Preparation and Properties of Viscosification and Drainage Integrated Polymer Dispersion

-

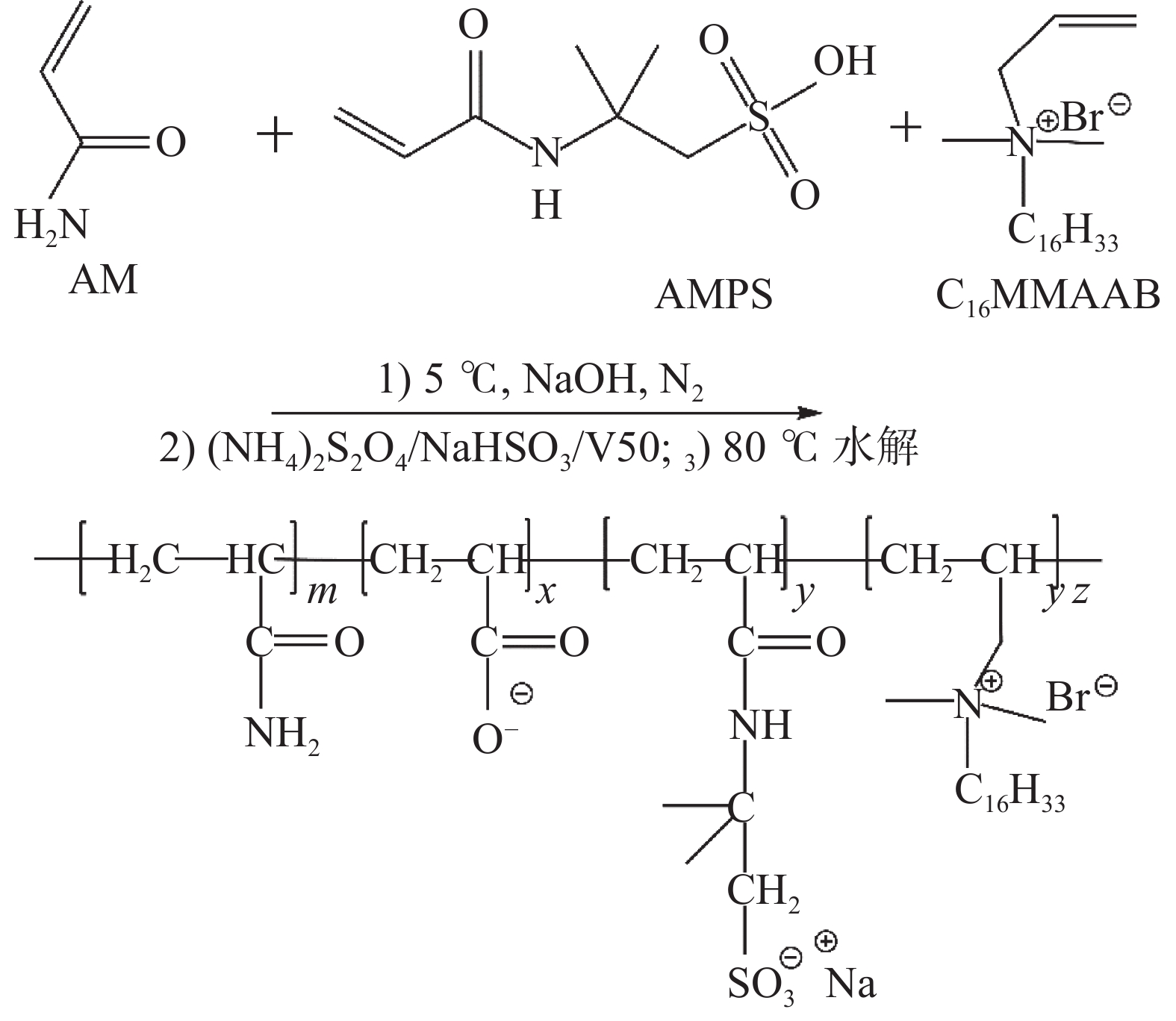

摘要: 速溶耐盐聚合物是高矿化度地层水和返排水有效利用的关键产品,实现增黏助排一体化是稠化剂研发的主要方向。设计合成了一种弱疏水缔合聚合物,优化形成了增黏助排一体化分散液,并对压裂液的综合性能进行了评价研究。该聚合物分散液可满足194 557.93 mg/L的超高矿化水在线配制要求,在分散液用量0.1%~1.2%情况下可以实现黏度2~106 mPa·s可调;分散液用量大于0.4 %以后压裂液破胶液表面张力小于27 mN/m;90 ℃下,剪切1h后增黏助排一体化压裂液黏度大于50 mPa·s;1.0%聚合物分散液在80 ℃下破胶2 h,破胶液黏度为4 mPa·s左右;在聚合物分散液用量为0.1%时,压裂液减阻率大于65%。该聚合物分散液可以满足超高矿化度地层水及返排液配液要求,可以实现在线变黏及助排一体化,大幅度降低压裂液成本,简化现场配液流程,具有广泛应用前景。Abstract: Rapid dissolution and salt-tolerance polymers are the key products for effective utilization of highly mineralized formation water and backflow water. The integration of viscosification and drainage is the main research direction of thickeners. A weak hydrophobic association polymer was designed and synthesized, and an integrated dispersing fluid with the properties of viscosification and drainage was optimized. The overall performance of fracturing fluid was evaluated. The polymer dispersion can meet the online preparation requirements using 194 557.93 mg/L ultra-high mineralized water, and the viscosity can be adjusted from 2 to 106 mPa·s when the amount of salt-resistant thickener was 0.1-1.2%. The surface tension of breaking fluid was less than 27 mN/m when the amount of dispersion was greater than 0.4%.At 90 ℃, under shearing for 1h, the viscosity of the integrated fracturing fluid was greater than 50 mPa·s. The viscosity of 1.0% polymer dispersion was about 4 mPa·s under 80 ℃ water bath for 2 h. When the amount of polymer dispersion was 0.1%, the drag reduction rate of fracturing fluid was greater than 65%. The polymer dispersion can meet the requirements of mixing ultra-high salinity formation water and flowback fluid, realize the integration of online viscosity change and drainage, greatly reduce the cost of fracturing fluid, and simplify the on-site liquid mixing process, so it has a wide application prospect.

-

Key words:

- Ultra-high salinity /

- Salt-tolerance fracturing fluid /

- Polymer dispersion /

- Drainage /

- Integration

-

表 1 青海油田高矿化度地层水成分

ρ/(g·cm−3) K++Na+/(mg·L-1) Ca2+/(mg·L-1) Mg2+/(mg·L-1) Cl−/(mg·L-1) SO42−/(mg·L-1) 总矿化度/(mg·L-1) 1.18 67 924.29 6063.65 734.44 111 463.93 8136.28 194 557.93 -

[1] 俞路遥,许可,石阳,等. 复杂水配制压裂液技术研究进展[J]. 当代化工,2022,51(9):2231-2234,2239. doi: 10.13840/j.cnki.cn21-1457/tq.2022.09.040YU Luyao, XU Ke, SHI Yang, et al. Research progress of fracturing fluid preparation technology with complex water[J]. Contemporary Chemical Industry, 2022, 51(9):2231-2234,2239. doi: 10.13840/j.cnki.cn21-1457/tq.2022.09.040 [2] 薛俊杰,朱卓岩,欧阳坚,等. 耐盐耐高温三元聚合物压裂液稠化剂的制备与性能评价[J]. 油田化学,2018,35(1):41-46,59. doi: 10.19346/j.cnki.1000-4092.2018.01.008XUE Junjie, ZHU Zhuoyan, OU YANG Jian, et al. Preparation and performance evaluation of terpolymer thickening agent with salt tolerance and high temperature resistance for oilfield fracturing fluid[J]. Oilfield Chemistry, 2018, 35(1):41-46,59. doi: 10.19346/j.cnki.1000-4092.2018.01.008 [3] WENFENG J, CHENGGANG X, BAO J, et al. A high temperature retarded acid based on self-assembly of hydrophobically associating polymer and surfactant[J]. Journal of Molecular Liquids, 2023, 370:121017. doi: 10.1016/j.molliq.2022.121017 [4] ZHANG Y, MAO J C, ZHAO J Z, et al. Preparation of a hydrophobic-associating polymer with ultra-high salt resistance using synergistic effect[J]. Polymers, 2019, 11(4):626. doi: 10.3390/polym11040626 [5] GAUTAM S, GURIA C. Optimal synthesis, characterization, and performance evaluation of high-pressure high-temperature polymer-based drilling fluid: the effect of viscoelasticity on cutting transport, filtration loss, and lubricity[J]. SPE Journal, 2020, 25(3):1333-1350. doi: 10.2118/200487-PA [6] 郭建春,任山,唐朝钧,等. 一体化变黏抗盐降阻剂的研制及应用[J]. 石油与天然气化工,2022,51(5):80-86. doi: 10.3969/j.issn.1007-3426.2022.05.012GUO Jianchun, REN Shan, TANG Chaojun, et al. Development and application of an integrated variable viscosity and anti-salt drag reducing agent[J]. Chemical Engineering of Oil and Gas, 2022, 51(5):80-86. doi: 10.3969/j.issn.1007-3426.2022.05.012 [7] 贾金亚,魏娟明,贾文峰,等. 页岩气压裂用滑溜水胶液一体化稠化剂研究[J]. 应用化工,2019,48(6):1247-1250. doi: 10.3969/j.issn.1671-3206.2019.06.001JIA Jinya, WEI Juanming, JIA Wenfeng, et al. Study of thickener used in shale gas fracturing for slide water and gel-liquid integration[J]. Applied Chemical Industry, 2019, 48(6):1247-1250. doi: 10.3969/j.issn.1671-3206.2019.06.001 [8] 魏娟明. 滑溜水–胶液一体化压裂液研究与应用[J]. 石油钻探技术,2022,50(3):112-118.WEI Juanming. Research and application of slick water and gel-liquid integrated fracturing fluids[J]. Petroleum Drilling Techniques, 2022, 50(3):112-118. [9] 魏娟明,贾文峰,陈昊,等. 深层页岩气压裂用高黏高降阻一体化稠化剂的制备与性能评价[J]. 油田化学,2022,39(2):234-238. doi: 10.19346/j.cnki.1000-4092.2022.02.008WEI Juanming, JIA Wenfeng, CHEN Hao, et al. Preparation and performance evaluation of integrated thickener with high viscosity and high drag reduction used for fracturing deeper shale gas[J]. Oilfield Chemistry, 2022, 39(2):234-238. doi: 10.19346/j.cnki.1000-4092.2022.02.008 [10] 徐栋,王玉斌,白坤森,等. 煤系非常规天然气一体化压裂液体系研究与应用[J]. 煤田地质与勘探,2022,50(10):35-43. doi: 10.12363/issn.1001-1986.21.12.0772XU Dong, WANG Yubin, BAI Kunsen, et al. Research and application of integrated fracturing fluid system for unconventional natural gas in coal measures[J]. Coal Geology & Exploration, 2022, 50(10):35-43. doi: 10.12363/issn.1001-1986.21.12.0772 [11] WEVER D A Z, PICCHIONI F, BROEKHUIS A A. Polymers for enhanced oil recovery: a paradigm for structure-property relationship in aqueous solution[J]. Progress in Polymer Science, 2011, 36(11):1558-1628. doi: 10.1016/j.progpolymsci.2011.05.006 [12] RELLEGADLA S, PRAJAPAT G, AGRAWAL A. Polymers for enhanced oil recovery: fundamentals and selection criteria[J]. Applied Microbiology and Biotechnology, 2017, 101(11):4387-4402. doi: 10.1007/s00253-017-8307-4 [13] MAO J C, XUE J X, ZHANG H. Investigation of a hydrophobically associating polymer’s temperature and salt resistance for fracturing fluid thickener[J]. Colloid and Polymer Science, 2022, 300(5):569-582. doi: 10.1007/s00396-022-04965-3 [14] MAO J C, TAN H Z, YANG B, et al. Novel hydrophobic associating polymer with good salt tolerance[J]. Polymers, 2018, 10(8):849. doi: 10.3390/polym10080849 [15] 汪艳,刘彭城. 抗高温耐盐型聚丙烯酰胺产品的研究进展[J]. 广州化工,2017,45(3):9-10,20. doi: 10.3969/j.issn.1001-9677.2017.03.004WANG Yan, LIU Pengcheng. Research progress on temperature resistant and salt resistant properties of polyacrylamide products[J]. Guangzhou Chemical Industry, 2017, 45(3):9-10,20. doi: 10.3969/j.issn.1001-9677.2017.03.004 [16] 贾文峰,任倩倩,王旭,等. 高温携砂酸液体系及其性能评价[J]. 钻井液与完井液,2017,34(4):96-100. doi: 10.3969/j.issn.1001-5620.2017.04.018JIA Wenfeng, REN Qianqian, WANG Xu, et al. A high temperature sand carrying acid and its performance evaluation[J]. Drilling Fluid & Completion Fluid, 2017, 34(4):96-100. doi: 10.3969/j.issn.1001-5620.2017.04.018 -

下载:

下载: