The Performance of Set Aluminate Cement Modified by Micro Silica Compounded Sodium Hexametaphosphate under Condition of Shale Oil In-situ Conversion

-

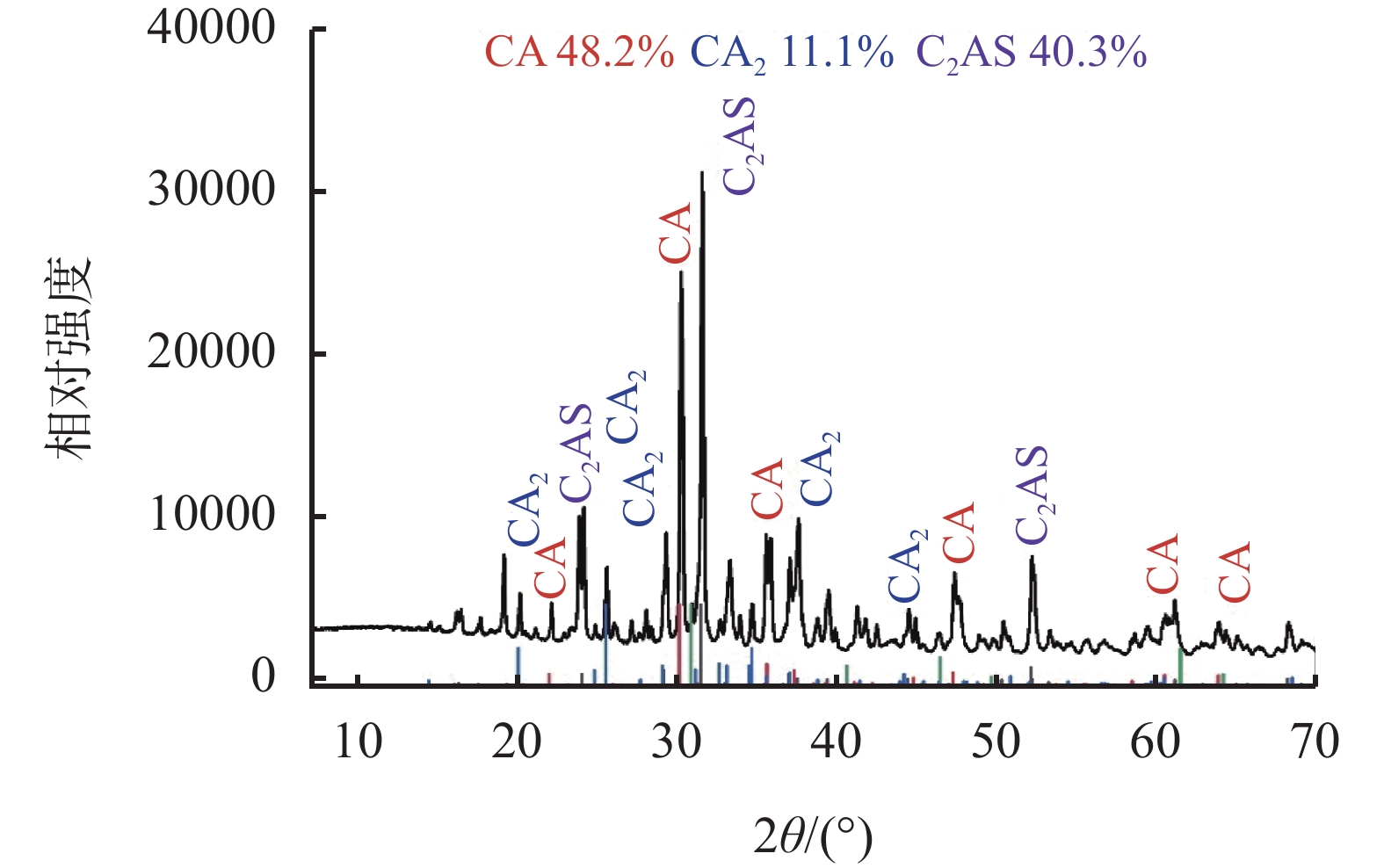

摘要: 低成熟度页岩油原位转化工况下极端高温会导致固井水泥石强度发生衰退。因此,研究了微硅复合六偏磷酸钠改性铝酸盐水泥在650 ℃处理前后的宏观性能及微观结构。结果表明,50 ℃下六偏磷酸钠能显著降低铝酸盐水泥石的渗透率,但对抗压强度提升不明显,微硅复合六偏磷酸钠改性铝酸盐水泥石的渗透率明显降低,同时抗压强度提升明显。650 ℃处理后,5.0%六偏磷酸钠改性铝酸盐水泥石的抗压强度最高,为47.19 MPa,而微硅复合六偏磷酸钠改性铝酸盐水泥石的抗压强度呈现降低趋势。铝酸盐水泥石在650 ℃处理前后水化产物发生明显转化,主要是C3AH6和AH3转化为C12A7和CA,其中,C3AH6和AH3主要在180~400 ℃期间发生热分解,同时水泥石由于晶型的转化导致孔隙增大。微硅促使铝酸盐水泥石在50 ℃环境下生成的C2ASH8,有助于改善水泥石的微观结构,但是,650 ℃处理后由于C2ASH8的分解同样会导致水泥石孔隙增大。Abstract: In the in-situ conversion of low purity shale oils, extremely high temperature will result in strength retrogression of the set cement. To solve this problem, study was conducted on the macro-properties and microstructures of an aluminate cement before and after aging 650 ℃. The aluminate cement is a cement modified by micro silica compounded sodium hexametaphosphate. It is found that at 50 ℃, sodium hexametaphosphate can significantly reduce the permeability of a set aluminate cement, and the compressive strength of the set cement is significantly increased. After treatment at 650 ℃, the aluminate cement modified with 5.0% sodium hexametaphosphate has the highest compressive strength, which is 47.19 MPa, while the aluminate cement modified with micro silica compounded sodium hexametaphosphate has strengths that are declining. The hydrational products of the aluminate cement before and after treatment at 650 ℃ have experienced significant changes, from C3AH6 and AH3 to C12A7 and CA, respectively. Among these products, C3AH6 and AH3 are thermally degraded in temperatures between 180 ℃ and 400 ℃, and because of the changes of the crystal form, the permeability of the set cement is increased. Micro silica accelerates the formation of C2ASH8 by the set cement at 50 ℃, and this is beneficial to the improvement of the microstructure of the set cement. Since C2ASH8 will degrade after treatment at 650 ℃, the sizes of the pores in the set cement will also increase.

-

表 1 铝酸盐水泥及微硅的组分组成

% 物质 CaO Al2O3 SiO2 TiO2 铝酸盐水泥 47.14 39.13 4.61 4.58 微硅 0.38 0.31 83.06 物质 Fe2O3 K2O SO3 MgO 铝酸盐水泥 2.52 0.59 0.56 0.29 微硅 3.22 2.70 2.43 表 2 水泥浆配方

g 配方 CAC 微硅 定优胶 分散剂 六偏

磷酸钠降失

水剂消泡剂 水 0# 100 0 0.1 0.1 5.0 4 1 37.56 1# 95 5 0.1 0.2 5.0 4 1 35.55 2# 90 10 0.1 0.2 5.0 4 1 34.35 表 3 水泥石水化产物类型及相对质量损失

T/ ℃ 物相 0#配方/% 1#配方/% 50 ℃ 650 ℃ 50 ℃ 650 ℃ 105~180 AH3-gel 0.53 0.28 1.11 0.28 180~220 AH3-gel、C2ASH8* 0.91 0.21 1.32 0.22 220~290 AH3 6.07 0.39 5.63 0.24 290~400 C3AH6 4.40 0.20 2.82 0.23 400~800 AH3 、 C3AH6 2.91 0.39 2.71 0.45 800~1000 C12A7 0.52 0.27 0.59 0.31 表 4 不同类型水泥石的孔径分布对比

试样 处理

温度<10 nm/% 10~100 nm/% ˃100 nm/% 孔隙度/

%5.0%六偏磷

酸钠改性常温 0.48 7.45 18.98 26.92 650 ℃ 1.56 14.88 26.43 42.89 5.0%微硅复合六

偏磷酸钠改性常温 0.64 18.43 1.78 20.86 650 ℃ 1.97 20.00 20.44 42.40 -

[1] 赵文智,胡素云,侯连华. 页岩油地下原位转化的内涵与战略地位[J]. 石油勘探与开发,2018,45(4):537-545.ZHAO Wenzhi, HU Suyun, HOU Lianhua. Connotation and strategic role of in-situ conversion processing of shale oil underground in the onshore China[J]. Petroleum Exploration and Development, 2018, 45(4):537-545. [2] 马中良,郑伦举,赵中熙. 不同边界条件对油页岩原位转化开采的影响及启示[J]. 吉林大学学报(地球科学版),2017,47(2):431-441.MA Zhongliang, ZHENG Lunju, ZHAO Zhongxi. Influence and its revelation of oil shale in-situ mining simulation in different boundary conditions[J]. Journal of Jilin University (Earth Science Edition) , 2017, 47(2):431-441. [3] LI H L, PANG X Y, CHEN X R, et al. Physical and mechanical performance of oil well cement systems under simulated shale oil in-situ conversion condition[C]//56th U. S. Rock Mechanics/Geomechanics Symposium. Santa Fe, New Mexico, USA: ARMA, 2022: ARMA-2022-0412. [4] PANG X Y, QIN J K, SUN L J, et al. Long-term strength retrogression of silica-enriched oil well cement: a comprehensive multi-approach analysis[J]. Cement and Concrete Research, 2021, 144:106424. doi: 10.1016/j.cemconres.2021.106424 [5] QIN J K, PANG X Y, CHENG G D, et al. Influences of different admixtures on the properties of oil well cement systems at HPHT conditions[J]. Cement and Concrete Composites, 2021, 123:104202. doi: 10.1016/j.cemconcomp.2021.104202 [6] 郭华,马倩芸,武治强,等. 高炉矿渣改性铝酸盐水泥材料腐蚀机理与性能[J]. 钻井液与完井液,2022,39(2):221-226.GUO Hua, MA Qianyun, WU Zhiqiang, et al. Research on the effect of blast furnace slag on low-temperature hydration characteristics and high-temperature mechanical properties of aluminate cement[J]. Drilling Fluid & Completion Fluid, 2022, 39(2):221-226. [7] PACEWSKA B, NOWACKA M. Studies of conversion progress of calcium aluminate cement hydrates by thermal analysis method[J]. Journal of Thermal Analysis and Calorimetry, 2014, 117(2):653-660. doi: 10.1007/s10973-014-3804-5 [8] LEE N K, KOH K T, PARK S H, et al. Microstructural investigation of calcium aluminate cement-based ultra-high performance concrete (UHPC) exposed to high temperatures[J]. Cement and Concrete Research, 2017, 102:109-118. doi: 10.1016/j.cemconres.2017.09.004 [9] 李早元,张松,张弛,等. 热力采油条件下粉煤灰改善铝酸盐水泥石耐高温性能及作用机理研究[J]. 硅酸盐通报,2012,31(5):1101-1105.LI Zaoyuan, ZHANG Song, ZHANG Chi, et al. Study on aluminates cement with fly ash for heavy crude oil thermal recovery in well cementation[J]. Bulletin of the Chinese Ceramic Society, 2012, 31(5):1101-1105. [10] 李早元,伍鹏,程小伟,等. 矿渣对铝酸盐水泥石性能影响的研究[J]. 硅酸盐通报,2014,33(12):3338-3342.LI Zaoyuan, WU Peng, CHENG Xiaowei, et al. Influence study on the performance of aluminate cement with slag[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(12):3338-3342. [11] 马聪,步玉环,赵邵彪,等. 固井用铝酸盐水泥改性试验研究[J]. 建筑材料学报,2015,18(1):100-106.MA Cong, BU Yuhuan, ZHAO Shaobiao, et al. Experimental study on modification of aluminate cement used in oil-well cementing[J]. Journal of Building Materials, 2015, 18(1):100-106. [12] 马聪,高义,范明星,等. 稻壳灰改性铝酸盐水泥的试验研究[J]. 哈尔滨工程大学学报,2016,37(7):986-989.MA Cong, GAO Yi, FAN Mingxing, et al. Experimental study on the aluminate cement modified with rice hull ash[J]. Journal of Harbin Engineering University, 2016, 37(7):986-989. [13] CHENG B J, YAO C, XIONG J, et al. Effects of sodium hexametaphosphate addition on the dispersion and hydration of pure calcium aluminate cement[J]. Materials, 2020, 13(22):5229. doi: 10.3390/ma13225229 [14] PALOU M, KUZIELOVÁ E, ŽEMLIČKA M, et al. The influence of sodium hexametaphosphate (Na6P6O18) on hydration of calcium aluminate cement under hydrothermal condition[J]. Procedia Engineering, 2016, 151:119-126. doi: 10.1016/j.proeng.2016.07.371 [15] XU W T, DAI J G, DING Z, et al. Polyphosphate-modified calcium aluminate cement under normal and elevated temperatures: phase evolution, microstructure, and mechanical properties[J]. Ceramics International, 2017, 43(17):15525-15536. doi: 10.1016/j.ceramint.2017.08.102 [16] ZAPATA J F, COLORADO H A, GOMEZ M A. Effect of high temperature and additions of silica on the microstructure and properties of calcium aluminate cement pastes[J]. Journal of Sustainable Cement-Based Materials, 2020, 9(6):323-349. doi: 10.1080/21650373.2020.1737593 [17] 李宁,庞学玉,艾正青,等. 200 ℃加砂硅酸盐水泥配方优化设计及强度衰退机理[J]. 硅酸盐学报,2020,48(11):1824-1833.LI Ning, PANG Xueyu, AI Zhengqing, et al. Composition optimization and strength decline mechanism of oil well cement slurry at 200 ℃[J]. Journal of the Chinese Ceramic Society, 2020, 48(11):1824-1833. [18] YURTDAS I, BURLION N, SKOCZYLAS F. Triaxial mechanical behaviour of mortar: effects of drying[J]. Cement and Concrete Research, 2004, 34(7):1131-1143. doi: 10.1016/j.cemconres.2003.12.004 [19] YURTDAS I, PENG H, BURLION N, et al. Influences of water by cement ratio on mechanical properties of mortars submitted to drying[J]. Cement and Concrete Research, 2006, 36(7):1286-1293. doi: 10.1016/j.cemconres.2005.12.015 [20] 董庆广. 稠油热采工况用铝酸盐水泥石性能研究[D]. 成都: 西南石油大学, 2019.DONG Qingguang. Study on the performance of aluminate cement stone for thick oil hot recovery conditions[D]. Chengdu: Southwest Petroleum University, 2019. [21] CHENG X W, DONG Q G, MA Y, et al. Mechanical and thermal properties of aluminate cement paste with blast furnace slag at high temperatures[J]. Construction and Building Materials, 2019, 228:116747. doi: 10.1016/j.conbuildmat.2019.116747 [22] PACEWSKA B, NOWACKA M, WILIŃSKA I, et al. Studies on the influence of spent FCC catalyst on hydration of calcium aluminate cements at ambient temperature[J]. Journal of Thermal Analysis and Calorimetry, 2011, 105(1):129-140. doi: 10.1007/s10973-011-1303-5 [23] SCHEINHERROVÁ L, TRNÍK A. Hydration of calcium aluminate cement determined by thermal analysis[J]. AIP Conference Proceedings, 2017, 1866(1):040034. -

下载:

下载: