Study on Methods of Evaluating Plugging Capacity of Nanometer and Micrometer Sized Plugging Agents for Shale Formations

-

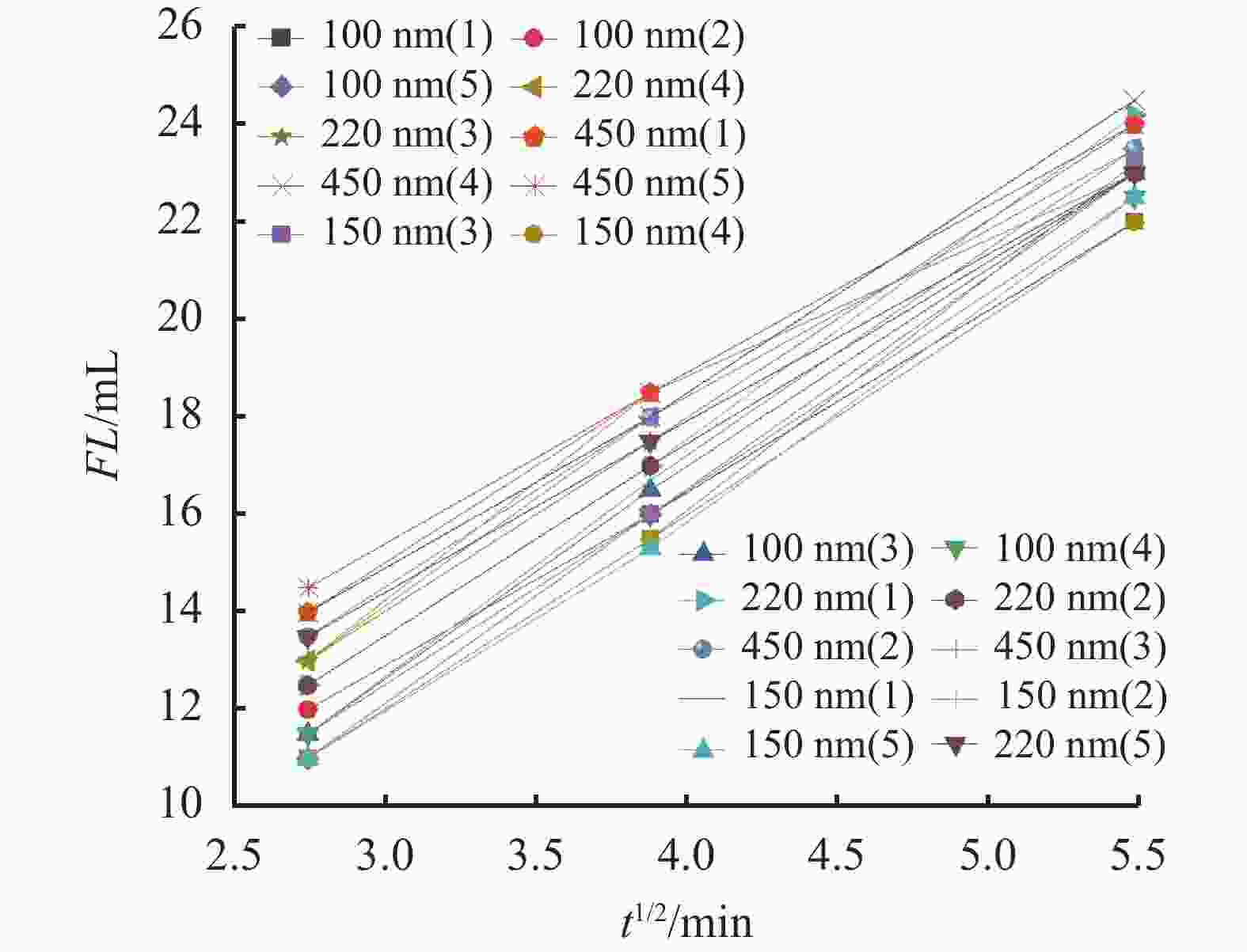

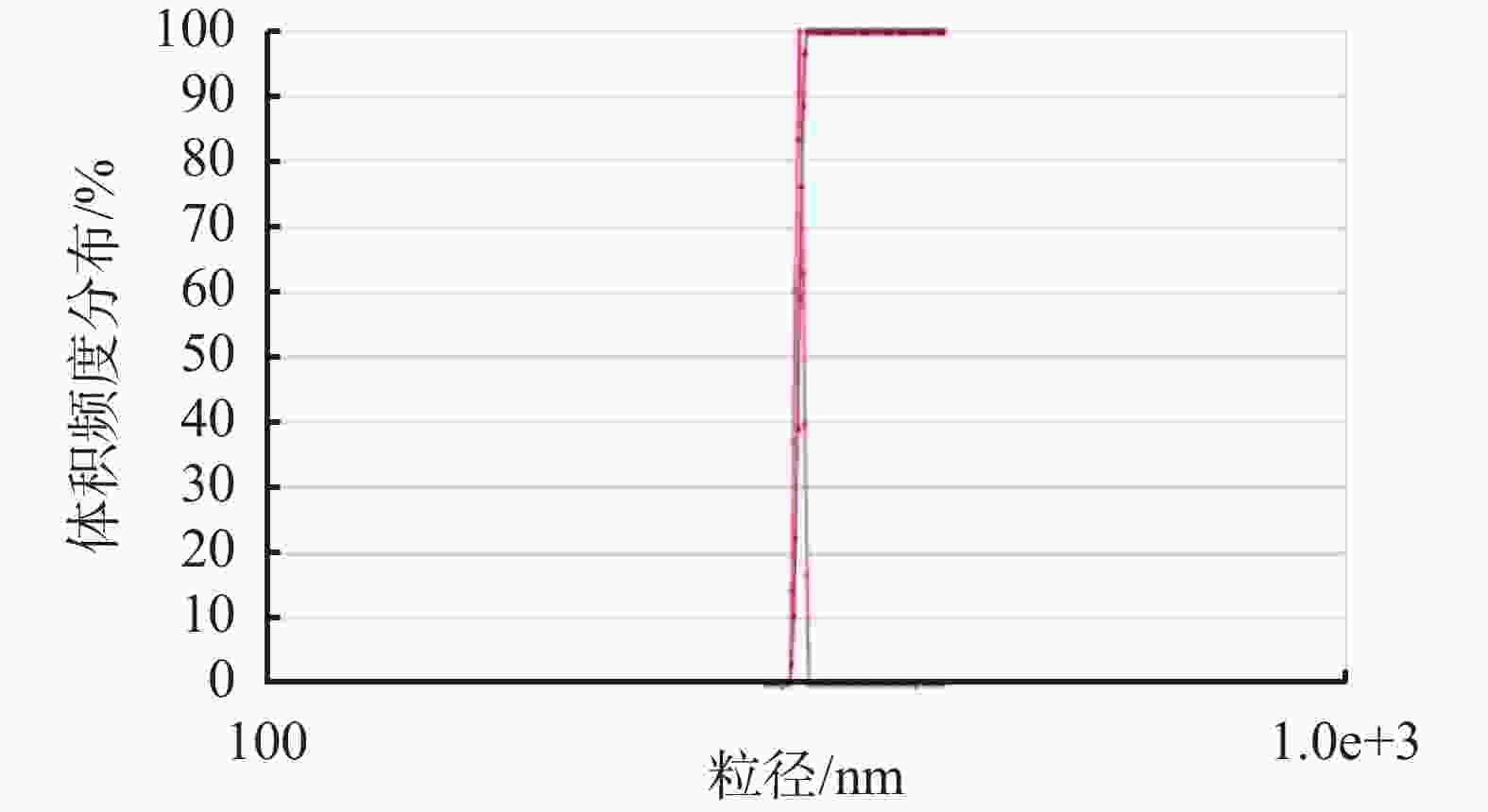

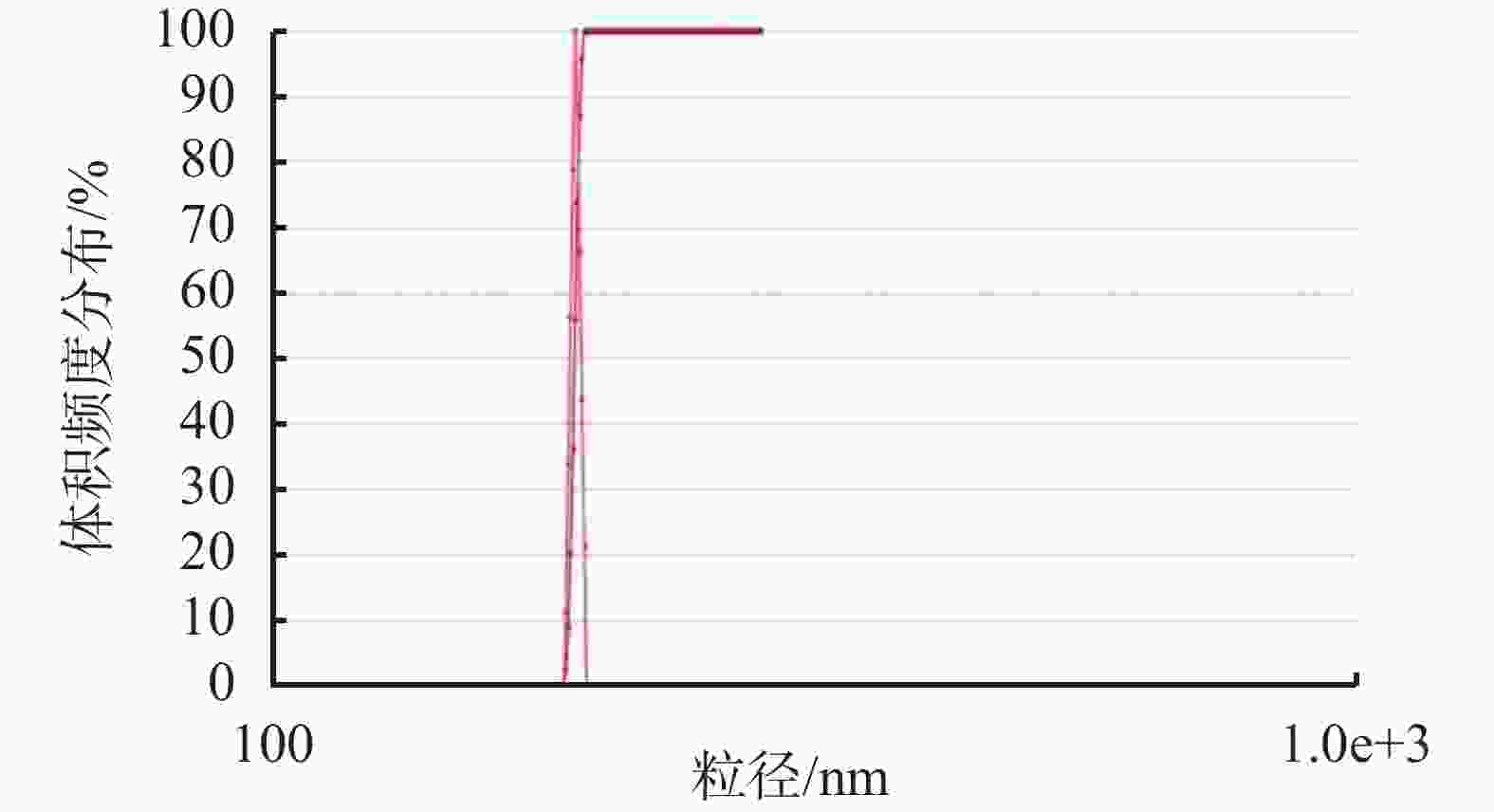

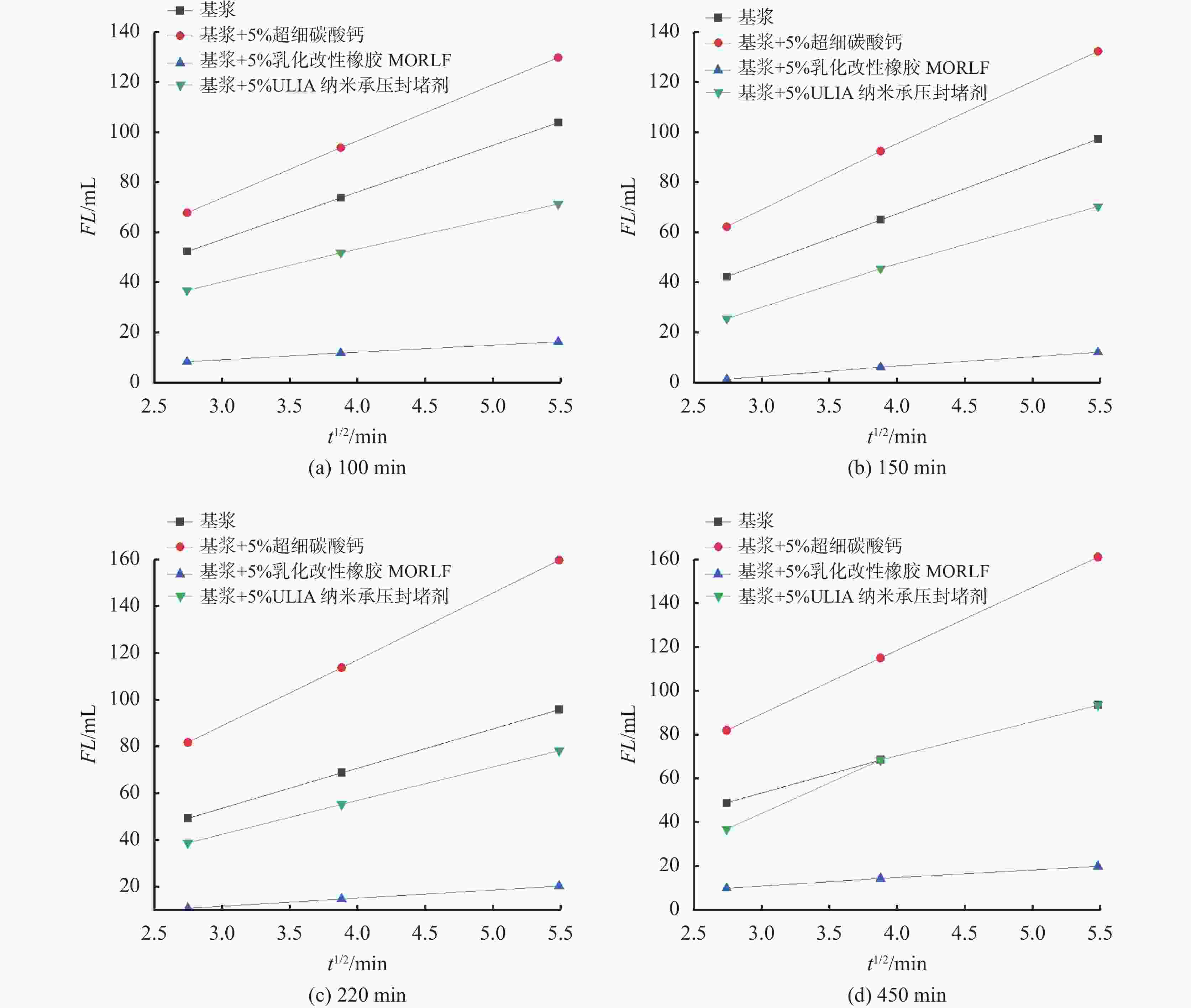

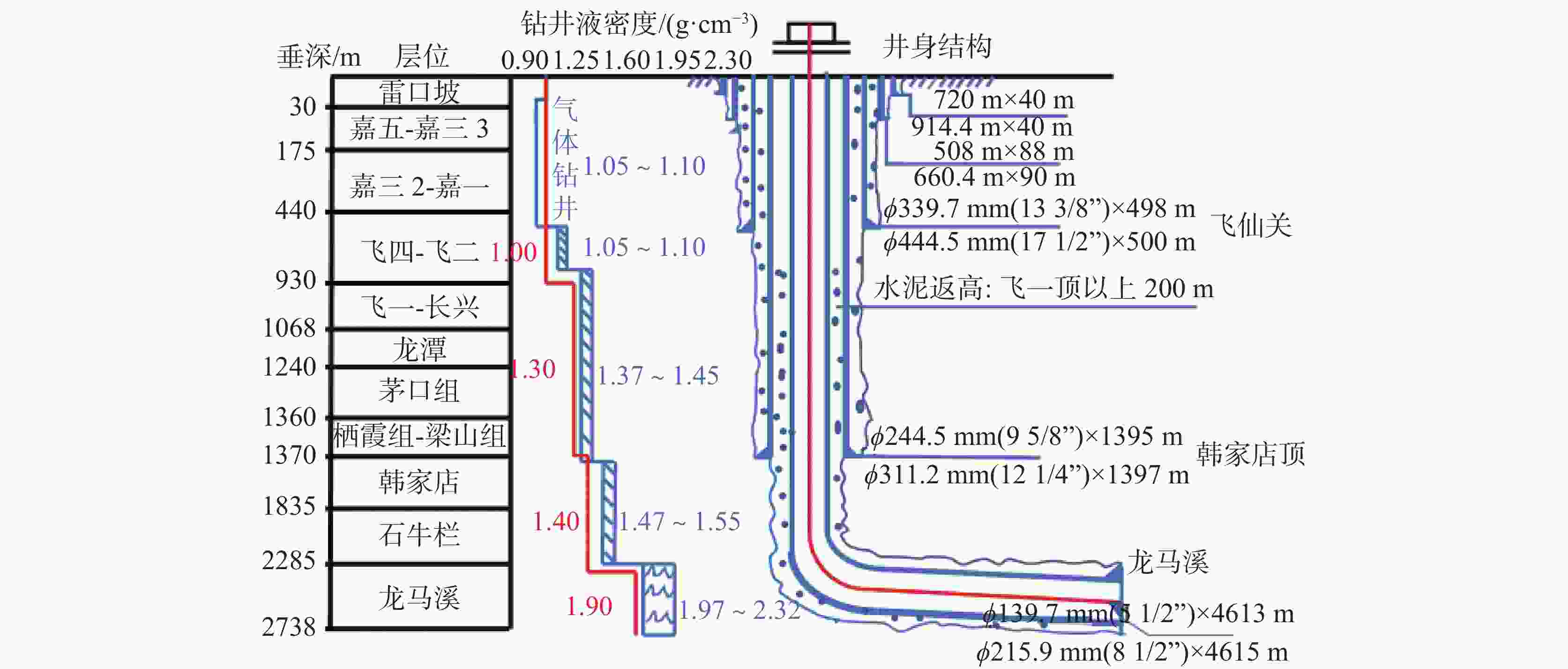

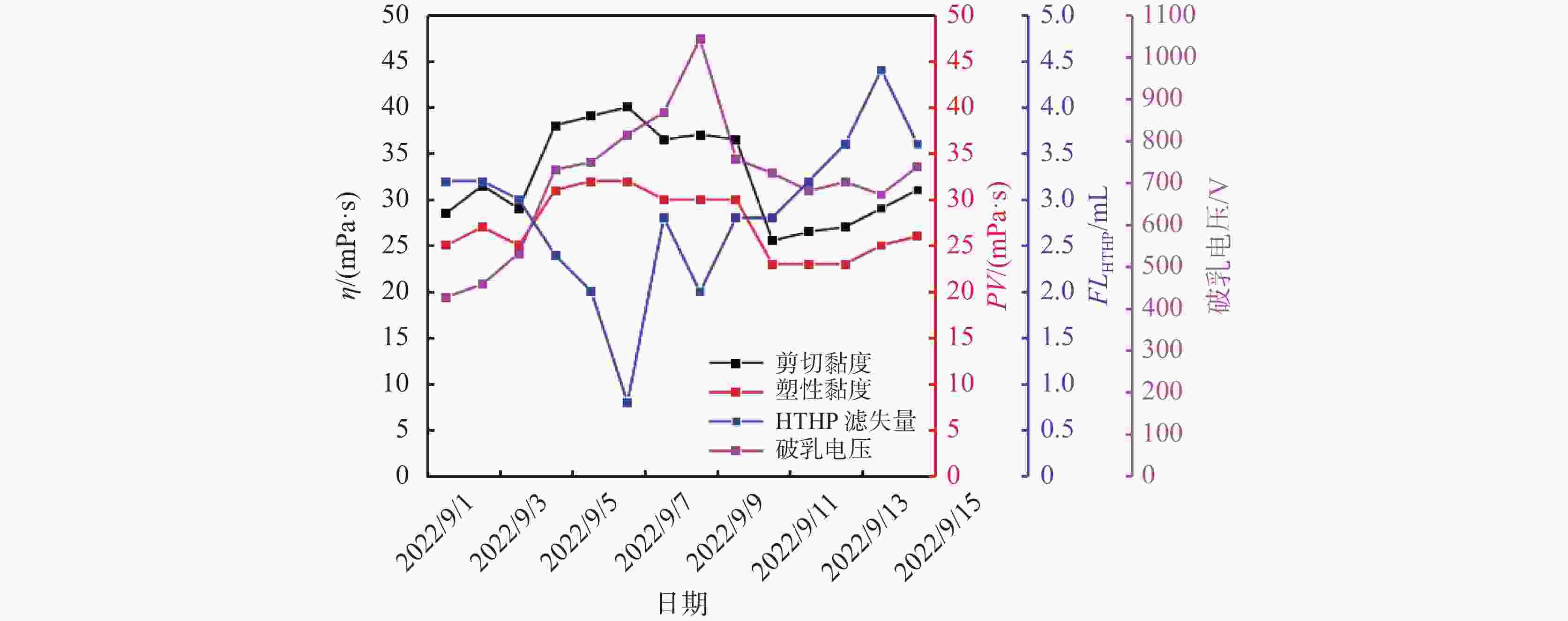

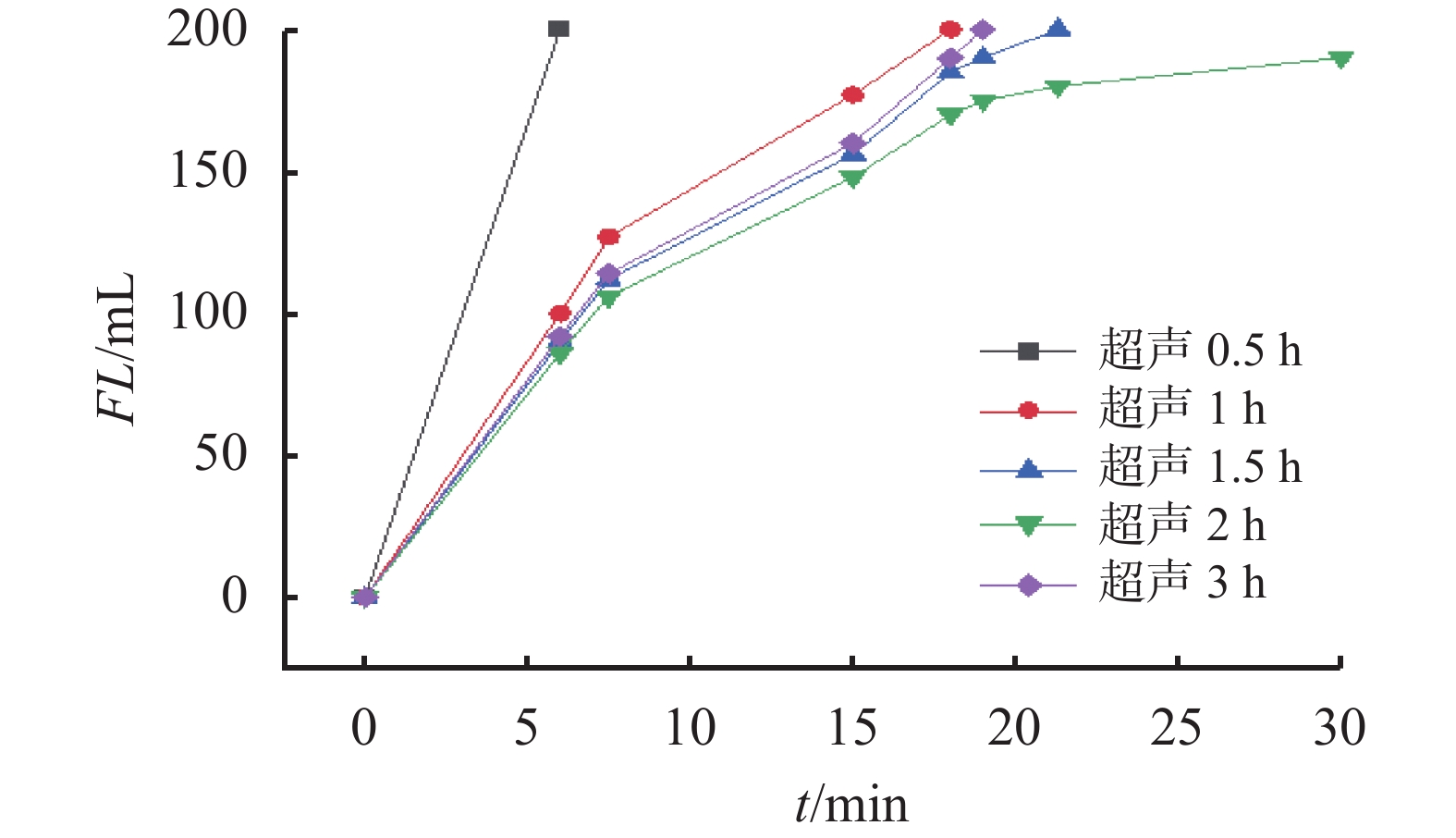

摘要: 纳微米封堵剂种类虽然较多,目前的评价方法从纳微米尺度评价封堵剂性能的准确性和有效性不足,且没有统一的标准。针对纳微米封堵剂的评价方法问题,选用了纳米孔膜和致密砂床作为介质模拟页岩地层微裂隙,以滤失量和砂床湿润深度作为指标来评价纳微米封堵剂的封堵性能。纳米孔膜法使用100~450 nm孔径的滤膜,平行实验数据拟合线波动很小,适用于评价35~450 nm的纳微米封堵剂;致密砂床法使用200目石英砂填充,多组实验数据方差值为0.2131、平行性好,适用于评价24.6~500 μm的纳微米封堵剂。采用该方法对3种粒径差别较大的封堵剂超细碳酸钙、乳化改性橡胶MORLF、ULIA纳米承压封堵剂进行了评价,优选出具有形变性的乳化改性橡胶MORLF为最优纳米封堵剂。建立方法和优选出的纳米封堵剂在长宁区块现场应用7口井,与同区块采用常规油基钻井液的其他已完钻井相比,复杂地层的井径扩大率平均降低12.74%、建井周期平均缩短12 d,进一步证实评价方法具有平行性和准确性。Abstract: Methods presently in use for evaluating the performance of many kinds of plugging agents in nanometer and micrometer levels still lack the required accuracy and effectiveness, and no commonly followed standards are available. To deal with these problems, a mesoporous membrane and a dense sand-bed are selected as the media to simulate the microfractures in shale formations, and the filtration rate and the wetted depth of the sand-bed are used as the indices for evaluating the performance of a nanometer or micrometer plugging agents. The mesoporous membrane method uses a filter membrane with pore sizes between 100 nm and 450 nm, the fitting lines of the parallel experimental data have minimal fluctuations, and this method is thus suitable for evaluating the performance of the plugging agents with particle sizes distributed between 35 nm and 450 nm. The dense sand-bed method uses 200-mesh quartz sands as the packing material, and the variance of several experimental data is 0.2131, meaning that the parallelism of the experiments is good. This method is suitable for evaluating plugging agents with particle sizes distributed between 500 nm and 24.6 μm. Using this method, three ultra-fine plugging agents with big differences in particle sizes, which are ultra-fine calcium carbonate, emulsified rubber MORLF and ULIA, were evaluated for their performance, and the MORLF with deformability, was finally selected as the most suitable nanometer plugging agent. The evaluation methods presented and the nanometer-sized plugging agents have been applied on 7 wells drilled in the Changning block. Compared with other wells drilled with conventional oil based drilling fluids, the average percent hole washout of the 7 wells is reduced by 12.74%, and average drilling time reduced by 12 d, further proving that the methods presented have good parallelism and high accuracy.

-

表 1 水测砂床的滤失实验结果

序号 300目砂∶200目砂 FL/mL t滤失/s 填砂高度/cm 1# 10∶0 100 247 7.9 2# 10∶0 100 275 7.9 3# 5∶5 100 176 7.0 4# 7∶3 100 300 6.9 5# 8∶2 100 427 6.8 6# 9∶1 100 400 7.1 7# 9∶1 100 309 7.0 表 2 4%膨润土基浆在200 g砂床中的滤失实验

细砂目数 比例 FL/mL t滤失/s 填砂高度/cm 300∶200 8∶2 14 1800 7.00 300∶200 8∶2 6 1800 6.90 200 0 1800 7.50 150 0 1800 7.30 表 3 4%膨润土基浆在400 g砂床中的滤失实验

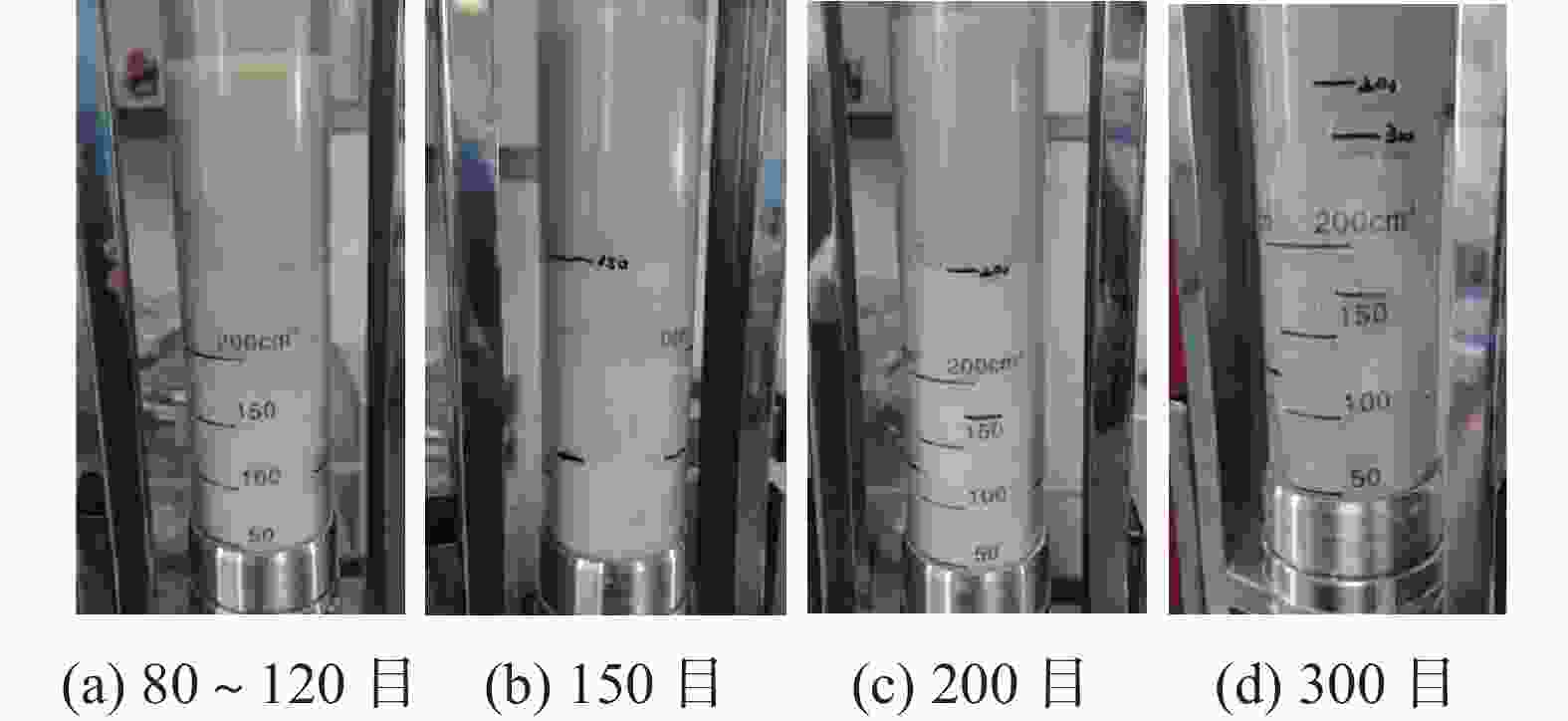

细砂目数 FL/mL t滤失/s 湿润高度/cm 80~120 0 1800 8.20 150 0 1800 7.30 200 0 1800 5.65 表 4 砂床滤失重复实验结果

石英砂/

目湿润高度/cm 平均值/cm 方差 1 2 3 4 5 6 80~120 8.3 8.5 9.6 8.7 8.30 8.2 8.60 0.226 667 150 8.1 6.8 7.3 7.3 8.20 7.6 7.550 0.235 833 200 5.9 6.5 5.5 6.7 5.65 5.6 5.975 0.213 125 表 5 平行性分析实验结果

纳米孔膜孔径/

nm组数 FL/mL 瞬时滤失量/

mL7.5 min 15 min 30 min 100 1 11.0 16.0 22.0 2.0 2 12.0 16.0 23.0 1.5 3 11.5 16.5 23.0 2.0 4 11.5 16.0 22.5 1.5 5 11.0 16.0 23.0 2.0 150 1 11.5 16.5 23.0 2.5 2 11.5 16.7 23.5 2.0 3 11.0 15.5 23.2 2.0 4 11.0 15.5 22.0 2.5 5 11.0 15.3 22.5 2.0 220 1 13.0 18.0 23.5 3.5 2 12.5 17.0 24.2 3.0 3 12.5 17.0 23.0 3.5 4 13.0 17.5 24.0 4.5 5 13.5 17.5 23.0 4.0 450 1 14.0 18.5 24.0 4.5 2 13.5 18.0 23.5 4.5 3 13.0 18.5 23.0 5.0 4 14.0 18.0 24.5 5.5 5 14.5 18.5 24.0 5.0 表 6 基浆对200目石英砂填充的致密砂床滤失重复实验

次数/次 湿润深度/cm 次数/次 湿润深度/cm 1 5.9 4 6.70 2 6.5 5 5.65 3 5.5 6 5.60 表 7 致密砂床法封堵性能评价实验结果

序号 湿润深度/cm 超细

碳酸钙乳化改性橡胶

MORLFULIA纳米

承压封堵剂1 7.8 4.0 6.2 2 8.0 3.8 6.1 3 8.3 4.1 5.9 4 7.5 3.5 6.1 5 7.9 3.9 6.2 平均值/cm 7.90 3.86 6.10 -

[1] 刘敬平,孙金声. 页岩气藏地层井壁水化失稳机理与抑制方法[J]. 钻井液与完井液,2016,33(3):5-11.LIU Jingping, SUN Jinsheng. Shale gas reservoir formation wellbore hydration instability mechanism and suppression method[J]. Drilling Fluid & Completion Fluid, 2016, 33(3):5-11. [2] 王晓军,白冬青,孙云超,等. 页岩气井强化封堵全油基钻井液体系——以长宁—威远国家级页岩气示范区威远区块为例[J]. 天然气工业,2020(6):107-114.WANG Xiaojun, BAI Dongqing, SUN Yunchao, et al. Enhanced plugging of shale gas wells with full oil-based drilling fluid system: Taking Weiyuan block of Changning-Weiyuan national shale gas demonstration area as an example[J]. Natural Gas Industry, 2020(6):107-114. [3] CHEN X , TAN C P , DETOURNAY C . A study on wellbore stability in fractured rock masses with impact of mud infiltration[J].Journal of Petroleum Science and Engineering, 2003, 38(3-4): 145-154. [4] 黄维安,邱正松,徐加放,等. 吐哈西部油田井壁失稳机理实验研究[J]. 石油学报,2007,28(3):24-28.HUANG Weian, QIU Zhengsong, XYU Jiafang, et al. Experimental study on the mechanism of wellbore instability in western Tuha oilfield[J]. Chinese Journal of Petroleum, 2007, 28(3):24-28. [5] 倪晓骁,蒋官澄,王建华,等. 油基钻井液用憎液性纳米封堵剂[J]. 钻井液与完井液,2021,38(3):298-304.NI Xiaoxiao, JIANG Guancheng, WANG Jianhua, et al. Lyphophobic nano plugging agent for oil-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2021, 38(3):298-304. [6] 刘可成,周俊,崔鑫,等. 阜康凹陷井壁失稳机理与封堵防塌油基钻井液体系[J]. 钻井液与完井液,2022,39(4):451-458.LIU Kecheng, ZHOU Jun, CUI Xin, et al. Mechanisms of borehole wall instability in Fukang sag block and an oil based drilling fluid with plugging and inhibitive capacities[J]. Drilling Fluid & Completion Fluid, 2022, 39(4):451-458. [7] 张洪伟,黄国强,吴红玲,等. 水基钻井液用石墨烯封堵剂[J]. 钻井液与完井液,2023,40(4):462-466.ZHANG Hongwei, HUANG Guoqiang, WU Hongling, et al. Study and application of a graphene lugging agent for water based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2023, 40(4):462-466. [8] 闫晶. 封堵评价用微裂缝岩心的模拟及模拟封堵实验[J]. 探矿工程(岩土钻掘工程),2018,45(5):18-21.YAN Jing. Simulation of micro-fracture cores for plugging evaluation and simulated plugging experiments[J]. Exploration Engineering(Geotechnical Drilling Engineering) , 2018, 45(5):18-21. [9] 陈良. 钻井液防塌封堵评价方法及封堵机理研究[D]. 西南石油大学, 2013.CHEN Liang. Research on the evaluation method of drilling fluid anti-slump plugging and plugging mechanism [D]. Southwest Petroleum University, 2013. [10] 赵海洋,范胜,连世鑫,等. 顺北油气田用抗高温弱凝胶防气侵钻井液体系[J]. 钻井液与完井液,2023,40(3):332-339.ZHAO Haiyang, FAN Sheng, LIAN Shixin, et al. Study on high temperature resistant weak gel anti gas invasion drilling fluid system in Shunbei oil and gas field[J]. Drilling Fluid & Completion Fluid, 2023, 40(3):332-339. [11] 左富银, 苏俊霖, 李立宗, 等. 有机纳米封堵剂的研究现状及存在问题分析[J]. 化学世界, 2020, 61(11): 733-737.ZUO Fuyin, SU Junlin, LI Lizong, et al. Research status and existing problems of organic nano plugging agents [J]. Chemistry World, 20, 61(11): 733-737. [12] 刘永贵,宋涛,徐用军. 高温深井微裂缝封堵评价方法及其应用——以松辽盆地徐深气田为例[J]. 天然气工业,2016,36(2):78-83.LIU Yonggui, SONG Tao, XU Yongjun. Evaluation method of microfracture plugging in high-temperature deep wells and its application: A case study of Xushen gas field in Songliao basin[J]. Natural Gas Industry, 2016, 36(2):78-83. [13] 徐传奇,李海燕,张小锋,等. 纳米封堵剂性能评价及机理分析[J]. 钻采工艺,2019,42(2):100-103.XYU Chuanqi, LI Haiyan, ZHANG Xiaofeng, et al. Performance evaluation and mechanism analysis of nanometer plugging agent[J]. Drilling & Production Technology, 2019, 42(2):100-103. [14] 林四元,卢运虎,张立权. 琼东南盆地高温高压井强承压堵漏技术[J]. 钻井液与完井液,2023,40(3):363-367.LIN Siyuan, LU Yunhu, ZHANG Liquan. Mud loss control technology in Qiongdongnan basin under high temperature and high pressure bearing conditions[J]. Drilling Fluid & Completion Fluid, 2023, 40(3):363-367. [15] 魏安超,刘书杰,蒋东雷,等. 裂缝性储层环氧树脂自降解堵漏剂的制备与评价[J]. 钻井液与完井液,2023,40(2):163-168.WEI Anchao, LIU Shujie, JIANG Donglei, et al. Synthesis and evaluation of epoxy resin self-degradation plugging agent for fractured formation[J]. Drilling Fluid & Completion Fluid, 2023, 40(2):163-168. -

下载:

下载: