Compound and Efficient Blockage-Removal Agent for Polymer Flooding Oilfield

-

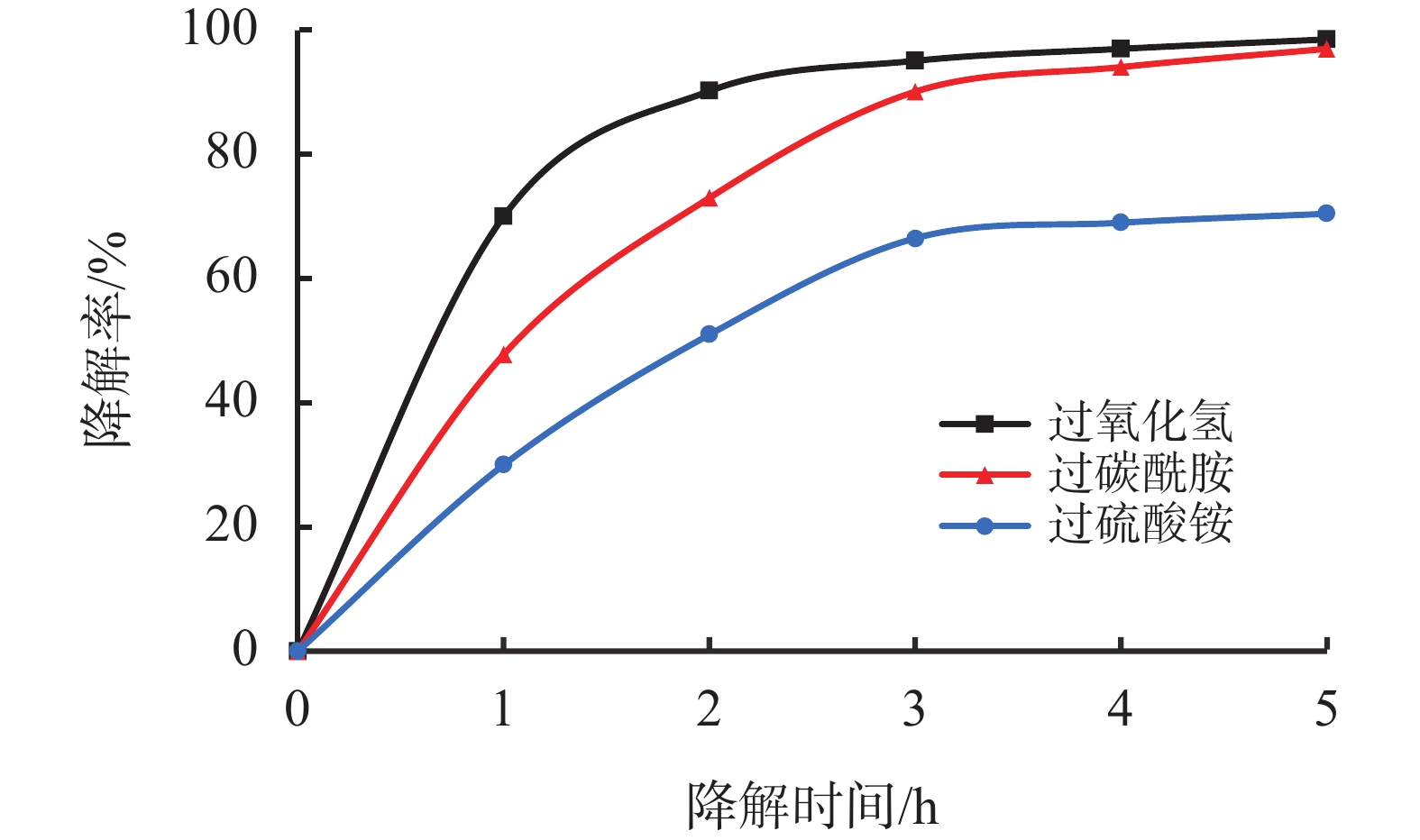

摘要: 针对聚驱油田长期注聚后形成聚合物、无机垢、稠油相互包裹的复杂堵塞物,导致地层严重堵塞的问题。以过碳酰胺为聚合物降解剂,乙酸为无机垢溶蚀剂,辛基酚聚氧乙烯醚10(OP-10)为原油清洗剂,辅以稳定剂以及缓蚀剂,形成稳定、高效的复合解堵体系。确定配方为0.6%过碳酰胺+3%乙酸+0.3%OP-10+1%二乙烯三胺五甲叉膦酸(DTPMP)+1%HSJ-3,并对体系的解堵性能、稳定性能、耐温性能以及耐矿化度性能进行评价。结果表明:在不同温度条件下,复合解堵体系均能对模拟堵塞物有效降解,80 ℃下4 h即可达到90%以上降解率,具有优良的解堵性能及耐温性能;80 ℃下放置1 h,稳定度保持在97%,具有良好的稳定性能;腐蚀速率为0.9871 g·m−2·h−1,达到行业一级标准;用15×104 mg/L高矿化度的盐水配制后,解堵效率基本无影响,耐矿化度性能优良。注入复合解堵体系后,岩心渗透率由0.244×10−3 μm2提高至6.391×10−3 μm2,渗透率提高倍数达25.192。复合解堵体系可有效地解决聚驱过程中形成的复杂堵塞物。Abstract: Aiming at the problem of complex blockages in which polymers, inorganic scales and heavy oils are wrapped around each other after long-term polymer injection in the polymer flooding oilfield, resulting in serious blockage of the formation, a stable and efficient compound blockage-removal agent with 0.6% percarbonamide, 1% acetic acid, 0.3% OP-10, 1%DTPMP, and 1%HSJ-3 was prepared. And the properties of the compound blockage-removal agent were evaluated. The results showed that the agent can effectively degrade the simulated blockages under different temperature conditions. Under the condition of 80 ℃, the degradation rate of more than 90% can be reached in 4 h, with excellent degradation performance and temperature resistance. Placed at 80 ℃ for 1 h, the stability was maintained at 97%, with good stability performance and the corrosion rate was 0.9871 g·m−2·h−1, which met the industry-level standard. When prepared with 15×104 mg/L high salinity brine, the blockage-removal efficiency was basically not affected and the salinity resistance is excellent. The compound blockage removal agent can effectively solve the complex blockages formed in the process of polymer flooding through gradual stripping and continuous degradation. After injecting the composite blockage-removal agent, the core permeability increased from 0.244×10−3 μm2 to 6.391×10−3 μm2, and the permeability increased by a factor of 25.192. The compound block-removal agent can effectively solve the complex blockages.

-

Key words:

- Polymer flooding oilfield /

- Complex blockages /

- Percarbamide /

- Compound agent

-

表 1 不同表面活性剂水溶液与原油界面张力

表面活性剂类型 界面张力/(mN ·m−1) 去离子水 35.806 辛基酚聚氧乙烯醚10(OP-10) 0.6718 N-月桂酰基氨酸钠(SNS) 1.1152 聚氧乙烯十二烷基醚硫酸钠(SLES) 1.4230 α-烯基磺酸钠(AOS) 2.0181 十二烷基苯磺酸钠(SDBS) 2.2979 吐温80 4.0202 表 2 正交实验设计表

水平 因素 过碳酰胺/% OP-10/% 酸液/% 1 0.3 0.2 1 2 0.4 0.3 2 3 0.5 0.4 3 4 0.6 0.5 4 表 3 缓蚀剂在解堵体系中缓蚀能力测量结果

T/℃ t/h 缓蚀剂 失重/g 腐蚀速率/(g·m−2·h−1) 缓蚀率/% 80 4 未添加 0.0675 12.4026 HSJ-1 0.0265 4.8640 60.800 HSJ-2 0.0114 2.0956 83.111 HSJ-3 0.0054 0.9871 92.045 -

[1] 袁士义,王强. 中国油田开发主体技术新进展与展望[J]. 石油勘探与开发,2018,45(4):657-668. doi: 10.11698/PED.2018.04.11YUAN Shiyi, WANG Qiang. New progress and prospect of oilfields development technologies in China[J]. Petroleum Exploration & Development, 2018, 45(4):657-668. doi: 10.11698/PED.2018.04.11 [2] 孙龙德,伍晓林,周万富,等. 大庆油田化学驱提高采收率技术[J]. 石油勘探与开发,2018,45(4):636-645. doi: 10.11698/PED.2018.04.09SUN Longde, WU Xiaolin, ZHOU Wanfu, et al. Technologies of enhancing oil recovery by chemical flooding in Daqing Oilfield, NE China[J]. Petroleum Exploration & Development, 2018, 45(4):636-645. doi: 10.11698/PED.2018.04.09 [3] 郑俊德,张英志,任华,等. 注聚合物井堵塞机理分析及解堵剂研究[J]. 石油勘探与开发,2004(6):108-111. doi: 10.3321/j.issn:1000-0747.2004.06.029ZHENG Junde, ZHANG Yingzhi, REN Hua, et al. Blockage mechanism and blockage reducer for polymer-injection well[J]. Petroleum Exploration & Development, 2004(6):108-111. doi: 10.3321/j.issn:1000-0747.2004.06.029 [4] 高尚,刘义刚,兰夕堂,等. 渤海油田注聚合物井堵塞物组分分析及相互作用机理[J]. 油田化学,2020,37(2):340-343,380. doi: 10.19346/j.cnki.1000-4092.2020.02.027GAO Shang, LIU Yigang, LAN Xitang, et al. Component analysis and interaction mechanism of fouling in polymer flooding well in Bohai Oilfield[J]. Oilfield Chemistry, 2020, 37(2):340-343,380. doi: 10.19346/j.cnki.1000-4092.2020.02.027 [5] 高尚,张璐,刘义刚,等. 渤海油田聚驱受效井液气交注复合深部解堵工艺[J]. 石油钻采工艺,2017,39(3):375-381. doi: 10.13639/j.odpt.2017.03.022GAO Shang, ZHANG Lu, LIU Yigang, et al. In-depth combined blockage removing technology with liquid alternating gas injection for polymer flooding response wells in Bohai Oilfield[J]. Oil Drilling & Production Technology, 2017, 39(3):375-381. doi: 10.13639/j.odpt.2017.03.022 [6] CHEN H X, WANG Y F, PANG M, et al. Research on plugging mechanism and optimisation of plug removal measure of polymer flooding response well in Bohai Oilfield[C]//International Petroleum Technology Conference, 2021: 1-10. [7] 卢大艳,孟祥海,吴威,等. 渤海注聚油田堵塞井堵塞机理分析及复合解堵工艺设计[J]. 中国海上油气,2016,28(5):98-103.LU Dayan, MENG Xianghai, WU Wei, et al. Analysis on the plugging mechanism and the removal technology for polymer flooding blocks in Bohai Sea[J]. China Offshore Oil and Gas, 2016, 28(5):98-103. [8] LIRIO Q, MARY J F, KYLE M, et al. Microemulsions increase well productivity by removing organic deposits and inorganic scale in one step[C]//SPE International Conference and Exhibition on Formation Damage Control, 2018: 1-10. [9] 宋爱莉,孙林,刘春祥,等. BHJ3-D注聚井解堵剂效果评价与应用[J]. 钻采工艺,2011,34(4):76-79+6-7. doi: 10.3969/j.issn.1006-768X.2011.04.024SONG Aili, SUN Lin, LIU Chunxiang, et al. Study and application of BHJ3-D blocking remover for polymer injection well[J]. Drilling & Production Technology, 2011, 34(4):76-79+6-7. doi: 10.3969/j.issn.1006-768X.2011.04.024 [10] 姜学明,刘明立,张学昌,等. 二氧化氯与酸液协同解堵工艺与应用效果[J]. 石油勘探与开发,2002(6):103-104. doi: 10.3321/j.issn:1000-0747.2002.06.034JIANG Xueming, LIU Mingli, ZHANG Xuechang, et al. The technique of plug removal by combination of chlorine dioxide and acid solution and its application results[J]. Petroleum Exploration & Development, 2002(6):103-104. doi: 10.3321/j.issn:1000-0747.2002.06.034 [11] 樊世忠,王彬. 二氧化氯解堵技术[J]. 钻井液与完井液,2005(S1):113-116+130. doi: 10.3969/j.issn.1001-5620.2005.z1.038FAN Shizhong, WANG Bin. Chlorine dioxide plugging relief technology[J]. Drilling Fluid & Completion Fluid, 2005(S1):113-116+130. doi: 10.3969/j.issn.1001-5620.2005.z1.038 [12] 陈振. 高压注聚井解堵体系的研制与评价[D]. 中国石油大学(华东), 2016: 18.CHEN Zhen. Development and evaluation of plug removal agent for high pressure polymer flooding wells[D]. China University of Petroleum, 2016: 18. [13] 赵林,高申领,陈渊,等. 砂岩油藏聚合物堵塞机理及解堵方法研究[J]. 特种油气藏,2022,29(03):156-161. doi: 10.3969/j.issn.1006-6535.2022.03.023ZHAO Lin, GAO Shenling, CHEN Yuan, et al. Study on polymer plugging mechanism and plug removal method in sandstone reservoirs[J]. Special Oil & Gas Reservoirs, 2022, 29(03):156-161. doi: 10.3969/j.issn.1006-6535.2022.03.023 [14] 朱麟勇,常志英,李明宇,等. 聚丙烯酰胺水溶液的氧化降解作用研究[J]. 高分子材料科学与工程,2000(2):112-114. doi: 10.3321/j.issn:1000-7555.2000.02.033ZHU Linyong, CHANG Zhiying, LI Mingyu, et al. Oxidative degradation of partially hydrolyzed polyacrylamide in aqueous solution[J]. Polymer Materials Science & Engineering, 2000(2):112-114. doi: 10.3321/j.issn:1000-7555.2000.02.033 [15] 蓝强,李公让,薛玉志,等. 聚丙烯酰胺的生物降解特性[J]. 钻井液与完井液,2010,27(01):11-13+87-88. doi: 10.3969/j.issn.1001-5620.2010.01.004LAN Aiang, LI Gongrang, XUE Yuzhi, et al. Biodegradable properties of polyacrylamide[J]. Drilling Fluid & Completion Fluid, 2010, 27(01):11-13+87-88. doi: 10.3969/j.issn.1001-5620.2010.01.004 [16] 詹亚力,郭绍辉,闫光绪. 部分水解聚丙烯酰胺降解研究进展[J]. 高分子通报,2004(2):70-74. doi: 10.3969/j.issn.1003-3726.2004.02.010ZHAN Yali, GUO Shaohui, YAN Guangxu. Study on degradation of partially hydrolyzed polyacrylamide[J]. Polymer Bulletin, 2004(2):70-74. doi: 10.3969/j.issn.1003-3726.2004.02.010 [17] ZHU T Y, YANG H B, JIANG H Z, et al. Study on an emulsion-type blockage removal agent for heavy oil recovery enhanced by polymer[J]. Journal of Industrial and Engineering Chemistry, 2020, 89:273-279. doi: 10.1016/j.jiec.2020.05.023 [18] WANG F, YANG H B, JIANG H Z, et al. Formation mechanism and location distribution of blockage during polymer flooding[J]. Journal of Petroleum Science and Engineering, 2020, 194:1-10. -

下载:

下载: