Study and Application of a High Temperature Retarding Agent for Well Cementing

-

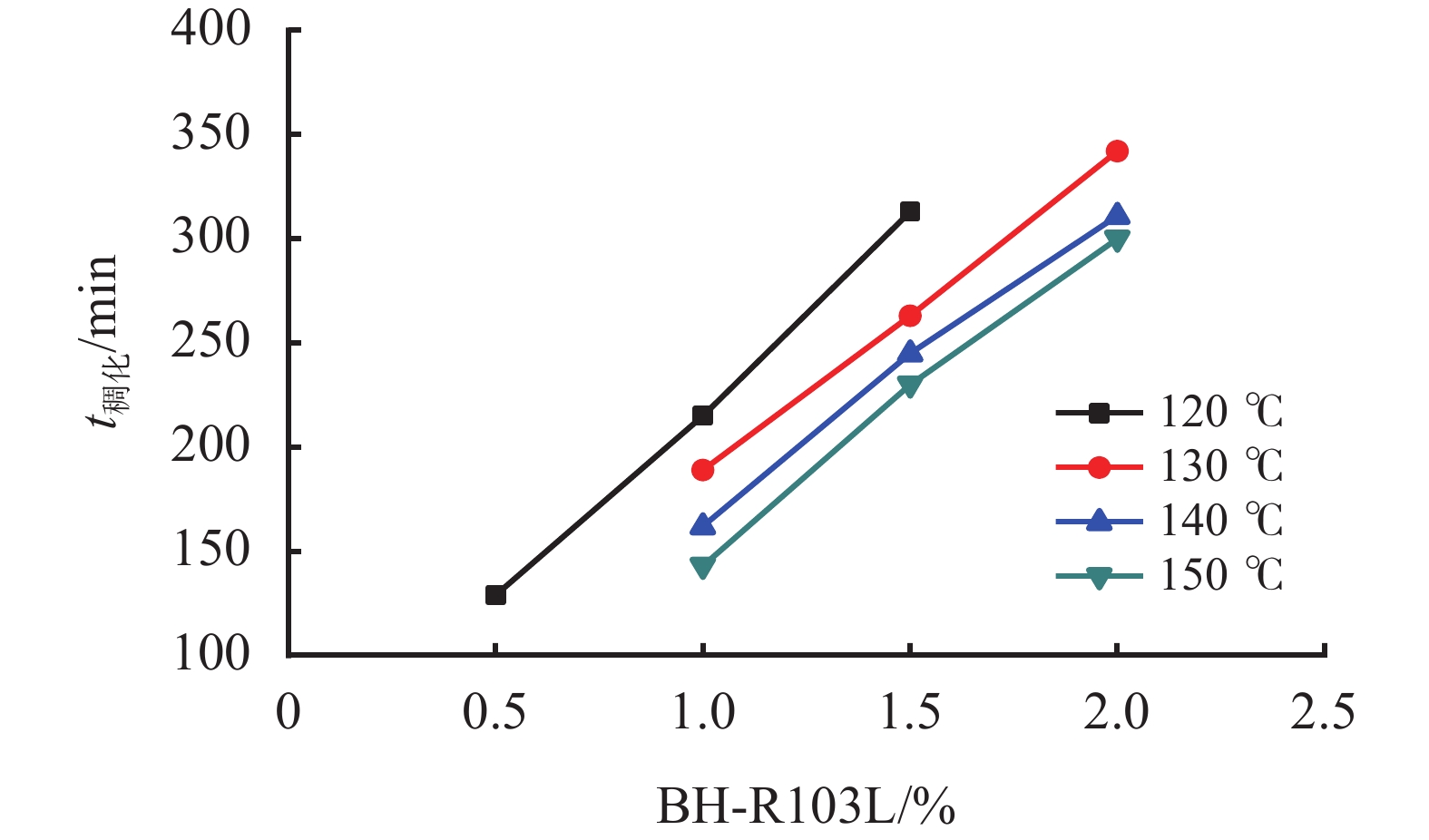

摘要: 针对油井水泥常用的AMPS/IA共聚物类缓凝剂在130~150 ℃区间易出现稠化时间“倒挂”现象,影响固井施工安全和固井质量的问题。通过AMPS和IA单体进行自由基溶液共聚,在共聚过程中与乙二胺四乙酸二钠EDTA-2Na、十六烷基三甲基氯化铵CTAC复配,研制了一种可防止高温稠化时间倒挂的缓凝剂BH-R103L,并对其综合性能进行了评价。评价结果表明:BH-R103L具有可靠的抗温及调凝效果,加有BH-R103L的水泥浆体系在120~150 ℃范围内稠化时间可调,150 ℃下加量为2%(BWOC)时,水泥浆的稠化时间大于300 min,稠化时间与加量呈线性关系,稠化时间倒挂现象消除、初始稠度低、温度和加量敏感性小、稠化线形正常、与AMPS类高温降失水剂配伍性良好,能抑制高温浆体“包心”现象,在60 ℃下养护的水泥石抗压强度发展快,其他综合性能均满足固井施工要求。BH-R103L在四川泸州区块泸203H153平台深井页岩层进行了现场应用,声幅测井检测封固段固井质量合格。Abstract: At temperatures between 130 ℃ and 150 ℃, a cement slurry treated with the commonly used retarding agent AMPS/IA has a thickening time that is longer than the thickening time at lower temperatures. This is an abnormal phenomenon that is risky to the well cementing operation and negatively affects the quality of cementing jobs. In laboratory experiment, AMPS and IA were reacted with each other through radical solution copolymerization. During the copolymerization, EDTA-2Na (disodium ethylene-diamine tetra-acetic acid) and CTAC (cetyl trimethyl ammonium chloride) were added to compound with the copolymerization product. The final product of the copolymerization, BH-R103L, is a retarding agent which can be used to prevent the abnormal thickening time. Comprehensive evaluation of the retarding agent BH-R103L revealed that it has reliable high temperature resistance and gel strength adjustment property. A cement slurry treated with BH-R103L has a thickening time that is adjustable between 120 ℃ and 150 ℃. At 150 ℃, a cement slurry treated with 2% (BWOC) BH-R103L has a thickening time longer than 300 min, and the thickening time has a linear relationship with the concentration of BH-R103L in the cement slurry. Using BH-R103L, the abnormal thickening time is eliminated, the cement slurry has a low initial consistency, the temperature and concentration sensitivity become low, and the thickening timeline becomes normal. BH-R103L has good compatibility with high temperature filter loss reducers such as AMPS, and can be used to inhibit “soft core” phenomenon of a cement slurry at elevated temperatures. Cured at 60 ℃, the set cement has a strength that develops very fast, other general properties of the set cement all satisfy the needs of well cementing operation. BH-R103L has been used in the cementing operation on the 203H153 platform in Luzhou block, Sichuan Province, sonic logging results showed that the cementing job quality met the designed requirements.

-

表 1 缓凝剂中EDTA-2Na和CTAC加量对水泥浆的影响

EDTA-2Na/% CTAC/% T/℃ 稠化线形 t稠化/min 0.15 0 130 鼓包 170 140 鼓包、台阶 153 150 鼓包 141 0 0.8 130 正常 122 140 正常 140 150 正常 146 0.12 1.0 130 正常 189 140 正常 162 150 正常 143 注:水泥浆配方:药王山G级水泥+35%硅粉+5%降失水剂BH-F201L+1%BH-R103L+水,密度为1.90 g/cm3 表 2 温度和加量变化对BH-R103L缓凝性能的影响

BH-R103L/g T/℃ P/MPa t过渡/min t稠化/min R/% 5.4 130 65 6 172 9.0 6.0 130 65 5 189 6.6 130 65 5 201 6.4 6.0 135 67 3 174 7.9 6.0 125 62 6 198 4.5 注:水泥浆配方:药王山G级水泥+35%硅粉+5%降失水剂BH-F201L+BH-R103L+水,密度为1.90 g/cm3 表 3 BH-R103L与常用降失水剂的配伍性能

降失水剂 BH-R103L/% FLAPI/mL 初始稠度/Bc t稠化/min BH-F201L 0 38 1 36 11 189 2 40 10 342 3 38 HX-12L 0 42 1 38 13 177 2 36 11 325 3 36 G33S 0 28 1 34 13 182 2 38 16 331 3 36 DRF-1S 0 36 1 36 15 196 2 34 16 348 3 40 注:水泥浆配方:药王山G级水泥+35%硅粉+降失水剂+缓凝剂+水,密度为1.90 g/cm3。其中,液体降失水剂加量为5%,固体降失水剂为3.5%,实验温度为130 ℃ 表 4 加有BH-R103L的水泥浆流变性能

BH-R103L/

%Τ/

℃φ100 φ 200 φ 300 n K/

Pa·sn流动度/

cm0 27 62 80 109 0.51 2.26 21 2.0 27 54 65 100 0.56 1.55 22 0 130 35 49 67 0.59 0.88 23 1.0 130 30 44 58 0.60 0.70 24 2.0 130 29 39 59 0.65 0.53 24 2.5 150 23 31 48 0.67 0.38 24 注:水泥浆配方:药王山G级水泥+35%硅粉+5%降失水剂BH-F201L+x%BH-R103L+自来水,密度为1.90 g/cm3 表 5 BH-R103L对水泥石抗压强度的影响

BH-R103L/

%TBHCT/

℃t稠化/

minP养护/

MPap24 h/

MPa60 ℃顶部抗压强度/MPa 24 h 48 h 72 h 1.5 120 313 21 30.1 14.5 22.3 23.5 2.0 130 342 21 31.6 12.1 17.9 21.7 2.0 140 311 21 34.5 2.5 150 362 21 36.2 9.6 15.8 20.1 注:水泥浆配方:药王山G级水泥+35%硅粉+5%降失水剂BH-F201L+x%BH-R103L+自来水,密度为1.90 g/cm3 表 6 掺有BH-R103L的水泥浆综合性能

TBHCT/

℃BH-R103L/

%流动度/

cmFL/

mLt稠化/

mint过渡/

min游离液/

%沉降稳定性/

g·cm−3p48 h/

MPa110 1.0 21 34 296 8 0 0.01 25.2 120 1.5 22 32 283 6 0 0 26.9 130 2.0 22 36 301 4 0 0 26.1 140 2.5 23 40 330 5 0 0.01 25.4 150 2.7 23 34 313 3 0 0.01 29.3 -

[1] 齐志刚,王瑞和,徐依吉,等. 衣康酸/AMPS 共聚物作为油井水泥缓凝剂的研究[J]. 北京化工大学学报,2007,34(2):32-35.QI Zhigang, WANG Ruihe, XU Yiji, et al. Itaconic acid/2-acrylamido-2-methlpropanesulfonic acid (AMPS) copolymer as an oil well cement retarder[J]. Journal of BeiJing University of Chemical Technology, 2007, 34(2):32-35. [2] 于斌,丹美涵,姜经帅,等. 抗温敏大温差聚合物缓凝剂的合成与应用[J]. 钻井液与完井液,2017,34(3):85-88. doi: 10.3969/j.issn.1001-5620.2017.03.017YU Bin, DAN Meihan, JIANG Jingshuai, et al. The synthesis and application of temperature sensitivity resistance retarder suitable for big temperature difference environment[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):85-88. doi: 10.3969/j.issn.1001-5620.2017.03.017 [3] 姚明,任强,叶智,等. 高分子聚合物/有机物复合型高温缓凝剂的构建及其性能研究[J]. 合成化学,2020,28(12):1022-1030.YAO Ming, REN Qiang, YE Zhi, et al. Construction and properties of polymer /organic compound high temperature retarder[J]. Chinese Journal of Synthetic Chemistry, 2020, 28(12):1022-1030. [4] 卢娅,李明,杨燕,等. 油井水泥缓凝剂AID的合成与性能评价[J]. 石油钻探技术,2015,43(6):40-45.LU Ya, LI Ming, YANG Yan, et al. Synthesis and performance evaluation of a cement retardant AID for oil well[J]. Petroleum Drilling Techniques, 2015, 43(6):40-45. [5] 张瑞,霍锦华,陈大钧,等. HJH-1 型高温油井水泥缓凝剂的合成及其性能评价[J]. 精细化工,2015,32(9):1061-1066.ZHANG Rui, HUO Jinhua, CHEN Dajun, et al. Synthesis and characterization of retarder HJH-1 used in high temperature oil well cement[J]. Fine Chemicals, 2015, 32(9):1061-1066. [6] 刘文明,付家文,胡星彤,等. 抗高温抗盐多元共聚物类降失水剂的研究与应用[J]. 钻井液与完井液,2014,31(6):52-54.LIU Wenming, FU Jiawen, HU Xingtong, et al. Synthesis and evaluation of a copolymer filter loss reducer BZF-L1[J]. Drilling Fluid & Completion Fluid, 2014, 31(6):52-54. [7] 李均星. 高温聚羧酸类缓凝剂的合成及异常胶凝现象机理研究[D], 天津: 天津大学, 2019.LI Junxing. Study on synthesis of high temperature polycarboxylic acid retarder and mechanism of abnormal gelation[D]. TianJin: Tianjin University, 2019. [8] 李明,靳建洲,于永金,等. 2-丙烯酰胺基-2-甲基丙磺酸/衣康酸/丙烯酰胺缓凝剂的黏温特性[J]. 精细石油化工,2013,30(6):1-3.LI Ming, JIN Jianzhou, YU Yongjin, et al. Viscosity- temperature characteristics of the AMPS/IA/AM terpolymer as a retarder[J]. Speciality Petrochemicals, 2013, 30(6):1-3. [9] 卢娅,李明,郭子涵,等. 聚合物类油井水泥缓凝剂的研究现状概述[J]. 塑料工业,2016,44(2):23-26.LU Ya, LI Ming, GUO Zihan, et al. Advances in polymer-based oil well cement retarder[J]. China Plastics Industry, 2016, 44(2):23-26. [10] PLANK J, LUMMER N R, DUGONJIC-BILIC F. Competitive adsorption between an AMPS-based fluid loss polymer and Welan gum biopolymer in oil well cement[J]. Journal of Applied Polymer Science, 2010, 116(5):2913-2919. -

下载:

下载: