Synthesis and Evaluation of Epoxy Resin Self-Degradation Plugging Agent for Fractured Formation

-

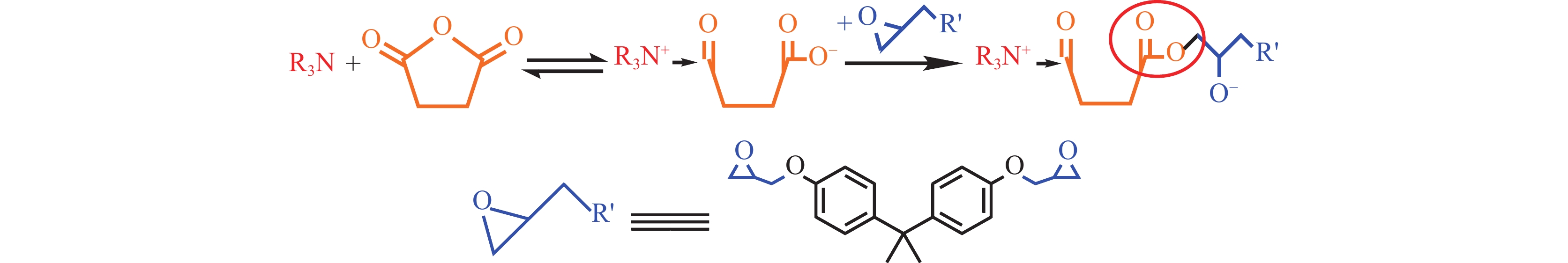

摘要: 针对裂缝性储层承压封堵与保护储层技术难题,基于环氧树脂材料自降解机理分析,研制了一种新型环氧树脂自降解堵漏剂,并探究了固化剂及改性剂加量对新型环氧树脂自降解堵漏剂性能的影响。借助承压强度实验、长裂缝封堵模拟实验装置、储层保护实验仪等,开展了抗压强度、裂缝封堵及储层保护性能测试。实验结果表明,新研制的环氧树脂自降解堵漏剂具有良好的降解性能,在不同温度下最终降解率均能达到90%以上,120 ℃下96 h降解率大于95%,且通过调整改性剂加量可实现降解速率可调,使其匹配施工时间窗口;同时自降解堵漏剂具有较高的弹性模量和良好的抗压破碎率,在30 MPa下抗压破碎率仅为6.2%,结合粒度级配优选,新型环氧树脂自降解堵漏剂可有效封堵0.5~4.0 mm之间的裂缝,具有较好的裂缝承压封堵效果,储层保护实验结果表明,自降解堵漏剂降解8 d后,岩心渗透率恢复率达99.1%,储层保护效果良好。Abstract: In view of the technical difficulties in plugging and protecting fractured reservoirs, based on the analysis of the self-degradation mechanism of epoxy resin materials, this paper developed a new type of epoxy resin self-degradation plugging agent, and experimentally explored the influence of the dosage of curing agent and modifier on the performance of the new type of epoxy resin self-degradation plugging agent. With the help of pressure bearing strength experiment, long fracture plugging simulation experiment device, reservoir protection tester, etc., the compressive strength, fracture plugging and reservoir protection performance were systematically tested. The experimental results show that the newly developed epoxy resin self-degradable plugging agent has good degradation performance. The final degradation rate can reach more than 90% at all temperatures, and the degradation rate is more than 95% at 120 ℃ for 96 h. The environmental temperature and pH can promote its degradation; At the same time, the self-degradable plugging agent has a high elastic modulus and a good compression crushing rate, and the compression crushing rate is only 6.2% under 30 MPa. Combined with the particle size grading optimization, the new epoxy resin self-degradable plugging agent can effectively block the cracks between 0.5-4 mm, and has a good crack pressure bearing sealing effect, the result of reservoir protection experiment shows that after 8 days of degradation of self-degradable plugging agent, the core permeability recovery rate reaches 99.1%, and the reservoir protection effect is good.

-

表 1 不同堵漏材料的抗压破碎率及弹性模量

堵漏

材料抗压破碎率/% 弹性

模量15 MPa 30 MPa 石灰石 22.6 36.7 20.0~50.0 石英 14.2 27.6 30.0~65.0 核桃壳 0.3 1.6 10.0~15.0 橡胶 1.3 2.7 0.1~5.0 自降解材料 4.6 6.2 20.0 表 2 8%自降解堵漏剂实验浆对长裂缝封堵性能的影响

自降解堵

漏剂/%裂缝开度/

mm封堵突破压力/MPa 漏失量/

mL封堵有效区域位置/cm 8 1.0×0.5 12.0 9 封门 2.0×1.0 11.2 24 26~46 3.0×2.0 10.5 38 38~62 4.0×3.0 9.8 76 45~71 -

[1] 邱正松,暴丹,李佳,等. 井壁强化机理与致密承压封堵钻井液技术新进展[J]. 钻井液与完井液,2018,35(4):1-6. doi: 10.3969/j.issn.1001-5620.2018.04.001QIU Zhengsong, BAO Dan, LI Jia, et al. Mechanisms of wellbore strengthening and new advances in lost circulation control with dense pressure bearing zone[J]. Drilling Fluid & Completion Fluid, 2018, 35(4):1-6. doi: 10.3969/j.issn.1001-5620.2018.04.001 [2] 孙金声,白英睿,程荣超,等. 裂缝性恶性井漏地层堵漏技术研究进展与展望[J]. 石油勘探与开发,2021,48(3):630-638. doi: 10.11698/PED.2021.03.18SUN Jinsheng, BAI Yingrui, CHENG Rongchao, et al. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation[J]. Petroleum Exploration and Development, 2021, 48(3):630-638. doi: 10.11698/PED.2021.03.18 [3] 邱正松,暴丹,刘均一,等. 裂缝封堵失稳微观机理及致密承压封堵实验[J]. 石油学报,2018,39(5):587-596. doi: 10.7623/syxb201805010QIU Zhengsong, BAO Dan, LIU Junyi, et al. Microcosmic mechanism of fracture-plugging instability and expe "mental study on pressure bea "ng and tight plugging[J]. Acta Petrolei Sinica, 2018, 39(5):587-596. doi: 10.7623/syxb201805010 [4] 许成元,张洪琳,康毅力,等. 深层裂缝性储层物理类堵漏材料定量评价优选方法[J]. 天然气工业,2021,41(12):99-109. doi: 10.3787/j.issn.1000-0976.2021.12.011XU Chengyuan, ZHANG Honglin, KANG Yili, et al. Quantitative evaluation and selection method of physical plugging materials in deep fractured reservoirs[J]. Natural Gas Industry, 2021, 41(12):99-109. doi: 10.3787/j.issn.1000-0976.2021.12.011 [5] 宋吉锋,梁玉凯,周玉霞,等. 海上低渗储层自降解暂堵液研究与应用[J]. 钻井液与完井液,2018,35(4):73-76. doi: 10.3969/j.issn.1001-5620.2018.04.013SONG Jifeng, LIANG Yukai, ZHOU Yuxia, et al. Study and application of self-degrading temporary plugging fluid for offshore low permeability reservoirs[J]. Drilling Fluid & Completion Fluid, 2018, 35(4):73-76. doi: 10.3969/j.issn.1001-5620.2018.04.013 [6] 叶链,邱正松,陈晓华,等. 新型自降解堵漏剂封堵裂缝与保护储层特性评价[J]. 钻井液与完井液,2020,37(6):731-736. doi: 10.3969/j.issn.1001-5620.2020.06.009YE Lian, QIU Zhengsong, CHEN Xiaohua, et al. Evaluation on the ability of a new self-degrading lost circulation agent to plug fractures and protect reservoirs[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):731-736. doi: 10.3969/j.issn.1001-5620.2020.06.009 [7] 刘书杰,刘和兴,王成文,等. 超深水裂缝储层自降解随钻堵漏剂性能研究[J]. 中国海上油气,2022,34(2):107-115. doi: 10.11935/j.issn.1673-1506.2022.02.013LIU Shujie, LIU Hexing, WANG Chengwen, et al. Study on properties of self-degrading lost circulation agent while drilling in ultra-deepwater fractured reservoir[J]. China Offshore Oil and Gas, 2022, 34(2):107-115. doi: 10.11935/j.issn.1673-1506.2022.02.013 [8] 孙金声,朱跃成,白英睿,等. 改性热固性树脂研究进展及其在钻井液领域应用前景[J]. 中国石油大学学报(自然科学版),2022,46(2):60-75.SUN Jinsheng, ZHU Yuecheng, BAI Yingrui, et al. Research progress of modified thermosetting resin and its application pros-pects in field of drilling fluids[J]. Journal of China University of Petroleum (Edition of Natural Science) , 2022, 46(2):60-75. [9] HAO Cheng, LIU Tuan, ZHANG Shuai, et al. Triethanolamine-mediated covalent adaptable epoxy network: excellent mechanical properties, fast repairing, and easy recycling[J]. Macromolecules, 2020, 53:3110-3118. doi: 10.1021/acs.macromol.9b02243 [10] QIAN Zizhao, XIAO Yuanxiang, ZHANG Xujun, et al. Bio-based epoxy resins derived from diphenolic acid via amidation showing enhanced performance and unexpected autocatalytic effect on curing. Chemical Engineering Journal, 2022, 435: 135022. [11] SHAO Z B, ZHANG J, JIAN R K, et al. A strategy to construct multifunctional ammonium polyphosphate for epoxy resin with simultaneously high fire safety and mechanical properties[J]. Composites Part A:Applied Science and Manufacturing, 2021, 149:106529. doi: 10.1016/j.compositesa.2021.106529 [12] YANG S, WANG J, HUO S, et al. Preparation and flame retardancy of an intumescent flame-retardant epoxy resin system constructed by multiple flame-retard-ant compositions containing phosphorus and nitrogen heterocycle[J]. Polymer Degradation and Stability, 2015, 119:251-259. doi: 10.1016/j.polymdegradstab.2015.05.019 [13] XU Z Z, HUANG J Q, CHEN M J, et al. Flame retard-ant mechanism of an efficient flame-retardant polymerie synergist with ammonium polyphosphate for polypropylene[J]. Polymer Degradation and Stability, 2013, 98(10):2011-2020. doi: 10.1016/j.polymdegradstab.2013.07.010 [14] KIM M, KO H, PARK S M. Synergistic effects of amine-modified ammonium polyphosphate on curing behaviors and flame retardation properties of epoxy composites[J]. Composites Part B:Engineering, 2019, 170:19-30. doi: 10.1016/j.compositesb.2019.04.016 [15] 暴丹,邱正松,叶链,等. 热致形状记忆“智能”型堵漏剂的制备与特性实验[J]. 石油学报,2020,41(1):106-115. doi: 10.7623/syxb202001010BAO Dan, QIU Zhengsong, YE Lian, et al. Preparation and characteristic experiments of intelligent lost circulation materials based on thermally shape memory polymer[J]. Acta Petrolei Sinica, 2020, 41(1):106-115. doi: 10.7623/syxb202001010 [16] 暴丹,邱正松,赵欣,等. 基于温敏形状记忆特性的智能化堵漏材料研究展望[J]. 钻井液与完井液,2019,36(3):265-272. doi: 10.3969/j.issn.1001-5620.2019.03.001BAO Dan, QIU Zhengsong, ZHAO Xin, et al. Outlook on the research on intelligent LCM with temperature sensitive shape memory property[J]. Drilling Fluid & Completion Fluid, 2019, 36(3):265-272. doi: 10.3969/j.issn.1001-5620.2019.03.001 [17] 臧晓宇,邱正松,暴丹,等. 新型延迟膨胀堵漏剂特性实验研究[J]. 钻井液与完井液,2020,37(5):602-607.ZANG Xiaoyu, QIU Zhengsong, BAO Dan, et al. Laboratory study on the properties of a new delayed expansion lost circulation material[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):602-607. [18] 冯杰,臧晓宇,邱正松,等. 温敏形状记忆堵漏材料实验研究[J]. 钻井液与完井液,2022,39(5):545-549.FENG Jie, ZANG Xiaoyu, QIU Zhengsong, et al. Characteristic study of thermosensitive shape memory lost circulation materials[J]. Drilling Fluid & Completion Fluid, 2022, 39(5):545-549. [19] 康毅力,张敬逸,许成元,等. 刚性堵漏材料几何形态对其在裂缝中滞留行为的影响[J]. 石油钻探技术,2018,46(4):1-20.KANG Yili, ZHANG Jingyi, XU Chengyuan, et al. The effect of geometry of rigid plugging material on its retention behavior in fractures[J]. Petroleum Drilling Techniques, 2018, 46(4):1-20. -

下载:

下载: