Study on the Influence of Elastic Toughness Cement Slurry Performance and Short-term Corrosion Mechanism under HPHTHS Conditions

-

摘要: 针对固井水泥石所处的高温高压含H2S/CO2腐蚀环境以及复杂工况,开展三高条件下弹韧性水泥浆的性能变化及短期腐蚀机理研究。基于弹韧性外掺料的3种主要类型,采用向G级油井水泥中分别加入10%橡胶粉末、0.3%玄武岩纤维以及10%丁苯胶乳的方式制备弹性水泥浆。通过力学性能测试、XRD、FTIR、MIP及SEM-EDS测试,分析弹韧性材料添加前后及腐蚀前后,水泥石的力学性能、孔径分布、水化产物类型及微观结构变化。结果表明,掺入3种弹韧性材料均有利于水泥石的脆度系数降低、韧性提高,其中玄武岩纤维最利于控制材料破坏时裂缝的发展,而丁苯胶乳最利于降低材料的弹性模量和保持较大的抗折强度。经过短期液相腐蚀后,水泥试样的力学强度均出现增长,特别是掺入玄武岩纤维和丁苯胶乳的试样。玄武岩纤维在该研究中的腐蚀条件下性能稳定,腐蚀反应生成的致密碳酸钙晶体堆积于玄武岩纤维与水泥基质界面孔隙处,引起了腐蚀后材料总孔容的减小及力学强度的大幅度增长。丁苯胶乳在水泥石中形成聚合物膜,覆盖及包裹水泥基质,可提高复合水泥表面的耐腐蚀性能。Abstract: To understand the corrosion environment of a set cement at high temperature, high pressure and high H2S/CO2 conditions and the complex work condition thus formed, a series of experiments were conducted to study the property change and short-term corrosion mechanisms of elastic tough cement slurries under the “three-high” conditions. A class G cement slurry was treated with three main elastic tough additives commonly used, i.e., rubber powder at 10%, basalt fiber at 0.3% and styrene-butadiene latex at 10%. The cement slurry thus formulated was rendered elasticity to some extent. Using several methods such as mechanical property measurement, XRD, FTIR, MIP and SEM-EDS etc., changes were studied in the mechanical properties, distribution of pore throat sizes, types of hydration products and micro-structures before and after the cement slurry was treated with the three additives and was cured under corrosion conditions. The measurement results show that the addition of the three elastic tough additives is beneficial to the decrease of the brittleness and to the increase of the toughness of the set cement. Among these additives, the basalt fiber is the best additive for controlling the fracture development in the set cement when it fails, and the styrene-butadiene latex is the best additive for reducing the elastic modulus and maintaining a high flexural strength of the set cement. After undergoing a short-term corrosion in liquid environment, the mechanical strengths of the cement samples were all improved, especially the set cement containing basalt fiber and styrene-butadiene latex. Basalt fiber under the corrosion conditions showed stable properties, the dense calcium carbonate crystals produced in the corrosion process were piled in the pores located at the interfaces between the basalt fiber and the cement matrix, leading to a decrease in the total pore volume in the corroded set cement and a substantial increase in the mechanical strength of the set cement. The styrene-butadiene latex can form a polymer membrane inside the set cement, which covers and wraps up the cement matrix, thereby improving the anti-corrosion property of the cement surfaces.

-

Key words:

- Elastic and tough cement slurry /

- High temperature /

- High pressure /

- H2S /

- CO2 /

- Corrosion /

- Northeast area of Sichuan Province

-

表 1 弹韧性水泥浆实验配方

配方 油井

水泥/g橡胶

颗粒/g玄武

岩纤维/g丁苯

胶乳/g消泡

剂/g稳定

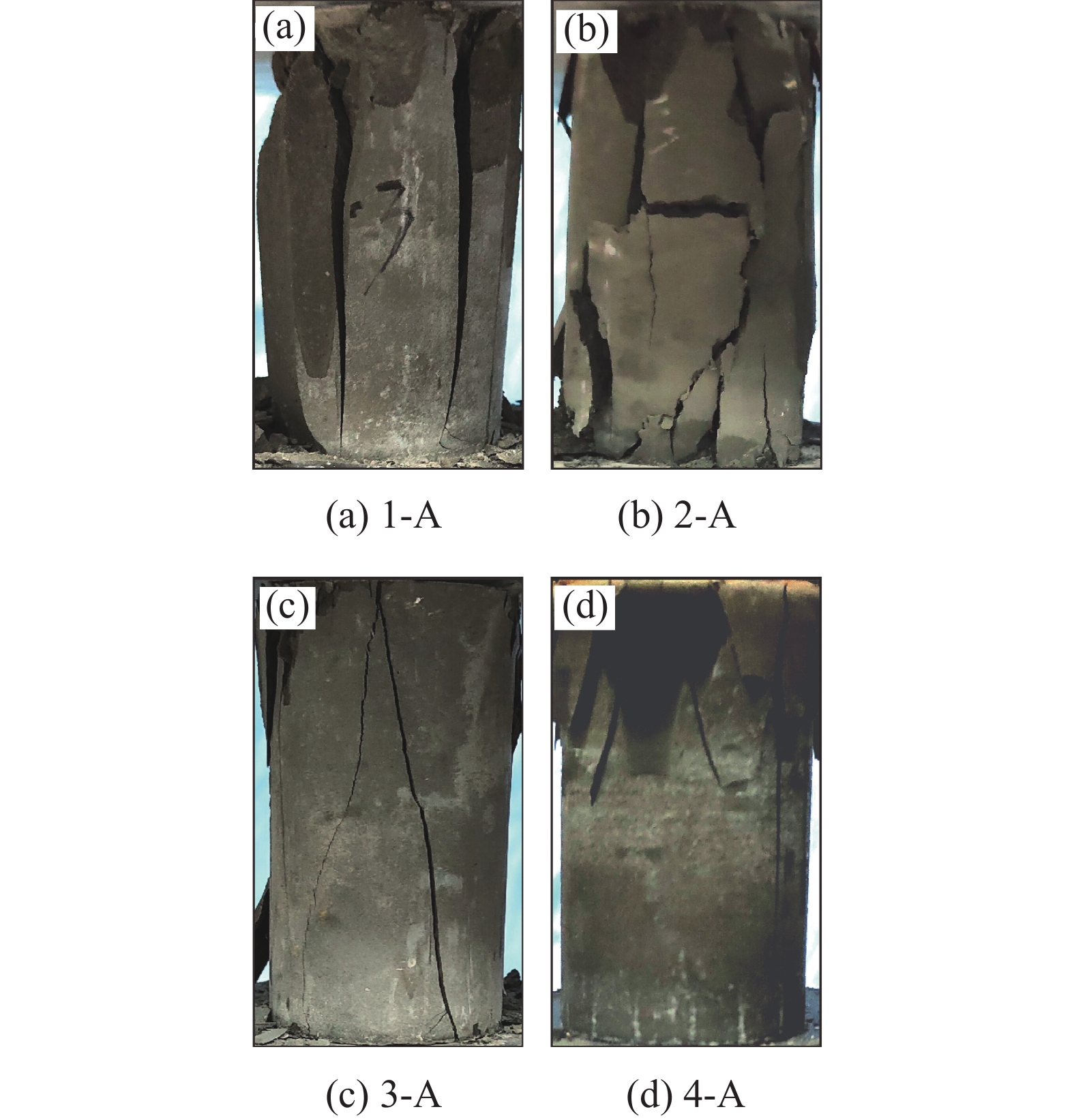

剂/g水灰比 1# 1000 0 0 0 0 0 0.44 2# 1000 100 0 0 0 0 0.44 3# 1000 0 3 0 0 0 0.44 4# 1000 0 0 100 3 3 0.44 表 2 试块腐蚀前后的力学性能

试块 抗压强度/

MPa抗折强度/

MPa弹性模量/

GPa脆度系数 1-A 39.57 6.52 6.89 6.07 2-A 16.24 4.63 1.40 3.51 3-A 21.47 5.39 2.31 3.98 4-A 15.49 5.65 1.35 2.74 1-B 46.94 7.31 7.04 6.42 2-B 18.53 5.24 1.57 3.54 3-B 29.12 6.67 3.22 4.37 4-B 21.34 6.82 1.46 3.13 表 3 试样腐蚀前后压汞数据统计

试块 总孔容/

mL·g−1平均孔径/

4V/A中间孔径 V/

nm中间孔径 A/

nm1-A 0.2179 40.7 88.1 15.2 2-A 0.2246 118.5 303.9 44.9 3-A 0.2241 43.5 15.7 96.0 4-A 0.1616 69.7 69.6 57.9 1-B 0.1868 32.5 70.2 12.7 2-B 0.2299 42.5 122.9 13.9 3-B 0.1859 30.5 63.3 12.9 4-B 0.2100 30.4 56.5 14.5 -

[1] 李明,刘萌,杨元意,等. 碳酸钙晶须与碳纤维混杂增强油井水泥石力学性能[J]. 石油勘探与开发,2015,42(1):94-100. doi: 10.11698/PED.2015.01.12LI Ming, LIU Meng, YANG Yuanyi, et al. Mechanical properties of oil well cement stone reinforced with hybrid fiber of calcium carbonate whisker and carbon fiber[J]. Petroleum Exploration and Development, 2015, 42(1):94-100. doi: 10.11698/PED.2015.01.12 [2] 李斐. 抗高温弹韧性水泥浆体系优化研究[J]. 钻井液与完井液,2021,38(5):623-627.LI Fei. Study on optimization of high temperature cement slurry with elasticity and toughness[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):623-627. [3] 李早元. 有助于改善层间封隔能力的聚合物多元水泥体系材料特性研究[D]. 成都: 西南石油大学, 2006.LI Zaoyuan. Multi-polymer material cement system properties research increasing zonal isolation performance[D]. Chengdu: Southwest Petroleum University, 2006. [4] 程小伟,张明亮,杨永胜,等. 玄武岩纤维对铝酸盐水泥石性能的影响[J]. 石油钻采工艺,2016,38(1):42-47.CHENG Xiaowei, ZHANG Mingliang, YANG Yongsheng, et al. Effects of basalt fiber on the performance of aluminate cement stone[J]. Oil Drilling & Production Technology, 2016, 38(1):42-47. [5] 姜宏图,肖志兴,鲁胜,等. 丁苯胶乳水泥浆体系研究及应用[J]. 钻井液与完井液,2004,21(1):32-35. doi: 10.3969/j.issn.1001-5620.2004.01.010JIANG Hongtu, XIAO Zhixing, LU Sheng, et al. Styrene-butadiene latex cement slurry system and its application[J]. Drilling Fluid & Completion Fluid, 2004, 21(1):32-35. doi: 10.3969/j.issn.1001-5620.2004.01.010 [6] 严思明,王杰,卿大咏,等. 硫化氢对固井水泥石腐蚀研究[J]. 油田化学,2010,27(4):366-370,394.YAN Siming, WANG Jie, QING Dayong, et al. Research on corrosion of oil well cement stone by H2S[J]. Oilfield Chemistry, 2010, 27(4):366-370,394. [7] 天娇,庞忠和,李义曼,周晓成. 地热气体研究进展[J]. 地质学报,2022,96(5):1752-1766. doi: 10.3969/j.issn.0001-5717.2022.05.015TIAN Jiao, PANG Zhonghe, LI Yiman, et al. Research progress on geothermal gas[J]. Acta Geologica Sinica, 2022, 96(5):1752-1766. doi: 10.3969/j.issn.0001-5717.2022.05.015 [8] 夏杰勤,窦斌,谷俊廷,等. 深井CO2爆破致裂干热岩系统综合效应预评价[J]. 太阳能学报,2022,43(5):21-29.XIA Jieqin, DOU Bin, GU Junting, et al. Pre-evaluation of comprehensive effect of deepwell CO2 blasting and fracturing hot dry rock system[J]. Acta Energiae Solaris Sinica, 2022, 43(5):21-29. [9] 岑芳,李治平,张彩,等. 含硫气田硫化氢腐蚀[J]. 资源·产业,2005(4):79-81.CEN Fang, LI Zhiping, ZHANG Cai, et al. Hydrogen sulfide corrosion in sour gas reservoir[J]. Resources & Industries, 2005(4):79-81. [10] 陆沛青,桑来玉,谢少艾,等. 苯丙胶乳水泥浆防气窜效果与失重规律分析[J]. 石油钻探技术,2019,47(1):52-58. doi: 10.3969/j.issn.1008-9446.2009.03.005LU Peiqing, SANG Laiyu, XIE Shaoai, et al. Analysis of the anti-gas channeling effect and weight loss law of styrene-acrylic latex cement slurry[J]. Petroleum Drilling Techniques, 2019, 47(1):52-58. doi: 10.3969/j.issn.1008-9446.2009.03.005 [11] XU B H, YUAN B, WANG Y Q. Anti-corrosion cement for sour gas (H2S-CO2) storage and production of HTHP deep wells[J]. Applied Geochemistry, 2018, 96:155-163. doi: 10.1016/j.apgeochem.2018.07.004 [12] PENG Z G, LV F L, FENG Q, et al. Enhancing the CO2-H2S corrosion resistance of oil well cement with a modified epoxy resin[J]. Construction and Building Materials, 2022, 326:126854. doi: 10.1016/j.conbuildmat.2022.126854 [13] 徐璧华,宋茂林,李霜,等. 水泥石抗盐防CO2/H2S腐蚀研究[J]. 钻井液与完井液,2010,27(5):58-60.XU Bihua, SONG Maolin, LI Shuang, et al. Study on salt-resisting and anti-corrosive with CO2/H2S of set cement[J]. Drilling Fluid & Completion Fluid, 2010, 27(5):58-60. [14] 刘伟刚. H2S与CO2环境下油井水泥石腐蚀规律研究[D]. 成都: 西南石油大学, 2017.LIU Weigang. Study on corrosion rule of oil well cement slurry in H2S and CO2 environment [D]. Chengdu: Southwest Petroleum University, 2016. [15] XU B H, YUAN B, WANG Y Q, et al. H2S-CO2 mixture corrosion-resistant Fe2O3-amended wellbore cement for sour gas storage and production wells[J]. Construction and Building Materials, 2018, 188:161-169. doi: 10.1016/j.conbuildmat.2018.08.120 [16] ZHANG Y H, XU M B, SONG J J, et al. Study on the corrosion change law and prediction model of cement stone in oil wells with CO2 corrosion in ultra-high-temperature acid gas wells[J]. Construction and Building Materials, 2022, 323:125879. doi: 10.1016/j.conbuildmat.2021.125879 [17] А·Ф·阿克拉莫维奇,刘春全. H2S对固井材料的腐蚀过程研究[J]. 西南石油大学学报(自然科学版),2010,32(6):1-4.Агзамов·Фарит·Акрамович, LIU chunquan. Study on the corrosion process of H2S on cementing materials[J]. Journal of Southwest Petroleum University (Science&Technology Edition) , 2010, 32(6):1-4. [18] CHENG X W, MEI K Y, LI Z Y, et al. Research on the Interface Structure during Unidirectional Corrosion for Oil-Well Cement in H2S Based on Computed Tomography Technology[J]. Industrial & Engineering Chemistry Research, 2016, 55:10889-10895. [19] KUTCHKOA B G, STRAZISARA B R, HAWTHORNEB S B, et al. H2S-CO2 reaction with hydrated class H well cement acid gas injection and CO2[J]. International Journal of Greenhouse Gas Control, 2011, 5:880-888. doi: 10.1016/j.ijggc.2011.02.008 -

下载:

下载: