Application of Gravity Displacement Drilling Fluid and Low Friction Drilling Fluid in ST2-4 Well

-

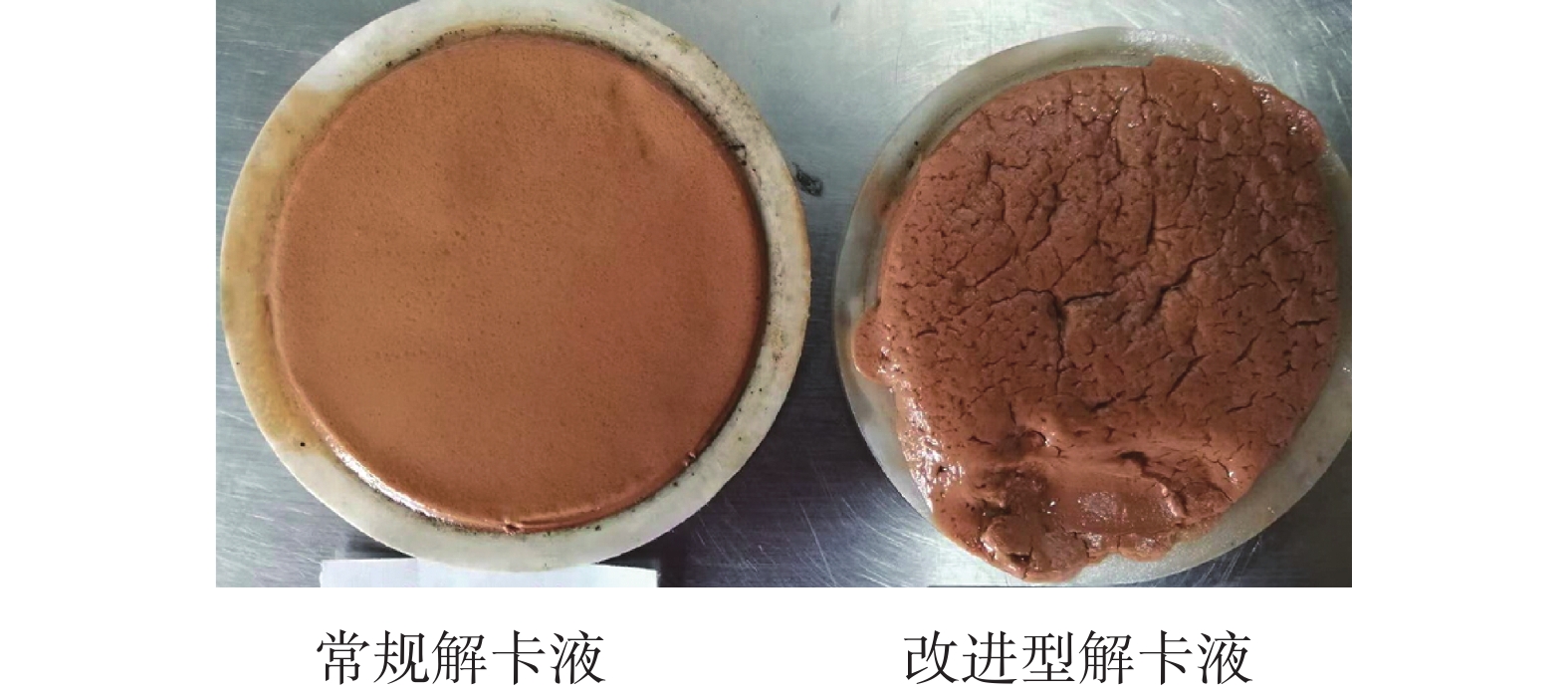

摘要: ST2-4井是位于塔里木盆地桑塔木断垒带2号构造的一口侧钻井,其Φ152.4 mm井眼4350~4800 m井段井斜为0°~61.1°,中途完钻直推存储式测井过程中发生电测仪器被卡,井底50.95 m电测仪器无水眼通道,不能建立循环,第一次浸泡常规解卡液未解卡,第二次对常规解卡液配方改造升级为改进型解卡液,成功解卡,避免了超千万的电测仪器损失。改进型解卡液的改进措施包括:(1)将配制解卡液的清水替换浓度为10%的CaCl2盐水;(2)将快速渗透剂快T的浓度提高至30%;(3)将解卡液密度提至高于井浆密度0.5 g/cm3,利用重力置换原理将解卡液置换至井底浸泡电测仪器。解卡后采用“低黏度切力轻浆+重稠浆段塞”携砂工艺保持井眼通畅,引入有机减阻剂YJJZ-1将常规KCl聚磺体系转换为低摩阻钻井液降低摩阻,通过提高HTHP泥饼质量、加强井浆防塌抑制性结合,完成了斜井段易黏卡井段电测、下套管作业。Abstract: Well ST2.4 in 152.4 mm hole 4350~4800 m interval well deviation 0°-61.1°, in the process of the middle-completion direct-push memory logging, the electric logging tool got stuck, the non-water hole channel of the 50.95 m electric logging tool could not set up a cycle, and the conventional unstuck fluid did not get unstuck after the first immersion, for the second time, the formula of the conventional unblocking agent was upgraded to an improved unblocking agent. Firstly, the clean water of the unblocking agent was replaced with 10% CaCl2 salt water, and secondly, the concentration of the rapid penetrant fast T was increased to 30% , the third is to raise the density of the unblocking fluid to 0.5 g/cm3 above the mud density, and to replace the unblocking fluid to the bottom of the well by using the gravity replacement principle, thus successfully unblocking the electric measuring instrument, avoiding the loss of over ten million electric measuring instruments. The“Low viscosity, light slurry + heavy slurry slug” sand-carrying technology was used to keep the wellbore unblocked after the break-up, and the organic drag reducer YJJZ-1 was introduced to convert the conventional KCl polysulfonate system into the low friction drilling fluid to reduce the friction, through improving the quality of HTHP mud cake and strengthening the combination of anti-sloughing and inhibition of mud, the electric logging and casing running operations in the inclined section are completed.

-

表 1 常规解卡液与改进型解卡液滤液速度

滤液 不同时间下(min)解卡液的滤液体积/mL 1 2 5 10 15 30 60 常规解卡液 4 6 11 16 20 30 46 改进型解卡液 9 12 20 30 39 55 85 注:2种解卡液不同时间的滤液体积为累计量。 表 2 ST2-4井浆中加入YJJZ-1后的 流变性能与泥饼黏滞系数

YJJZ-1/

%ρ/

g·cm−3PV/

mPa·sYP/

Paφ6 φ3 Gel/

PaFLAPI/

mLpH Kf 0 1.30 30 7.5 3 2 1.5/6.0 2.0 9 0.15 0.5 1.30 30 7.5 3 2 1.5/6.0 2.0 9 0.07 1.0 1.30 30 7.5 3 2 1.5/6.0 2.0 9 0.05 1.5 1.30 30 7.5 3 2 1.5/6.0 2.0 9 0.04 表 3 ST2-4井井深4800 m的低摩阻钻井液流变性能

钻井液体系 ρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH Cl-/

mg·L−1Ca2+/

mg·L−1MBT/

g·L−1Kf KCl-聚磺 1.30 73 48 12 1.5/6.0 3.2 9 8 22 470 100 28 0.15 低摩阻 1.30 68 42 14 2.5/9.0 2.0 8 9 32 130 382 35 0.04 低摩阻 1.30 66 38 15 2.5/10.0 1.4 7 9 33 590 450 35 0.03 -

[1] 吕晓平,王卫国,张禄远,等. CaCl2水基解卡剂的研究与医用[J]. 石油地质与工程,2011,25(sl):56-57.LYU Xiaoping, WANG Weiguo, ZHANG Luyuan, et al. Research and medical application of CaCl2 water-based card release agent[J]. Petroleum Geology & Engineering, 2011, 25(sl):56-57. [2] 黎凌,吉永忠,许期聪,等. 巴基斯坦北部区块抗高温高密度柴油基钻井液体系[J]. 钻井液与完井液,2020,37(5):572-577.LI Ling, JI Yongzhong, XU Qicong, et al. High temperature and high density diesel based drilling fluid system[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):572-577. [3] 袁则名,何鹏飞,丁胜,等. 利用机械工具改善大斜度岩屑床问题的研究[J]. 钻采工艺,2019,42(2):83-85.YUAN Zeming, HE Pengfei, DING Sheng, et al. Study on the improvement of high-angle cuttings bed by mechanical tools[J]. Drilling & Production Technology, 2019, 42(2):83-85. [4] 房炎伟,吴义成,张蔚,等. 滴西区块侧钻小井眼水平井钻井液技术[J]. 钻井液与完井液,2021,38(5):611-615.FANG Yanwei, WU Yicheng, ZHANG Wei, et al. Drilling fluid technology for sidetracking slim hole horizontal well in Dixi block[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):611-615. [5] 谢中成,曹明辉,王涛,等. 井眼清洁技术在东海超深大斜度井中的应用[J]. 钻采工艺,2021,44(5):25-30.XIE Zhongcheng, CAO Minghui, WANG Tao, et al. Application of wellbore cleaning technology in ultra-deep and highly deviated wells in the East China Sea[J]. Drilling & Production Technology, 2021, 44(5):25-30. [6] 李振川,姚昌顺,胡开利,等. 水平井井眼清洁技术研究与实践[J]. 新疆石油天然气,2022,18(1):48-53.LI ZhenChuan, YAO Changshun, HU Kaili, et al. Research and practice of wellbore cleaning technology in horizontal wells[J]. Xinjiang Oil & Gas, 2022, 18(1):48-53. [7] 王平全, 马瑞. 泥饼质量的影响因素研究[J]. 钻井液与完井液, 2012, 29(5): 21-25.WANG Pingquan, MA Rui. Study on influencing factors of mud cake quality [ J ] . Drilling Fluid & Completion Fluid, 2012, 29(5) : 21-25. [8] 孙俊,艾佳伟,舒义勇,等. FDM-1成膜封堵剂的实验评价与应用[J]. 钻井液与完井液,2020,37(1):54-58.SUN Jun, AI Jiawei, SHU Yiyong, et al. Experimental evaluation and application of FDM-1 film-forming plugging agent[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):54-58. [9] 杨小华. 提高井壁稳定性的途径及水基防塌钻井液研究与应用进展[J]. 中外能源, 2012, 17(5): 53-58.YANG Xiaohua . Ways to improve wellbore stability and progress in research and application of water-based anti-sloughing drilling fluid [J ] . Sino-Global Energy, 2012, 17(5) : 53-58. [10] 祝学飞, 孙俊, 徐思旭, 等. HT2井三开水基钻井液CO32-和HCO3-污染处理工艺[J]. 钻井液与完井液, 2019, 36(1): 36-40.ZHU Xuefei, SUN Jun, XU Sixu, et al. Treatment process of CO32-and HCO3- contamination in HT2 well tri-open water base drilling fluid [J ] . Drilling Fluid & Completion Fluid, 2019, 36(1) : 36 -40. [11] 王伟吉,高伟,范胜,等. 新型非磺化环保低摩阻钻井液[J]. 钻井液与完井液,2022,39(4):459-465.WANG Weiji, GAO Wei, FAN Sheng, et al. The development and application of a new environmentally friendly low friction non-sulfonate drilling fluid[J]. Drilling Fluid & Completion Fluid, 2022, 39(4):459-465. [12] 赵向阳,孟英峰,侯绪田,等. 沥青质稠油与钻井液重力置换规律与控制技术[J]. 石油钻采工艺,2016,38(5):622-627.ZHAO Xiangyang,MENG Yingfeng,HOU Xutian,et al. Pattern and control of gravity displacement between asphaltic heavy oil and drilling fluid[J]. Oil Drilling & Production Technology, 2016, 38(5):622-627. [13] 李巍,吉永忠,杨刚,等. 一种高效液体型解卡剂在巴基斯坦的研究与应用[J]. 钻井液与完井液,2022,39(1):52-59.LI Wei, JI Yongzhong, YANG Gang, et al. Study and application of a high efficiency liquid pipe freeing agent in Pakistan[J]. Drilling Fluid & Completion Fluid, 2022, 39(1):52-59. [14] 马永乐,张勇,刘晓栋,等. 海域天然气水合物低温抑制性钻井液体系[J]. 钻井液与完井液,2021,38(5):544-551.MA Yongle, ZHANG Yong, LIU Xiaodong, et al. A drilling fluid which inhibits formation of natural gas hydrate at low temperatures in offshore drilling[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):544-551. [15] 孔维升,李晓明,韩成福,等. 致密气藏二开结构水平井钻井液体系及现场应用[J]. 钻井液与完井液,2023,40(1):73-81.KONG Weisheng, LI Xiaoming, HAN Chengfu, et al. The field application of a drilling fluid for a two-interval horizontal well penetrating tight gas reservoir[J]. Drilling Fluid & Completion Fluid, 2023, 40(1):73-81. [16] 胡祖彪,张建卿,王清臣,等. 长庆油田华H50-7井超长水平段钻井液技术[J]. 石油钻探技术,2020,48(4):28-36.HU Zubiao, ZHANG Jinqin, WANG Qingchen,et al. Drilling fluid technology for ultra-long horizontal section of well Hua H50-7 in the Changqing oilfield[J]. Petroleum Drilling Techniques, 2020, 48(4):28-36. [17] 王鼎,万向臣,杨晨. 低摩阻耐压防漏低密度水泥浆固井技术[J]. 钻井液与完井液,2022,39(5):608-614.WANG Ding, WAN Xiangchen, YANG Chen. Well cementing with low friction pressure resistant leaking preventive low density cement slurry[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):608-614. -

下载:

下载: