Model for Predicting Drilling Fluid Rheological Parameters in Wide Temperature and Pressure Range

-

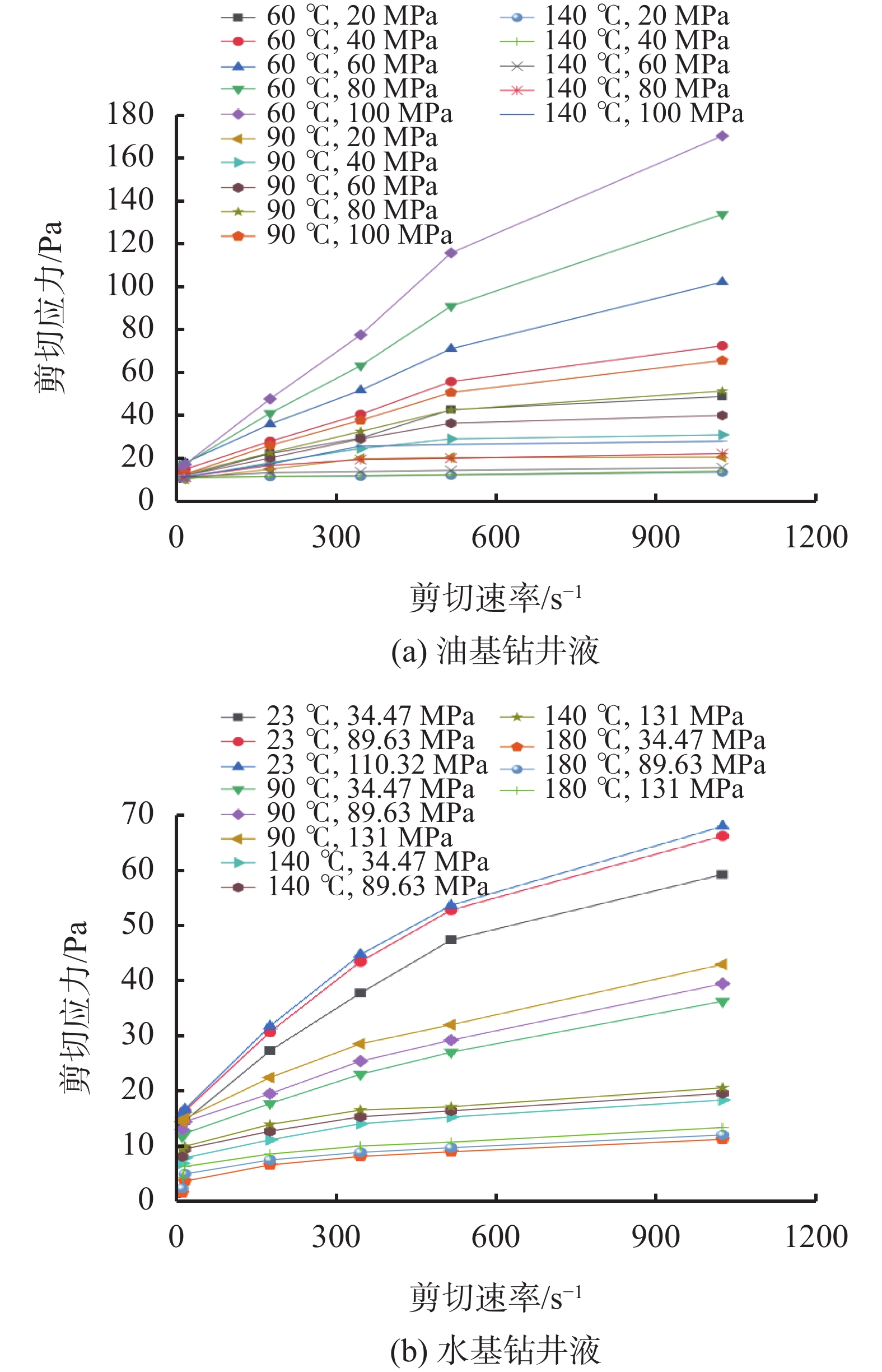

摘要: 钻井液流变参数的精准预测对于高温高压井水力参数及井筒压力精确计算、保证钻井安全具有重要意义。基于构建的钻井液流变性实验数据库,对不同钻井液体系大温压范围内九种流变模式进行了适用性评价,其中油基钻井液体系优选了赫巴流变模式(中低温低压)和四参数流变模式(高温高压),水基钻井液体系在大温压范围内优选了双曲流变模式。优选的流变模式是高温高压井井筒压力准确预测的基础。基于实验数据开发与多元非线性拟合,提出了一种新的适用于大温压范围下不同钻井液体系、不同流变模式的流变参数预测模型,并对某高温高压井井筒压力进行了计算验证。计算结果表明:以双曲模式流变参数模型为基础计算的井底压力误差为1.31%,可以满足深层、超深层高温高压井井筒压力精确计算要求。Abstract: Accurate prediction of drilling fluid rheological parameters is of great importance to the accurate computation of high temperature high pressure (HTHP) hydraulic parameters and borehole pressure, and to maintain the safety of drilling operation. Based on the database of drilling fluid rheological parameters obtained in laboratory experiments, nine flow models were evaluated for their adaptability to different drilling fluid systems in a wide temperature and pressure range. Among these models, the Herschel-Bulkley model (medium and low temperature, low pressure) and the four-parameter flow model were selected for evaluating their adaptability to oil based drilling fluids, the hyperbolic flow model was selected for evaluating its adaptability in a wide temperature and pressure range to water based drilling fluids. The selected flow models are the bases for accurately predicting the borehole pressures in HTHP wells. Based on the experiment data development and multivariate nonlinear fitting, a new model was established for predicting the rheological parameters of different drilling fluid systems with different flow models in a wide temperature and pressure range. This new model was then verified with borehole pressure data obtained from an HTHP well. The verification results show that the error existed for using the hyperbolic flow model as the basis to calculate the bottom hole pressure is 1.31%, indicating that the new model has satisfied the needs for accurate computation of borehole pressures in deep and ultra-deep HTHP wells.

-

表 1 钻井液流变性的实验数据库

序号 数据源 时间 实验组数 T/ ℃ P/MPa 1 赵怀珍[18] 2009 5 90.00~240.00 100.00 2 Steve Young[19] 2012 24 4.44~65.56 10.34~51.71 3 Khaled J. Hassiba[20] 2012 8 20.00~232.22 0~241.39 4 Emanuel Stamatakis[21] 2013 10 65.56~315.56 0~275.79 5 Kumapayi Olamide[22] 2014 16 48.89~82.22 3.40 6 H. Fan[15] 2015 48 20.00~180.00 0~4.00 7 Kay A. Galindo[23] 2015 6 48.89~204.44 13.79 8 P K S Sairam[24] 2015 4 23.89~148.89 6.89~68.95 9 滕学清[14] 2015 30 20.00~180.00 1.00~8.00 10 许洁[25] 2015 13 60.00~200.00 6.00 11 马光曦[26] 2016 16 20.00~180.00 6.00~8.00 12 Erna Kakadjian[27] 2019 11 4.44~121.11 0.10~137.90 13 周号博[28] 2019 48 20.00~180.00 0~8.00 14 Vikrant Wagle[29] 2020 9 65.56~166.11 13.47~64.11 15 Ashok Santra[30] 2021 21 65.56~232.22 68.95 表 2 钻井液的流变模式分类

类别 流变模式 表达式 双参数 宾汉模式 $ \tau = {\tau _0} + {\mu _p}\gamma $ 幂律模式 $ \tau = K{\gamma ^n} $ 卡森模式 $ {\tau ^{1/2}} = \tau _c^{1/2} + \eta _\infty ^{1/2}{\gamma ^{1/2}} $ 三参数 赫巴模式 $ \tau = {\tau _0} + K{\gamma ^n} $ 罗斯模式 $ \tau = A{\left( {\gamma + C} \right)^B} $ Sisko模式 $ \tau = a\gamma + b{\gamma ^c} $ 双曲模式 $\tau = {\tau _0} + \dfrac{ {a\gamma } }{ {1 + b\gamma } }$ 林伯亨模式 $\tau = {\tau _s} + {\eta _P}\gamma {\left( {1 + \dfrac{\beta }{\gamma } } \right)^{1/2} }$ 四参数 四参数模式 $ \tau = {\tau _0} + a\gamma + b{\gamma ^c} $ 表 3 不同钻井液流变模式R2统计表

流变模式 油基钻井液R2范围/% 水基钻井液R2范围/% <0.95 0.95~

0.998>0.998 <0.95 0.95~

0.998>0.998 宾汉模式 3.14 64.55 32.31 17.65 57.84 24.51 幂律模式 16.40 64.55 9.53 26.47 65.69 7.84 卡森模式 1.59 59.79 38.62 13.73 72.55 13.72 赫巴模式 0.53 15.96 83.51 0 39.22 60.78 罗斯模式 1.59 42.33 56.08 0.98 47.06 52.94 Sisko模式 0.53 16.93 82.54 4.90 44.12 50.98 双曲模式 0.53 25.40 74.07 0 46.08 53.92 林伯亨模式 0.74 14.08 85.18 6.56 44.26 49.18 四参数模式 1.59 20.21 78.25 13.73 49.02 37.25 表 4 钻井液流变模式的优选结果

钻井液类型 温压范围

(以150 ℃、69 MPa为界)流变模式优选结果 油基钻井液 中低温低压 赫巴模式 油基钻井液 高温高压 四参数模式 水基钻井液 大温压范围 双曲模式 表 5 不同流变参数预测模型的决定系数R2对比

数据源 流变模式 钻井液类型 流变参数 本文模型 赵胜英 高禹 蒋官澄[33] 宾汉 水基 AV

PV0.999

0.9990.998

0.9990.999

0.998谢春林[34] 宾汉 油基 AV

PV

YP0.995

0.995

0.9750.994

0.992

0.9620.995

0.995

0.968Emanuel Stamatakis 宾汉 油基 AV

PV

YP0.978

0.975

0.9820.977

0.971

0.9810.973

0.965

0.982Ashok Santra 宾汉 油基 PV

YP0.985

0.9840.974

0.9680.975

0.974Erna Kakadjian 宾汉 油基 PV

YP0.992

0.9770.994

0.9650.991

0.978H. Fan 赫巴 油基 YP 0.981 0.942 0.957 稠度系数 0.923 0.952 0.979 流性指数 0.916 滕学清 赫巴 油基 YP 0.972 0.965 0.970 稠度系数 0.984 0.946 0.972 流性指数 0.935 Ashok Santra 四参数 油基 YP 0.977 0.9644 0.971 黏度系数 0.981 0.952 0.981 稠度系数 0.992 0.985 0.979 流性指数 0.948 Erna Kakadjian 四参数 油基 YP 0.985 0.983 0.983 黏性系数 0.995 0.997 0.991 稠度系数 0.985 0.963 0.972 流性指数 0.922 Emanuel Stamatakis 四参数 油基 YP 0.991 0.976 0.982 黏性指数 0.983 0.986 0.980 稠度系数 0.987 0.982 0.976 流性指数 0.956 Khaled J. Hassiba 双曲 水基 YP 0.986 0.969 0.982 稠度系数 0.939 0.921 0.921 剪切稀释系数 0.894 周号博 双曲 水基 YP 0.979 0.958 0.986 稠度系数 0.998 0.987 0.998 剪切稀释系数 0.931 许洁 双曲 水基 YP 0.979 0.984 0.979 稠度系数 0.979 0.984 0.979 剪切稀释系数 0.923 表 6 各流变参数计算的平均误差

流变模式 流变参数 平均误差/% 赫巴模式 动切力 6.73 稠度系数 7.88 流性指数 9.36 双曲模式 动切力 8.03 稠度系数 5.86 剪切稀释系数 9.81 -

[1] 李阳,薛兆杰,程喆,等. 中国深层油气勘探开发进展与发展方向[J]. 中国石油勘探,2020,25(1):45-57. doi: 10.3969/j.issn.1672-7703.2020.01.005LI Yang, XUE Zhaojie, CHENG Zhe, et al. Progress and development direction of deep oil and gas exploration and development in China[J]. China Petroleum Exploration, 2020, 25(1):45-57. doi: 10.3969/j.issn.1672-7703.2020.01.005 [2] 赵胜英,鄢捷年,舒勇,等. 油基钻井液高温高压流变参数预测模型[J]. 石油学报,2009,30(4):603-606. doi: 10.3321/j.issn:0253-2697.2009.04.023ZHAO Shengying, YAN Jienian, SHU Yong, et al. Prediction model of high temperature and high pressure rheological parameters of oil-based drilling fluid[J]. Acta Petrolei Sinica, 2009, 30(4):603-606. doi: 10.3321/j.issn:0253-2697.2009.04.023 [3] BINGHAM E C. Fluidity and plasticity[M]. New York: McGraw-Hill, 1922. [4] OSTWALD W. About the rate function of the viscosity of dispersed systems[J]. IKolloid-Zeitschrift, 1925, 36(2):99-117. doi: 10.1007/BF01431449 [5] HERSCHEL W H, BULKLEY R. Konsistenzmessungen von gummi-benzollösungen[J]. Kolloid-Zeitschrift, 1926, 39: 291-300. [6] SISKO A W. The flow of lubricating greases[J]. Industrial & Engineering Chemistry, 1958, 50(12):1789-1792. [7] CASSON N. A flow equation for pigment oil suspensions of the printing ink type[J]. In Rheology of Disperse Systems, 1959:84-104. [8] ROBERTSON R E. An improved mathematic model for relating shear stress to shear rate in drilling fluids and cement slurries[J]. Society of Petroleum Engineers Journal, 1976, 16(1):31-36. doi: 10.2118/5333-PA [9] 白家祉. 带屈服值的假塑性流体的双曲模式方程与压降计算式[J]. 石油学报,1980(2):57-63. doi: 10.7623/syxb198002008BAI JIazhi. Hyperbolic mode equation and pressure drop calculation formula of pseudoplastic fluid with yield value[J]. Acta Petrolei Sinica, 1980(2):57-63. doi: 10.7623/syxb198002008 [10] 林柏亨. 一个新的钻井液流变模型[J]. 石油学报,1999,20(4):78-82. doi: 10.7623/syxb199904015LIN Baiheng. A new rheological model of drilling fluid[J]. Acta Petrolei Sinica, 1999, 20(4):78-82. doi: 10.7623/syxb199904015 [11] 樊洪海,王果,张辉,等. 四参数流变模式及其水力计算模型[J]. 石油学报,2010,31(3):511-515. doi: 10.7623/syxb201003030FAN Honghai, WANG Guo, ZHANG Hui, et al. Four-parameter rheological mode and hydraulic calculation model[J]. Acta Petrolei Sinica, 2010, 31(3):511-515. doi: 10.7623/syxb201003030 [12] FISK J V, JAMISON D E. Physical properties of drilling fluids at high temperatures and pressures[J]. Spe Drilling Engineering, 1989, 4(4):341-346. doi: 10.2118/17200-PA [13] 周福建,刘雨晴,杨贤友,等. 水包油钻井液高温高压流变性研究[J]. 石油学报,1999(3):85-89. doi: 10.7623/syxb199903014ZHOU Fujian, LIU Yuqing, YANG Xianyou, et al. Study on high temperature and high pressure rheology of oil-in-water drilling fluid[J]. Acta Petrolei Sinica, 1999(3):85-89. doi: 10.7623/syxb199903014 [14] 滕学清,樊洪海,杨成新,等. 一种新的高温高压流变性分析模型[J]. 科学技术与工程,2015,15(34):162-167. doi: 10.3969/j.issn.1671-1815.2015.34.028TENG Xueqing, FAN Honghai, YANG Chengxin, et al. A new high temperature and high pressure rheology analysis model[J]. Science Technology and Engineering, 2015, 15(34):162-167. doi: 10.3969/j.issn.1671-1815.2015.34.028 [15] FAN H, ZHOU H, MENG X, et al. Accurate prediction model for rheological properties of drilling fluids at high temperature and high pressure conditions[C]//SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition. OnePetro, 2015. [16] 陈彬,李超,张春杰,等. 深水合成基钻井液高温高压流变特性[J]. 科学技术与工程,2022,22(4):1408-1415. doi: 10.3969/j.issn.1671-1815.2022.04.014CHEN Bin, LI Chao, ZHANG Chunjie, et al. Rheological characteristics of deepwater synthetic-based drilling fluid at high temperature and high pressure[J]. Science Technology and Engineering, 2022, 22(4):1408-1415. doi: 10.3969/j.issn.1671-1815.2022.04.014 [17] 樊洪海,彭齐,滕学清,等. 不同流变模式钻井流体圆管层流压耗的通用精确算法[J]. 中国石油大学学报(自然科学版),2014,38(1):70-74.FAN Honghai, PENG Qi, TENG Xueqing, et al. General and accurate algorithm for laminar flow pressure loss of round pipe of drilling fluid with different rheological modes[J]. Journal of China University of Petroleum(Natural Science Edition) , 2014, 38(1):70-74. [18] 赵怀珍,薛玉志,李公让,等. 抗高温水基钻井液超高温高压流变性研究[J]. 石油钻探技术,2009,37(1):5-9. doi: 10.3969/j.issn.1001-0890.2009.01.002ZHAO Huaizhen, XUE Yuzhi, LI Gongrang, et al. Study on ultra-high temperature and high pressure rheology of water-based drilling fluid[J]. Petroleum Drilling Technology, 2009, 37(1):5-9. doi: 10.3969/j.issn.1001-0890.2009.01.002 [19] YOUNG S, FRIEDHEIM J E, LEE J, et al. A New Generation of Flat Rheology Invert Drilling Fluids[M]. 2012. [20] AMANI M, HASSIBA K J. Salinity effect on the rheological properties of water based mud under high pressures and high temperatures of deep wells[M]. 2012. [21] STAMATAKIS E, YOUNG S, STEFANO G D. Meeting the Ultrahigh-Temperature/Ultrahigh-Pressure Fluid Challenge[J]. Spe Drilling & Completion, 2013, 28(1):86-92. [22] KUMAPAYI O, BELLO K, ADEKOMAYA O, et al. Investigating the effects of contaminants on the performance of mineral oil based versathin dispersant[M]. Society of Petroleum Engineers, 2014. [23] GALINDO K A, ZHA W, HUI Z, et al. High temperature, high performance water-based drilling fluid for extreme high temperature wells. 2015. [24] SAIRAM P, PANGU G, GAJJI B. Innovative and modular equipment design for rheology and compatibility measurement of complex wellbore fluids[C]// SPE/IADC Drilling Conference and Exhibition. 2015. [25] 许洁. 超高温水基钻井液技术及其流变模型研究[D]. 中国地质大学, 2015.XU Jie. Research on ultra-high temperature water-based drilling fluid technology and its rheological model[D]. China University of Geosciences, 2015. [26] 马光曦. 高温高压井ECD校核与控制技术研究[D]. 中国石油大学(北京), 2016.MA Guangxi. Research on ECD calibration and control technology of high temperature and high pressure wells[D]. China University of Petroleum(Beijing), 2016. [27] KAKADJIAN E, SHI A, PORTER J, et al. Low impact drilling fluid for deepwater drilling frontier[C]// Offshore Technology Conference Brasil. 2019. [28] 周号博. 基于黏度计读值预测的高温高压流变性预测方法[J]. 钻井液与完井液,2019,36(3):325-332. doi: 10.3969/j.issn.1001-5620.2019.03.011ZHOU Haobo. High temperature and high pressure rheology prediction method based on viscometer reading prediction[J]. Drilling Fluid & Completion Fluid, 2019, 36(3):325-332. doi: 10.3969/j.issn.1001-5620.2019.03.011 [29] WAGLE V, YAMI A, ONORIODE M, et al. Design, qualification and field deployment of low ECD organoclay-free invert emulsion drilling fluids[C]. SPE Russian Petroleum Technology Conference, Virtual, October 2020. [30] SANTRA A, PATEL H, SHANMUGAM S. Next generation high performance invert emulsion drilling fluids with flat-rheological behavior[C]//SPE International Conference on Oilfield Chemistry. OnePetro, 2021. [31] Recommended practice on the rheology and hydraulics of oil-well drilling fluids [superseded:Api bull 13d]:API RP 13D-1995[S]. [32] 高禹. 高温高压钻井液流变性研究[D]. 中国石油大学(华东), 2019.GAO Yu. Study on rheology of high temperature and high pressure drilling fluid[D]. China University of Petroleum (East China), 2019. [33] 蒋官澄,吴学诗,鄢捷年,等. 深井水基钻井液高温高压流变特性的研究[J]. 钻井液与完井液,1994(5):21-26.JIANG Guancheng, WU Xueshi, YAN Jienian, et al. Study on high temperature and high pressure rheological characteristics of water-based drilling fluid in deep well[J]. Drilling Fluid & Completion Fluid, 1994(5):21-26. [34] 谢春林,杨丽丽,蒋官澄,等. 高温高压耦合条件下油基钻井液的流变特性规律及其数学模型[J]. 钻井液与完井液,2021,38(5):568-575.XIE Chunlin, YANG Lili, JIANG Guancheng, et al. Rheological characteristics and mathematical model of oil-based drilling fluid under high temperature and high pressure coupling conditions[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):568-575. [35] 陈彬,张伟国,姚磊,等. 基于井壁稳定及储层保护的钻井液技术[J]. 石油钻采工艺,2021,43(2):184-188.CHEN Bin, ZHANG Weiguo, YAO Lei, et al. Drilling fluid technology based on well stability and reservoir protection[J]. Oil Drilling & Production Technology, 2021, 43(2):184-188. [36] 黄志洋,赵雄虎,苗留洁,等. 智能流体研究进展及其在钻井液中的应用与展望[J]. 石油钻采工艺,2022,44(3):283-290.HUANG Zhiyang, ZHAO Xionghu, MIAO Liujie, et al. Research progress of intelligent fluid and its application to drilling fluids[J]. Oil Drilling & Production Technology, 2022, 44(3):283-290. [37] 路保平. 基于地层性质与环空状态的钻井液流变参数优选[J]. 钻井液与完井液,2020,37(4):438-443.LU Baoping. Optimization of drilling fluid rheology based on formation characteristics and annular state[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):438-443. -

下载:

下载: