Preparation and Performance Evaluation of Environment-friendly Anti-high Temperature Composite Anti-mud-bag Lubricant

-

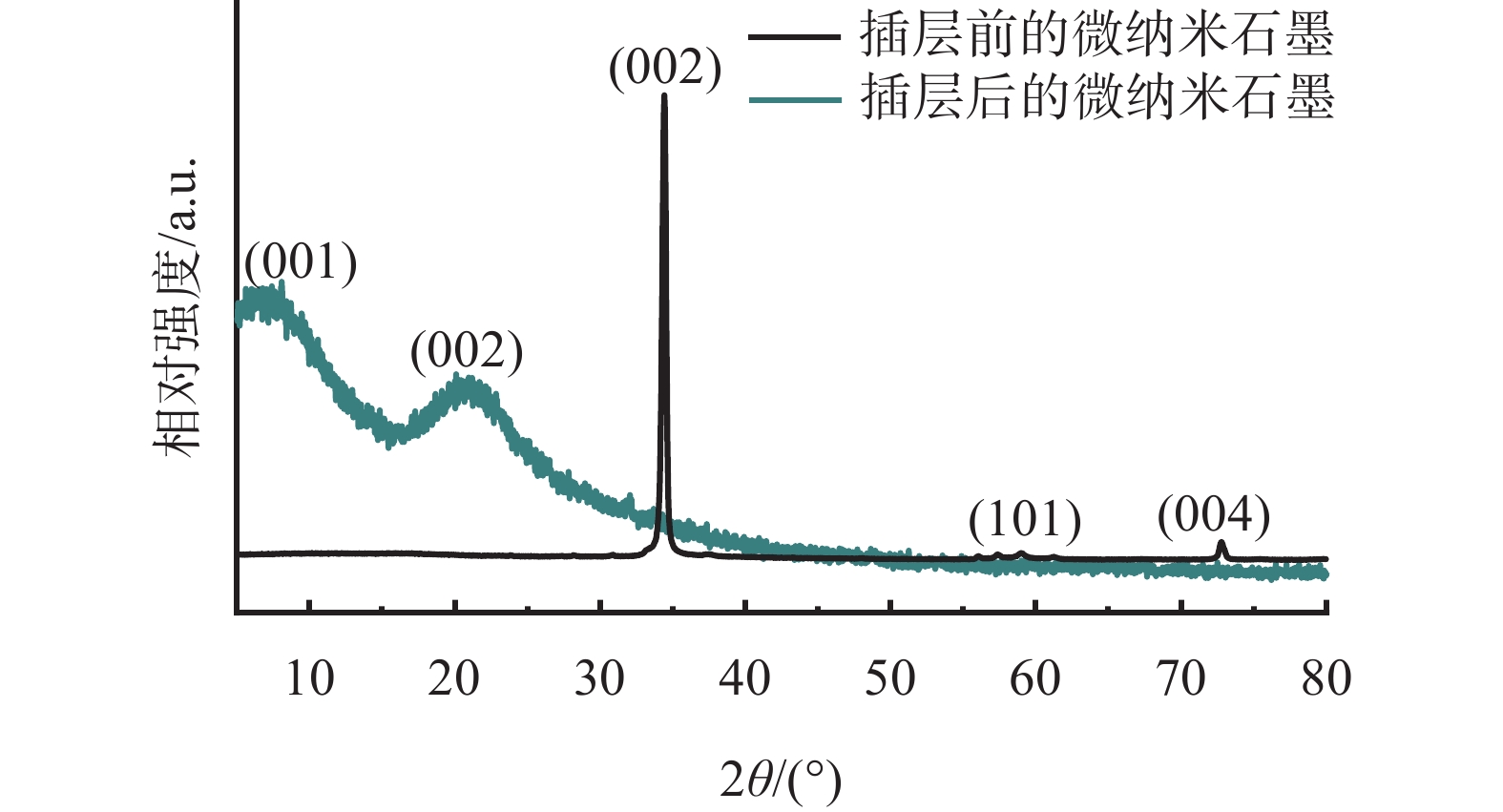

摘要: 在深井、超深井和超长水平段井的开发过程中,钻进时摩阻高、扭矩波动大和托压频繁等难题严重影响了施工进度。随着环保法的深入实施,对水基钻井液的抗温、环保和润滑性能要求也日益提高。为解决以上技术难题,通过胶束共聚法合成了一种具有多识别位点的共聚物,并通过插层纳米石墨,研发出一种新型的微纳米石墨-高分子复合抗泥包润滑减阻剂,该产品兼具防泥包和润滑的双重性能,产品抗温不小于160 ℃,荧光级别小于2,润滑系数降低率达85.0%,钻井液滤液的表面张力低于25 mN·m。接触角和X-射线光电子能谱结果表明,该润滑剂相比于水会优先吸附在钢片表面呈现疏水状态,并与Fe元素形成稳定的配位作用,从而提高润滑性能。Abstract: With the development of exploration and development in the direction of deep well, ultra-deep well and ultra-long horizontal section, the formation is complex during drilling. In view of the technical difficulties such as the formation with high mud content and strong hydration easily producing bit mud pack, as well as the high frictional resistance, high torque fluctuation and frequent supporting pressure during drilling in long horizontal section, which seriously affect the construction progress, a kind of copolymer with multiple recognition sites was synthesized by micellar copolymerization, and a new type of micro-nano graphite-polymer composite anti-mud-bag lubricant and drag reducer was developed by intercalating nano-graphite, the results of contact angle and x-ray photoelectron spectroscopy show that the lubricant adsorbs on the surface of the steel sheet preferentially than water, and has a stable coordination with Fe, to improve lubrication. The temperature resistance is more than 160 ℃, the fluorescence grade is less than 2, the lubricating coefficient of base mud with 0.5% lubricant is reduced by 80.0% , and the surface tension of filtrate of drilling fluid is lower than 25 mN/m.The product has significant potential application value in the exploration and development of deep oil and gas.

-

Key words:

- Eco-friendly /

- Heat-resistant /

- Mud-resistant /

- Lubricant

-

表 1 复合抗泥包润滑剂产品效果评价

复合抗泥包

润滑剂/%ρ/

g·cm−3φ600 润滑

系数润滑系数

降低率 %0 1.03 10 0.515 0.5 1.02 11 0.162 68.3 1.0 1.02 11 0.075 85.6 1.5 1.02 11 0.065 86.5 2.0 1.02 11 0.065 86.5 表 2 产品在基浆中的抗温性能评价

润滑

剂/%T/

℃ρ/

g·cm−3AV/

mPa∙sPV/

mPa∙sFLAPI/

mL润滑

系数润滑系数

降低率/%0 室温 1.03 7.5 6.0 15.6 0.53 120 1.02 8.5 5.5 18.4 0.50 160 1.02 7.5 5.0 17.6 0.49 180 1.01 7.5 5.0 17.2 0.46 1.0 室温 0.97 8.0 7.0 15.0 0.08 85.00 120 0.96 8.5 7.5 14.6 0.13 73.80 160 0.95 10.0 9.0 14.0 0.14 71.20 180 0.96 11.0 9.5 14.6 0.14 69.56 1.5 室温 0.96 11.0 10.0 18.0 0.07 86.20 120 0.95 6.5 8.5 16.2 0.08 84.60 160 0.95 9.5 8.5 16.0 0.09 81.20 180 0.96 11.0 9.5 17.0 0.09 80.43 表 3 井浆加入防泥包润滑剂产品 前后的钻井液性能变化情况

复合抗泥包

润滑剂/%FV/

sρ/

g·cm−3FL/

mLφ600 φ300 滑块摩阻

系数0 65 1.18 5.2 80 61 0.0524 0.5 65 1.18 5.0 80 61 0.0362 1.0 65 1.18 5.0 81 61 0.0362 1.5 66 1.18 5.0 81 61 0.0362 2.0 66 1.18 5.0 82 62 0.0362 表 4 应用井钻井数据与前期平均数据对比

井号 井段/

m平均复合钻进

机械钻速/(m·h−1)平均滑动钻进

机械钻速/(m·h−1)钻压/

MT钻头转速/

r·min−1泵压/

MPa扭矩/

kN·m前期平均 2600~3200 14.6 2.1 18~25 110 17.1~18.8 14.9~25.2 CB**-2 15.1 2.6 19~26 110 17.2~19.3 13.2~20.6 -

[1] 孙永兴,范生林,乔李华. 页岩气水平井卡钻主要原因及预防对策[J]. 天然气工业,2018,38(12):113-119.SUN Yongxing, FAN Shenglin, QIAO Lihua. The main reasons for sticking of horizontal wells in shale gas and their preventive countermeasures[J]. Natural Gas Industry, 2018, 38(12):113-119. [2] 王建龙,张长清,郭云鹏,等. 大斜度井井眼清洁影响因素及对策研究[J]. 钻采工艺,2020,43(6):28-30.WANG Jianlong, ZHANG Changqing, GUO Yunpeng, et al. Research on factors and countermeasures of wellbore cleaning in highly deviated wells[J]. Drilling and Production Technology, 2020, 43(6):28-30. [3] 陈彬,张伟国,姚磊,等. 基于井壁稳定及储层保护的钻井液技术[J]. 石油钻采工艺,2021,43(2):5-9.CHEN Bin, ZHANG Weiguo, YAO Lei, et al. Drilling fluid technology based on wellbore stability and reservoir protection[J]. Petroleum Drilling and Production Technology, 2021, 43(2):5-9. [4] 闫丽丽,李丛俊,张志磊,等. 基于页岩气"水替油"的高性能水基钻井液技术[J]. 钻井液与完井液,2015,32(5):1-6.YAN Lili, LI Congjun, ZHANG Zhilei, et al. High-performance water-based drilling fluid technology based on shale gas "water for oil"[J]. Drilling Fluid & Completion Fluid, 2015, 32(5):1-6. [5] 刘芳. 钻井液用液体润滑剂LRH的研究与应用[D]. 东北石油大学, 2015.LIU Fang. Research and application of liquid lubricant LRH for drilling fluids [D]. Northeast Petroleum University, 2015. [6] 赵泽宗,卓然,李荷香,等. 高效水基钻井液用润滑剂的研制与现场试验[J]. 钻采工艺,2019,42(4):93-96.ZHAO Zezong, ZHUO Ran, LI Hexiang, et al. Development and field test of lubricants for high-efficiency water-based drilling fluids[J]. Drilling and Production Technology, 2019, 42(4):93-96. [7] 姚倩,许明标,由福昌. 硅酸盐钻井液泥包形成的趋势研究[J]. 钻井液与完井液,2019,36(6):700-705.YAO Qian, XU Mingbiao, YOU Fuchang. Research on the trend of mud bag formation in silicate drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):700-705. [8] 胡郁乐,胡晨,张恒春,等. 钻头泥包原因分析及松科二井防泥包钻井液的应用[J]. 煤田地质与勘探,2020,48(5):254-261,268.HU Yule, HU Chen, ZHANG Hengchun, et al. Analysis of the causes of mud bag in the drill bit and application of mud bag prevention drilling fluid in Songke No. 2 Well[J]. Coalfield Geology and Exploration, 2020, 48(5):254-261,268. [9] 姜峰,蒲万芬,杜代军,等. 双尾型丙烯酰胺类疏水缔合共聚物的合成与表征[J]. 化工学报,2015,66(3):1215-1220.JIANG Feng, PU Wanfen, DU Daijun, et al. Synthesis and characterization of two-tailed acrylamide hydrophobically associating copolymers[J]. Chinese Journal of Chemical Engineering, 2015, 66(3):1215-1220. -

下载:

下载: