Application and Mechanisms of Dopa Biomimetic Lubricant in Water Based Drilling Fluids

-

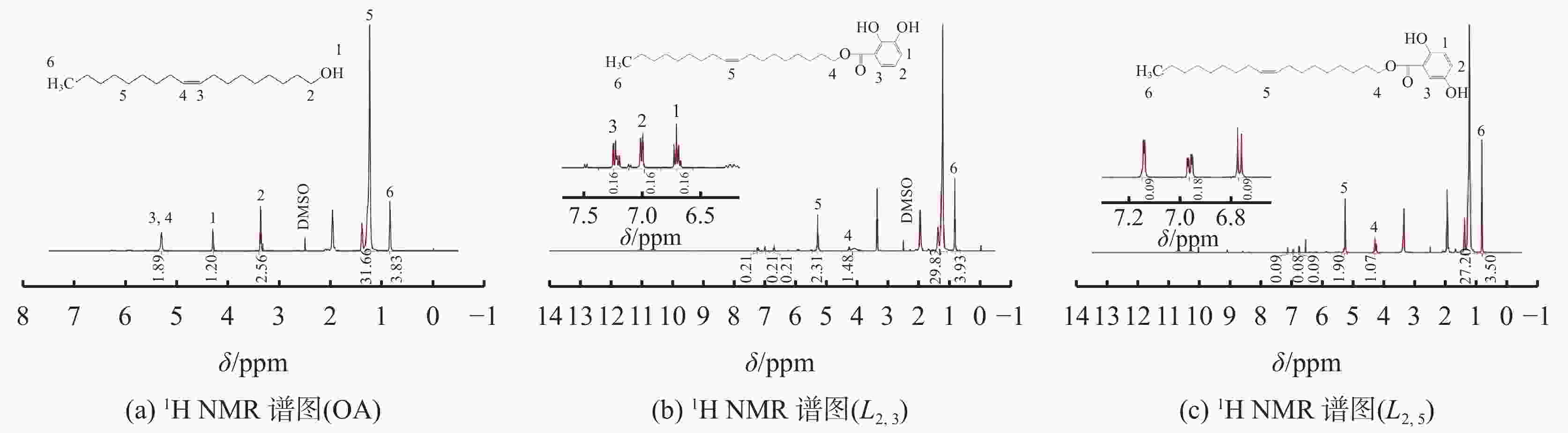

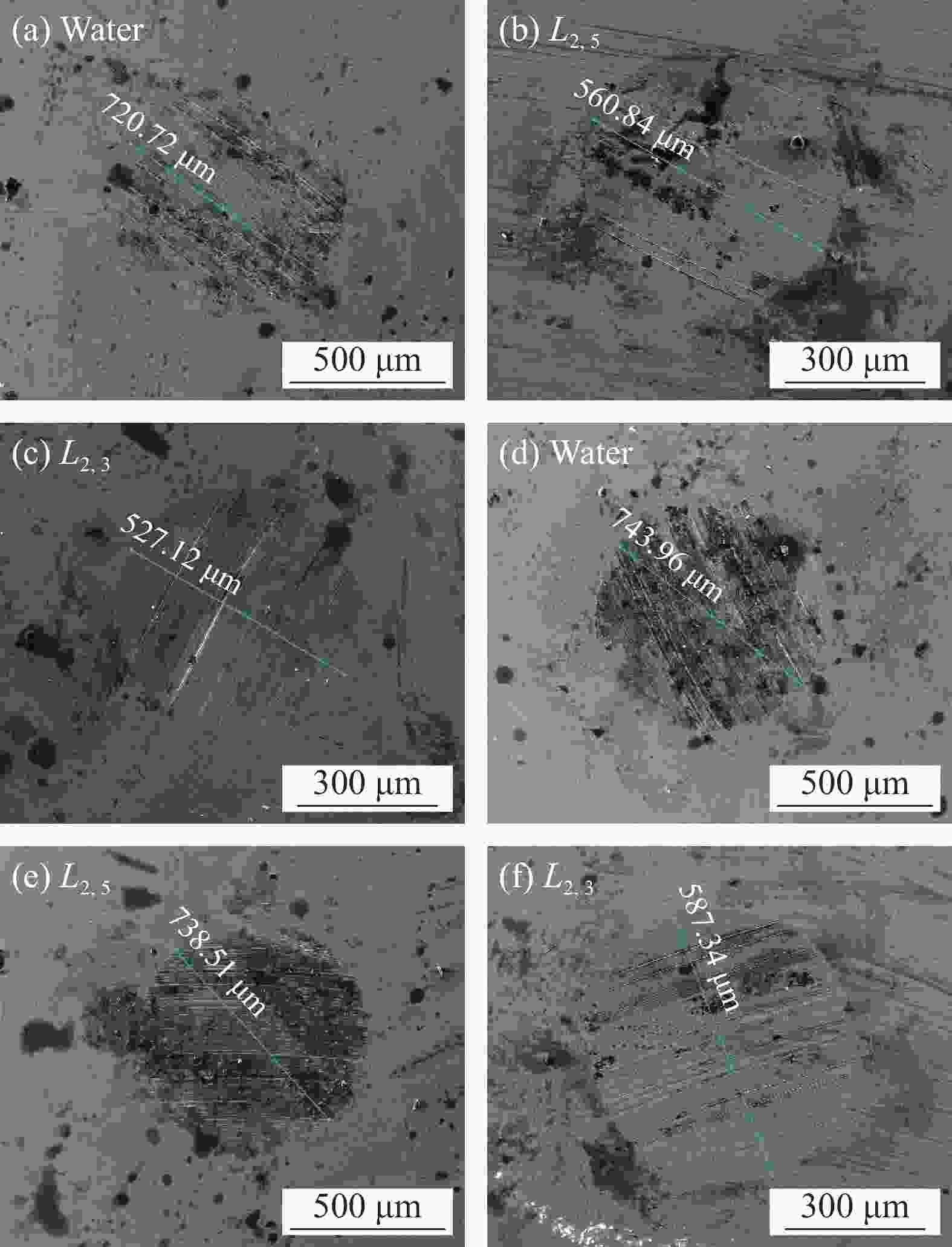

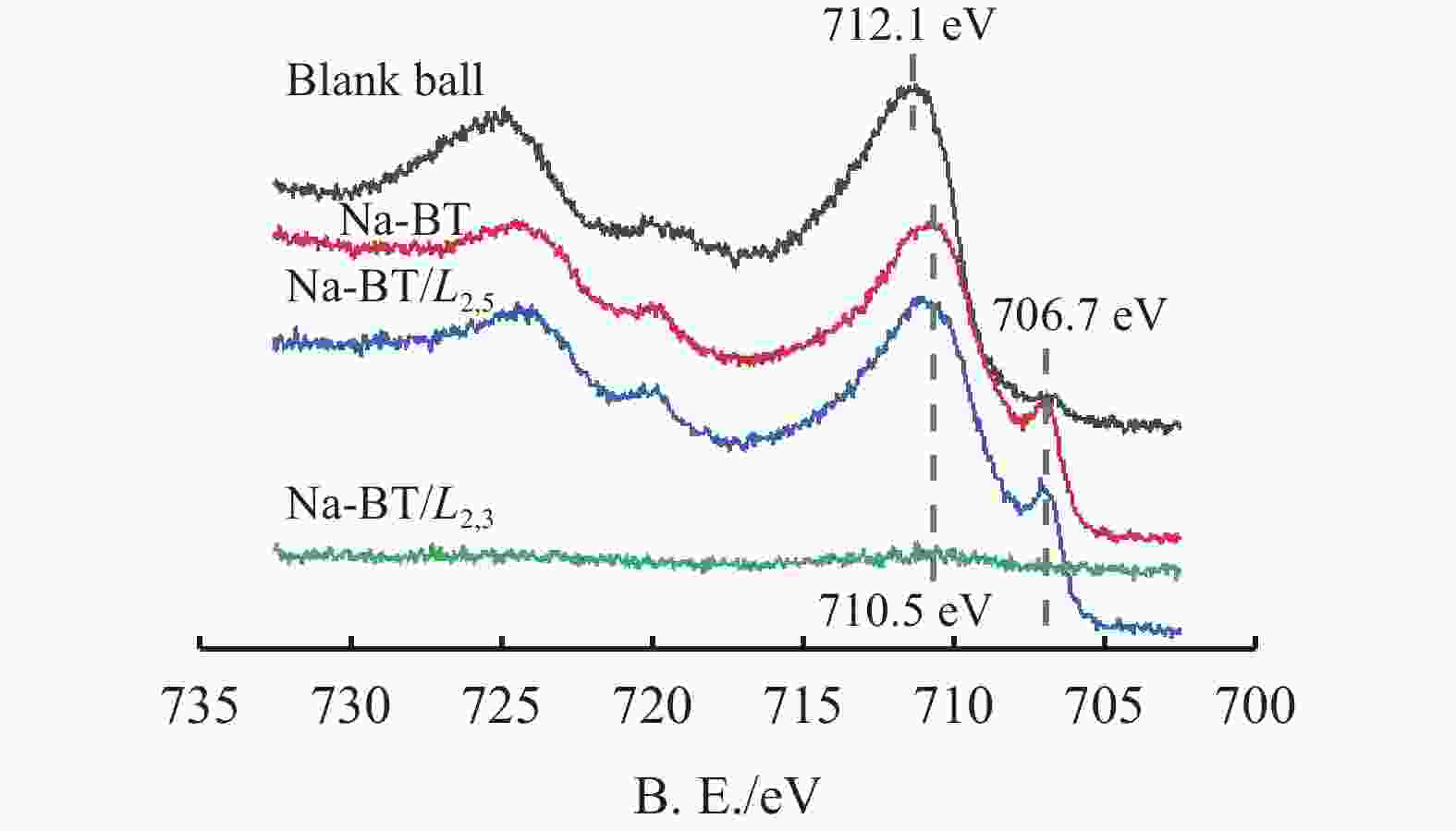

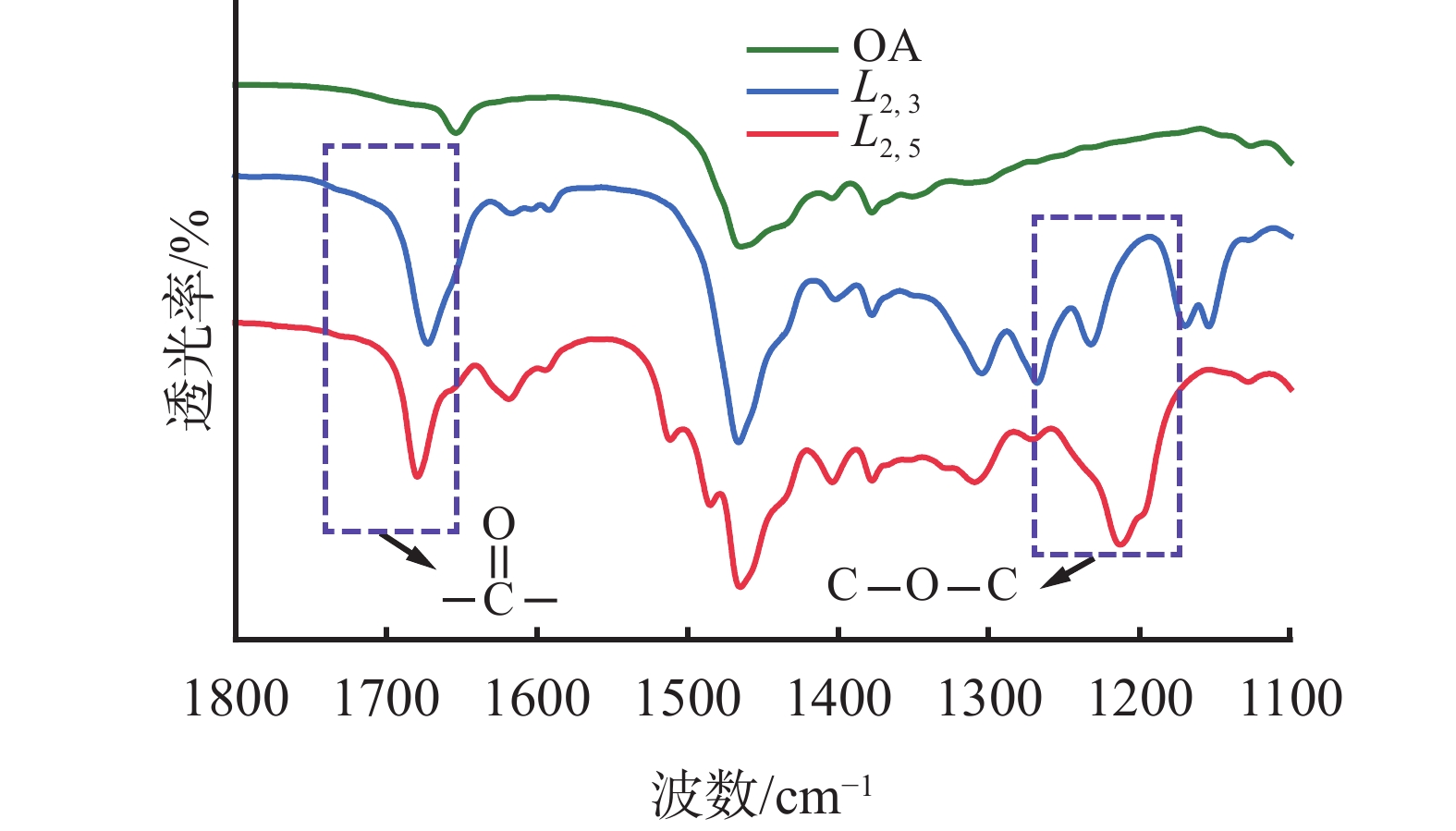

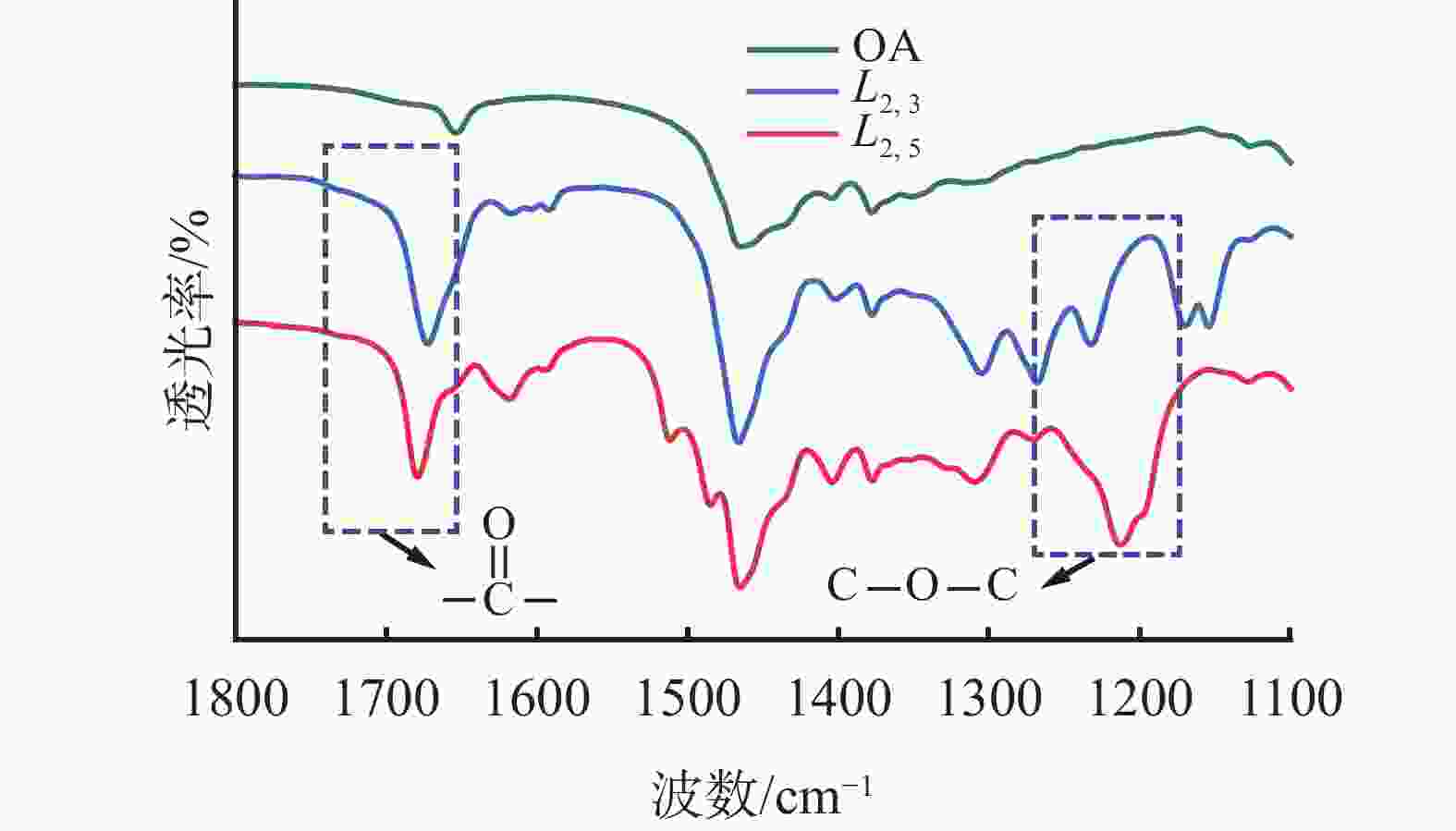

摘要: 利用多巴强大的水下黏附性能,合成了一种适用于水基钻井液的多巴仿生润滑剂L2,3。这种新型润滑剂解决了长期以来酯类润滑剂在水中因黏附性较差无法在钻具表面形成有效润滑膜而导致的润滑性能变差的问题。此外,合成了酚羟基位置不同的润滑剂L2,5,并通过FT-IR光谱和1H NMR对其进行表征。通过极压润滑仪、泥饼黏附系数测试仪、四球摩擦仪和扫描电子显微镜(SEM)评估润滑性能和耐磨性。在钠基膨润土基浆(Na-BT)中, L2,3具有最好的润滑性能,1%加量下摩擦系数(COF)低至0.07,COF降低率达到87.7%,磨痕直径(WSD)为0.587 mm,在210 ℃以内,均能保持良好的润滑性能且不起泡。相比之下,L2,5在清水中润滑性较好,摩擦系数为0.1,但在Na-BT中无法抵御黏土颗粒的剪切,润滑膜脱落,摩擦系数为0.57,接近未添加润滑剂的空白Na-BT。通过X射线光电子能谱(XPS)分析了表面润滑膜的成分和厚度,发现酚羟基结构提高了润滑剂在金属表面的黏附能力,进而提高了其润滑和抗磨性能,具体还与酚羟基类型有关。含有邻苯二酚结构的L2,3通过双齿金属配位键在金属表面形成了一层致密的厚度超过80 nm的有机膜;而含有对位羟基结构的L2,5只能在表面形成一层厚度低于20 nm的润滑膜。由于L2,3在金属表面形成的双齿金属配位键更加稳定,所以其润滑和抗磨性能远高于L2,5。Abstract: A Dopa biomimetic lubricant L2,3 for water based drilling fluids was developed with Dopa which has strong adhesive capacity in water environment, and this new lubricant is expected to be able to solve the problem of poor lubrication performance of ester lubricants in water because of the poor adhesivity of the esters on the surfaces of drilling tools in water. Another lubricant L2,5 with phenolic hydroxyl groups on different positions in the molecules of the lubricant was also synthesized and characterized by FT-IR and 1H NMR. The lubricity and wear resistance of the two lubricants were evaluated using extreme pressure lubricity tester, mud cake adhesion coefficient tester, four-ball friction tester and SEM. L2,3 in sodium bentonite (Na-BT) based fluid has the best lubricity, the coefficient of friction (COF) of an Na-BT based fluid treated with 1% L2,3 is as low as 0.07, a percent reduction of COF of 87.7%, and the wear scar diameter (WSD) is 0.587 mm. At temperatures less than 210 °C, the base fluid has good lubricity and does not foam. The L2,5 lubricant, on the other hand, has goo lubricity in fresh water, with COF of 0.1, while in Na-BT based fluid, the lubrication film of the lubricant is unable to resist the shear of the clay particles and is damaged, and the COF is 0.57, a value close to the COF of the blank base fluid. Analyses of the components and thickness of the lubrication film with XPS show that the phenolic hydroxyl groups help enhance the adhesion ability of the lubricant on the surfaces of the metals, hence improving the lubricity and wear resistance of the lubricant. The performance of the lubricants has a relation to the type of the phenolic hydroxyls. The L2,3, which contains catechol structure, can form a dense organic film of 80 nm in thickness on the surfaces of a metal through bidentate metal coordination bonds, while L2,5 containing para-hydroxyl groups can only form a film of less than 20 nm on the surfaces of the metal. Compared with the L2,5 lubricant, the L2,3 lubricant has better lubricity and wear resistance because it can form more stable bidentate metal coordination bonds on the surfaces of metals.

-

表 1 润滑剂L2,3和L2,5在清水中或钠膨润土浆的极压润滑系数

样品 极压润滑系数 润滑系数降低率/% 清水 0.37 清水+1% L2,3 0.08 78.4 清水+1% L2,5 0.16 56.8 Na-BT 0.56 Na-BT+1% L2,3 0.09 83.9 Na-BT+1% L2,5 0.48 14.3 表 2 润滑剂L2,3和L2,5对泥饼黏附系数和体积的影响

样品 泥饼

黏附系数黏附系数

降低率/%体积变化

率/%Na-BT 0.2672 Na-BT+1% L2,3 0.0436 83.6 0 Na-BT+1% L2,5 0.2195 17.9 0 -

[1] JIANG G C, SUN J S, HE Y B, et al. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs[J]. Engineering, 2021, 18:129-142. [2] LI M C, WU Q L, SONG K L, et al. Soy protein isolate as fluid loss additive in Bentonite-Water-Based drilling fluids[J]. ACS Applied Materials & Interfaces, 2015, 7(44):24799-24809. [3] NAVARRO A R, DANNELS W R. Maximizing drilling operations by mitigating the adverse affects of friction through advanced drilling fluid technology[C]//Presentation at the 2011 AADE National Technical Conference and Exhibition, Houston, Texas: American Association of Drilling Engineers, 2011: AADE-11-NTCE-17. [4] ESPAGNE B J L, LAMRANI-KERN S, RODESCHINI H. Biodegradable lubricating composition and use thereof in a drilling fluid, in particular for very deep reservoirs: AU-A-2010331833[P]. 2010-12-14. [5] Arumugam S, Ellappan R, Sriram G. Degradation of engine components upon exposure to chemically modified vegetable oil - Based automotive lubricant[J]. Journal of the Indian Chemical Society, 2021, 98(11):100227. doi: 10.1016/j.jics.2021.100227 [6] Pettersson A. High-performance base fluids for environmentally adapted lubricants[J]. Tribology International, 2007, 40(4):638-645. doi: 10.1016/j.triboint.2005.11.016 [7] MIAN S A, GAO X F, NAGASE S, et al. Adsorption of catechol on a wet silica surface: density functional theory study[J]. Theoretical Chemistry Accounts, 2011, 130(2):333-339. [8] GAO Z J, DUAN L J, YANG Y Q, et al. Mussel-inspired tough hydrogels with self-repairing and tissue adhesion[J]. Applied Surface Science, 2018, 427, Part B: 74-82. [9] LAVOIE M J, OSTASZEWSKI B L, WEIHOFEN A, et al. Dopamine covalently modifies and functionally inactivates parkin[J]. Nature Medicine, 2005, 11(11):1214-1221. doi: 10.1038/nm1314 [10] BURZIO L A, WAITE J H. Cross-linking in adhesive quinoproteins: studies with model decapeptides[J]. Biochemistry, 2000, 39(36):11147-11153. doi: 10.1021/bi0002434 [11] GILLICH T, BENETTI E M, RAKHMATULLINA E, et al. Self-assembly of focal point oligo-catechol ethylene glycol dendrons on titanium oxide surfaces: adsorption kinetics, surface characterization, and nonfouling properties[J]. Journal of the American Chemical Society, 2011, 133(28):10940-10950. doi: 10.1021/ja202760x [12] LI S C, LOSOVYJ Y, DIEBOLD U. Adsorption-site-dependent electronic structure of catechol on the anatase TiO2(101) surface[J]. Langmuir:the ACS Journal of Surfaces and Colloids, 2011, 27(14):8600-8604. doi: 10.1021/la201553k [13] YU M, DEMING T J. Synthetic polypeptide mimics of marine adhesives[J]. Macromolecules, 1998, 31(15):4739-4745. doi: 10.1021/ma980268z [14] KHARE E, HOLTEN-ANDERSEN H, BUEHLER M J, et al. Transition-metal coordinate bonds for bioinspired macromolecules with tunable mechanical properties[J], Nature Reviews Materials, 2021, 6(5): 421-436. [15] MIAN S A, YANG L M, SAHA L C, et al. A fundamental understanding of catechol and water adsorption on a hydrophilic silica surface: exploring the underwater adhesion mechanism of mussels on an atomic scale[J]. Langmuir:the ACS Journal of Surfaces and Colloids, 2014, 30(23):6906-6914. doi: 10.1021/la500800f [16] LI S C, CHU L N, GONG X Q, et al. Hydrogen bonding controls the dynamics of catechol adsorbed on a TiO2(110)surface[J]. Science & Technology Libraries, 2010, 328(5980):882-884. [17] BOYDE S. Hydrolytic stability of synthetic ester lubricants[J]. Lubrication Science, 2000, 16(4):297-312. [18] WILSON D, LANGELL M A. XPS analysis of oleylamine/oleic acid capped Fe3O4 nanoparticles as a function of temperature[J]. Applied Surface Science, 2014, 303:6-13. doi: 10.1016/j.apsusc.2014.02.006 [19] PATRICK C R, PROSSER G S. A molecular complex of benzene and hexafluorobenzene[J]. Nature, 1960, 187:1021. [20] FOXENBERG E W, Ali S A, LONG T P, et al. Field experience shows that new lubricant reduces friction and improves formation compatibility and environmental impact[C]//Paper presented at the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA: 2008: SPE-112483-MS. [21] LEE B P, HUANG K, NUNALEE F N, et al. Synthesis of 3, 4-dihydroxyphenylalanine (DOPA) containing monomers and their co-polymerization with PEG-diacrylate to form hydrogels[J]. Journal of Biomaterials Science. Polymer Edition, 2004, 15(4):449-464. doi: 10.1163/156856204323005307 [22] NORTH M A, DEL GROSSO C A, WILKER J J. High strength underwater bonding with polymer mimics of mussel adhesive proteins[J]. Acs Applied Materials & Interfaces, 2017, 9(8):7866-7872. [23] LEE B P, CHAO C Y, NUNALEE F N, et al. Rapid gel formation and adhesion in photocurable and biodegradable block copolymers with high DOPA content[J]. Macromolecules, 2006, 39(5):1740-1748. doi: 10.1021/ma0518959 -

下载:

下载: