Study and Application of High-temperature Resistant Non-sulfonated Semi-saturated Salt Water Drilling Fluid

-

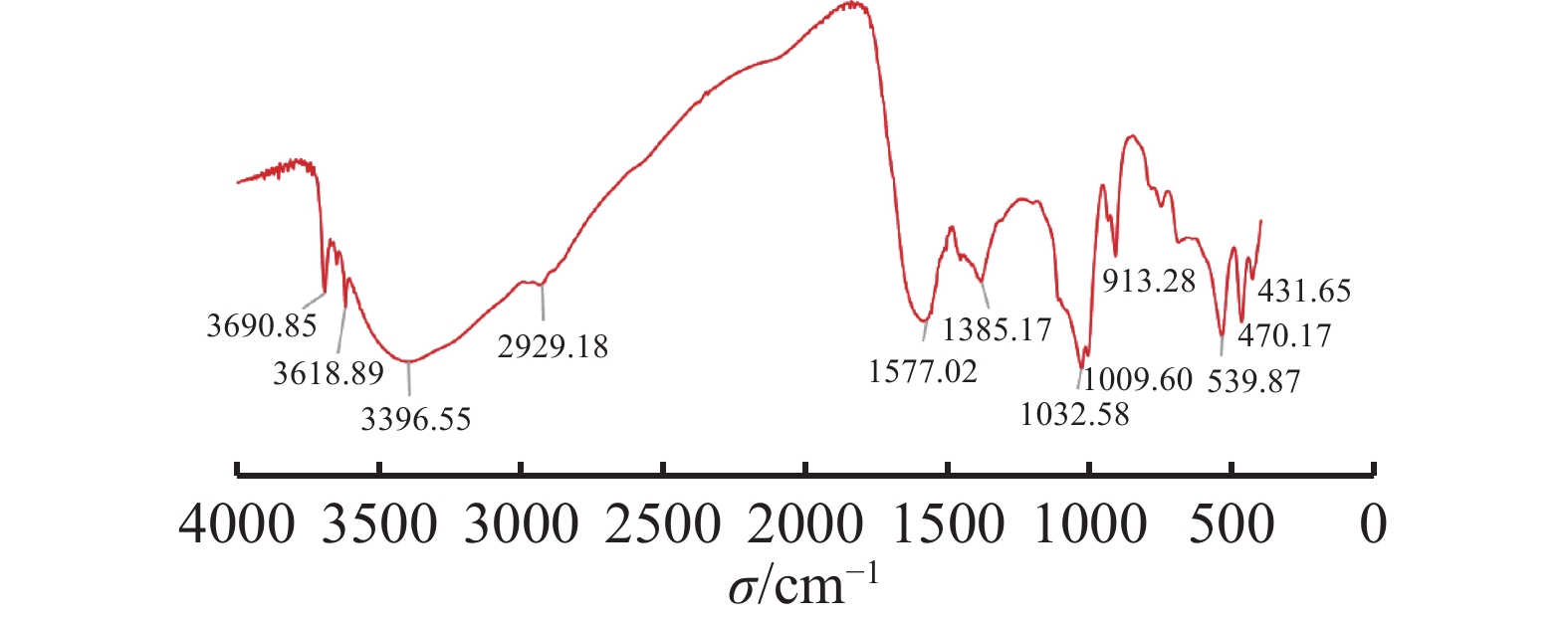

摘要: 针对含磺水基钻井液环保性能差及现有非磺水基钻井液抗温不足的问题,基于腐植酸为主、木质素及栲胶为辅的混合原料,采用硅烷偶联剂、有机酸和二元胺进行多重复合改性,合成制备了抗高温非磺腐植酸树脂类降滤失剂DEM-SEAL,并利用红外光谱、热重及凝胶色谱进行表征。结果表明,DEM-SEAL抗温达180 ℃,且96 h的LC50值达101 020 mg/L,全硫含量为0,无毒环保;当DEM-SEAL加量为4.0%时,基浆180 ℃老化后API滤失量和高温高压滤失量仅7.6 mL和16.8 mL,降低率高达75.2%和83.0%,且对黏度影响较小。结合DEM-SEAL的优良特性,以其为核心构建了一套抗高温非磺化半饱和盐水钻井液体系,密度范围为1.30~1.80 g/cm3,抗温达180 ℃,API滤失量小于5.0 mL,高温高压滤失量小于15.0 mL,具有良好的流变性和低滤失特性;抗泥岩污染达20%,抗盐污染达10%,抗钙污染达1%,96 h的LC50值为55 600 mg/L,BOD5/CODcr为23.51%,无毒可生物降解。高温非磺化半饱和盐水钻井液体系在新疆某油田高温深井进行了应用,该井井底温度为179 ℃,钻井过程中钻井液的流变性能稳定,失水造壁性能良好,无井下复杂事故。在满足安全钻井前提下实现了抗高温钻井液“去磺化”目标,为国内高温非磺钻井液的研究与发展提供了技术参考。Abstract: Aiming at the problems of poor environmental performance of sulfonated water-based drilling fluid and the insufficient temperature resistance of existing non-sulfonated water-based drilling fluid, the non-sulfonated humic acid resin filtration reducer DEM-SEAL was synthesized on the basis of the mixed raw materials of humic acid, lignin and tannin extract, and was modified by silane coupling agent, organic acid and diamine, and it was analyzed and characterized by infrared spectrum, thermogravimetry and gel chromatography. The experimental results show that the temperature resistance of DEM-SEAL was 180 ℃, the LC50-96 h was 101,020 mg/L, the total sulfur content was 0, which is non-toxic and environmentally friendly. When the dosage of DEM-SEAL was 4.0%, the API filtration and HTHP filtration of the base slurry aged at 180 ℃ were only 7.6 mL and 16.8 mL, with a reduction rate of 75.2% and 83.0%, and it was little impact on the viscosity of mud. Combined with the excellent characteristics of DEM-SEAL, a set of high-temperature resistant non-sulfonated semi-saturated salt water drilling fluid system was constructed. The density range was 1.30~1.80 g/cm3, the temperature resistance reached 180 ℃, the API filtration was less than 5.0 mL, the HTHP filtration was less than 15.0 mL, which has good performance of rheological and low filtration. The LC50-96 h was 55,600 mg/L, and the BOD5/CODcr was 23.51%, which is non-toxic and biodegradable. The system has been successfully applied in a high temperature and deep well in Xinjiang oilfield. The bottom hole temperature was 179 ℃, the rheological property was stable in the drilling process, the filtration and wall building performance was good, and there were no complex accidents of borehole. Under the premise of safe drilling, the objective of "non-sulfonation" of high-temperature resistant drilling fluid was realized, which provided technical reference for the research and development of high-temperature non-sulfonated drilling fluids in China.

-

表 1 DEM-SEAL及磺化改性树脂对基浆性能影响对比

降滤失剂 AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLFLHTHP/

mL空白 6 5 1.0 30.6 98.8 2%DEM-SEAL 9 7 2.0 14.5 46.6 4%DEM-SEAL 12 9 2.5 7.6 16.8 2%磺化酚醛树脂 10 7 3.0 11.5 35.0 4%磺化酚醛树脂 16 11 5.0 7.8 19.6 2%磺化褐煤树脂 12 8 4.0 11.0 32.6 4%磺化褐煤树脂 20 13 7.0 7.0 16.0 注:钻井液密度为1.3 g/cm3;FLHTHP测试条件为150 ℃、3.5 MPa;老化条件为180 ℃、16 h 表 2 DEM-SEAL及磺化改性树脂对钻井液性能的影响

降滤失剂 状态 AV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 FLAPI/

mLFLHTHP/

mL空白 滚前 23 16 7 5 4.0 滚后 15 13 2 1 0.5 8.7 26.6 4%DEM-SEAL 滚前 27 19 8 6 5.0 滚后 25 19 6 5 4.0 3.0 10.0 2%磺化酚醛树脂+

2%磺化褐煤树脂滚前 40 29 11 8 6.0 滚后 34 25 9 6 4.5 3.2 11.6 注:钻井液密度为1.3 g/cm3; FLHTHP测试条件为150 ℃、3.5 MPa;老化条件为180 ℃、16 h 表 3 非磺化半饱和盐水钻井液长时间高温老化后的性能

老化时间/

hAV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 FLAPI/

mLFLHTHP/

mL0 27.0 19 8.0 6.0 5 4.8 14.6 24 25.0 19 6.0 5.0 4 3.2 10.2 48 23.5 18 5.5 4.5 3 4.0 13.8 72 21.0 16 5.0 3.0 2 4.6 14.2 注:钻井液密度为1.3 g/cm3;FLHTHP测试条件为150 ℃、3.5 MPa;老化温度为180 ℃ 表 4 老化温度对非磺化半饱和盐水钻井液性能的影响

老化温度/

℃AV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 FLAPI/

mLFLHTHP/

mL室温 27.0 19 8.0 6.0 5.0 4.8 14.6 130 28.0 21 7.0 5.0 4.0 2.6 8.2 150 27.0 19 8.0 5.5 4.0 2.8 8.6 170 25.5 19 6.5 5.0 4.0 3.0 9.2 180 25.0 19 6.0 5.0 4.0 3.0 10.0 200 14.5 12 2.5 1.0 0.5 5.6 18.8 注:钻井液密度为1.3 g/cm3;FLHTHP测试条件为150 ℃、3.5 MPa;老化时间为16 h 表 5 污染样对非磺化半饱和盐水钻井液性能的影响

污染样 AV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 FLAPI/

mLFLHTHP/

mL空白 25.0 19 6.0 5.0 4.0 3.0 10.0 5%泥岩钻屑 25.0 19 6.0 5.0 4.0 2.9 9.6 10%泥岩钻屑 26.5 20 6.5 5.5 4.0 2.7 9.0 20%泥岩钻屑 30.0 22 8.0 6.0 5.0 3.0 10.2 5%氯化钠 26.0 20 6.0 5.0 3.5 3.3 11.2 10%氯化钠 23.0 18 5.0 4.0 3.0 3.5 12.8 0.5%氯化钙 24.0 19 5.0 4.0 3.0 3.4 12.2 1.0%氯化钙 21.0 17 4.0 3.0 2.0 4.0 14.8 注:钻井液密度为1.3 g/cm3;FLHTHP测试条件为150 ℃、3.5 MPa;老化条件为180 ℃、16 h 表 6 密度对非磺化半饱和盐水钻井液性能影响

ρ/

g·cm−3AV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 FLAPI/

mLFLHTHP/

mL1.30 25.0 19.0 6 5.0 4.0 3.0 10.0 1.40 27.0 21.0 6 5.0 4.0 3.0 10.2 1.50 30.0 23.0 7 6.0 4.5 2.8 9.6 1.60 34.0 26.0 8 6.5 5.0 2.9 10.0 1.70 38.0 30.0 8 6.0 5.0 2.7 9.2 1.80 41.5 32.5 9 7.0 5.0 2.5 8.4 注:FLHTHP测试条件为150 ℃、3.5 MPa;老化条件为180 ℃、16 h 表 7 新疆某油田高温井现场钻井液主要性能

开次 井段/

mρ/

g·cm−3FV/

sPV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLCl − /

mg·L−1三开 5137~7481 1.28~1.40 42~51 17~22 5~8 2~3/4~4.5 2.8~3.6 10.0~13.6 50 000~80 000 四开 7481~8054 1.27~1.36 40~48 15~20 5~7 2~2.5/3.5~4 2.2~3.0 9.2~12.2 -

[1] 韩立群. 百年变局下国际能源安全新态势[J]. 现代国际关系,2022(9):1-9.HAN Liqun. International energy security under the changes unseen in a century[J]. Contemporary International Relations, 2022(9):1-9. [2] 刘瑞,于培志. 抗高温水基钻井液处理剂研究进展[J]. 应用化工,2021,50(6):1618-1621.LIU Rui, YU Peizhi. Research progress of high temperature resistant water based drilling fluid additives[J]. Applied Chemical Industry, 2021, 50(6):1618-1621. [3] 潘谊党. 抗高温高密度水基钻井液体系研究[D]. 中国地质大学(北京), 2020.PAN Yidang. Reasearch on high temperature and high density water based drilling fluid[D]. Beijing: China University of Geosciences (Beijing), 2020. [4] 张雁,屈沅治,张志磊,等. 超高温水基钻井液技术研究现状及发展方向[J]. 油田化学,2022,39(3):540-547.ZHANG Yan, QU Yuanzhi, ZHANG Zhilei, et al. Research progress and development direction of technologies for water-based drilling fluid in ultra-high temperature[J]. Oilfield Chemistry, 2022, 39(3):540-547. [5] 邓楚娈. 新型抗200 ℃高温水基聚磺钻井液体系研究[D]. 西南石油大学, 2017.DENG Chuxuan. Research on a new type of anti-200 ℃ high temperature water-based polys-ulfonated drilling fluid system[D]. Chengdu: Southwest Petroleum University, 2017. [6] 黄聿铭. 适于松科2井深部取心钻进的超高温聚磺钻井液室内研究[D]. 中国地质大学(北京), 2017.HUANG Yuming. Study on ultra-high temperature poly-sulfonated drilling fluid for deep coring drilling in well Songke 2[D]. Beijing: China University of Geosciences (Beijing), 2017. [7] 许春田,张瑞芳,徐同台,等. SMP-Ⅰ与SMP-Ⅱ的抗温抗盐性能对比[J]. 钻井液与完井液,2017,34(2):79-82.XU Chuntian, ZHANG Ruifang, XU Tongtai, et al. Comparison of performances of SMP-I and SMP-II at high temperature and in salt environment[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):79-82. [8] DICKERT J J, HEILWEIL I J. Vinyl sulfonate amide copolymer and terpolymer combinations for control of filtration in water based drilling fluids at high temperature: US 4 608 182[P]. 1986-08-26. [9] 常晓峰,孙金声,吕开河,等. 一种新型抗高温降滤失剂的研究和应用[J]. 钻井液与完井液,2019,36(4):420-426.CHANG Xiaofeng, SUN Jinsheng, LYU Kaihe, et al. Research and application of a novel high temperature filter loss reducer[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):420-426. [10] 潘丽娟,吴宇,翟科军,等. 无黏土相钻开液用抗温增黏降滤失剂的研制与性能评价[J]. 油田化学,2021,38(3):388-394.PAN Lijuan, WU Yu, ZHAI Kejun, at al. Development and performance evaluation of filtration reducer with temperature resistance and viscosity increase for clay-free drilling fluid[J]. Oilfield Chemistry, 2021, 38(3):388-394. [11] 王红军,张太亮. 高效脱色絮凝剂ANF制备及处理聚磺钻井液废水研究[J]. 内蒙古石油化工,2021,47(5):7-11.WANG Hongjun, ZHANG Tailiang. Preparation of high efficient decolorizing flocculant ANF and Its application in treatment of polysulfonate drilling fluid wastewater[J]. Inner Mongolia Petrochemical Industry, 2021, 47(5):7-11. [12] 刘宇程,刘骞,吴东海,等. 新疆油田聚磺钻井废液固化处理技术[J]. 石油与天然气化工,2017,46(5):106-112.LIU Yucheng, LIU Qian, WU Donghai, et al. Solidification treatment technology on the wasted polysulfide drilling fluid in Xinjiang Oilfield[J]. Chemical Engineering of Oil & Gas, 2017, 46(5):106-112. [13] 宋波凯,阮彪,谢建安,等. 新疆油田环保钻井液体系的研究与评价[J]. 化学工程师,2018,32(11):43-46.SONG Bokai, RUAN Biao, XIE Jianan, et al. Research and evaluation of environmentally friendly drilling fluid system in Xinjiang Oilfield[J]. Chemical Engineer, 2018, 32(11):43-46. [14] 袁洋,唐华强,游佳春. 一种去磺化钻井液体系环保性能评价[J]. 科学技术创新,2019(06):43-44.YUAN Yang, TANG Huaqiang, YOU Jiachun. Environmental performance evaluation of a desalfonated drilling fluid system[J]. Science and technological innovation, 2019(06):43-44. [15] 郑成胜,蓝强,张敬辉,等. 玛湖油田MaHW1602水平井低活度钻井液技术[J]. 石油钻探技术,2019,47(6):48-53.ZHENG Chengsheng, LAN Qiang, ZHANG Jinghui, et al. Low-activity drilling fluid technology for the MaHW1602 horizontal well in the Mahu Oilfield[J]. Petroleum Drilling Techniques, 2019, 47(6):48-53. [16] 张佳寅,周代生,刘阳,等. 去磺化环保钻井液的研究[J]. 钻采工艺,2020,43(S1):85-90.ZHANG Jiayin, ZHOU Daisheng, LIU Yang, et al. Study on desulfonated environmental drilling fluid[J]. Drilling & Production Technology, 2020, 43(S1):85-90. [17] 付宇,刘祥,李丽华,等. 抗高温降滤失剂研究概述[J]. 应用化工,2022,51(10):3049-3052.FU Yu, LIU Xiang, LI Lihua, et al. Overview of research on anti-high temperature fluid loss agent[J]. Applied Chemical Industry, 2022, 51(10):3049-3052. -

下载:

下载: