A Storable Liquid Cement Technology

-

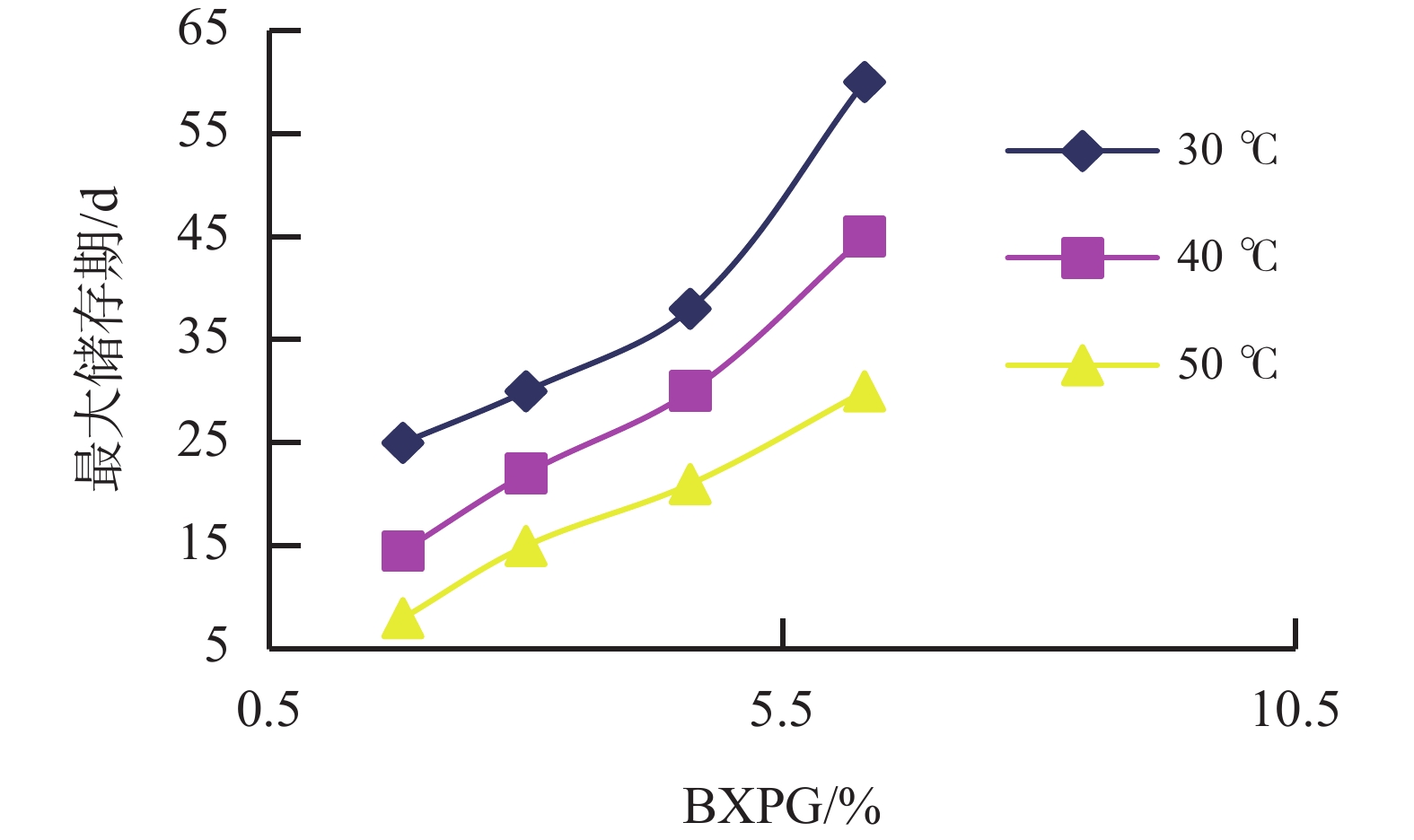

摘要: 介绍了一种新型固井水泥浆——可储存液体化水泥。可储存液体化水泥是一种可在液体状态下稳定保存,并在需要时可凝结硬化的液体化水泥。该项技术可提前预制水泥浆,解决了传统固井水泥浆密度波动大的难题,实现水泥浆密度精确控制,满足路途遥远、现场施工极端困难条件下的固井需要。详细介绍了可储存液体化水泥的组成、性能、技术特点及应用领域。该水泥浆储存期间浆体稳定,储存期长,可达90 d以上。激活后的可储存液体化水泥在性能上与传统水泥浆性能相近,可满足40~180 ℃的水泥浆设计要求,水泥浆静胶凝强度过渡时间短,SPN性能系数低,有良好的防气窜性能。该水泥浆可在基地混配好,不用在现场进行混配,浆体配好后性能也会被“锁定”,会一直保持设计的性能。当水泥浆泵入井下后,才被激活,而后固化。Abstract: This paper introduces a new cement slurry – a storable liquid cement. This is a cement that can be stably stored in liquid state, and can set and be made hardened when necessary. Using this technology, the cement slurry can be made in advance, thus solving the problem of large density fluctuation of conventional cement slurries, realizing the accurate control of the density of a cement slurry, and satisfying the requirements of cementing a well that is far away and with hard rig-site operation conditions. The composition, properties, technical features and applications of the storable liquid cement are described in detail. The cement has stable properties when in storage, and can be stored for a long time of more than 90 days, for instance. The liquid cement, after being activated, has properties that are quire close to the conventional cement slurries, and can meet the requirements of operation at 40 – 180 ℃. The cement slurry has short transitional time of static gel strengths, low SPN value, and good anti-channeling performance. This cement slurry can be formulated at the operation base and is not necessarily formulated at the rig-site. The properties of the slurry, after well formulated, can be “locked up”, that is, its properties will always be maintained at the levels when the cement slurry was formulated. When the cement slurry is pumped down the hole, it is activated and then becomes hardened.

-

Key words:

- Liquid cement /

- Storage period /

- Activate /

- Density of cement slurry /

- Settling stability /

- Anti-channeling

-

表 1 悬浮剂的筛选实验结果

悬浮剂 水泥浆性能 0.2%HYJ 浆体很稠,1 h后出现大量游离液,水泥沉降 0.4%HYJ 浆体非常稠,水灰比为0.44时无法搅浆 0.2%HZSN 无悬浮作用 0.1%H-1 浆体较好,但6 h后出现大量游离液 0.3%H-1 浆体较稠,24 h后有少量游离液(10 mL) 0.2%BXM 浆体稳定,7 d后有少量游离液 0.3%BXM 浆体稳定,7 d后无游离液,但水泥浆比较稠 0.2%RT-4 浆体较稳定,24 h有极少量游离液 0.3%RT-4 浆体稳定,7 d后有少量游离液,但含气量高 表 2 激活剂的筛选实验结果(90 ℃、50 MPa)

激活剂 加量/% t稠化/min NaOH 3 >500 5 >500 8 >500 Na2SO4 3 >500 8 >500 BXA-1 2 480 3 325 4 215 注:水泥基浆组成为100 gG级水泥+35 g水+0.2 g悬浮剂+0.8 g水化抑制剂+0.4 g分散剂;储存期为5~7 d;激活剂组成为100 g基浆+6 g水+激活剂。 表 3 分散剂的筛选实验结果

分散剂 t稠化/min

(90 ℃/50 MPa)p24 h/MPa

(90 ℃/常压)流动度/

mm空白 112 23 209 CF40L 115 24 225 ASPF 169 27 240 注:水泥浆组成为100 gG级水泥+44 g水+1.6%分散剂。 表 4 BXF-200L对水泥浆降失水性能的影响

BXF-200L/

%不同温度(℃)下水泥浆失水量/mL 60 70 80 90 3.0 46 44 47 54 3.5 37 36 45 50 4.5 30 28 37 42 5.0 28 28 30 34 注:水泥浆组成为100 gG级水泥+44 g水+BXF-200L。 表 5 激活前可储存液体化水泥性能

储存期/d φ300 φ200 φ100 φ6 φ3 游离液/% 0 179 130 77 11 8 0 3 210 145 80 14 9 0.1 7 208 139 81 11 7 0 12 217 144 87 13 11 0 28 207 143 86 12 10 0.2 56 210 149 88 13 10 0.2 90 221 148 90 12 11 0.1 表 6 激活后可储存液体化水泥流变性

T/ ℃ φ300 φ200 φ100 φ6 φ3 27 199 148 80 19 14 60 109 79 43 8 3 90 96 70 40 6 3 表 7 液体化水泥激活后抗压强度实验结果

水泥浆 ρ/(g·cm−3) 养护条件 储存期/d p24 h/MPa p7 d/MPa 1# 1.90 90 ℃/常压 3 22.7 29.0 90 ℃/常压 16 23.6 30.6 90 ℃/21 MPa 20 32.0 34.8 2# 1.90 60 ℃/常压 6 16.3 21.3 60 ℃/常压 15 16.9 25.3 3# 1.50 60 ℃/常压 4 13.2 24.9 60 ℃/常压 11 13.0 25.4 60 ℃/21 MPa 13 16.5 27.6 表 8 可储存液体化水泥的SPN值

ρ/

g·cm−3T/

℃t稠化/

mint30 Bc/

minFL/

mLSPN值 1.9 60 352 345 36 1.23 1.9 90 247 239 40 1.87 表 9 激活后可储存液体化水泥的综合性能

T/℃ FL/mL t稠化/min t过渡/min p24 h/MPa 游离液 /mL 40 30 309 20 16.0 0 50 38 296 15 16.5 0 60 40 262 12 17.7 0 70 40 354 10 18.6 0 80 42 295 10 20.4 0 90 52 338 10 23.7 0 120 40 350 8 30.1 0 180 45 223 5 33.8 0 注:激活后水泥浆密度为1.9 g/cm3;水泥浆储存期为7 d。 表 10 可储存液体化水泥与传统水泥浆固井经济性对比

水泥浆 操作面积/

m2占用面积/

m2重量/

kg总费用

比较/%传统固井水泥浆 74 43 26 000 100 可储存液体化水泥浆 35 21 16 000 38.6 -

[1] RAE P, JOHNSTON N. Liquid cement premix introduces new solutions to conventional cementing problems [C]//IADC/SPE Drilling Conference. New Orleans: SPE, 1996: SPE-35086-MS. [2] 张兴国,高兴原,冯明. 固井质量影响因素分析[J]. 钻采工艺,2002,25(2):10-13.ZHANG Xingguo, GAO Xingyuan, FENG Ming. Analysis of influence factors on cementing quality[J]. Drilling & Production Technology, 2002, 25(2):10-13. [3] 周守为. 中国近海典型油田开发实践[M]. 北京: 石油工业出版社, 2009: 4-22.ZHOU Shouwei. Development practice of typical offshore oilfields in china[M]. Beijing: Petroleum Industry Press, 2009: 4-22. [4] RAE P, JOHNSTON N.Liquid cement premix for improved abandonment and workover operations[C]//SPE Annual Technical Conference and Exhibition. Denver: SPE, 1996: SPE-36477-MS. [5] 齐奉忠,庄晓谦,唐纯静,等. 国外新型水泥浆体系——Liquid Stone液态可存储水泥浆[J]. 石油钻探技术,2006,34(1):23.QI Fengzhong, ZHUANG Xiaoqian, TANG Chunjing, et al. New external cement slurry system-liquid stonestorable cement slurry[J]. Petroleum Drilling Techniques, 2006, 34(1):23. [6] 张兴国,刘晓明,李跃明,等. 微硅对水泥浆、水泥石的改善作用[J]. 西部探矿工程,2006,18(12):232-233,239.ZHANG Xingguo, LIU Xiaoming, LI Yueming, et al. Improvement of micro silicon on cement slurry and cement paste[J]. West-China Exploration Engineering, 2006, 18(12):232-233,239. [7] 屈建省, 徐同台, 徐璧华, 等. 油气井注水泥理论与应用[M]. 第2版. 北京: 石油工业出版社, 2022: 624-643.QU Jiansheng, XU Tongtai, XU Bihua, et al. Cementing theory and application of oil and gas wells[M]. 2nd ed. Beijing: Petroleum Industry Press, 2022: 624-643. [8] NELSON E B.现代固井技术[M].刘大为, 田锡君, 廖润康, 译. 沈阳: 辽宁科学技术出版社, 1994: 122-135.NELSON E B. Well cementing[M]. LIU Dawei, TIAN Xijun, LIAO Runkang, translated. Shenyang: Liaoning Science and Technology Publishing House, 1994: 122-135. [9] 向浩天,蒋炳,李之军,等. 外加剂对低温水泥浆性能的影响试验研究[J]. 探矿工程(岩土钻掘工程),2020,47(1):36-42.XIANG Haotian, JIANG Bing, LI Zhijun, et al. Study on effect of additives on cement slurry at low temperature[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2020, 47(1):36-42. -

下载:

下载: