Study on Aggregation Morphology and Resistance Reducing Properties of Drag Reducing Agents

-

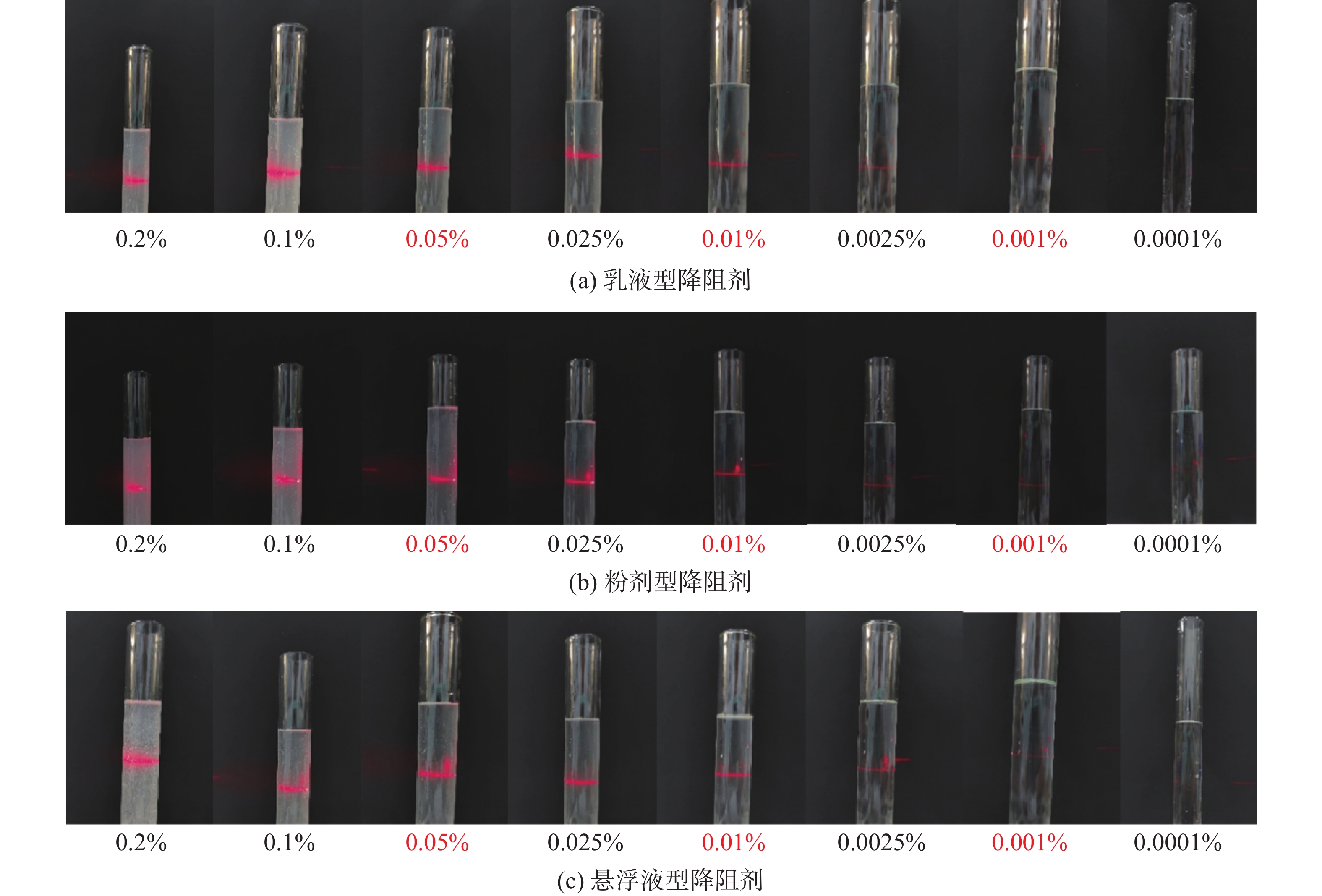

摘要: 为明确滑溜水压裂液降阻剂宏观降阻性能的微观控制机制,利用环境扫描电镜对不同类型的聚合物降阻剂形成的聚集体结构进行大量微观表征,结合体系降阻性能测试,从聚合物分子聚集态层次揭示浓度对不同降阻剂体系降阻性能作用的微观机理。研究发现,滑溜水降阻剂在极低浓度下聚集形成丝状结构,随着降阻剂浓度的不断提高,这些丝线状结构逐渐缠结连接形成骨架,最终围成多层次的“蛛网状”聚集体网络结构。同时不同类型的滑溜水降阻剂所形成的网络结构又具有各自的特点,其中以乳液型和悬浮液型降阻剂网络结构最为完整,而粉剂型降阻剂由于溶解速度较慢,形成聚集体网络结构分布不均,网络强度普遍不高。降阻剂浓度对降阻剂聚集状态影响极大,在低浓度条件下,3种降阻剂形成的网络结构平均骨架厚度约为0.1~0.3 μm。随着降阻剂浓度的增大,体系网眼形状由不规则逐渐转变为多边形,部分降阻剂可形成强度较高、稳定性较好的圆形网络支撑结构,网眼尺寸减小,骨架厚度增加。当降阻剂浓度增加为0.05%时,骨架厚度可达0.3~0.9 μm,网络结构强度显著提高。滑溜水降阻剂形成的聚集体网络结构会对体系降阻性能产生重要影响,降阻剂加量与体系降阻性能之间并非表现出简单的线性关系,只有在合适浓度下形成的适中尺寸的聚集体网络结构才能与体系中的水分子紧密作用,稳定溶液流动状态,减少湍流脉动,降低湍流流动过程中的能量耗散,最终实现高效降阻的效果。Abstract: In order to clarify the micro control mechanism of the macro drag reduction performance of slick-water drag reducer, a large number of micro characterization of the aggregate structure formed by different types of polymer drag reducing agents were carried out by environmental scanning electron microscope. Combined with the test of the drag reduction performance of the system, the micro mechanism of the effect of concentration on the drag reduction performance of different drag reducing agents systems was revealed from the level of polymer molecular aggregation structure. It was found that the slick-water drag reducer aggregated to form a filament structure at very low concentration. With the increasing concentration of the resistance reducer, these filament structures gradually entangled and connected to form a skeleton, and finally form a multi-level "spider net" aggregate network structure. At the same time, the network structure formed by different types of slick water resistance reducer had its own characteristics. Among them, emulsion and suspension type drag reducing agents had the most complete network structures, while powder type drag reducing agents had uneven distribution of aggregated network structures and low network strength due to slow dissolution speed. At low concentration, the average mesh wall thickness of the network structure formed by the three drag reducing agents was about 0.1-0.3 μm. With the increase of the concentration of drag reducing agents, the mesh shape of the system gradually changed from irregular to polygonal. Some drag reducing agents can form a circular network support structure with high strength and good stability. The mesh size decreased and the mesh wall thickness increased. When the concentration of drag reducing agents increased to 0.05%, the mesh wall thickness can reach 0.3-0.9 μm. The strength of network structure had been significantly improved. The aggregate network structure formed by the slick-water drag reducer will have an important impact on the resistance reducing performance of the system. The addition of the resistance reducing agent and the resistance reducing performance of the system did not show a simple linear relationship. Only an appropriate size aggregate network structure formed at a suitable concentration can closely interact with the water molecules in the system, stabilize the solution flow state, reduce the turbulence pulsation, and reduce the energy dissipation in the turbulent flow process, Finally, the effect of high-efficiency resistance reduction was realized.

-

表 1 乳液型降阻剂微观网络结构参数统计表

降阻剂 降阻剂/% 网眼形状 网络强度模糊评价 平均网眼直径/μm 网眼壁厚/μm 结节程度模糊评价 结节尺寸/μm R-1 0.0001 不规则 0.1 13.63 0.25 0.7 1.11~2.54 0.0100 多边形 0.7 5.44 0.22 0 0.0500 圆形 0.8 2.72 0.37 0 R-2 0.0010 不规则 0.1 0.13 0.9 2.11~9.58 0.0100 多边形 0.4 9.32 0.18 0.8 0.41~1.83 0.0500 多边形 0.5 8.48 0.24 0.3 0.58~0.92 R-3 0.0010 多边形 0.2 13.25 0.16 0.6 0.32~2.03 0.0100 圆形 0.5 11.53 0.64 0 0.0500 圆形 0.6 7.68 0.83 0 R-4 0.0010 不规则 0.3 0.16 0.7 0.26~1.64 0.0100 多边形 0.5 8.65 0.32 0 0.0500 多边形 0.8 1.74 0.67 0 表 2 粉剂型降阻剂微观网络结构参数统计表

降阻剂 降阻剂/% 网眼形状 网络强度模糊评价 平均网眼直径/μm 网眼壁厚/μm 结节程度模糊评价 结节尺寸/μm F-1 0.0010 不规则 0.1 1.92 0.11 0.4 0.25~1.51 0.0100 不规则 0.5 6.76 0.28 0.6 0.33~1.74 0.0500 不规则 0.6 8.45 0.34 0.2 0.66~1.18 F-2 0.0010 不规则 0.2 0.07 0.7 0.74~2.95 0.0100 不规则 0.5 7.42 0.25 0.7 0.41~2.72 0.0500 多边形 0.6 5.69 0.33 0.3 0.73~3.21 表 3 悬浮液型降阻剂微观网络结构参数统计表

降阻剂 降阻剂/% 网眼形状 网络强度模糊评价 平均网眼直径/μm 网眼壁厚/μm 结节程度模糊评价 结节尺寸/μm X-1 0.0010 不规则 0.2 9.34 0.31 0.4 0.33~1.42 0.0100 多边形 0.6 7.68 0.35 0 0.0500 多边形 0.8 4.56 0.44 0 X-2 0.0001 不规则 0.3 13.53 0.08 0.2 0.39~0.86 0.0100 不规则 0.5 8.47 0.23 0.6 0.54~1.18 0.0500 圆形 0.8 2.52 0.52 0 X-3 0.0001 不规则 0.4 8.53 0.16 0.4 0.28~2.17 0.0100 多边形 0.3 6.86 0.42 0.1 0.41~1.15 0.0500 多边形 0.5 6.27 0.37 0.3 0.67~2.08 X-4 0.0010 不规则 0.3 7.38 0.19 0.4 0.27~4.48 0.0100 多边形 0.7 6.82 0.32 0.3 0.36~1.16 0.0500 多边形 0.6 5.39 0.43 0.3 0.49~1.25 表 4 不同浓度的悬浮液型X-2降阻剂微观网络参数及降阻率统计表

降阻剂 降阻剂/% 网眼形状 网络强度模糊评价 平均网眼直径/μm 网眼壁厚/μm 结节程度模糊评价 降阻率/% X-2 0.02 不规则 0.6 7.14 0.28 0.2 21 0.03 多边形 0.7 5.68 0.45 0.1 37 0.05 圆形 0.8 2.52 0.52 0 50 0.10 圆形 0.9 1.55 0.71 0 72 表 5 不同浓度的乳液型R-4降阻剂微观网络参数及降阻率统计表

降阻剂 降阻剂/% 网眼形状 网络强度模糊评价 平均网眼直径/μm 网眼壁厚/μm 结节程度模糊评价 降阻率/% R-4 0.05 多边形 0.8 1.74 0.67 0 69.0 0.10 圆形 0.9 1.73 0.72 0 75.0 0.15 圆形 0.9 1.35 0.81 0 73.0 0.20 圆形 1.0 1.05 0.96 0 72.5 0.25 圆形 1.0 0.91 1.21 0 70.0 -

[1] 刘洪林,王红岩,刘人和,等. 非常规油气资源发展现状及关键问题[J]. 天然气工业,2009(9):113-116,146.LIU Honglin, WANG Hongyan, LIU Renhe, et al. Current situation and key problems of unconventional oil and gas resources development[J]. Natural Gas Industry, 2009(9):113-116,146. [2] ZARGARI S. Field development strategies for Bakken shale formation[D]. Morgantown: West Virginia University, 2010. [3] DONG K X, JIANG M Z, LI J B, et al. Research progresses in formation mechanism of complex fracture network for unconventional reservoir[J]. Arabian Journal of Geosciences, 2020, 13(15):1-10. [4] 潘继平. 非常规天然气资源开发政策困境及对策建议[J]. 石油科技论坛,2019(39):1-7. doi: 10.3969/j.issn.1002-302x.2019.01.001PAN Jiping. Difficulties of unconventional natural gas resource development policies and countermeasures[J]. Petroleum Science and Technology Forum, 2019(39):1-7. doi: 10.3969/j.issn.1002-302x.2019.01.001 [5] 陈昊,毕凯琳,张军,等. 非常规油气开采压裂用降阻剂研究进展[J]. 油田化学,2021,38(2):347-359.CHEN Hao, BI Kailin, ZHANG Jun, et al. Research progress of drag reducing agents for unconventional oil and gas production fracturing[J]. Oilfield Chemistry, 2021, 38(2):347-359. [6] HAO B A, Fz A, Mz A, et al. Optimization and friction reduction study of a new type of viscoelastic slickwater system[J]. Journal of Molecular Liquids, 2021, 344:117876. doi: 10.1016/j.molliq.2021.117876 [7] 蒋廷学,卞晓冰,王海涛,等. 深层页岩气水平井体积压裂技术[J]. 天然气工业,2017,37(1):90-96. doi: 10.3787/j.issn.1000-0976.2017.01.011JIANG Tingxue, BIAN Xiaobing, WANG Haitao, et al. Volume fracturing technology for deep shale gas horizontal wells[J]. Natural Gas Industry, 2017, 37(1):90-96. doi: 10.3787/j.issn.1000-0976.2017.01.011 [8] 姚奕明,魏娟明,杜涛,等. 深层页岩气压裂滑溜水技术研究与应用[J]. 精细石油化工,2019,36(4):15-19. doi: 10.3969/j.issn.1003-9384.2019.04.004YAO Yiming, WEI Juanming, DU Tao, et al. Research and application of gas fracturing and sliding water technology for deep shale[J]. Fine Petrochemical, 2019, 36(4):15-19. doi: 10.3969/j.issn.1003-9384.2019.04.004 [9] 柳慧,侯吉瑞,王宝峰. 降阻水及其添加剂的研究进展及展望[J]. 广州化工,2012,40(11):35-37. doi: 10.3969/j.issn.1001-9677.2012.11.014LIU Hui, HOU Jirui, WANG Baofeng. Research progress and prospect of drag reducing water and its additives[J]. Guangzhou Chemical Industry, 2012, 40(11):35-37. doi: 10.3969/j.issn.1001-9677.2012.11.014 [10] 刘致屿. 滑溜水压裂液降阻机理研究[D]. 北京: 中国石油大学(北京), 2019.LIU Zhiyu. Study on mechanism of resistance reduction of slippery hydraulic fracturing fluid[D]. Beijing: China University of Petroleum (Beijing), 2019. [11] SUN Y, WU Q, BAI B, et al. The flow behavior of friction reducer in microchannels during slickwater fracturing[C]//SPE Production and Operations Symposium, Oklahoma, USA, 2013. [12] FU Z, IWAKI Y, MOTOZAWA M, et al. Characteristic turbulent structure of a modified drag-reduced surfactant solution flow via dosing water from channel wall[J]. International Journal of Heat and Fluid Flow, 2015, 53:135-145. doi: 10.1016/j.ijheatfluidflow.2015.03.006 [13] YANG S Q, DING D. Drag-reducing flows in laminar-turbulent transition region[J]. Journal of Fluids Engineering, 2014, 136(10):1-9. [14] PAKTINAT J, O’NEIL B, AFTEN C, et al. Critical evaluation of high brine tolerant additives used in shale slick water fracs[C]//SPE production and operations symposium, Oklahoma, USA, 2011. [15] CHENG Y. Impact of water dynamics in fractures on the performance of hydraulically fractured wells in gas-shale reservoirs[J]. Journal of Canadian Petroleum Technology, 2012, 51(2):143-151. doi: 10.2118/127863-PA [16] BRONIARZ-PRESS L, ROZANSKI J, ROZANSKA S. Drag reduction effect in pipe systems and liquid falling film flow[J]. Reviews in Chemical Engineering, 2007, 23(3):149-246. [17] 李涛,陆丹. 利用指数律了解溶液中复杂高分子单链及聚集态结构的形状特征[J]. 化学学报,2016,74(8):649-656.LI Tao, LU Dan. Using exponential law to understand the shape characteristics of single chain and aggregate structures of complex polymers in solution[J]. Journal of Chemistry, 2016, 74(8):649-656. [18] 冯绪胜, 刘洪国, 郝京诚. 胶体化学[M]. 北京: 化学工业出版社, 2005.FENG Xusheng, LIU Hongguo, HAO Jingcheng. Colloid chemistry[M]. Beijing: Chemical Industry Press, 2005. [19] 张师愚, 夏厚林. 物理化学[M]. 北京: 中国医药科技出版社, 2014.ZHANG Shiyu, XIA Houlin. Physical chemistry[M]. Beijing: China Pharmaceutical Science and Technology Press, 2014. [20] 秦雅玲. 基于数字图像的丁达尔现象与胶体溶液浓度检测方法研究[D]. 桂林: 桂林理工大学, 2020.QIN Yaling. Study on detection method of tindall phenomenon and colloid solution concentration based on digital Image[D]. Guilin: Guilin University of Technology, 2020. [21] 许可,侯宗锋,翁定为,等. 耐高温压裂液及其添加剂研究进展[J]. 当代化工,2022,51(4):936-940. doi: 10.3969/j.issn.1671-0460.2022.04.039XU Ke, HOU Zongfeng, WENG Dingwei, et al. Research progress of high temperature resistant fracturing fluid and its additives[J]. Contemporary Chemical Industry, 2022, 51(4):936-940. doi: 10.3969/j.issn.1671-0460.2022.04.039 [22] 卜涛. 滑溜水用耐盐速溶减阻剂的制备与应用研究[D]. 成都: 西南石油大学, 2018.BU Tao. Study on preparation and application of salt resistant instant drag deducing agent for slippery water[D]. Chengdu: Southwest Petroleum University, 2018. [23] 廖子涵,陈馥,卜涛,等. 水包水乳液减阻剂的减阻机理研究[J]. 石油化工,2019,48(7):724-730. doi: 10.3969/j.issn.1000-8144.2019.07.011LIAO Zihan, CHEN Fu, BU Tao, et al. Study on drag reduction mechanism of water in water lotion drag reducer[J]. Petrochemical industry, 2019, 48(7):724-730. doi: 10.3969/j.issn.1000-8144.2019.07.011 [24] 刘晓瑞,周福建,石华强,等. 聚合物减阻剂微观减阻机理研究[J]. 石油化工,2017,46(1):97-102. doi: 10.3969/j.issn.1000-8144.2017.01.014LIU Xiaorui, ZHOU Fujian, SHI Huaqiang, et al. Study on micro drag reduction mechanism of polymer drag reducing agent[J]. Petrochemical Industry, 2017, 46(1):97-102. doi: 10.3969/j.issn.1000-8144.2017.01.014 -

下载:

下载: