Impact Resistance Mechanical Properties and Damage Characteristics of Set Cement Containing Nitril Rubber Powders

-

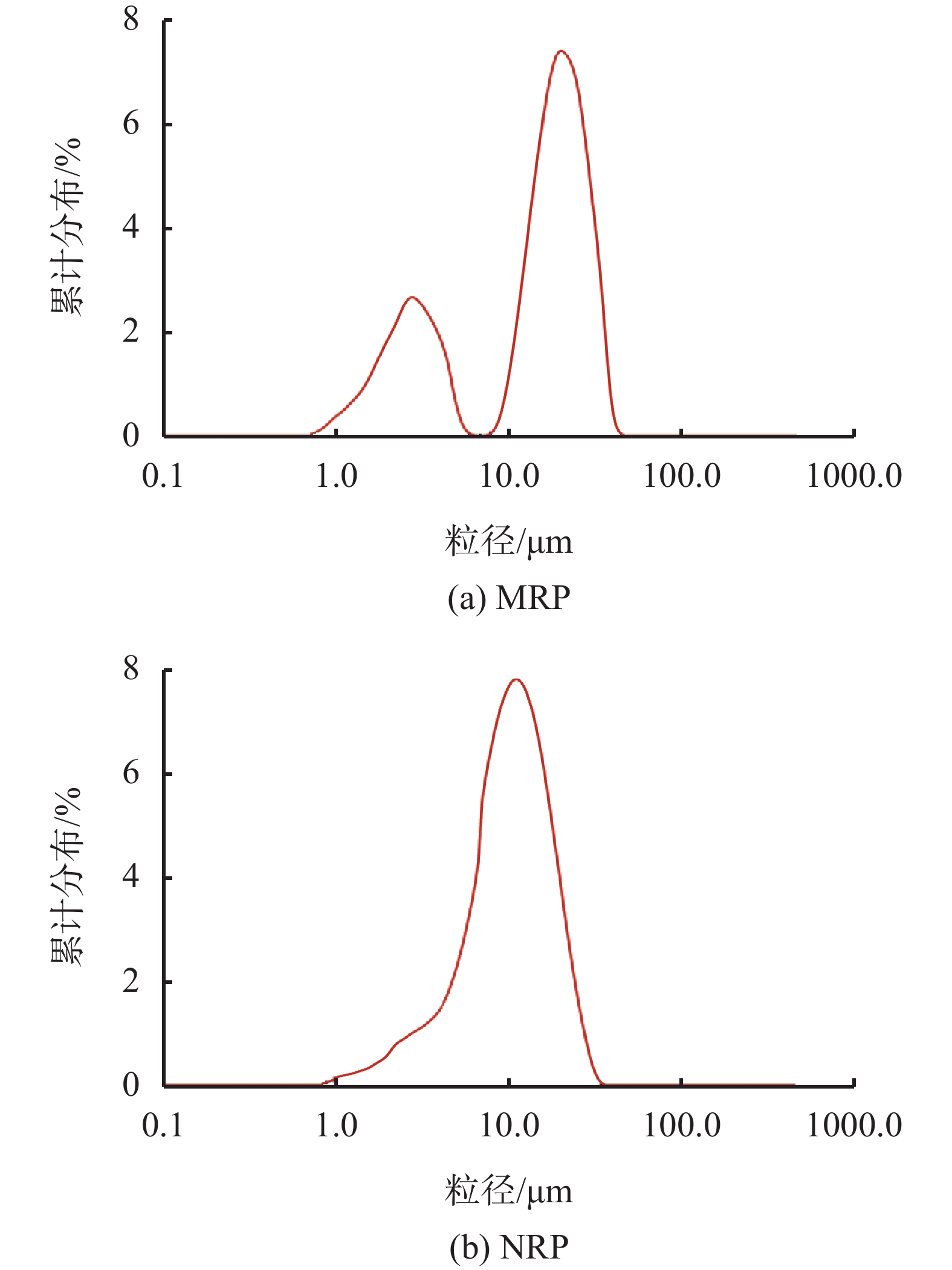

摘要: 油井水泥是一种典型的脆性材料,提高水泥环韧性和降低水泥环脆性是目前的研究热点,在保证油气井安全生产的前提下还能延长油气井使用寿命。该研究将球形丁腈橡胶颗粒(Microsphere nitrile Rubber Powder,MRP)与不规则丁腈橡胶颗粒(Nitrile Rubber Powder,NRP)分别加入到油井水泥中,探讨其抗冲击力学性能与损伤特征。采用直径为50 mm的分离式霍普金森压杆(Split Hopkinson Pressure Bar-SHPB)设备测试了不同体系水泥石的动态抗冲击性能,讨论了动态抗压强度、能量演化、损伤特征的变化规律。球形丁腈橡胶颗粒加量为6%的油井水泥石试样动态抗压强度可达(64.0±1.6) MPa,试样吸收能为39.93 J,吸能率可达49.91%;不规则丁腈橡胶颗粒加量为6%的油井水泥石试样动态抗压强度为(74.1±1.8) MPa,试样吸收能为46.56 J,吸能率可达58.20%。通过高速摄影和微观形貌发现,不规则丁腈橡胶颗粒与水泥基体间结合更加紧密,通过裂纹偏转机制提高阻裂能力,利于延长试样承载时间,加大载荷能量的消耗。Abstract: Oil well cement is a typical brittle material, presently many studies are focused on improving the toughness and reducing the brittleness of the cement sheath, as well as prolonging the service life of an oil/a gas well without impairing the safety of the well. In this study, the microsphere nitrile rubber powder (MRP) and the irregular nitrile rubber powder (NRP) were separately added to cement slurry to investigate the mechanical performance of impact resistance and the damage characteristics of the set cement. Using a split Hopkinson pressure bar (SHPB) with a diameter of 50 mm, the dynamic impact resistance performance of different set cement samples was tested. The dynamic compressive strength, energy evolution and damage characteristics of the set cement samples were discussed using the test results. A set cement sample containing 6% MRP had dynamic compressive strength of 64.02 MPa, and the absorbed energy of the sample was 39.93 J, equivalent to an absorbed energy rate of 49.91%. Another set cement sample containing 6% NRP had dynamic compressive strength of 74.06 MPa, and the absorbed energy of the sample was 46.56 J, equivalent to an absorbed energy rate of 58.20%. It was found from high-speed photographing and micromorphology observation that NRP is more closely bonded with the set cement matrix, and the crack resistance of the set cement was improved through crack deflection mechanism, which is beneficial to prolonging the load bearing time of the sample and increasing the consumption of the load energy.

-

表 1 不同水泥石试样SHPB测试能量特征数据

试样

编号入射能/

J反射能/

J透射能/

J吸收能/

J吸能率/

%峰值强度/

MPaControl 80 36.32 35.94 7.74 9. 68 19.3±1.5 MRP-2% 80 31.08 20.70 28.22 35.28 42.1±2.7 MRP-4% 80 29.50 18.45 32.05 40.06 53.7±2.0 MRP-6% 80 26.39 13.68 39.93 49.91 64.0±1.6 MRP-8% 80 28.92 16.84 34.24 42.80 57.5±2.0 NRP-2% 80 29.02 23.64 27.34 34.18 46.0±2.5 NRP-4% 80 26.95 13.07 39.98 49.98 63.7±2.0 NRP-6% 80 24.49 8.95 46.56 58.20 74.1±1.8 NRP-8% 80 26.17 11.58 42.25 52.81 66.6±2.1 -

[1] DENG K H, LIU W Y, XIA T G, et al. Experimental study the collapse failure mechanism of cemented casing under non-uniform load[J]. Engineering Failure Analysis, 2017, 73:1-10. doi: 10.1016/j.engfailanal.2016.12.002 [2] WANG W, TALEGHANI A D. Three-dimensional analysis of cement sheath integrity around wellbores[J]. Journal of Petroleum Science and Engineering, 2014, 121:38-51. doi: 10.1016/j.petrol.2014.05.024 [3] XI Y, LI J, LIU G H, et al. A new numerical investigation of cement sheath integrity during multistage hydraulic fracturing shale gas wells[J]. Journal of Natural Gas Science and Engineering, 2018, 49:331-341. doi: 10.1016/j.jngse.2017.11.027 [4] 程小伟,秦丹,赵殊勋,等. 动态冲击下纤维素固井水泥石力学性能及增韧机理研究[J]. 硅酸盐通报,2019,38(6):1918-1922,1928.CHENG X W, QIN D, ZHAO S X, et al. Mechanical properties and toughening mechanism of cellulose cement under dynamic impact[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(6):1918-1922,1928. [5] ZHANG W G, ZHANG Y L, LIU B C. Hybrid effect of basalt fiber and carbon fiber on the mechanical properties and microstructure of oil well cement[J]. Construction and Building Materials, 2021, 286:12269. [6] CHENG X W, HUANG S, GUO X Y, et al. Crumb waste tire rubber surface modification by plasma polymerization of ethanol and its application on oil-well cement[J]. Applied Surface Science, 2017, 409(1):325-342. [7] 王秀玲,任文亮,周战云,等. 储气库固井用油井水泥增韧材料的优选与应用[J]. 钻井液与完井液,2017,34(03):89-93,98. doi: 10.3969/j.issn.1001-5620.2017.03.018WANG X L, REN W L, ZHOU Z Y, et al. Selection and application of toughening agent used in cementing gas storage well[J]. Drilling Fluid & Completion Fluid, 2017, 34(03):89-93,98. doi: 10.3969/j.issn.1001-5620.2017.03.018 [8] 何智海,李增,詹培敏,等. 橡胶粉对水泥基材料性能影响的研究进展[J]. 混凝土,2020(6):73-78. doi: 10.3969/j.issn.1002-3550.2020.06.017HE Z H, Ll Z, ZHAN P M, et al. Research progress of effect of rubber powder on the properties of cement-based materials[J]. Concrete, 2020(6):73-78. doi: 10.3969/j.issn.1002-3550.2020.06.017 [9] 陈胜霞,张亚梅,罗天岚,等. 橡胶颗粒细度、掺量及成型工艺对橡胶混凝土抗冻性能的影响[J]. 工业建筑,2020,43(6):73-78.CHEN S X, ZHANG Y M, LUO T L, et al. Influenceofrubber fineness, content and casting method on frostresistance of recycled rubber concrete[J]. Industrial Construction, 2020, 43(6):73-78. [10] 龙丹,程小伟,时宇,等. 微细橡胶粉对油井水泥基复合材料性能的影响[J]. 硅酸盐通报,2015,34(9):2629-2633,2638.LONG D, CHENG X W, SHI Y, et al. Properties of oil well cement-based composite with minute rubber powder[J]. Bulletin of the Chinese Ceramic Society, 2015, 34(9):2629-2633,2638. [11] 李进,龚宁,李早元,等. 射孔完井工况下固井水泥环破坏研究进展[J]. 钻井液与完井液,2016,33(6):10-16. doi: 10.3969/j.issn.1001-5620.2016.06.002LI J, GONG N, LI Z Y, et al. Progress in studying cement sheath failure in perforated wells[J]. Drilling Fluid & Completion Fluid, 2016, 33(6):10-16. doi: 10.3969/j.issn.1001-5620.2016.06.002 [12] CHENG X W, LIU K Q, ZHANG Y G, et al. Integrity changes of cement sheath due to contamination by drilling fluid[J]. Advances in Cement Research, 2018, 30(2):47-55. doi: 10.1680/jadcr.16.00121 [13] 闫炎,管志川,阎卫军,等. 射孔过程中井筒力学响应与完整性失效研究[J]. 石油机械,2022,50(7):1-9. doi: 10.16082/j.cnki.issn.1001-4578.2022.07.001YAN Y, GUAN Z C, YAN W J, et al. Mechanical response and integrity failure of wellbore during perforation[J]. China Petroleum Machinery, 2022, 50(7):1-9. doi: 10.16082/j.cnki.issn.1001-4578.2022.07.001 [14] SHIYAN S I, SHUTOV D V, FESENKO M Y, et al. Application of drilling oscillator during drilling directional wells in the field conditions of gubkinskoye oil and gas field while drilling No. 2156[J]. IOP Conference Series:Earth and Environmental Science, 2021, 720:012071. doi: 10.1088/1755-1315/720/1/012071 [15] DENG Q, ZHANG H, CHEN A M, et al. Effects of perforation fluid movement on downhole packer with shock loads[J]. Journal of Petroleum Science and Engineering, 2020, 195:107566. doi: 10.1016/j.petrol.2020.107566 [16] American Petroleum Institute (API), API 10B-2, Recommended prectice for testing well cements, Second Edition, 2013. [17] LI D Y, HAN Z Y, SUN X L, et al. Dynamic mechanical properties and fracturing behavior of marble specimens containing single and double flaws in SHPB tests[J]. Rock Mechanics and Rock Engineering, 2019, 52(6):1623-1643. doi: 10.1007/s00603-018-1652-5 [18] LI X B, LOK T S, ZHAO J. Dynamic characteristics of granite subjected to intermediate loading rate[J]. Rock Mechanics and Rock Engineering, 2005, 38(1):21-39. doi: 10.1007/s00603-004-0030-7 [19] LUO L, LI X B, TAO M, et al. Mechanical behavior of rock-shotcrete interface under static and dynamic tensile loads[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research, 2017, 65:215-224. [20] HAN Z Y, LI D Y, ZHOU T, et al. Experimental study of stress wave propagation and energy characteristics across rock specimens containing cemented mortar joint with various thicknesses[J]. International Journal of Rock Mechanics and Mining Sciences, 2020:131. [21] HAN Z Y, LI D Y, ZHU Q Q, et al. Dynamic fracture evolution and mechanical behavior of sandstone containing noncoplanar elliptical flaws under impact loading[J]. Advances in Civil Engineering, 2018, 2018(10):5649357. [22] GUO Y B, GAO G F, JING L, et al. Response of high-strength concrete to dynamic compressive loading[J]. International Journal of Impact Engineering, 2017, 108:114-135. doi: 10.1016/j.ijimpeng.2017.04.015 [23] LIU P, HU D, WU Q K, et al. Sensitivity and uncertainty analysis of interfacial effect in SHPB tests for concrete-like materials[J]. Construction and Building Materials, 2018, 163:414-427. doi: 10.1016/j.conbuildmat.2017.12.118 [24] LI J, ZHAO J, GONG S Y, et al. Mechanical anisotropy of coal under coupled biaxial static and dynamic loads[J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 143:104807. doi: 10.1016/j.ijrmms.2021.104807 [25] CHENG X W, QIN D, CHEN Z W, et al. Mechanical response and crack propagation of oil well cement under dynamic and static loads[J]. Journal of Adhesion Science and Technology, 2019, 33(15):1658-1675. doi: 10.1080/01694243.2019.1610203 [26] XIE Y J, FU Q, ZHENG K R, et al. Dynamic mechanical properties of cement and asphalt mortar based on SHPB test[J]. Construction and Building Materials, 2014, 70:217-225. doi: 10.1016/j.conbuildmat.2014.07.092 [27] WANG Q Z, LI W, XIE H P. Dynamic split tensile test of flattened brazilian disc of rock with SHPB setup[J]. Mechanics of Materials, 2008, 41(3):252-260. [28] WANG S, LE H, POH L H, et al. Effect of high strain rate on compressive behavior of strain-hardening cement composite in comparison to that of ordinary fiber-reinforced concrete[J]. Construction and Building Materials, 2016, 136:31-43. -

下载:

下载: