The Inhibitive Performance and Mechanisms of a Compound Corrosion Inhibitor in Inhibiting P110 Steel in a High Temperature High Density Inorganic Salt Completion Fluid

-

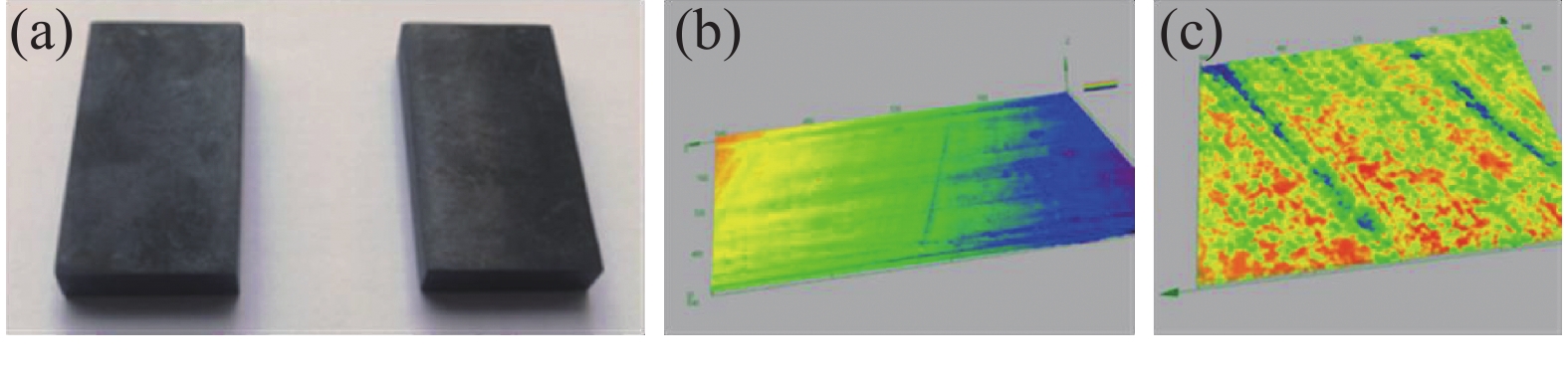

摘要: 针对高温深井(井温>160 ℃,井深>5000 m)的油气勘探开发过程中平衡地层压力、减轻储层伤害及防腐的需要,开发了一种低腐蚀性高密度无机盐完井液体系。采用高温高压腐蚀仪及失重法评价了在不同温度(160~180 ℃)、密度(1.80~2.30 g/cm3)及缓蚀剂加量(1%~5%)下该完井液对P110钢片的腐蚀规律。研究结果表明,随着温度的增加,平均腐蚀速率及点腐蚀速率增加,随着缓蚀剂加量的增加,腐蚀速率随之降低,完井液中的缓蚀剂具有较好的缓蚀效果。采用场发射扫描电镜(SEM)观察了P110钢片表面形成了致密的缓蚀产物膜。采用X-射线能谱仪(EDS)、X-射线光电子能谱仪(XPS)揭示了完井液中缓蚀剂与P110钢片的缓蚀作用机理,在P110钢片表面主要形成了Fe3O4及Fe2O3,以及三价铁与完井液缓蚀剂中有机成分形成的有机铁络合物。缓蚀剂不仅参与了产物膜的生成,而且促进了铁的氧化钝化,协同实现了高密度无机盐完井液在高温下对P110钢的缓蚀效果。低腐蚀性高密度无机盐完井液体系在安徽无为现场试验1口井,在平衡地层压力的基础上,降低了无机盐完井液对完井管柱的腐蚀作用,推广应用前景广阔。Abstract: A high density low-corrosion inorganic completion fluid was developed to try to satisfy the needs of developing petroleum from high temperature deep wells (bottom hole temperature > 160 ℃ and well depth > 5 000 m). These needs include formation pressure balancing, formation damage mitigation and corrosion inhibition. Corrosion of this completion fluid to the P110 steel was evaluated with a high temperature high pressure (HTHP) corrosion tester and weight-loss method at different temperatures (160 – 180 ℃), completion fluid densities (1.80 – 2.30 g/cm3) and corrosion inhibitor concentrations (1% – 5%). The study shows that the average rate of corrosion and the rate of pitting corrosion increase with temperature, and decrease with the concentration of the corrosion inhibitor. The corrosion inhibitor in the completion fluid has good corrosion inhibition effect. The dense film of the corrosion products on the surface of the P110 steel plate tested was observed using SEM. The mechanisms of corrosion inhibition of the corrosion inhibitor in the completion fluid were revealed through X-ray energy spectrometer (EDS) and X-ray photoelectron spectrometer (XPS). It was found that there were Fe3O4, Fe2O3 and an organic iron complex between the trivalent iron and the organic components of the corrosion inhibitor in the completion fluid formed on the surface of the P110 steel plate. The corrosion inhibitor not only takes part in the formation of the product film, it also accelerates the oxidation passivation of the iron, thereby synergistically achieving the inhibition of the corrosion to the P110 steel by the high density inorganic salt completion fluid at elevated temperatures. This high density low-corrosion inorganic salt completion fluid was tried on a well drilled in Wuwei county, Anhui province. The completion fluid not only balanced the formation pressure, it also mitigated the corrosion of the completion fluid to the completion string. This high density low-corrosion completion fluid has broad application prospect.

-

表 1 P110钢片在无机盐高密度完井液及清水中的静态腐蚀规律

BH-HSJ/

%ρ/

g·cm−3T/

℃t/

d平均腐蚀速率/

mm·a−1最大点腐蚀速率/

mm·a−15.0 1.8 160 3 0.2120 7.970 5.0 1.9 160 3 0.0638 未见点蚀 5.0 2.0 160 3 0.4790 2.120 5.0 1.8 180 3 0.8289 3.950 5.0 1.9 180 3 0.2130 1.380 5.0 2.0 180 3 0.6496 3.980 1.0 2.3 180 7 7.1542 15.930 3.6 2.3 180 7 3.4299 7.290 5.0 2.3 180 7 1.6925 5.620 清水 180 7 0.3251 1.732 注:①表1中同一密度的无机盐高密度完井液由同一无机盐配方的基础加重液与特定加量的缓蚀剂制备而成;②高温高压腐蚀实验测试温度为160~180 ℃,压力为25 MPa,测试时间为3~7 d 表 2 P110钢表面各元素含量分析

样品号 ωFe ωC ωO ωN ωZn ωCa ωCl ωBr ωSi 1# 95.80 1.65 1.86 0.38 0.32 2# 53.12 3.97 38.02 3.16 0.63 0.35 0.34 0.20 0.20 注:①1#为未经浸泡的P110空白样;②2#为在高密度无机盐完井液中及在180 ℃及25 MPa下浸泡3 d后的P110试样 -

[1] 唐胜蓝,王茜,张宏强,等. 无固相完井液研究进展[J]. 广州化工,2020,48(6):43-46.TANG Shenglan, WANG Xi, ZHANG Hongqiang, et al. Research progress on solid-free completion fluids[J]. Guangzhou Chemical Industry, 2020, 48(6):43-46. [2] 罗宇峰. 抗高温高密度饱和盐水钻井液在川西地区的应用[J]. 钻采工艺,2017,40(5):98-101. doi: 10.3969/J.ISSN.1006-768X.2017.05.30LUO Yufeng. Application of high-temperature high-density saturated-brine drilling fluid system at west Sichuan[J]. Drilling & Production Technology, 2017, 40(5):98-101. doi: 10.3969/J.ISSN.1006-768X.2017.05.30 [3] 王京光,张小平,杨斌,等. 一种抗高温高密度饱和盐水钻井液的研制[J]. 天然气工业,2012,32(8):79-81. doi: 10.3787/j.issn.1000-0976.2012.08.017WANG Jingguang, ZHANG Xiaoping, YANG Bin, et al. Research and development of a saturated saltwater drilling fluid system with high density and high temperature resistance[J]. Natural Gas Industry, 2012, 32(8):79-81. doi: 10.3787/j.issn.1000-0976.2012.08.017 [4] 史凯娇,徐同台,彭芳芳,等. 国外抗高温高密度甲酸铯/钾钻完井液处理剂与配方[J]. 油田化学,2010,27(2):227-232. doi: 10.19346/j.cnki.1000-4092.2010.02.026SHI Kaijiao, XUN Tongtai, PENG Fangfang, et al. High temperature resistant and high density cesium/potassium formate drilling/completion fluids: additives, composition, and performance properties[J]. Oilfield Chemistry, 2010, 27(2):227-232. doi: 10.19346/j.cnki.1000-4092.2010.02.026 [5] 臧伟伟,徐同台,赵忠举,等. 甲酸铯及其他甲酸盐水溶液的物理化学特性[J]. 油田化学,2010,27(1):100-105. doi: 10.19346/j.cnki.1000-4092.2010.01.027ZANG Weiwei, XU Tongtai, ZHAO Zhongju, et al. Physical and chemical properties of cesium and other formate brines as drilling/completion fluids[J]. Oilfield Chemistry, 2010, 27(1):100-105. doi: 10.19346/j.cnki.1000-4092.2010.01.027 [6] 吴若宁,熊汉桥,岳超先,等. 新型高密度清洁复合盐水完井液[J]. 钻井液与完井液,2018,35(2):138-142. doi: 10.3969/j.issn.1001-5620.2018.02.023WU Ruoning, XIONG Hanqiao, YUE Chaoxian, et al. A new high density solid-free clear saltwater completion fluid[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):138-142. doi: 10.3969/j.issn.1001-5620.2018.02.023 [7] 万里平,孟英峰,卢清兰,等. 塔里木油田有机盐完井液腐蚀研究[J]. 西南石油大学学报,2009,31(1):133-136.WANG Liping, MENG Yingfeng, LU Qinglan, et al. Study on organic salt completion fluid corrosivity in Tarim oilfield[J]. Journal of Southwest Petroleum University(Science & Technoligy Edition) , 2009, 31(1):133-136. [8] 王立翀,吕祥鸿,赵荣怀,等. 超级13Cr与高强15Cr马氏体不锈钢在酸化液中的耐蚀性能对比[J]. 机械工程材料,2014,38(5):57-58.WANG Lichong, LYU Xianghong, ZHAO Ronghuai,et al. Comparison for corrosion properties of super 13Cr and high strength 15Cr martensitic stainless steels in acid solution[J]. Materials for Mechanical Engineering, 2014, 38(5):57-58. [9] 吕祥鸿,赵国仙,张建兵,等. 超级13Cr马氏体不锈钢在CO2及H2S/CO2环境中的腐蚀行为[J]. 北京科技大学学报,2010,32(2):207-212.LYU Xianghong, ZHAO Guoxian, ZHANG Jianbing, et al. Corrosion behaviors of super 13Cr martensitic stainless steel under CO2 and H2S/CO2 environment[J]. Journal of University of Science and Technology Beijing, 2010, 32(2):207-212. [10] 杨向同,吕祥鸿,谢俊峰,等. 高强15Cr马氏体不锈钢在有机盐完井液中的腐蚀行为[J]. 腐蚀与防护,2018,39(12):901-911. doi: 10.11973/fsyfh-201812002YANG Xiangtong, LYU Xianghong, XIE Junfeng, et al. Corrosion behavior of high strength 15Cr martensitic stainless steel in organic salt completion fluid[J]. Corrosion & Protection, 2018, 39(12):901-911. doi: 10.11973/fsyfh-201812002 [11] 朱金阳,张玉楠,郑子易,等. 高温高压含O2溴盐完井液中13Cr不锈钢的腐蚀行为研究[J]. 工程科学与技术,2020,52(5):257-262.ZHU Jinyang, ZHANG Yunan, ZHENG Ziyi, et al. Corrosion behaviors of 13Cr btainless bteels in O2-contained bromine completion fluids under high temperature and high pressure[J]. Advanced Engineering Sciences, 2020, 52(5):257-262. [12] 梁发书,唐力,冷曼希. 盐水完井液缓蚀剂的合成及性能评价[J]. 西南石油大学学报(自然科学版),2009,31(1):128-132.LIANG Fashu, TANG Li, LENG Manxi. Synthesis and performance evaluation of corrosion inhibitor for brine completion fluids[J]. Journal of Southwest Petroleum University (science & technology edition) , 2009, 31(1):128-132. [13] 傅建湘,姚安林,蒋宏业,等. 套管钢在饱和盐水中的腐蚀机理研究[J]. 天然气与石油,2007,25(1):26-28. doi: 10.3969/j.issn.1006-5539.2007.01.009FU Jianxiang, YAO Anlin, JIANG Hongye, et al. Research on corrosion mechanism of casing steel in saturated brine[J]. Natural Gas and Oil, 2007, 25(1):26-28. doi: 10.3969/j.issn.1006-5539.2007.01.009 -

下载:

下载: