(钻井液密度与地层破裂压力当量钻井液密度的差值)、排量、井深和层位是导致井漏的主要影响因素。同时针对库车山前地区的盐膏层和目的层的地质情况,深入分析了层内地质影响和层间垂直分布影响。由此,现场工程师能够准确、快速地判断井漏类型,为防漏堵漏措施制定提供了有力支持。Abstract: In the Kuche piedmont structure in the Tarim Basin where complex geological conditions prevail, frequent mud losses into the salt/gypsum formations and the target zones cause huge economic losses. To identity the types of the mud losses, a judgement model is established using the LightGBM algorithm. The LightGBM model, with good discriminative performance, has average recall rate of 85%, precision of 91% and F1-Score of 86.7%. In analyzing the types of mud losses, the interpretable machine learning techniques based on SHAP values are adopted to analyze a single mud loss event and all mud loss events as a whole. The SHAP value method, which is based on Cooperative Game Theory, breaks down the occurrence of mud loss events into contribution values of different features, and explains the effects of each feature on the mud loss event. Studies show that the main factors affecting mud losses include the difference between the mud density and the equivalent density calculated from the fracture pressure of the formation, the flow rate of mud, the well depth and the formation drilled. For the geology of the salt/gypsum formations and the target zones in the Kuche piedmont structure, the effects of the formation geology and the vertical distribution of the interlayer are in depth analyzed. This study enables the field engineers to fast and accurately determine the types of mud losses, and provides a strong support to the design of measures for preventing and controlling mud losses.

-

Key words:

- Mud loss /

- LightGBM /

- Interpretable machine learning /

- Main controlling factor /

- Type of mud loss

-

表 1 模型评价指标表

井漏类型 召回率 精确率 F1-Score 诱导裂缝型漏失 0.88 0.97 0.92 裂缝扩展型漏失 0.96 0.76 0.85 天然裂缝型漏失 0.71 1.00 0.83 表 2 克深区带盐膏层和目的层漏失类型

层位 代号 主要漏失成因类型 次要漏失成因类型 盐膏层 上泥岩段 E1-2km1 诱导裂缝型 裂缝扩展型 盐岩段 E1-2km2 诱导裂缝型 裂缝扩展型 中泥岩段 E1-2km3 诱导裂缝型 裂缝扩展型 膏岩段 E1-2km4 诱导裂缝型 天然裂缝型漏失 下泥岩段 E1-2km5 天然裂缝型漏失 裂缝扩展型 目的层 第一段 K1bs1 天然裂缝型漏失 裂缝扩展型 第二段 K1bs2 天然裂缝型漏失 裂缝扩展型 第三段 K1bs3 裂缝扩展型 天然裂缝型漏失 -

[1] MESSENGER J U. Lost circulation[M]. United States, 1981. [2] 徐同台. 钻井工程防漏堵漏技术[M]. 北京: 石油工业出版社, 2021.XU Tongtai. Lost circulation prevention and plugging technology for drilling engineering[M]. Beijing: Petroleum industry press, 2021. [3] NAYBERG T M. Laboratory study of lost circulation materials for use in both oil-based and water-based drilling muds[J]. SPE Drilling & Completion, 1987, 2(3):229-236. [4] HOWARD G C, SCOTT P P, J. An analysis and the control of lost circulation[J]. Journal of Petroleum Technology, 1951, 3(6):171-182. doi: 10.2118/951171-G [5] 熊继有,程仲,薛亮,等. 随钻防漏堵漏技术的研究与应用进展[J]. 钻采工艺,2007,30(2):7-10,19.XIONG Jiyou, CHENG Zhong, XUE Liang, et al. Research and application of leak resistance and sealing technology while drilling[J]. Drilling & Production Technology, 2007, 30(2):7-10,19. [6] 王茜,张菲菲,李紫璇,等. 基于钻井模型与人工智能相耦合的实时智能钻井监测技术[J]. 石油钻采工艺,2020,42(1):6-15.WANG Qian, ZHANG Feifei, LI Zixuan, et al. Real-time intelligent drilling monitoring technique based on the coupling of drilling model and artificial intelligence[J]. Oil Drilling & Production Technology, 2020, 42(1):6-15. [7] 陈凯枫,杨学文,宋先知,等. 基于工程录井数据的井漏智能诊断方法[J]. 石油机械,2022,50(11):16-22.CHEN Kaifeng, YANG Xuewen, SONG Xianzhi, et al. An intelligent diagnosis method for lost circulation based on engineering logging data[J]. China Petroleum Machinery, 2022, 50(11):16-22. [8] 蔺研锋,闵超,代博仁,等. 基于动态特征和深度神经网络的钻井漏失事故预测[J]. 西安石油大学学报(自然科学版),2022,37(3):64-69.LIN Yanfeng, MIN Chao, DAI Boren, et al. Prediction of drilling leakage accident based on dynamic features and deep neural network[J]. Journal of Xi'an Shiyou University(Natural Science Edition) , 2022, 37(3):64-69. [9] 张欣,田英英,韩泽龙,等. 基于机器学习算法的井漏预测与诊断理论模型研究[J]. 钻探工程,2022,49(2):58-66.ZHANG Xin, TIAN Yingying, HAN Zelong, et al. Research on lost circulation prediction and diagnosis theoretical model based on machine learning algorithm[J]. Drilling Engineering, 2022, 49(2):58-66. [10] 李根生,宋先知,田守嶒. 智能钻井技术研究现状及发展趋势[J]. 石油钻探技术,2020,48(1):1-8.LI Gensheng, SONG Xianzhi, TIAN Shouceng. Intelligent drilling technology research status and development trends[J]. Petroleum Drilling Techniques, 2020, 48(1):1-8. [11] SLACK D, HILGARD S, JIA E, et al. Fooling LIME and SHAP: adversarial attacks on post hoc explanation methods[C]//Proceedings of the AAAI/ACM Conference on AI, Ethics, and Society. New York, NY, USA: Association for Computing Machinery, 2020: 180-186. [12] 李宁,李龙,王涛,等. 库车山前盐膏层与目的层漏失机理分析与治漏措施研究[J]. 广州化工,2020,48(11):101-103.LI Ning, LI Long, WANG Tao, et al. The study of leakage mechanism and plugging measures of gypsum-salt formations and target zones in the Tian mountain front block in tarim basin[J]. Guangzhou Chemical Industry, 2020, 48(11):101-103. [13] CHEN T Q, GUESTRIN C. XGBoost: A scalable tree boosting system[C]//Proceedings of the 22nd acm sigkdd international conference on knowledge discovery and data mining. San Francisco, California, USA: Association for Computing Machinery, 2016: 785-794. [14] MARCÍLIO W E, ELER D M. From explanations to feature selection: assessing SHAP values as feature selection mechanism[C]//2020 33rd SIBGRAPI Conference on Graphics, Patterns and Images (SIBGRAPI). Porto de Galinhas, Brazil: IEEE, 2020: 340-347. [15] 王雅蓉,雨松,王桂同,等. 库车山前复合盐膏层复杂事故处理及分析[J]. 石化技术,2020,27(7):119-120.WANG Yarong, YU Song, WANG Guitong, et al. Treatment and analysis of complex accidents of compound salt gypsum layer in front of Kuqa mountain[J]. Petrochemical Industry Technology, 2020, 27(7):119-120. [16] 王建华,闫丽丽,谢盛,等. 塔里木油田库车山前高压盐水层油基钻井液技术[J]. 石油钻探技术,2020,48(2):29-33.WANG Jianhua, YAN Lili, XIE Sheng, et al. Oil-Based drilling fluid technology for high pressure brine layer in Kuqa piedmont of the Tarim oilfield[J]. Petroleum Drilling Techniques, 2020, 48(2):29-33. [17] 宗世玉,邹林兵,史方,等. 塔里木盆地库车山前盐膏层钻井技术应用[J]. 石油工业技术监督,2021,37(10):14-16,29.ZONG Shiyu, ZOU Linbing, SHI Fang, et al. Drilling technology for Kuqa piedmont salt gypsum layer in Tarim basin[J]. Technology Supervision in Petroleum Industry, 2021, 37(10):14-16,29. -

下载:

下载: