Using RSM to Determine Electric Gel Breaking Conditions for Waste High Density Water Based Drilling Fluids

-

摘要: 随着深层、超深层油气资源开发力度的不断加大,地层压力逐渐升高,高密度废弃钻井液处理量也不断增长。传统的化学絮凝剂存在成本高、普适性差及潜在的二次污染等问题,利用外加电场是高密度废弃钻井液绿色处理的新手段。在单因素实验的基础上,运用响应曲面法(RSM)研究了电流强度、破胶时间、极板间距3个因素及其交互作用对钻井液体系的Zeta电位和粒径分布的影响。结果表明,在电流强度为8 A、极板间距为3 cm、破胶时间为10 min的条件下,废弃钻井液破胶效果达到最优。破胶后的钻井液体系的Zeta电位上升率为38.29 %,达到了−26.2 mV,其体系的粒径分布D90达到了562.5 μm。废弃钻井液体系的胶体稳定性得以破坏,为后续体系中有用组分的回收及废弃组分的处理工作提供有力支撑。Abstract: As oil and gas wells are drilled deeper and deeper, higher formation pressures need to be balanced with high density drilling fluids, and this leads to another problems: the treatment of more and more high density waste muds. Waste muds are generally treated with chemical flocculants and problems such as high treatment cost, poor universality and potential secondary pollution are the norm. In a study an electric field was applied to treat a high density waste mud. Based on the results of a single-factor experiment, the effects of three factors, i.e., current intensity, time of gel breaking and the distance between two electrodes, as well as the interaction of the three factors on the Zeta potential and particle size distribution of the drilling fluid were studied using response surface methodology (RSM). It was found that an optimum gel breaking can be obtained when the electric current intensity = 8 A, the time of gel breaking = 10 min, and the distance between two electrodes = 3 cm. After gel breaking, the Zeta potential of the drilling fluid was increased by 38.29%, reaching −26.2 mV, and the particle size distribution factor D90 reached 562.5 μm, indicating that the gel stability of the waste drilling fluid was broken, and this provided a powerful support to the subsequent recovery of the useful mud components as well as the treatment of the waste portion of the waste drilling fluid.

-

随着深层油气资源的开发,深井、超深井的数量不断增多,地层压力也不断升高,这使得需要处理的高密度废弃钻井液逐年增长。废弃钻井液的处理方法和技术包括:固化填埋、机械物理破胶、化学絮凝等[1-8],这些处理方式通常耗能大、成本高并有二次污染[9-14]。陆玉香等[15]对比了电絮凝和化学絮凝对污泥脱水性能的影响,并优化了电絮凝最佳条件,结果表明,电絮凝技术可显著提升污泥沉降性能和脱水能力。谢水祥等[16]利用响应曲面法,探究了外加电场对钻井液废水的影响。结果表明,电场能较好的提高钻井废水的再生能力。外加电场处理废弃物原理包括电絮凝、电氧化和电吸附等[17]。电场破胶一方面是电极通过电流释放出的适量阳离子来压缩由黏土组成的扩散双电层,使体系失稳,有助于絮凝作用,以更好的进行后续处理;另一方面,高价阳离子与废弃钻井液体系中的多种处理剂可能发生氧化、缔合等反应,破坏其原有的稳定网络结构,生成较大的絮凝体,但有关电场对钻井液破胶、絮凝的工艺参数及机理解释尚未阐明。基于此,通过响应曲面法分析了电流强度、极板间距和破胶时间及其交互作用对钻井液体系胶体稳定性的影响并优选出最佳电破胶条件;结合电破胶后钻井液体系的Zeta电位、粒径分布阐明电场对钻井液破胶行为的机理[18-24]。

1. 实验材料与方法

1.1 实验材料与配方

聚丙烯酰胺(PAM)、降滤失剂(DSP-2)、磺甲基酚醛树脂(SMP)、降黏剂(SF-4)、磺化沥青、钠基膨润土、重晶石和高密度废弃钻井液,均来自中石化胜利工程有限公司钻井液技术服务中心;氯化钾、氯化钠、碳酸钠,均为分析纯,上海国药集团化学试剂有限公司。

钻井液配方为:4%预水化膨润土浆 + 0.3%PAM + 3%SMP-1 + 3%SMC + 0.5%DSP-2 + 3%改性沥青 + 1%SF-4 + 7%KCl + 5%NaCl+重晶石

1.2 实验仪器

数字直流电源(DC power supply);GJSS-B12K变频高搅机;Bettersize2000 激光粒度分布仪,Omni Zeta电位分析仪;有机玻璃电破胶池、铝制电极板,(自制)。

1.3 实验方法与评价指标

1.3.1 实验步骤

为了保证实验结果的准确性,极板在使用前经稀盐酸溶液浸泡20 min后,冲洗并以砂纸打磨,彻底清除表面的氧化膜。具体实验步骤如下:(1)将配置好的钻井液每次以500 mL的量转移至破胶槽中,以铝制极板为阴阳电极,设定间距,将极板插入钻井液中,打开搅拌装置,设定转速为600 r·min−1;(2)开启电源,待电流强度达到指定数值时开始计时,待其达到设定时间后关闭电源;(3)电破胶结束后,取20 mL样品转移至试样瓶中,测定体系的Zeta电位和粒径分布,测定Zeta电位时,以去离子水将处理后的钻井液稀释20倍。

1.3.2 实验设计与分析方法

响应曲面法是一组特殊的数学和统计方法,用于设计实验、构建模型、确定变量的影响和研究最佳操作条件[18]。正交实验法和控制变量法可用于获得最佳的实验操作条件及单个因素对响应结果的影响,由于不仅要明确最佳的实验操作条件,更要明确电流强度、极板间距和破胶时间三因素两两之间的协同效果。因此,需要利用响应曲面法,通过多元二次回归方程定量的描述研究中的各个因素及其交互作用、协同效果对最终响应结果的影响,同时获得最佳实验参数。如公式(1)所示。

$$ \begin{split} &{\rm{Y}}= {\beta _{\rm{0}}}+{\beta _{\rm{1}}}{{\rm{X}}_{\rm{1}}}+{\beta _{\rm{2}}}{{\rm{X}}_{\rm{2}}}+{\beta _{\rm{3}}}{{\rm{X}}_{\rm{3}}}+{\beta _{{\rm{12}}}}{{\rm{X}}_{\rm{1}}}{{\rm{X}}_{\rm{2}}}+\\&{\beta _{{\rm{13}}}}{{\rm{X}}_{\rm{1}}}{{\rm{X}}_{\rm{3}}}+{\beta _{{\rm{23}}}}{{\rm{X}}_{\rm{2}}}{{\rm{X}}_{\rm{3}}}+{\beta _{{\rm{11}}}}{\rm{X}}_{\rm{1}}^{\rm{2}}+{\beta _{{\rm{22}}}}{\rm{X}}_{\rm{2}}^{\rm{2}}+{\beta _{{\rm{33}}}}{\rm{X}}_{\rm{3}}^{\rm{2}} \end{split} $$ (1) 式中,βXX为各个因子、因子间交互作用和因子平方项的系数。

采用RSM的中心复合设计(Central composite design,CCD)进行探究。以钻井液体系的Zeta电位和粒径分布值D90作为响应变量,讨论了电破胶过程中3个最重要的操作变量:电流强度、破胶时间和极板间距对响应变量的影响见表1。

表 1 CCD设计方案及响应值实验编号 电流强度/A t破胶/min 极板间距/cm D90/μm ζ/mV 1 6 5.0 3 220.0 −33.75 2 10 5.0 3 910.0 −28.94 3 6 10.0 3 140.0 −34.30 4 10 10.0 3 811.6 −30.12 5 6 5.0 5 660.0 −28.53 6 10 5.0 5 1138.0 −26.57 7 6 10.0 5 217.3 −30.80 8 10 10.0 5 1065.0 −27.33 9 6 7.5 4 180.0 −35.33 10 10 7.5 4 1024.0 −29.46 11 8 5.0 4 506.4 −27.92 12 8 10.0 4 208.2 −31.33 13 8 7.5 3 198.4 −32.45 14 8 7.5 5 562.5 −26.18 15 8 7.5 4 250.6 −30.94 16 8 7.5 4 290.0 −30.56 17 8 7.5 4 250.0 −30.33 18 8 7.5 4 270.0 −29.88 19 8 7.5 4 260.8 −31.04 20 8 7.5 4 310.8 −28.66 2. 结果与讨论

2.1 响应曲面法的方差分析

在本研究中为明确各因素(X1=电流强度、X2=破胶时间、X3=极板间距)对响应值的影响,利用分析软件Minitab 17,对表1中的实验结果进行回归拟合,得到以Zeta电位和粒径D90为响应值的二次回归方程2~3。具有一个因素(X1、X2 或 X3)的系数表示线性主因素的影响,具有两个因素(X1X2、X1X3 或 X2X3)的系数和二阶项(X12、X22 或 X32)的系数表示2个因素之间的交互作用和二次效应,见式(2)和式(3)。

$$ \begin{split} &{Y_1} = 3197 - 914{X_1} + 27.3{X_2} + 3{X_3} + 68.6{X_1}^2 +\\& 8.43{X_3}^2 - 0.90{X_1}{X_3} - 16.9{X_2}{X_3} \end{split} $$ (2) $$ \begin{split} &{Y_2} = - 56.78 + 7.77{X_1} - 0.816{X_2} - 2.23{X_3} -\\& 0.380{X_1}^2 + 0.2497{X_3}^2 - 0.0892{X_1}{X_3} ^{ } \end{split}$$ (3) 利用Minitab 17 软件对粒径分布和ζ电位进行方差分析。因素的系数为正,则该因素表现为正效应,反之亦然。方差分析结果如表2所示。可知,电流强度和破胶时间表现为正效应,而极板间距表现为负效应。调整后的方差为90 %以上,pre-R2接近90 %,表明该经验方程与实验结果的拟合程度较高,这与上述观点一致。

表 2 响应曲面的方差分析结果项 效应 系数 标准误差 T值 P值 显著性 粒径分布 X1 706.300 353.100 23.400 15.09 0 显著 X2 −198.500 −99.200 23.400 −4.24 0.002 显著 X3 272.600 136.300 23.400 5.82 0 显著 X12 532.300 266.200 44.600 5.96 0 显著 X22 42.900 21.400 44.600 0.48 0.641 不显著 X32 89.200 44.600 44.600 1.00 0.341 不显著 X1X2 87.800 43.900 26.200 1.68 0.124 不显著 X1X3 −9 .000 −4.500 26.200 −0.17 0.867 不显著 X2X3 −84.300 −42.200 26.200 −1.61 0.138 不显著 Zeta电位 X1 4.059 2.029 0.345 5.88 0 显著 X2 −1.633 −0.816 0.345 −2.37 0.040 显著 X3 4.031 2.016 0.345 5.84 0 显著 X12 −3.724 −1.862 0.658 −2.83 0.018 不显著 X22 1.819 0.910 0.658 1.38 0.197 不显著 X32 2.439 1.220 0.658 1.85 0.093 不显著 X1X2 0.218 0.109 0.386 0.28 0.783 不显著 X1X3 −0.892 −0.446 0.386 −1.16 0.275 不显著 X2X3 −0.325 −0.162 0.386 −0.42 0.682 不显著 2.2 钻井液体系的粒径

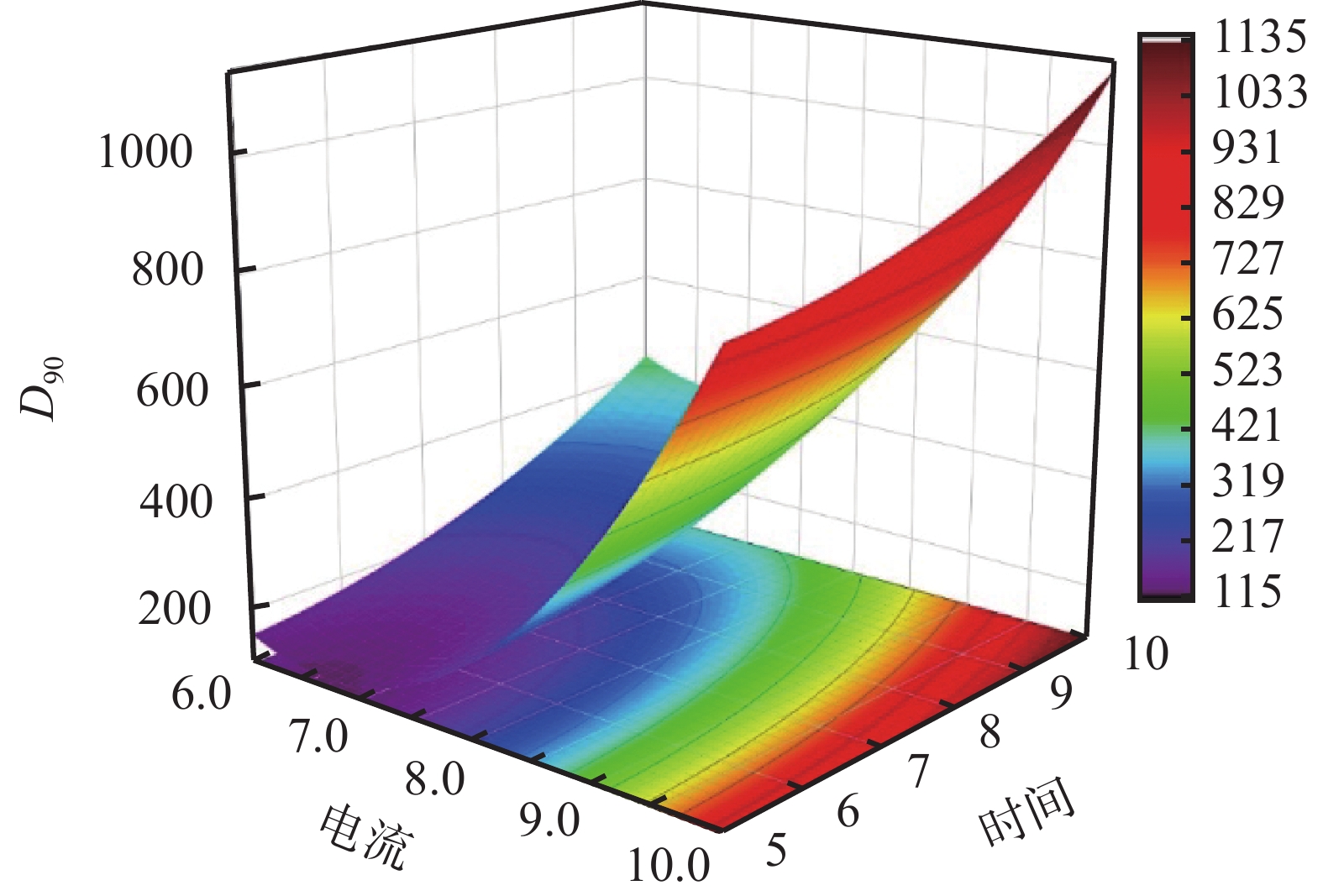

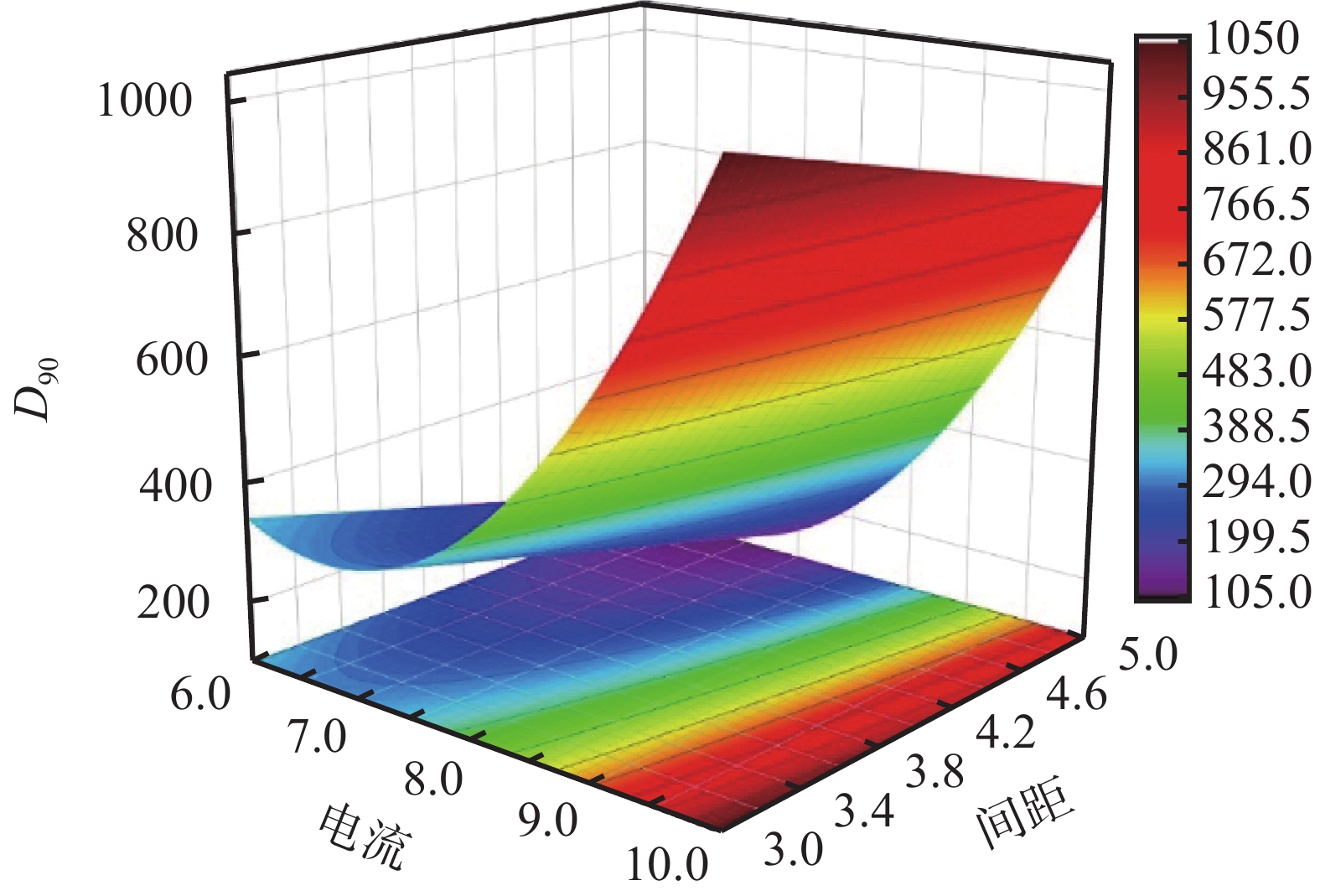

电流强度、破胶时间、极板间距对钻井液体系粒径的影响如见图1、图2和图3。

可知,低电流强度下,产生Al3+的量较少,减小极板间距对破胶效果没有明显的影响。同样,较短的破胶时间所产生的Al3+的量对体系的破胶效果也是有限的。因此低电流条件下无法有效的破坏钻井液的胶体稳定性,随着电流强度的增大,Al3+通过电性中和、压缩双电层等作用使胶粒脱稳进而凝聚成大的絮体,钻井液体系的粒径极速增加,D90的峰值达到了1138 μm。

2.3 钻井液体系的Zeta电位

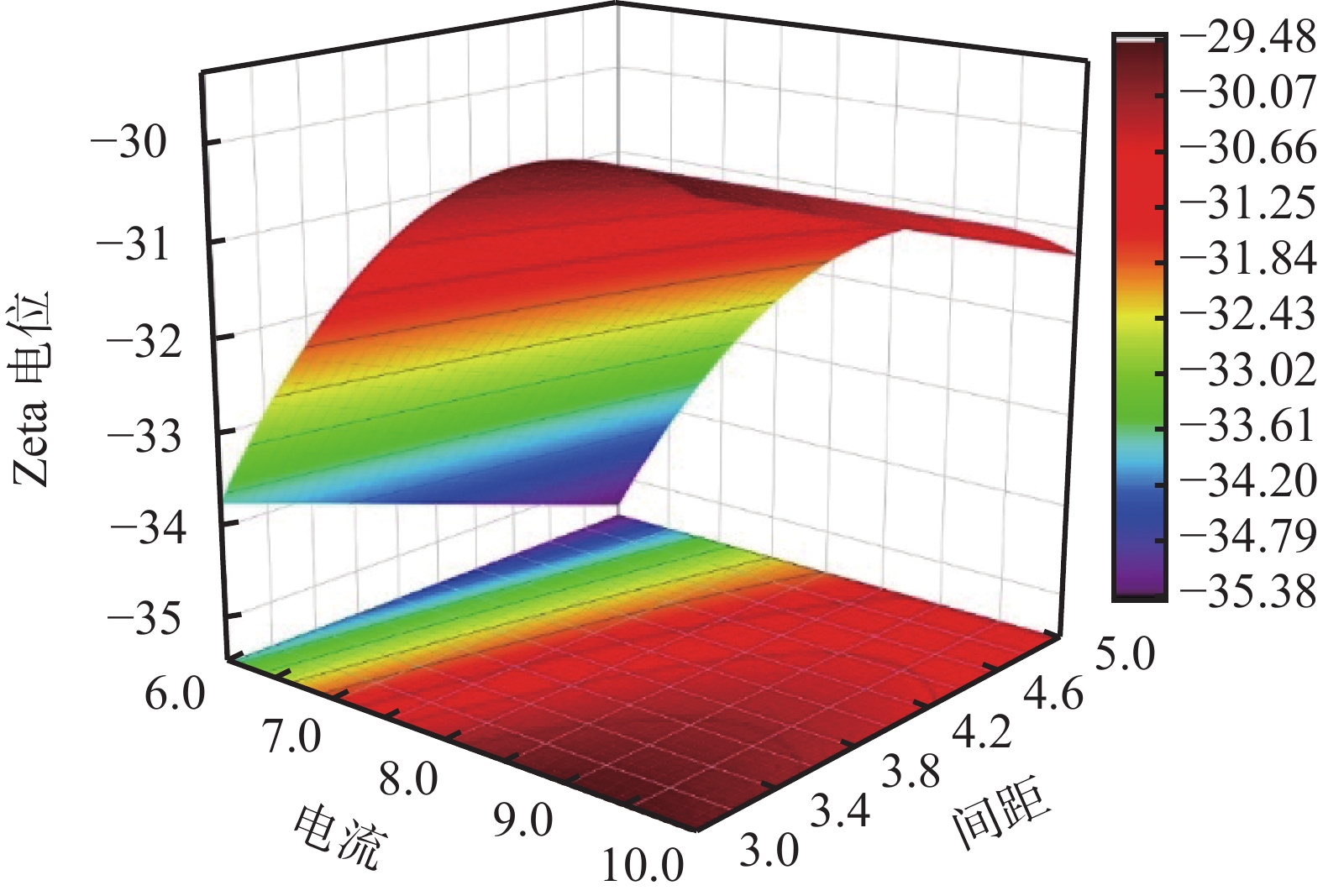

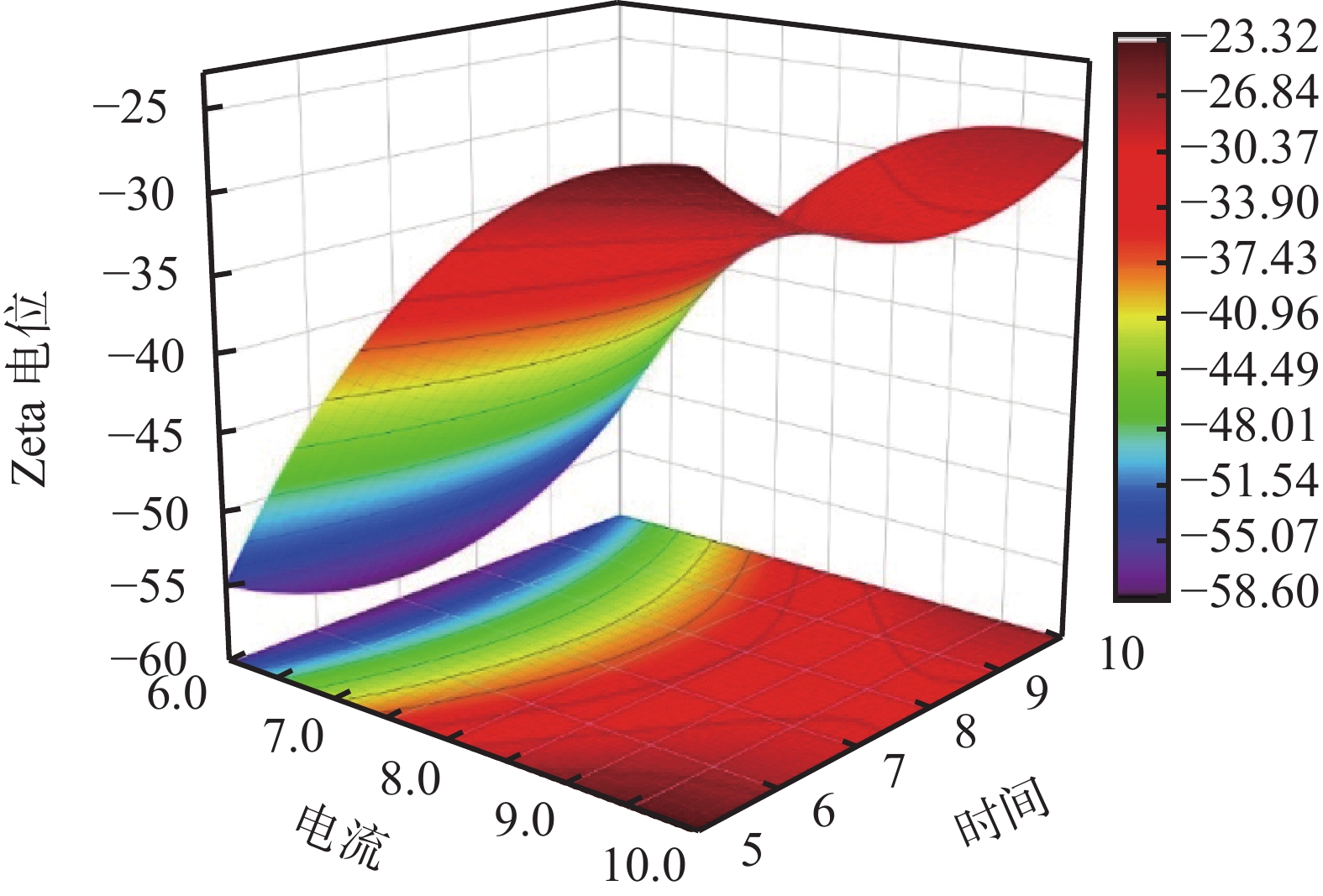

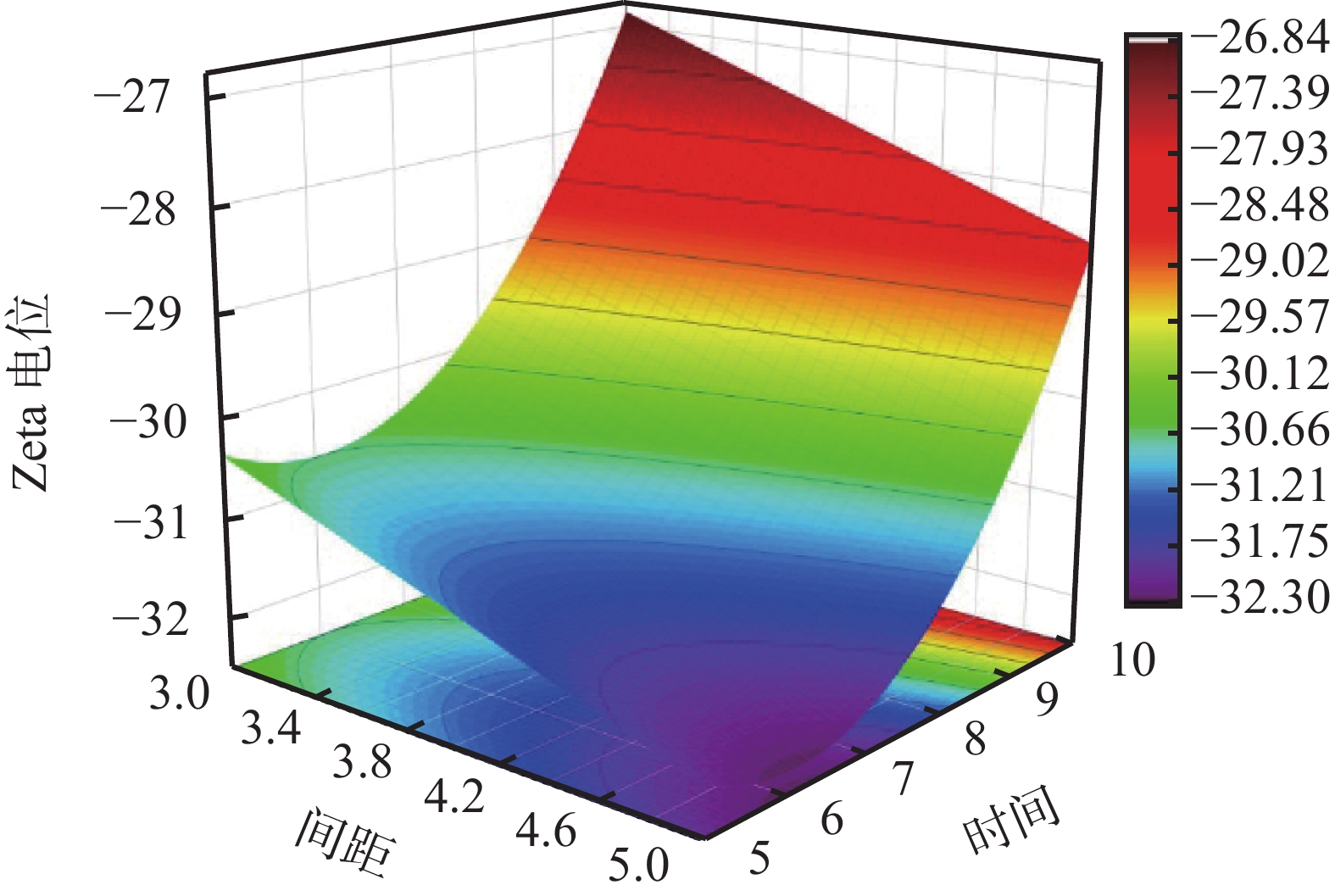

电流强度、破胶时间、极板间距对钻井液体系Zeta电位的影响如图4 ~ 图6所示。钻井液体系中黏土与阴离子聚合物、阳离子所形成扩散双电层厚度较大,可形成稳定的胶体体系以保证钻井液的正常功能。极板所释放的Al3+可吸附在带负电的黏土表面,从而压缩扩散双电层、降低Zeta电位。可知,低电流条件下,少量的Al3+对扩散双电层的压缩作用及破坏聚合物的缔合能力有限,Zeta电位降低的幅度较小。随着电流强度的增大及破胶时间的延长,电极产生Al3+的量增多,一方面负电聚合物会吸附在极板表面,有利于钻井液体系的脱稳,另一方面Al3+可与钻井液中负电性的胶体结构相互吸引。因Al3+的态较高、离子半径较大,可吸附在黏土表面,有效的压缩扩散双电层厚度、减小胶粒之间的排斥作用或者Al3+自身与体系中处理剂发生交联、缔合反应,从而降低钻井液原有的胶体稳定性。在破胶过程中,电压的变化较小,因此在各个间距条件下,电场强度的改变是可忽略的,因此电场强度对钻井液体系Zeta电位没有明显的影响,这与粒径的分析结果一致。以Zeta电位为影响因素,所得到的最佳破胶条件:电流强度为8 A、极板间距为3 cm、破胶时间为10 min。未经电破胶处理的钻井液体系的Zeta电位为−42.38 mV,该操作条件下,Zeta电位的可增至−26.15 mV,上升率为38.29%。

2.4 应用试验

废弃钻井液来自胜利油田某区块,在以响应曲面法获得最佳操作条件下,对500 mL废弃钻井液进行破胶处理。结果表明,废弃钻井液的稳定性本身较低,电场处理前的Zeta电位为−20.33 mV,经电场处理后Zeta电位提升至−13.15 mV,脱离了钻井液的稳定区间。而废弃钻井液的粒径分布D90电场处理前为273.15 μm,处理后为887.34 μm, 表明废弃钻井液体系中已经形成了较大的絮体,有脱稳的趋势。

2.5 成本预估

高密度废弃钻井液的电破胶室内实验,其成本来自设备费用及电能损耗,在对本实验成本的初步估算时,主要考虑电能的损耗。在电破胶过程中,指定电流强度条件下,电压变化较小,因此可以将其视为常数,计算公式为。

$$ {{\displaystyle C}}_{成本}\text{=a}\times \frac{U\times I\times t}{\text{1000}\times \text{3600}\times V} $$ 式中,C成本为电絮凝过程中消耗的总成本,元/m3;a为2022年中国平均工业用电费用,0.7268元/kW·h;U为电破胶过程中的电压强度,V;I为电破胶过程中的电流强度,A;t为电破胶时间,s;V为单次处理钻井液体积,m3。

图7为不同操作条件对电能成本的影响。电破胶成本随着破胶时间和电流强度的增加而增加。以粒径和Zeta电位为响应变量,在高密度废弃钻井液电破胶的最佳操作条件下,电能成本为12.36元/m3。

为了高效、经济的处理高密度废弃钻井液,工艺过程需兼顾电破胶效果和运行成本。在以Zeta电位为响应的最佳操作条件下,粒径分布的D90为562.5 μm,该结果对于整体实验效果也是可以接受的。因此电破胶的最佳参数确定为电流强度为8 A,极板间距为3 cm破胶时间为10 min。

3. 结论

1.电破胶工艺在高密度废弃钻井液的绿色、环保处理领域具有较大的应用价值。采用响应曲面法研究电流强度、极板间距、破胶时间对钻井液体系的Zeta电位和粒径分布的影响,方差分析结果表明,响应曲面法可实现工艺条件的优化、获得拟合准确性较高和较为可靠的破胶参数。

2.利用响应曲面法建立的二元回归模型,能有效预测各因素对钻井液体系粒径和Zeta电位的影响。在实验条件下,各因素对变量的影响程度排序为:电流强度>破胶时间>极板间距。考虑破胶效果和工艺成本,最佳工艺参数为电流强度8 A,极板间距3 cm,破胶时间10 min,电能成本为12.36元/m3。

-

表 1 CCD设计方案及响应值

实验编号 电流强度/A t破胶/min 极板间距/cm D90/μm ζ/mV 1 6 5.0 3 220.0 −33.75 2 10 5.0 3 910.0 −28.94 3 6 10.0 3 140.0 −34.30 4 10 10.0 3 811.6 −30.12 5 6 5.0 5 660.0 −28.53 6 10 5.0 5 1138.0 −26.57 7 6 10.0 5 217.3 −30.80 8 10 10.0 5 1065.0 −27.33 9 6 7.5 4 180.0 −35.33 10 10 7.5 4 1024.0 −29.46 11 8 5.0 4 506.4 −27.92 12 8 10.0 4 208.2 −31.33 13 8 7.5 3 198.4 −32.45 14 8 7.5 5 562.5 −26.18 15 8 7.5 4 250.6 −30.94 16 8 7.5 4 290.0 −30.56 17 8 7.5 4 250.0 −30.33 18 8 7.5 4 270.0 −29.88 19 8 7.5 4 260.8 −31.04 20 8 7.5 4 310.8 −28.66 表 2 响应曲面的方差分析结果

项 效应 系数 标准误差 T值 P值 显著性 粒径分布 X1 706.300 353.100 23.400 15.09 0 显著 X2 −198.500 −99.200 23.400 −4.24 0.002 显著 X3 272.600 136.300 23.400 5.82 0 显著 X12 532.300 266.200 44.600 5.96 0 显著 X22 42.900 21.400 44.600 0.48 0.641 不显著 X32 89.200 44.600 44.600 1.00 0.341 不显著 X1X2 87.800 43.900 26.200 1.68 0.124 不显著 X1X3 −9 .000 −4.500 26.200 −0.17 0.867 不显著 X2X3 −84.300 −42.200 26.200 −1.61 0.138 不显著 Zeta电位 X1 4.059 2.029 0.345 5.88 0 显著 X2 −1.633 −0.816 0.345 −2.37 0.040 显著 X3 4.031 2.016 0.345 5.84 0 显著 X12 −3.724 −1.862 0.658 −2.83 0.018 不显著 X22 1.819 0.910 0.658 1.38 0.197 不显著 X32 2.439 1.220 0.658 1.85 0.093 不显著 X1X2 0.218 0.109 0.386 0.28 0.783 不显著 X1X3 −0.892 −0.446 0.386 −1.16 0.275 不显著 X2X3 −0.325 −0.162 0.386 −0.42 0.682 不显著 -

[1] 田野. 废弃钻井液处理技术探讨[J]. 西部探矿工程,2021,33(3):30-31. doi: 10.3969/j.issn.1004-5716.2021.03.009TIAN Ye. Discussion on treatment technology of waste drilling fluid[J]. West-china Exploration Engineering, 2021, 33(3):30-31. doi: 10.3969/j.issn.1004-5716.2021.03.009 [2] 李月龙. 油田废弃钻井液无害化处理技术的研究[J]. 西部探矿工程,2022,34(1):48-51. doi: 10.3969/j.issn.1004-5716.2022.01.015LI Yuelong. Research on harmless treatment technology of waste drilling fluid in oilfield[J]. West-china Exploration Engineering, 2022, 34(1):48-51. doi: 10.3969/j.issn.1004-5716.2022.01.015 [3] 刘利明. 钻井工程废弃钻井液处理技术分析[J]. 西部探矿工程,2019,31(5):91-92. doi: 10.3969/j.issn.1004-5716.2019.05.031LIU Liming. Analysis on treatment technology of waste drilling fluid in drilling engineering[J]. West-china Exploration Engineering, 2019, 31(5):91-92. doi: 10.3969/j.issn.1004-5716.2019.05.031 [4] 何长明,李俊华,王佳. 废弃钻井液无害化处理技术的研究[J]. 应用化工,2016,45(9):1792-1794. doi: 10.16581/j.cnki.issn1671-3206.2016.09.004HE Changming, LI Junhua, WANG Jia. Research of waste drilling fluid disposal technology[J]. Applied Chemical Industry, 2016, 45(9):1792-1794. doi: 10.16581/j.cnki.issn1671-3206.2016.09.004 [5] 苏勤,何青水,张辉,等. 国外陆上钻井废弃物处理技术[J]. 石油钻探技术,2010,38(5):106-110.SU Qin, HE Qingshui, ZHANG Hui, et al. Foreign onshore drilling waste treatment technology[J]. Petroleum Drilling Techniques, 2010, 38(5):106-110. [6] 王眉山,郑毅. 中国废弃钻井液处理技术发展趋势[J]. 钻井液与完井液,2009,26(6):77-79. doi: 10.3969/j.issn.1001-5620.2009.06.023WANG Meishan, ZHENG Yi. The prospect of waste drilling fluid treatment technology in China[J]. Drilling Fluid & Completion Fluid, 2009, 26(6):77-79. doi: 10.3969/j.issn.1001-5620.2009.06.023 [7] 蔡利山,阮光明,王全周,等. 加重剂回收利用技术探讨与可行性分析[J]. 钻井液与完井液,2012,29(1):34-37. doi: 10.3969/j.issn.1001-5620.2012.01.010CAI Lishan, RUAN Guangming, WANG Quanzhou, et al. Research and feasibility analysis on recycling technology of weighting materials[J]. Drilling Fluid & Completion Fluid, 2012, 29(1):34-37. doi: 10.3969/j.issn.1001-5620.2012.01.010 [8] 刘培坤,徐金广,张悦刊,等. 钻井液加重剂回收试验研究[J]. 过滤与分离,2017,27(2):1-5. doi: 10.3969/j.issn.1005-8265.2017.02.001LIU Peikun, XU Jinguang, ZHANG Yuekan, et al. Experimental research on recovery of drilling fluid weighting compound[J]. Journal of Filtration & Separation, 2017, 27(2):1-5. doi: 10.3969/j.issn.1005-8265.2017.02.001 [9] 周礼. 废弃水基钻井液无害化处理技术研究及应用[D]. 成都: 西南石油大学, 2014.ZHOU Li. Research and application of harmless treatment technology of waste water-based drilling fluid. [D]. Chengdu: Southwest Petroleum University, 2014. [10] LARSON T R. Methods for recovery and reuse of lcm. US: 12001490[P]. 2009-6-11. [11] 蔡利山,杨健,彭琳. 离心机分离固相测定分析方法及其应用[J]. 钻井液与完井液,2018,35(6):31-36. doi: 10.3969/j.issn.1001-5620.2018.06.006CAI Lishan, YANG Jian, PENG Lin. Method of solids composition determination of centrifuge and the application thereof[J]. Drilling Fluid & Completion Fluid, 2018, 35(6):31-36. doi: 10.3969/j.issn.1001-5620.2018.06.006 [12] 张爱顺,黄达全,曹孜英,等. 废弃聚合物钻井液无害化处理技术实验研究[J]. 油气田环境保护,2014,24(3):17-21. doi: 10.3969/j.issn.1005-3158.2014.03.007ZHANG Aishun, HUANG Quanda, CAO Ziying, et al. Experimental research into harmless treatment technology of waste polymer drilling liquid[J]. Environmental Protection of Oil & Gas Fields, 2014, 24(3):17-21. doi: 10.3969/j.issn.1005-3158.2014.03.007 [13] 王学川,胡艳鑫,郑书杰,等. 国内外废弃钻井液处理技术研究现状[J]. 陕西科技大学学报(自然科学版),2010,28(6):169-174.WANG Xuechuan, HU Yanxin, ZHENG Shujie, et al. Application status of waste drilling fluid treatment technology at home and abroad[J]. Journal of Shaanxi University of Science & Technology, 2010, 28(6):169-174. [14] VLYSSIDES A G, KARLIS P K, ZORPAS A A. Eletrochemical oxidation of noncyanide strippers wastes[J]. Environment International, 1999, 25:663-670. doi: 10.1016/S0160-4120(99)00028-8 [15] 陆香玉,俞海祥,陈亚,等. 化学絮凝与电絮凝调理污泥脱水性能影响作用的对比研究[J]. 环境科学学报,2022,42(3):257-267. doi: 10.13671/j.hjkxxb.2021.0441LU Xiangyu, YU Haiyang, CHEN Ya, et al. Comparison of the effects of chemical flocculation and electric flocculation conditioning on sludge dewatering performance[J]. Acta Scientiae Circumstantiae, 2022, 42(3):257-267. doi: 10.13671/j.hjkxxb.2021.0441 [16] 谢水祥,任雯,李兴春,等. 电吸附再生废弃水基钻井液作用机理[J]. 天然气工业,2019,39(12):139-145. doi: 10.3787/j.issn.1000-0976.2019.12.018XIE Shuixiang, REN Wen, LI Xingchun, et al. Mechanism of electrosorption recycled waste water-based drilling fluid[J]. Natural Gas Industry, 2019, 39(12):139-145. doi: 10.3787/j.issn.1000-0976.2019.12.018 [17] SHER F, HANIF K, IQBAL S Z, et al. Implications of advanced wastewater treatment: Electrocoagulation and electroflocculation of effluent discharged from a wastewater treatment plant[J]. Journal of Water Process Engineering, 2020, 33(C):101101-101101. [18] TURAN N B, ERKAN H S, ENGIN G O. The investigation of shale gas wastewater treatment by electro-Fenton process: Statistical optimization of operational parameters[J]. Process Safety and Environmental Protection, 2017, 109:203-213. doi: 10.1016/j.psep.2017.04.002 [19] 袁青松,冯辉,张栋,等. 强封堵钻井液体系在河南页岩气钻井中的研究和应用[J]. 钻井液与完井液,2019,36(1):29-35.YAN Qingsong, FENG Hui, ZHANG Dong, et al. Study of a strong plugging drilling fluid used in shale gas drilling in He’nan province[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):29-35. [20] 陈彬,张伟国,姚磊,等. 基于井壁稳定及储层保护的钻井液技术[J]. 石油钻采工艺,2021,43(2):184-188.CHEN Bin, ZHANG Weiguo, YAO Lei, et al. Drilling fluid technology based on well stability and reservoir protection[J]. Oil Drilling & Production Technology, 2021, 43(2):184-188. [21] 夏海英,兰林,杨丽,等. 强抑制钻井液体系研究及现场应用[J]. 钻井液与完井液,2019,36(4):427-430.XIA Haiying, LAN Lin, YANG Li, et al. Study and field application of a highly inhibited drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):427-430. [22] 周启成,梁应红,单海霞,等. 抗高温高密度生物质钻井液体系研究及应用[J]. 石油钻探技术,2022,50(6):78-84.ZHOU Qicheng, LIANG Yinghong, SHAN Haixia, et al. Research and application of a high-temperature resistant and high-density biomass drilling fluid system[J]. Petroleum Drilling Techniques, 2022, 50(6):78-84. [23] 王景. 临兴-神府井区废弃钻井液处理技术[J]. 石油钻探技术,2022,50(1):60-64.WANG Jing. Treatment technology of waste drilling fluids in the Linxing-Shenfu Well Area[J]. Petroleum Drilling Techniques, 2022, 50(1):60-64. [24] 周姗姗,钟成兵,刘杰,等. 超低摩阻水基钻井液在页岩气水平井的应用[J]. 钻井液与完井液,2022,39(3):313-318.ZHOU Shanshan, ZHONG Chengbing, LIU Jie, et al. Application of ultra-low friction wwater-based ddrilling ffluid in shale gas horizontal wells[J]. Drilling Fluid & Completion Fluid, 2022, 39(3):313-318. -

下载:

下载:

下载:

下载: