Optimization of Preparation of Amphiphilic Polymer as High Temperature Retarder and Intelligent Control of Thickening Time of Cement Slurry by Response Surface Methodology

-

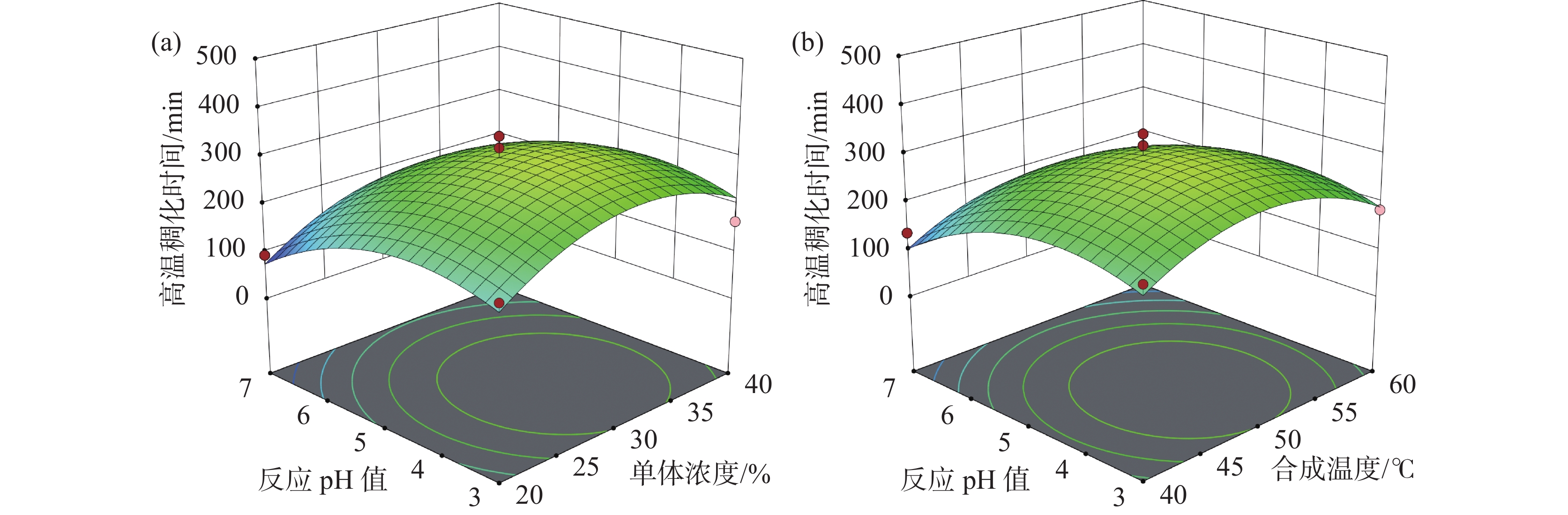

摘要: 针对深井长封固段固井面临的高温大温差环境,缓凝剂难以同时满足深井高温泵送时间长、顶部低温候凝时间短的要求,依据两亲聚合物自组装结构形成/解离过程中的分子构效变化原理,采用2-丙烯酰胺-2-甲基苯磺酸(AMPS)、丙烯酸(AA)、多元不饱和羧酸(PA)、阳离子单体(CM),通过可逆加成链转移法制备出两亲聚合物缓凝剂TRIR,利用响应面法优化了缓凝剂的温度响应智能调控特性,确定了缓凝剂TRIR较佳合成条件:单体浓度占比为28.7%、引发剂用量为0.6%、合成温度为50 ℃、反应pH值为4.5。评价结果表明,两亲聚合物缓凝剂TRIR耐温性能优异,4.0%(液体)加量下200 ℃高温稠化时间达356 min,在120~180 ℃范围内随温度升高缓凝性能显著增强,高温大温差下顶部水泥浆强度发展快,无超缓凝不良现象,可将候凝时间缩短到24 h,为深井高温大温差固井和未来智能型缓凝剂的发展提供新思路。Abstract: Cementing in long sealing section of deep well is faced with the problem of long thickening time in high temperature section and long solidification time in low temperature section. Based on the concept of molecular structure activity changes during the formation/dissociation of amphiphilic polymer self-assembly structure. AMPS, unsaturated carboxylic acid (PA) and cationic monomer (CM) are used to synthesis a temperature responsive intelligent retarder TRIR by RAFT polymerization. Response surface methodology was used to optimize the synthetic process conditions of the polymer. The optimal process conditions were determined as follows: monomer concentration 28.7%, initiator dosage 0.6%, synthesis temperature 50 ℃, and reaction pH 4.5. The structure and thermal stability of the polymer were characterized by infrared spectroscopy and thermogravimetric analysis, and its retarding performance was evaluated. The results show that TRIR has excellent temperature resistance, the thickening time at 200 ℃ can reach 356 min under 4.0% (liquid) dosage, and the retarding property is significantly enhanced with the temperature rise in the range of 120~180 ℃. The thermal response polymer proposed in this paper can provide a new idea for the development of intelligent polymer in the future petrochemical field.

-

表 1 不同盐加量下TRIR对水泥浆稠化时间影响

盐/% 初始稠度/Bc t过渡/min t稠化/min 0 6.9 4.6 398 5 6.6 1.2 336 15 6.0 1.0 315 20 5.0 0.7 364 25 6.8 2.2 370 30 6.0 1.1 545 36 4.7 4.9 598 表 2 缓凝剂TRIR对水泥石抗压强度的影响

TRIR/

%T养护/

℃p24 h/

MPa顶部低温段24 h抗压强度/MPa 60 ℃ 90 ℃ 3.0 160 25.7 17.9 20.1 3.5 180 26.4 12.1 16.5 4.0 180 25.8 4.5 14.9 表 3 TRIR实验室制备和中试实验对比结果

项目 TRIR中试 TRIR实验室小试 反应器及容量 2L反应釜 500 mL四口烧瓶 T反应/℃ 45 50 引发剂用量/% 0.55 0.6 产率/% 85.2% 87.3% -

[1] 罗鸣,冯永存,桂云,等. 高温高压钻井关键技术发展现状及展望[J]. 石油科学通报,2021,6(2):228-244. doi: 10.3969/j.issn.2096-1693.2021.02.018LUO Ming, FENG Yongcun, GUI Yun, et al. Development status and prospect of key technologies for high temperature and high pressure drilling[J]. Petroleum Science Bulletin, 2021, 6(2):228-244. doi: 10.3969/j.issn.2096-1693.2021.02.018 [2] 岳家平,徐翔,李早元,等. 高温大温差固井水泥浆体系研究[J]. 钻井液与完井液,2012,29(2):59-62. doi: 10.3969/j.issn.1001-5620.2012.02.019YUE Jiaping, XU Xiang, LI Zaoyuan, et al. Research on high temperature and large temperature difference cement slurry system[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):59-62. doi: 10.3969/j.issn.1001-5620.2012.02.019 [3] 郭锦棠,石英,于永金,等. 新型聚合物缓凝剂的合成与性能研究[J]. 天津大学学报(自然科学与工程技术版),2017,50(5):453-458.GUO Jintang, SHI Ying, YU Yongjin, et al. Synthesis and property of new copolymer retarder[J]. Journal of Tianjin University(Science and Technology) , 2017, 50(5):453-458. [4] 于斌,丹美涵,姜经帅,等. 抗温敏大温差聚合物缓凝剂的合成与应用[J]. 钻井液与完井液,2017,34(3):85-88. doi: 10.3969/j.issn.1001-5620.2017.03.017YU Bin, DAN Meihan, JIANG Jingshuai, et al. The synthesis and application of temperature sensitivity resistance retarder suitable for big temperature difference environment[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):85-88. doi: 10.3969/j.issn.1001-5620.2017.03.017 [5] PANG X, JIMENEZ W C, IVERSON B J. Hydration kinetics modeling of the effect of curing temperature and pressure on the heat evolution of oil well cement[J]. Cement & Concrete Research, 2013, 54:69-76. [6] 郭锦棠,夏修建,刘硕琼,等. 适用于长封固段固井的新型高温缓凝剂HTR-300L[J]. 石油勘探与开发,2013,40(5):611-615. doi: 10.11698/PED.2013.05.16GUO Jintang, XIA Xiujian, LIU Shuiqiong, et al. A high temperature retarder HTR-300L used in long cementing interval[J]. Petroleum Exploration & Development, 2013, 40(5):611-615. doi: 10.11698/PED.2013.05.16 [7] XIA X, GUO J, CHEN D, et al. Hydrophobic associated copolymer as a wide temperature range synthetic cement retarder and its effect on cement hydration[J]. Journal of Applied Polymer Science, 2017, 134(35):e45242. doi: 10.1002/app.45242 [8] 左天鹏,程小伟,吴昊,等. 一种长封固段固井用缓凝剂的制备及性能评价[J]. 精细化工,2022,39(3):618-626.ZUO Tianpeng, CHENG Xiaowei, WU Hao, et al. Preparation and performance evaluation of a kind of retarder used in long cementing interval[J]. Fine Chemicals, 2022, 39(3):618-626. [9] CHEN X, WANG C, XUE Y, et al. A novel thermo-thickening viscosity modifying admixture to improve settlement stability of cement slurry under high temperatures[J]. Construction & Building Materials, 2021, 295:123606. [10] CHEN X, WANG C, WANG Y, et al. Prevention strategy of cement slurry sedimentation under high temperature. Part 1: a polymer with continuous thermo-thickening behavior from 48 to 148 ℃[J]. The Journal of Physical Chemistry C, 2019, 123(30):18573-18584. doi: 10.1021/acs.jpcc.9b05255 [11] 王成文,王桓,薛毓铖,等. 高密度水泥浆高温沉降稳定调控热增黏聚合物研制与性能[J]. 石油学报,2020,41(11):1416-1424. doi: 10.7623/syxb202011011WANG Chengwen, WANG Huan, XUE Yucheng, et al. Development and performance of thermo-viscosifying polymer for high temperature sedimentation control of high density cement slurry[J]. Acta Petrolei Sinica, 2020, 41(11):1416-1424. doi: 10.7623/syxb202011011 -

下载:

下载: