Numerical Simulation Study on Mechanics of High Density Elastic and Tough Cement Slurries

-

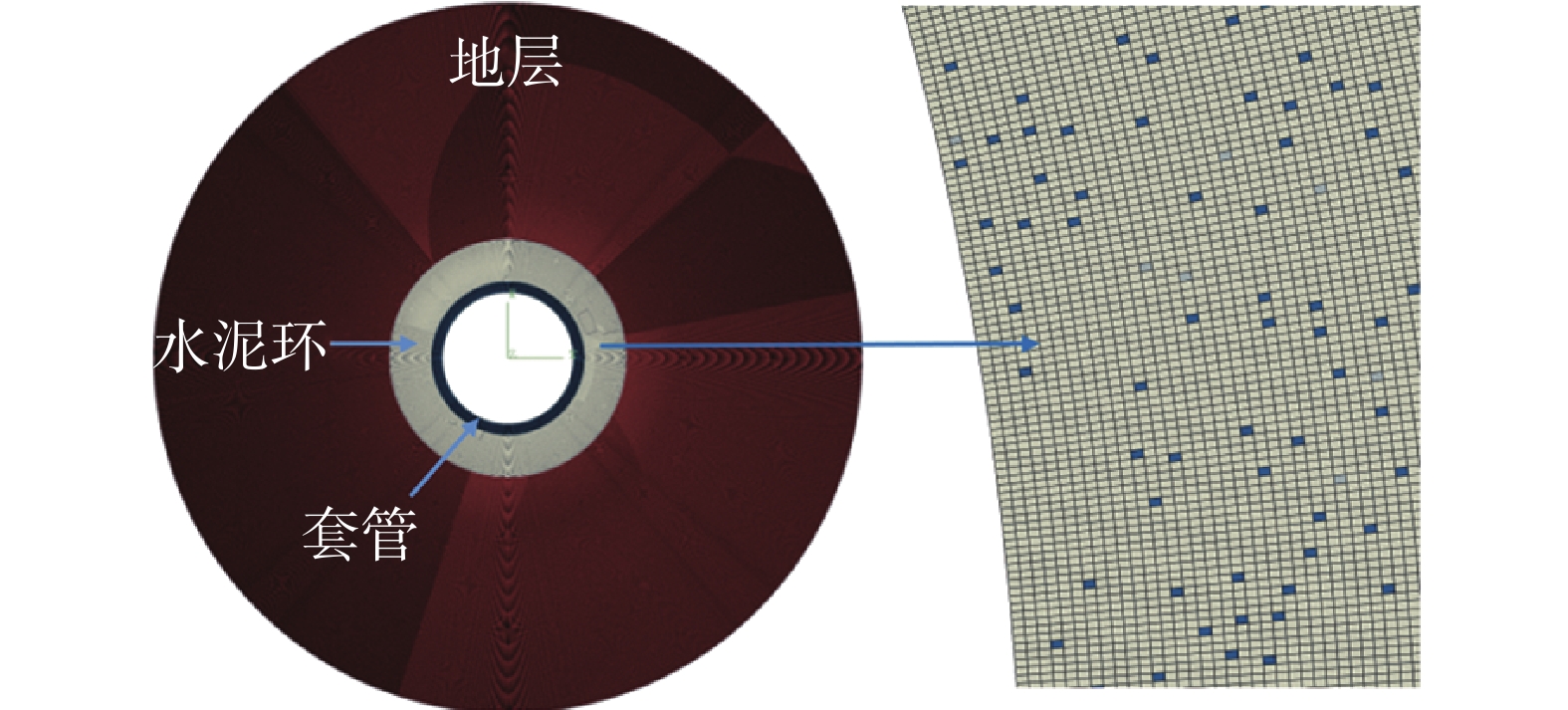

摘要: 深层页岩气具有埋藏深、地温高、破裂压力高等特点,压裂过程中,大排量、高泵压的施工方式导致气井环空带压问题较为突出。相较于浅层页岩气,深层页岩气井由于气层高压,水泥浆需要进行加重以满足现场施工需要,水泥环不仅是由纯水泥构成,还包含加重剂以及弹韧性改造用的弹性剂。因此,为从水泥浆配方上改善深层页岩气井水泥环的力学性能,针对高密度弹韧性水泥浆体系建立了相应的细观力学模型,初步分析了外掺料的加入对水泥石力学性能的影响。研究发现:①加重剂与弹性剂由于其刚度的差异,改变了水泥环的宏观力学性能;②水泥浆体系设计需考虑弹性剂与加重剂的几何尺寸,并提高弹性材料与水泥基体的胶结强度;③优选类菱形加重材料及亲水性弹性材料,通过合理配比设计出密度为2.3 g/cm3的高密度弹韧性水泥浆,该水泥浆48 h抗压强度大于20 MPa,弹性模量小于7 GPa,实现了深层页岩气水泥环低弹性模量、高强度的力学性能改造目标。研究成果对深层页岩气水泥浆体系的设计具有重要指导意义。Abstract: Deep shale gas reservoirs are buried in deep formations with high temperatures and high fracture pressures. In fracturing these reservoirs, high flowrate and high pump pressure result in severe problem of sustained annular pressure. Compared with shallow shale gas reservoirs, deep shale gas reservoirs, because of their high formation pressures, have to be cased off with weighted cement slurries. The cement sheath is composed of not only the pure cement, it also contains weighting agents and additives that are used to improve the elasticity of the cement sheath. Based on this idea, a meso-mechanical model for high density elastic cement slurries is established to guide the improvement of the mechanical performance of the cement sheath in deep shale gas reservoirs. The effects of the additives added into a cement slurry on the mechanical performance of the set cement has been preliminarily analyzed. It was found in the study that 1) weighting materials and elasticity additives, because of the difference in their rigidity, can change the macro-mechanical performance of the set cement; 2) the interaction between the physical dimensions of the elasticity additives and the weighting agents must be considered in cement slurry design, and the bonding strength of the elasticity additive with the cement must be strengthened; 3) a cement slurry was designed with a selected weight material, whose particles are in rhombus-like shape, and a hydrophilic elastic agent. The mass ratio of the two additives was determined through experiment. This cement slurry, which has a density of 2.3 g/cm3, has 48 h compressive strength of greater than 20 MPa, and a elastic modulus of less than 7 GPa. With this cement slurry, a cement sheath of low elastic modulus and high strength cement sheath can be obtained in cementing deep shale gas reservoirs. The study achievements are of great guiding importance to the design of cement slurries for use in deep shale gas reservoirs.

-

Key words:

- Deep shale gas reservoir /

- Elasticity additive /

- Weighting agent /

- Cement slurry /

- Well cementing

-

表 1 模型材料参数

介质 外径/mm 内径/mm 弹性模量/GPa 泊松比 套管 139.7 121.4 210 0.30 水泥环 215.9 139.7 14 0.15 地层 36 0.20 弹性剂 0.006 0.60 加重剂 206 0.30 表 2 水泥浆流变性能

ρ/

g·cm−3粒径/

目水灰比 稳定性 流变性能 ρ上/

(g·cm−3)ρ下/

(g·cm−3)7.0 300 0.5 2.30 2.30 25/34/280/-/-/- 7.0 200 0.5 2.15 2.45 5/8/120/145/210/- 6.0 200 0.5 2.27 2.33 7/13/130/200/275/- 5.0 200 0.5 2.30 2.30 19/23/198/-/-/- 表 3 弹性剂加量对不同粒径加重剂水泥石强度的影响

弹性剂/% 不同粒径加重剂水泥石的强度/MPa 90目 60目 2 30.27 28.86 4 29.35 27.38 6 27.20 24.95 8 23.46 19.06 -

[1] 陶谦,陈星星. 四川盆地页岩气水平井B环空带压原因分析与对策[J]. 石油钻采工艺,2017(5):588-593. doi: 10.13639/j.odpt.2017.05.011TAO Qian, CHEN Xingxing. Causal analysis and countermeasures on B sustained casing pressure of shale gas horizontal wells in the Sichuan basin[J]. Oil Drilling & Production Technology, 2017(5):588-593. doi: 10.13639/j.odpt.2017.05.011 [2] 孙坤忠, 陶谦, 周仕明, 等. 丁山区块深层页岩气水平井固井技术[J]. 石油钻探技术, 2015, 43(3): 55-60.SUN Kunzhong, TAO Qian, ZHOU Shiming, et al. Cementing technology for deep shale gas horizontal well in the Dingshan block[J]. Petroleum Drilling Techniques, 2015, 43(3): 55-60. [3] GOODWIN K J, CROOK R J. Cement sheath stress failure[J]. SPE Drilling Engineering, 1992, 7(4):291-296. doi: 10.2118/20453-PA [4] JACKSON P B, MURPHEY C E. Effect of casing pressure on gas flow through a sheath of set cement[C]// SPE/IADC Drilling Conference, Society of Petroleum Engineers, 1993. [5] TORSTER M , ALBAWI A , ANDRADE J D , et al. Experimental set-up for testing cement sheath integrity in Arctic wells[C]//OTC Arctic Technology Conference,2014. [6] 殷有泉,陈朝伟,李平恩. 套管-水泥环-地层应力分布的理论解[J]. 力学学报,2006,38(6):835-842. doi: 10.3321/j.issn:0459-1879.2006.06.015YIN Youquan, CHEN Zhaowei, LI Ping’en. Theoretical solutions of stress distribution in casing-cement and stratum system[J]. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(6):835-842. doi: 10.3321/j.issn:0459-1879.2006.06.015 [7] 李军,陈勉,柳贡慧,等. 套管、水泥环及井壁围岩组合体的弹塑性分析[J]. 石油学报,2005(6):99-103. doi: 10.3321/j.issn:0253-2697.2005.06.023LI Jun, CHEN Mian, LIU Gonghui, et al. Elastic-plastic analysis of casing-concrete sheath-rock combination[J]. Acta Petrolei Sinica, 2005(6):99-103. doi: 10.3321/j.issn:0253-2697.2005.06.023 [8] 陈朝伟, 蔡永恩. 套管-地层系统套管载荷的弹塑性理论分析[J]. 石油勘探与开发, 2009, 36(2): 242-246.CHEN Chaowei, CAI Yong’en. Study on casing load in a casing-stratum system by elastoplastic theory[J]. Petroleum Exploration and Development, 2009, 36(2): 242-246. [9] 初纬,沈吉云,杨云飞,等. 连续变化内压下套管-水泥环-围岩组合体微环隙计算[J]. 石油勘探与开发,2015,42(3):379-385. doi: 10.1016/S1876-3804(15)30028-8CHU Wei, SHEN Jiyun, YANG Yunfei, et al. Calculation of micro-annulus size in casing-cement sheath-formation system under continuous internal casing pressure change[J]. Petroleum Exploration and Development, 2015, 42(3):379-385. doi: 10.1016/S1876-3804(15)30028-8 [10] 范明涛,李军,柳贡慧,等. 页岩气体积压裂固井界面微环隙产生机理研究[J]. 石油机械,2018(10):78-82. doi: 10.16082/j.cnki.issn.1001-4578.2018.10.015FAN Mingtao, LI Jun, LIU Gonghui, et al. Research on micro-gap generation of shale gas well cementing interface during SRV fracturing[J]. China Petroleum Machinery, 2018(10):78-82. doi: 10.16082/j.cnki.issn.1001-4578.2018.10.015 [11] 刘奎,丁士东,周仕明,等. 套管内压周期变化水泥环应力计算与失效分析[J]. 石油机械,2021(5):1-8. doi: 10.16082/j.cnki.issn.1001-4578.2021.05.001LIU Kui, DING Shidong, ZHOU Shiming, et al. Stress calculation and failure analysis of cement sheath experiencing periodic variation of casing internal pressure[J]. China Petroleum Machinery, 2021(5):1-8. doi: 10.16082/j.cnki.issn.1001-4578.2021.05.001 [12] 张顺平,张森,覃毅,等. 威远页岩气水平井高密度防窜水泥浆固井技术[J]. 钻井液与完井液,2016,33(1):63-67.ZHANG Shunpin, ZHANG Sen, TAN Yi, etal. Anti-channeling high density cement slurry technology for horizontal shale gas well in Weiyuan[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):63-67. [13] 李坤,徐孝思,黄柏宗. 紧密堆积优化水泥浆体系的优势与应用[J]. 钻井液与完井液,2002,19(1):4-9. doi: 10.3969/j.issn.1001-5620.2002.01.001LI Kun, XU Xiaosi, HUANG Baizong. Advantages and application of the novel cement slurry systems developed by the concept of high packing density[J]. Drilling Fluid & Completion Fluid, 2002, 19(1):4-9. doi: 10.3969/j.issn.1001-5620.2002.01.001 -

下载:

下载: