Synthesis and Performance Evaluation of Nano SiO2 /Acrylamide Flocculant

-

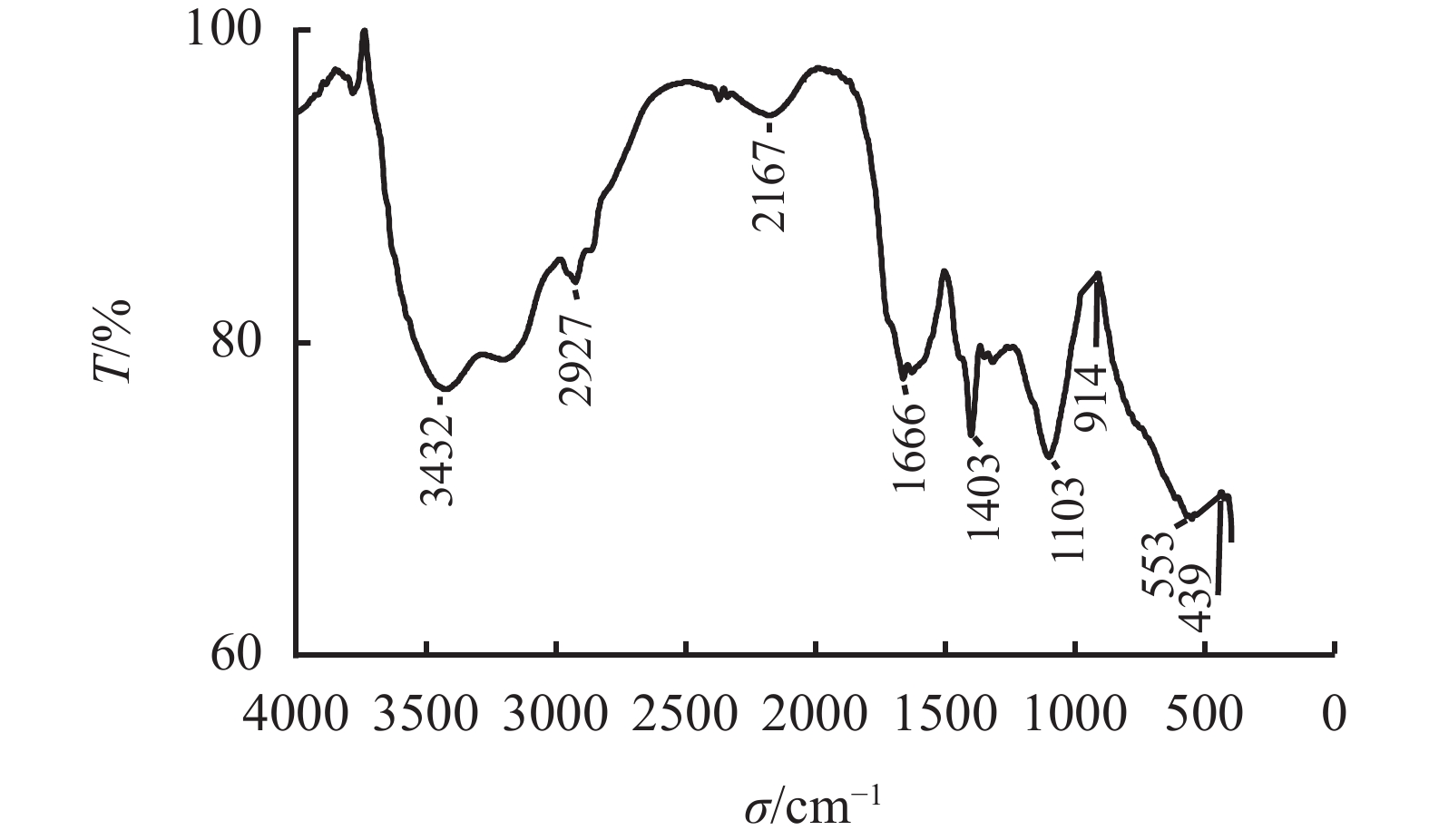

摘要: 以正硅酸乙酯(TEOS)为原料,采用溶胶-凝胶法制备了不同粒径的SiO2颗粒,对其表面进行改性后,与丙烯酰胺(AM)、二甲基二烯丙基氯化铵(DMDAAC),采用反相乳液聚合法合成了纳米SiO2/阳离子聚丙烯酰胺(SCPAM)。并对产品进行了测试与表征,根据表征结果确定该产品为目标产品。研究了SiO2的粒径以及其加量对SCPAM分子量、水溶性、增黏性及絮凝性等性能的影响。实验结果表明,以粒径为15 nm的SiO2加量占单体质量比0.9%时,所合成的SCPAM具有更佳的水溶性、增黏性及絮凝性,对以SCPAM为絮凝剂配制的钻井液的耐温、抗盐、抗剪切、耐老化及抗污染性进行了评价,结果显示当盐度达到30%,钻井液黏度仍保持在30 mPa·s左右;在老化时间达到96 h,钻井液黏度保持在33 mPa·s左右,展示了良好的抗盐性和抗老化性,且在有害固相含量低于5%、温度低于160 ℃时,该钻井液应用效果较好。Abstract: SiO2 of different particle sizes were prepared through sol-gel method using tetraethyl orthosilicate (TEOS) as the raw material. The SiO2 particles, after surface modification, was in turn used as raw material to react with acrylamide (AM) and dimethyl diallyl ammonium chloride (DMDAAC) to produce nano SiO2/cationic polyacrylamide (SCPAM) through inverse emulsion polymerization. Characterization of the final product determines that it is the required product. Study on the effects of the SiO2 particle size and concentration on the molecular weight, water solubility, viscosifying performance and flocculating capacity of SCPAM shows that SCPAM made from 15 nm SiO2 at mass fraction of 0.9% of the whole reaction monomers has the best water solubility, viscosifying performance and flocculating capacity. Evaluation of a drilling fluid formulated with SCPAM as a flocculant shows that the drilling fluid has a final viscosity of about 30 mPa·s at salt concentration of 30%. After aging for 96 h, the viscosity of the drilling fluid is still about 33 mPa·s, meaning that the drilling fluid has good salt and high temperature resistance. It is also found that the drilling fluid works satisfactorily at drilled solids contents less than 5% and temperatures lower than 160 ℃.

-

表 1 SiO2粒径尺寸对SCPAM-0.9的性能对比

粒径尺寸/nm AV/mPa·s 分子量/×106 不溶物/% t絮凝/min ≈300 21.00 8.85 0.075 508 ≈160 23.25 8.95 0.069 506 ≈90 25.50 9.51 0.053 498 ≈15 26.25 9.48 0.049 494 表 2 SCPAM的絮凝性能

SiO2/% t絮凝/min 沉降介质体积/mL 0 515 106 0.2 506 110 0.5 501 103 0.7 491 88 0.9 494 76 1.0 504 74 1.2 509 91 表 3 温度对钻井液流变性能的影响

T/℃ AV/mPa·s PV/mPa·s YP/Pa 80 38.75 19.5 19.25 100 38.50 19.5 19.00 120 37.50 19.0 18.50 140 35.25 19.0 16.25 160 30.75 18.0 12.75 180 20.00 12.0 8.00 表 4 不同浓度盐分含量的钻井液性能

盐/% NaCl CaCl2 AV/mPa·s PV/mPa·s YP/Pa AV/mPa·s PV/mPa·s YP/Pa 0 53.25 26.5 26.75 53.00 26.5 26.50 5 46.50 26.5 20.00 36.75 22.0 14.75 10 41.25 21.5 19.75 34.50 20.5 14.00 15 37.50 19.5 18.00 32.75 19.0 13.75 20 37.25 18.5 18.75 31.75 18.0 13.75 25 36.50 18.0 18.50 31.00 17.5 13.50 30 34.50 17.5 17.00 30.75 17.5 13.25 表 5 钻井液耐老化性能

t老化/h AV/ mPa·s PV/mPa·s YP/Pa 0 37.50 19.0 18.50 16 38.50 19.5 19.00 32 38.00 19.5 18.50 48 36.50 18.0 18.50 64 36.00 17.0 18.00 80 34.50 17.0 17.50 96 33.25 16.5 16.75 表 6 固相含量对钻井液性能的影响

膨润土/% AV/mPa·s PV/mPa·s YP/Pa 钻井液D50/µm 0 38.75 19.5 19.25 88.91 0.5 35.50 19.0 16.50 88.12 1 36.50 20.5 16.00 80.35 2.0 37.00 21.5 15.50 70.14 3.0 39.25 22.0 17.25 58.48 4.0 39.75 22.0 17.75 44.56 5.0 44.00 25.0 19.00 13.77 表 7 剪切时间对钻井液的性能影响

t剪切/min AV/mPa·s PV/mPa·s YP/Pa 10 38.75 19.5 19.25 20 38.00 19.5 18.50 30 37.75 19.0 18.75 40 37.00 18.5 18.50 50 36.75 18.5 18.25 60 35.50 17.5 18.00 -

[1] 宋武. 聚丙烯酰胺的合成及应用研究进展[J]. 中国石油和化工标准与质量,2018,38(15):189-190. doi: 10.3969/j.issn.1673-4076.2018.15.089SONG Wu. Progress in research on synthesis and application of polyacrylamide[J]. China Petroleum and Chemical Standard and Quality, 2018, 38(15):189-190. doi: 10.3969/j.issn.1673-4076.2018.15.089 [2] 张跃军,于艳秋,曹英斌,等. PAM的生产、应用及市场分析[J]. 化工科技市场,2001,19(12):911.ZHANG Yuejun, YU Yanqiu, CAO Yingbin, et al. PAM production, application and market analysis[J]. Chemical Technology Market, 2001, 19(12):911. [3] 孟飞,付尽国,黄俊生,等. 二甲基二烯丙基氯化铵-丙烯酰胺共聚物的合成及其絮凝效果研究[J]. 广东化工,2013,40(16):36-37,46. doi: 10.3969/j.issn.1007-1865.2013.16.017MENG Fei, FU Jinguo, HUANG Junsheng, et al. Synthesis and flocculation effect of dimethyldiallylammonium chloride-acrylamide copolymer[J]. Guangdong Chemical Industry, 2013, 40(16):36-37,46. doi: 10.3969/j.issn.1007-1865.2013.16.017 [4] 陈秋. 改性聚丙烯酰胺类絮凝剂的合成及应用研究[D]. 吉林: 吉林大学, 2014.CHEN Qiu. Study on synthesis and application of modified polyacrylamide flocculant[D]. Jilin: Jilin University, 2014. [5] 付长清. 星型核-多臂聚合物的合成与性能研究[D]. 江西: 江西师范大学, 2005.FU Changqing. Study on the synthesis and properties of star-shaped core-multi-arm polymers[D]. Jiangxi: Jiangxi Normal University, 2005. [6] 聂慧君. 杂臂星型聚合物纳米粒子及不同亲水性的嵌段共聚物纳米粒子的合成和性质研究[D]. 天津: 南开大学, 2020.NIE Huijun. Synthesis and properties of hybrid star-shaped polymer nanoparticles and block copolymer nanoparticles with different hydrophilicities[D]. Tianjin: Nankai University, 2020. [7] 陈振斌,周永山,陈长军,等. 反相乳液合成阳离子聚丙烯酰胺絮凝剂及其表征[J]. 兰州理工大学学报,2019,45(4):16-21. doi: 10.3969/j.issn.1673-5196.2019.04.004CHEN Zhenbin,ZHOU Yongshan,CHEN Changjun,et al. Synthesis and characterization of cationic polyacrylamide flocculant by inverse emulsion[J]. Journal of Lanzhou University of Technology, 2019, 45(4):16-21. doi: 10.3969/j.issn.1673-5196.2019.04.004 [8] 任豹,闵凡飞,陈军,等. 疏水改性聚丙烯酰胺的合成方法研究进展[J]. 洁净煤技术,2018,24(6):1-7. doi: 10.13226/j.issn.1006-6772.18060201REN Bao, MIN Fanfei, CHEN Jun, et al. Research progress in the synthesis of hydrophobically modified polyacrylamide[J]. Clean Coal Technology, 2018, 24(6):1-7. doi: 10.13226/j.issn.1006-6772.18060201 [9] 王学川,张莎,周亮,等. 胶原蛋白改性阳离子絮凝剂对废弃钻井液的絮凝[J]. 钻井液与完井液,2012,29(2):73-75. doi: 10.3969/j.issn.1001-5620.2012.02.024WANG Xuechuan, ZHANG Sha, ZHOU Liang, et al. Collagen modified cationic flocculant flocculation of waste drilling fluid[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):73-75. doi: 10.3969/j.issn.1001-5620.2012.02.024 [10] 李可. 二氧化硅气凝胶及其复合材料的常压干燥制备与性能研究[D]. 安徽: 中国科学技术大学, 2018.LI Ke. Preparation and properties of silica aerogels and their composites under atmospheric pressure drying [D]. Anhui: China University of Science and Technology, 2018. [11] 褚奇,石秉忠,李涛,等. 水基钻井液用低增黏提切剂的合成与性能评价[J]. 钻井液与完井液,2019,36(6):689-693.CHU Qi, SHI Bingzhong, LI Tao, et al. Synthesis and evaluation of a low viscosity gelling agent for water base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):689-693. [12] 张飞飞. 二氧化硅纳米颗粒的功能化改性及应用研究[D]. 山东: 济南大学, 2015.ZHANG Feifei. Functional modification and application of silica nanoparticles [D]. Shandong : Jinan University, 2015. [13] 李根,李国宇,李培礼,等. 纳米SiO2的表面改性及SiO2/WEPN复合材料的制备与性能研究[J]. 现代化工,2021,41(9):173-177.LI Gen, LI Guoyu, LI Peili, et al. Surface modification of nano-SiO2 and preparation and properties of SiO2 / WEPN composites[J]. Modern Chemical Industry, 2021, 41(9):173-177. -

下载:

下载: