Study and Application of a Tough Anti-Channeling Cement Slurry for Well Xingtan-1

-

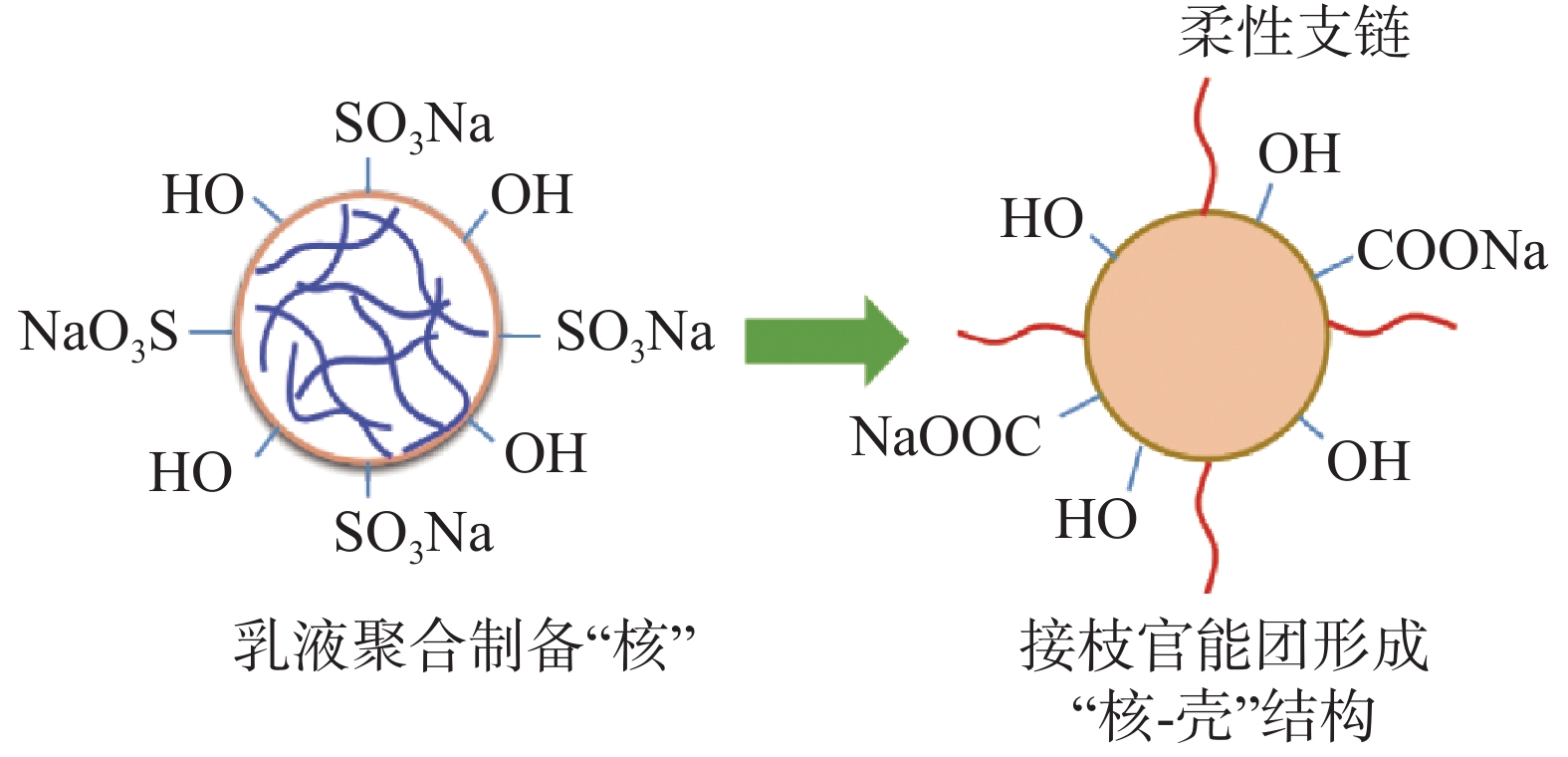

摘要: 星探1井是吉林油田部署在长春双阳区境内的一口深层水平井,完钻井深为5758 m,水平段长为2015 m。针对该井漏失问题以及后期大型压裂对水泥环抗冲击能力要求比较高的难题开展研究,研发了具有“核-壳”结构的增韧防窜剂TA-1,基于此形成了韧性防窜水泥浆体系。TA-1具有弹性内核与柔性支链,能发挥增韧、成膜、与水化产物形成级配的作用。水泥浆性能测试结果表明,浆体稳定性好,稠化时间在150~350 min可调;SPN值达1.15,表现出较好的防窜能力;TA-1能降低水泥石弹性模量达29.5%,抗冲击能力提升16.4%,同时24 h强度大于20 MPa。韧性防窜水泥浆体系在星探1井固井中得到成功应用,解决了固井层内油气窜通和后期压裂水泥石易开裂等难题。Abstract: The well Xingtan-1 is a deep horizontal well drilled in the Shuangyang district of Changchun city by the Jilin Oilfield. This well has a total depth of 5,758 m and horizontal section of 2,015 m. Studies were conducted on two problems, which are mud losses and strict requirement for the impact resistance of the cement sheath to withstand the effects of large scale fracturing jobs. A toughness enhancing anti-channeling agent TA-1 is developed. TA-1 is a product with “core-shell” structure, and is used to formulate an anti-channeling cement slurry with good toughness. The molecules of TA-1 have elastic cores and flexible molecular chains, and are able to improve the toughness of the cement slurry and form films. Test results of the performance of the cement slurry show that the slurry has good stability, with thickening time adjustable between 150 min and 350 min. The SPN value of the cement slurry is 1.15, indicating the cement slurry has good anti-channeling capacity. TA-1 reduces the elastic modulus of the set cement by 29.5% and enhances the impact resistance of the set cement by 16.4%. A cement slurry treated with TA-1 has 24-hour strength of greater than 20 MPa. Well cementing with this anti-channeling cement slurry on the well Xingtan-1 is successful, helping solve the problems of gas channeling through the cement sheaths and cracking of set cement during fracturing operation.

-

Key words:

- Cement slurry /

- Anti-channeling /

- Toughness /

- Mechanical property /

- Well cementing /

- Well Xingtan-1

-

表 1 增韧防窜剂加量对水泥浆性能的影响

TA-1/

%流动度/

cmFLAPI/

mLt30 Bc/

mint100 Bc/

mint过渡/

minSPN 2 25 87 173 183 10 5.95 4 24 63 173 181 8 3.45 6 23 42 174 178 4 1.15 8 21 42 172 176 4 1.16 注:未加增韧防窜剂的水泥浆流动度为25 cm;TA-1加量为2%~8%的水泥浆上下密度差均为0。 表 2 增韧防窜剂加量对水泥石力学特性的影响

TA-1/

%峰值抗压强度/

MPa弹性模量/

GPa0 65.02 8.97 2 60.01 8.34 4 56.74 8.09 6 52.42 7.84 8 49.01 7.53 表 3 韧性防窜水泥浆与常规降失水体系水泥浆力学性能对比

水泥浆 抗压强度/

MPa弹性模量/

GPa抗拉强度/

MPa抗折强度/

MPa常规降失水体系 29 7.8 2.0 3.6 韧性防窜体系 24 5.5 2.4 4.5 表 4 星探1井基础数据

关键参数 数据 关键参数 数据 油气层顶界/m 3080 套管下深/m 5756 油气层底界/m 5703 完钻井深/m 5758 阻流环位置/m 5723 技套下深/m 2640 水泥返高/m 2440(进技套200 m) 两凝界面/m 3000 -

[1] 贾承造,郑民,张永峰. 中国非常规油气资源与勘探开发前景[J]. 石油勘探与开发,2012,39(2):129-136.JIA Chengzao, ZHENG Min, ZHANG Yongfeng. Unconventional hydrocarbon resources in China and the prospect of exploration and development[J]. Petroleum Exploration and Development, 2012, 39(2):129-136. [2] 邹才能,赵群,丛连铸,等. 中国页岩气开发进展、潜力及前景[J]. 天然气工业,2021,41(1):1-14.ZOU Caineng, ZHAO Qun, CONG Lianzhu, et al. Development progress, potential and prospect of shale gas in China[J]. Natural Gas Industry, 2021, 41(1):1-14. [3] 袁进平,于永金,刘硕琼,等. 威远区块页岩气水平井固井技术难点及其对策[J]. 天然气工业,2016,36(3):55-62. doi: 10.3787/j.issn.1000-0976.2016.03.008YUAN Jinping, YU Yongjin, LIU Shuoqiong, et al. Technical difficulties in the cementing of horizontal shale gas wells in Weiyuan block and the countermeasures[J]. Natural Gas Industry, 2016, 36(3):55-62. doi: 10.3787/j.issn.1000-0976.2016.03.008 [4] 付茜,刘启东,刘世丽,等. 中国“夹层型”页岩油勘探开发现状及前景[J]. 石油钻采工艺,2019,41(1):63-70. doi: 10.13639/j.odpt.2019.01.011FU Qian, LIU Qidong, LIU Shili, et al. Exploration & development status and prospect of sandwich-type shale oil reservoirs in China[J]. Oil Drilling & Production Technology, 2019, 41(1):63-70. doi: 10.13639/j.odpt.2019.01.011 [5] 盛湘,张烨. 国外页岩油开发技术进展及其启示[J]. 石油地质与工程,2015,29(6):80-83,88. doi: 10.3969/j.issn.1673-8217.2015.06.021SHENG Xiang, ZHANG Ye. Development technology advances and the enlightement of foreign shale oil[J]. Petroleum Geology and Engineering, 2015, 29(6):80-83,88. doi: 10.3969/j.issn.1673-8217.2015.06.021 [6] 崔雷,李盈,宋国强,等. 吉林油田页岩油的开发利用前景研究[J]. 石油石化节能,2021,11(5):43-46.CUI Lei, LI Ying, SONG Guoqiang, et al. Research on development and utilization prospect of shale oil in Jilin Oilfield[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2021, 11(5):43-46. [7] 李小林,吴朝明,赵殊勋,等. 大港油田页岩油储层固井技术研究与应用[J]. 钻井液与完井液,2020,37(2):232-238. doi: 10.3969/j.issn.1001-5620.2020.02.017LI Xiaolin, WU Chaoming, ZHAO Shuxun, et al. Technology for cementing shale oil reservoirs in Dagang oilfield: study and application[J]. Drilling Fluid & Completion Fluid, 2020, 37(2):232-238. doi: 10.3969/j.issn.1001-5620.2020.02.017 [8] 盛湘,陈祥,章新文,等. 中国陆相页岩油开发前景与挑战[J]. 石油实验地质,2015,37(3):267-271. doi: 10.11781/sysydz201503267SHENG Xiang, CHEN Xiang, ZHANG Xinwen, et al. Prospects and challenges of continental shale oil development in China[J]. Petroleum Geology & Experiment, 2015, 37(3):267-271. doi: 10.11781/sysydz201503267 [9] 付茜. 中国页岩油勘探开发现状、挑战及前景[J]. 石油钻采工艺,2015,37(4):58-62. doi: 10.13639/j.odpt.2015.04.016FU Qian. The status, challenge and prospect of shale oil exploration and development in China[J]. Oil Drilling & Production Technology, 2015, 37(4):58-62. doi: 10.13639/j.odpt.2015.04.016 [10] 孟凡荣. 页岩气超长水平井固井难点及对策分析[J]. 西部探矿工程,2023,35(6):18-20. doi: 10.3969/j.issn.1004-5716.2023.06.006MENG Fanrong. Analysis of cementing difficulties and countermeasures in ultra-long horizontal wells of shale gas[J]. West-China Exploration Engineering, 2023, 35(6):18-20. doi: 10.3969/j.issn.1004-5716.2023.06.006 [11] 王银东. 页岩气储层弹韧性水泥浆体系研究[D]. 青岛: 中国石油大学(华东), 2015.WANG Yindong. The study of elastic and flexible cement slurry system for shale gas reservoirs[D]. Qingdao: China University of Petroleum(East China), 2015. [12] BANTHIA N, SAPPAKITTIPAKORN M. Toughness enhancement in steel fiber reinforced concrete through fiber hibridization[J]. Cement and Concrete Research, 2007, 37(9):1366-1372. doi: 10.1016/j.cemconres.2007.05.005 [13] WON J P, HONG B T, CHOI T J, et al. Flexural behaviour of amorphous micro-steel fibre-reinforced cement composites[J]. Composite Structures, 2012, 94(4):1443-1449. doi: 10.1016/j.compstruct.2011.11.031 [14] LEI M, HUANG W A, SUN J S, et al. Synthesis and characterization of high-temperature self-crosslinking polymer latexes and their application in water-based drilling fluid[J]. Powder Technology, 2021, 389:392-405. doi: 10.1016/j.powtec.2021.05.045 [15] 李成嵩,李社坤,范明涛,等. 高密度弹韧性水泥浆力学数值模拟[J]. 钻井液与完井液,2023,40(2):233-240. doi: 10.12358/j.issn.1001-5620.2023.02.012LI Chengsong, LI Shekun, FAN Mingtao, et al. Numerical simulation study on mechanics of high density elastic and tough cement slurries[J]. Drilling Fluid & Completion Fluid, 2023, 40(2):233-240. doi: 10.12358/j.issn.1001-5620.2023.02.012 [16] 陶谦,陈星星. 四川盆地页岩气水平井B环空带压原因分析与对策[J]. 石油钻采工艺,2017,39(5):588-593. doi: 10.13639/j.odpt.2017.05.011TAO Qian, CHEN Xingxing. Causal analysis and countermeasures on B sustained casing pressure of shale-gas horizontal wells in the Sichuan basin[J]. Oil Drilling & Production Technology, 2017, 39(5):588-593. doi: 10.13639/j.odpt.2017.05.011 [17] 孙坤忠,陶谦,周仕明,等. 丁山区块深层页岩气水平井固井技术[J]. 石油钻探技术,2015,43(3):55-60.SUN Kunzhong, TAO Qian, ZHOU Shiming, et al. Cementing technology for deep shale gas horizontal well in the Dingshan block[J]. Petroleum Drilling Techniques, 2015, 43(3):55-60. [18] 吕斌,周琛洋,邱爱民,等. 防漏早强韧性水泥浆体系的室内研究[J]. 钻井液与完井液,2020,37(2):226-231. doi: 10.3969/j.issn.1001-5620.2020.02.016LYU Bin, ZHOU Chenyang, QIU Aimin, et al. Laboratory study on leak-proof early strength tough cement surry[J]. Drilling Fluid & Completion Fluid, 2020, 37(2):226-231. doi: 10.3969/j.issn.1001-5620.2020.02.016 [19] 邹双,冯明慧,张天意,等. 多尺度纤维韧性水泥浆体系研究与应用[J]. 石油钻探技术,2020,48(6):40-46. doi: 10.11911/syztjs.2020084ZOU Shuang, FENG Minghui, ZHANG Tianyi, et al. Research and application of tough cement slurry systems with multi-scale fiber[J]. Petroleum Drilling Techniques, 2020, 48(6):40-46. doi: 10.11911/syztjs.2020084 [20] 张顺平,张森,覃毅,等. 威远页岩气水平井高密度防窜水泥浆固井技术[J]. 钻井液与完井液,2016,33(1):63-67.ZHANG Shunping, ZHANG Sen, QIN Yi, et al. Anti-channeling high density cement slurry technology for horizontal shale gas well in Weiyuan[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):63-67. [21] 郝海洋,刘俊君,何吉标,等. 页岩气超长水平井预控水泥环封固失效水泥浆技术[J]. 天然气勘探与开发,2022,45(3):108-115. doi: 10.12055/gaskk.issn.1673-3177.2022.03.013HAO Haiyang, LIU Junjun, HE Jibiao, et al. Cement slurry technology for preventing and controlling cement sheath integrity failure in ultra-long horizontal shale gas wells[J]. Natural Gas Exploration and Development, 2022, 45(3):108-115. doi: 10.12055/gaskk.issn.1673-3177.2022.03.013 [22] 辜涛,李明,魏周胜,等. 页岩气水平井固井技术研究进展[J]. 钻井液与完井液,2013,30(4):75-80. doi: 10.3969/j.issn.1001-5620.2013.04.023GU Tao, LI Ming, WEI Zhousheng, et al. Research development of horizontal shale well cementing technology[J]. Drilling Fluid & Completion Fluid, 2013, 30(4):75-80. doi: 10.3969/j.issn.1001-5620.2013.04.023 [23] 石鑫,徐玲玲,冯涛,等. 水分散聚合物乳液改性水泥砂浆的研究进展[J]. 硅酸盐通报,2021,40(8):2497-2507. doi: 10.16552/j.cnki.issn1001-1625.2021.08.002SHI Xin, XU Lingling, FENG Tao, et al. Research progress of water dispersed polymer emulsion modified cement mortar[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(8):2497-2507. doi: 10.16552/j.cnki.issn1001-1625.2021.08.002 [24] 周仕明,丁士东,曲中启. 利用修正SPN值预测环空气窜[J]. 石油钻探技术,2001,29(5):31-32. doi: 10.3969/j.issn.1001-0890.2001.05.010ZHOU Shiming, DING Shidong, QU Zhongqi. Predicting gas cut in annulus with modified coefficient-SPN[J]. Petroleum Drilling Techniques, 2001, 29(5):31-32. doi: 10.3969/j.issn.1001-0890.2001.05.010 [25] 朱礼平,廖忠会,刁素,等. 川西水平井水泥浆防气窜评价方法[J]. 石油钻采工艺,2012,34(1):60-62. doi: 10.3969/j.issn.1000-7393.2012.01.017ZHU Liping, LIAO Zhonghui, DIAO Su, et al. Evaluation method for gas channeling control of cement slurry on horizontal wells in west Sichuan area[J]. Oil Drilling & Production Technology, 2012, 34(1):60-62. doi: 10.3969/j.issn.1000-7393.2012.01.017 -

下载:

下载: