Design and Evaluation of an Integrated Drilling and Completion Fluid

-

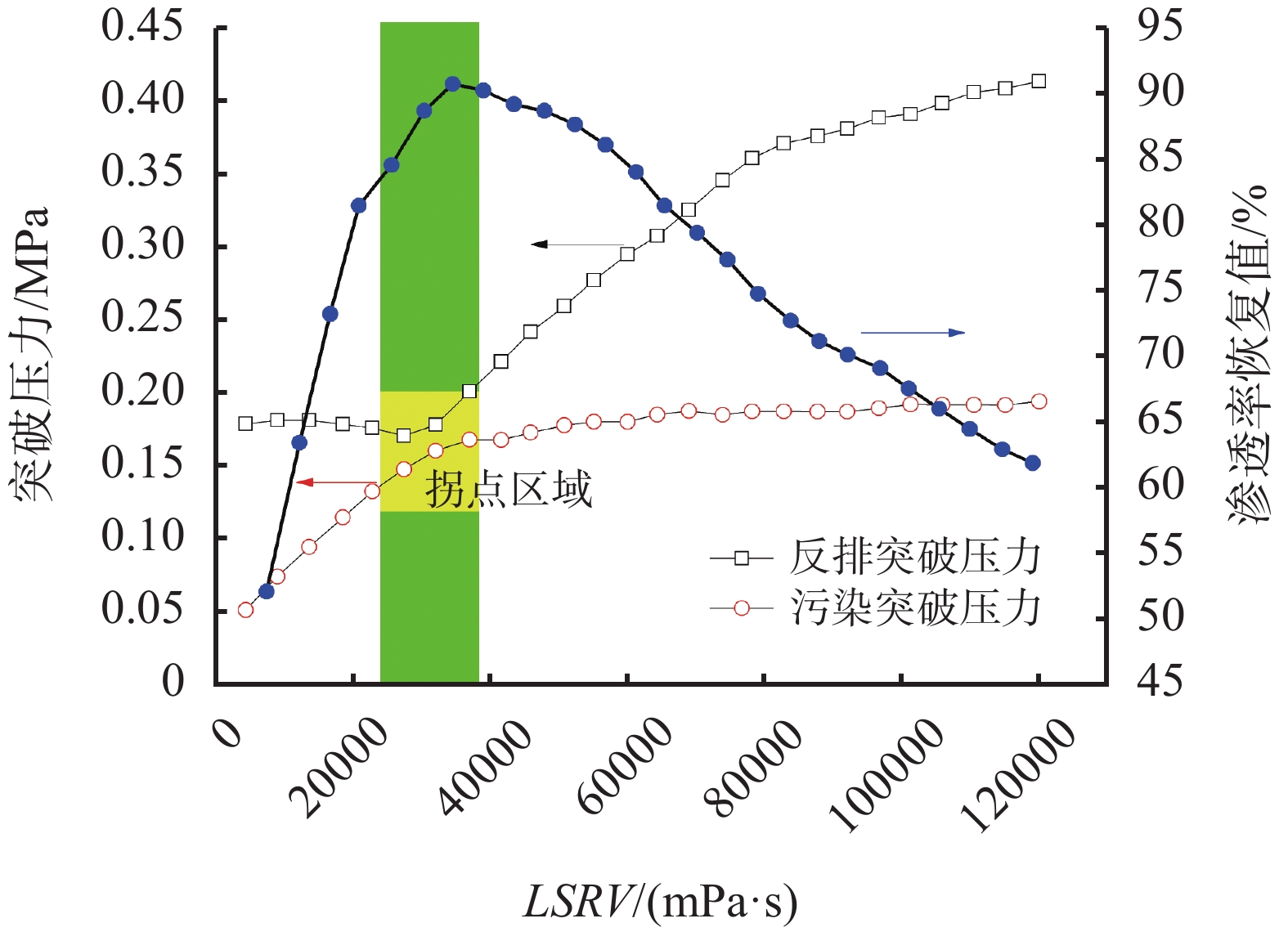

摘要: 钻井完井一体化工作液是对海洋油气传统裸眼钻井完井液技术的发展,该体系基于D90经验规则与膜屏蔽原理,引入低剪切速率黏度设计,通过暂堵剂的镶嵌、成膜作用在储层孔隙入口构造单向屏蔽环,不仅达到储层保护效果,还可直接返排,从而简化海洋钻井完井工序。阐述了钻井完井一体化工作液的设计思路,检测了关键组分微观结构及体系基本性能,并综合评价了体系储层保护效果。实验结果表明,钻井完井一体化工作液具有刚性和柔性2类暂堵剂粒子,可协同封堵孔隙入口,促进单向屏蔽环形成,其中刚性镶嵌粒子形貌不规则,中值粒径为9.5 μm,大于孔隙尺寸;而柔性成膜粒子呈规则球形,平均粒径为25.4 μm,粒径分布窄,有利于粒间填充及形变聚结。体系在5~130 ℃内具有良好流变性,其低剪切速率黏度平均值为30 802 ± 1892 mPa·s,满足直接返排解堵设计要求;体系展示了良好的润滑性、防塌性及抗海水、抗岩屑侵污性,且单向封堵能力强,直接返排的渗透率恢复效果好。现场应用证明,新型钻井完井一体化工作液不仅能确保储层钻井过程顺利,而且满足了直接返排解堵要求,达到了简化完井工艺的目的。Abstract: The integrated drilling and completion fluid is the development of the traditional drill-in fluid used in offshore open hole drilling. The formulation of this new-generation drill-in fluid is based on the D90 empirical rule and the membrane shielding principle, and the concept of low-shear-rate viscosity is used. The insertion of temporary plugging agent particles and film-forming at the pore entrance of the formation rocks form a unidirectional shielding ring, which not only protects the reservoir from being damaged, but also can be flowed back directly, thereby simplifying the well completion procedure. This paper describes the design of the new-generation drill-in fluid as well as the experiment for examining the micro structure of the key components and the basic performance of the drill-in fluid. Experiments on the reservoir protection performance of the drill-in fluid show that the flexible and the rigid temporary-plugging particles in the drill-in fluid plug the pore entrances in a synergetic way, promoting the formation of the unidirectional shielding ring. Of the temporary-plugging particles, the rigid particles have irregular shapes, with median particle size of 9.5 μm, which is greater than the sizes of the pores; whereas the flexible film-forming particles are in regular spherical shapes with average particle size of 25.4 μm, the narrow size distribution of the flexible particles is beneficial to inter-particle filling and deformation coalescence. The drill-in fluid has good rheology at temperatures between 5 ℃ and 130 ℃, and its average low-shear-rate viscosity is 30,802 ± 1,892 mPa∙s, which satisfy the needs of flowback and block removal. The drill-in fluid has good lubricity, high inhibitive capacity and high resistance to seawater and drilled cuttings contamination. It is a good one-way plugging agent and direct flowback operation produces a high permeability recovery. Field application of this drill-in fluid indicated that the drilling of the reservoir section was smooth and successful, the requirements of direct flowback were satisfied, and the procedure of completing the well was simplified.

-

表 1 钻井完井一体化工作液的抗温性能

T/

℃AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLLSRV/

mPa·s摩阻

系数5 39 21 18 4.5 33 364 0.11 10 41 21 20 4.2 34 796 0.10 20 39 20 19 4.4 32 896 0.11 40 37 20 17 4.1 31 353 0.11 80 32 17 15 4.3 30 250 0.10 90 31 16 15 4.2 30 190 0.11 100 32 16 16 4.3 31 062 0.10 110 30 15 15 4.8 29 034 0.10 120 29 15 14 4.4 28 595 0.11 130 27 13 14 5.1 26 482 0.11 表 2 钻井完井一体化工作液的抗岩屑及海水污染性能

污染物 加量/

%AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLLSRV/

mPa·s岩屑 0 30.5 16.0 14.5 4.5 29 176 5 33.0 18.0 15.0 4.0 26 775 10 37.0 20.0 17.0 4.3 24 856 15 34.0 19.0 15.0 4.2 25 042 海水 0 29.5 17.0 12.5 4.4 28 898 5 26.5 15.5 11.0 4.6 26 756 10 24.0 13.5 10.5 5.8 25 863 15 21.0 11.0 10.0 6.5 23 389 表 3 岩屑在钻井完井一体化工作液 中的防膨率和滚动回收率

样本 防膨率/

%滚动回收率/% 第一次 第二次 海水 77.02 12.34 一体化工作液 91.42 93.20 90.4 表 4 钻井完井一体化工作液的储层渗透率恢复实验结果

完井

方式岩心 直径/

cm长度/

cmKa/

mDK0/

mD直接返排 19# 5.102 2.470 30.98 14.85 酸溶解堵 27# 5.086 2.514 32.74 15.84 完井方式 岩心 Kd/

mDKd/K0

%Pt/

MPaPts/

MPa直接返排 19# 13.50 90.91 0.464 0.152 酸溶解堵 27# 15.08 95.22 0.415 0.115 -

[1] 马美娜,许明标,唐海雄,等. 有效降解PRD钻井液的低温破胶剂JPC室内研究[J]. 油田化学,2005,22(4):289-291. doi: 10.3969/j.issn.1000-4092.2005.04.001MA Meina, XU Mingbiao, TANG Haixiong, et al. Low temperature gel breaker JPC for breakdown of gelled PRD polymer drilling-in fluid in borehole bottom[J]. Oilfield Chemistry, 2005, 22(4):289-291. doi: 10.3969/j.issn.1000-4092.2005.04.001 [2] 权宝华,方培林,任强,等. 螯合酸完井液体系的研究及应用[J]. 钻井液与完井液,2016,33(4):122-126.QUAN Baohua, FANG Peilin, REN Qiang, et al. Study and application of a completion fluid containing acid chelating agents[J]. Drilling Fluid & Completion Fluid, 2016, 33(4):122-126. [3] 王晋玲, 赵峰, 唐洪明, 等. LF15-1油田ZJ10灰岩储层PRD钻完井液体系优化研究[J]. 现代化工, 2016, 36(8): 84-87.WANG Jinling, ZHAO Feng, TANG Hongming, et al. Optimization of PRD drilling and completion fluid system for ZJ10 limestone reservoir of LF15-1 oilfield[J]. Modern Chemical Industry, 2016, 36(8): 84-87. [4] 赵峰, 唐洪明, 张俊斌, 等. LF13-1油田PRD钻井完井液体系储层保护效果优化研究[J]. 特种油气藏, 2010, 17(6): 88-90.ZHAO Feng, TANG Hongming, ZHANG Junbin, et al. Optimization of reservoir protection effect of PRD drilling and completion fluid system for LF13-1 oilfield[J]. Special Oil and Gas Reservoirs, 2010, 17(6): 88-90. [5] 韦红术,张俊斌,张伟国,等. 泥饼可液化处理的UltraFLO钻井完井液[J]. 钻井液与完井液,2015,32(4):37-39. doi: 10.3969/j.issn.1001-5620.2015.04.010WEI Hongshu, ZHANG Junbin, ZHANG Weiguo, et al. UltraFlo drill-in fluid[J]. Drilling Fluid & Completion Fluid, 2015, 32(4):37-39. doi: 10.3969/j.issn.1001-5620.2015.04.010 [6] 张力,韩银府. 直接反排钻开液在南海东部的应用[J]. 石油天然气学报,2018,40(6):59-64. doi: 10.12677/JOGT.2018.406120ZHANG Li, HAN Yinfu. Application of direct flowback drilling fluid in the east of SouthChina Sea[J]. Journal of Oil and Gas Technology, 2018, 40(6):59-64. doi: 10.12677/JOGT.2018.406120 [7] 徐同台,陈永浩,冯京海,等. 广谱型屏蔽暂堵保护油气层技术的探讨[J]. 钻井液与完井液,2003,20(2):39-41. doi: 10.3969/j.issn.1001-5620.2003.02.013XU Tongtai, CHEN Yonghao, FENG Jinghai, et a1. The general-purpose temporary shield plugging technology in protecting hydrocarbon reservoir[J]. Drilling Fluid & Completion Fluid, 2003, 20(2):39-41. doi: 10.3969/j.issn.1001-5620.2003.02.013 [8] 李志刚,乌效鸣,郝蜀民,等. 储层屏蔽暂堵钻井完井液技术研究及应用[J]. 天然气工业,2005,25(3):74-78. doi: 10.3321/j.issn:1000-0976.2005.03.022LI Zhigang, WU Xiaoming, HAO Shumin, et al. Research on reservoir shielding-temporary plugging drilling-completion fluid technique and its application[J]. Natural Gas Industry, 2005, 25(3):74-78. doi: 10.3321/j.issn:1000-0976.2005.03.022 [9] 罗向东,罗平亚. 屏蔽式暂堵技术在储层保护中的应用研究[J]. 钻井液与完井液,1992,9(2):19-27.LUO Xiangdong, LUO Pingya. The application study of shielding temporary bridging technology in formation damage control[J]. Drilling Fluid & Completion Fluid, 1992, 9(2):19-27. [10] ABRAMS A. Mud design to minimize rock impairment due to particle invasion[J]. Journal of Petroleum Technology, 1977, 29(2):86-90. [11] DICK M A, HEINZ T J, SVOBODA C F, et al. Optimizing the selection of bridging particles for reservoir drilling fluids[R]. SPE 58793. 2000. [12] 王利国, 鄢捷年, 冯文强. 理想充填暂堵型钻井完井液的设计及室内评价[J]. 中国石油大学学报(自然科学版), 2007, 31(3): 72-76.WANG Liguo, YAN Jienian, FENG Wenqiang. Design and lab evaluation of ideal packing bridging drilling and completion fluids[J]. Journal of China University of Petroleum, 2007, 31(3): 72-76. [13] HANDS N, KOWBEL K, MAIKRANZ S. Drilling-in fluid reduces formation damage increases production rates[J]. Oil & Gas Journal, 1998, 96(28):65-68. [14] 蒋官澄,胡成亮,熊英,等. 广谱“油膜”暂堵钻井完井液体系研究[J]. 中国石油大学学报(自然科学版),2005,28(5):101-104.JIANG Guancheng, HU Chengliang, XIONG Ying, et al. Study on system of broad-spectrum oil-film temporary plugging drilling fluid[J]. Journal of China University of Petroleum, 2005, 28(5):101-104. [15] 王富华,邱正松,冯京海,等. “超广谱”屏蔽暂堵钻井完井液新技术室内研究[J]. 石油钻探技术,2001,29(5):39-42. doi: 10.3969/j.issn.1001-0890.2001.05.013WANG Fuhua, QIU Zhengsong, FENG Jinghai, et al. Lab study on the new techniques of superior shielding and temporary plugging drill-in fluids[J]. Petroleum Drilling Techniques, 2001, 29(5):39-42. doi: 10.3969/j.issn.1001-0890.2001.05.013 [16] 郭丽梅,薛锦华,陈曦. 新型屏蔽暂堵剂ZDJ室内性能评价[J]. 钻井液与完井液,2016,33(1):37-47.GUO Limei, XUE Jinhua, CHEN Xi. Laboratory evaluation of a new temporary plugging agent ZDJ[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):37-47. [17] 吕开河,邱正松,魏慧明,等. 自适应防漏堵漏钻井液技术研究[J]. 石油学报,2008,29(5):757-765. doi: 10.3321/j.issn:0253-2697.2008.05.023LYU Kaihe, QIU Zhengsong, WEI Huiming, et al. Study on techniques of auto-adapting lost circulation resistance and control for drilling fluid[J]. Acta Petrolei Sinica, 2008, 29(5):757-765. doi: 10.3321/j.issn:0253-2697.2008.05.023 [18] 郑力会,孔令琛,曹园,等. 绒囊工作液防漏堵漏机理[J]. 科学通报,2010,55(15):1520-1528.ZHENG Lihui, KONG Lingchen, CAO Yuan, et al. The mechanism for fuzy-ball working fluids for controlling & killing lost circulation[J]. Chinese Sci Bull, 2010, 55(15):1520-1528. [19] REID P, SANTOS H. Novel drilling completion and workover fluid for depleted zones: avoiding losses formation damage and stick pipe[R]. SPE/IADC 85326. 2003. [20] 张伟国,许明标,由福昌. 直接反排钻井完井液储层保护机理分析[J]. 钻井液与完井液,2017,34(1):87-91. doi: 10.3969/j.issn.1001-5620.2017.01.016ZHANG Weiguo, XU Mingbiao, YOU Fuchang. Analysis of reservoir protection mechanism by direct drilling fluid flowback[J]. Drilling Fluid & Completion Fluid, 2017, 34(1):87-91. doi: 10.3969/j.issn.1001-5620.2017.01.016 [21] 陈彬,张伟国,姚磊, 等. 基于井壁稳定及储层保护的钻井液技术[J]. 石油钻采工艺,2021,43(2):184-188CHEN Bin, ZHANG Weiguo, YAO Lei, et al. Drilling fluid technology based on well stability and reservoir protection[J]. Oil Drilling & Production Technology, 2021, 43(2): 184-188 [22] HEMPHILL T. Low shear rate rheology: clarifying muddied waters[R]. AADE-02-dfwm-HO-14. 2002. [23] 杨胜来, 魏俊之. 油层物理学[M]. 北京: 石油工业出版社, 2006: 157.YANG Shenglai, WEI Junzhi. Reservoir physics[M]. Beijing: Petroleum Industry Press, 2006: 157. [24] 袁锦彪,杨亚少,常旭轩,等. 页岩气油基钻井液堵漏技术及其在长宁区块应用[J]. 钻采工艺,2020,43(4):133-136. doi: 10.3969/J.ISSN.1006-768X.2020.04.37YUAN Jinbiao, YANG Yashao, CHANG Xuxuan, et al. Shale gas oil-based drilling fluid plugging technology and its application in Changning block[J]. Drilling & Production Technology, 2020, 43(4):133-136. doi: 10.3969/J.ISSN.1006-768X.2020.04.37 [25] 吕开河, 乔伟刚, 赵修太, 等. 镶嵌屏蔽钻井液研究及应用[J]. 钻井液与完井液, 2012, 29(1): 23-27.LYU Kaihe, QIAO Weigang, ZHAO Xiutai, et al. Study on research and application of mosaic and shielding drilling fluid system[J]. Drilling Fluid & Completion Fluid, 2012, 29(1): 23-27. [26] 邓红琳, 赵文彬, 王锦昌, 等. 大牛地气田镶嵌屏蔽钻井液技术[J]. 特种油气藏, 2015, 22(3): 101-103.DENG Honglin, ZHAO Wenbin, WANG Jinchang, et al. Inlay-shield drilling fluid technology in Daniudi gasfield[J]. Special Oil and Reservoirs, 2015, 22(3): 101-103. [27] 吕开河,韩立国,刘玉霞,等. 双层结构协同增效保护油气层技术及其室内实验评价[J]. 中国海上油气,2012,24(4):53-56. doi: 10.3969/j.issn.1673-1506.2012.04.011LYU Kaihe, HAN Liguo, LIU Yuxia, et al. The reservoir protection technology with synergy of double-layer structure and its laboratory evaluation[J]. China Offshore Oil and Gas, 2012, 24(4):53-56. doi: 10.3969/j.issn.1673-1506.2012.04.011 [28] 张琰,崔迎春. 镶嵌暂堵分形理论与应用研究[J]. 天然气工业,2000,20(6):54-56. doi: 10.3321/j.issn:1000-0976.2000.06.014ZHANG Yan, CUI Yingchun. Temporary plugging fractal theory and its application study[J]. Natural Gas Industry, 2000, 20(6):54-56. doi: 10.3321/j.issn:1000-0976.2000.06.014 [29] 黄孟,许林,许洁,等. 水基恒流变钻井液流型调节剂的制备与性能评价[J]. 油田化学,2018,35(2):191-196. doi: 10.19346/j.cnki.1000-4092.2018.02.001HUANG Meng, XU Lin, XU Jie, et al. Evaluation on preparation and performance of rheological modifier used in flat-rheology water-based drilling fluid[J]. Oilfield Chemistry, 2018, 35(2):191-196. doi: 10.19346/j.cnki.1000-4092.2018.02.001 -

下载:

下载: