Performance Optimization of Slim-Hole Drilling Fluids Under Hole Cleaning Condition

-

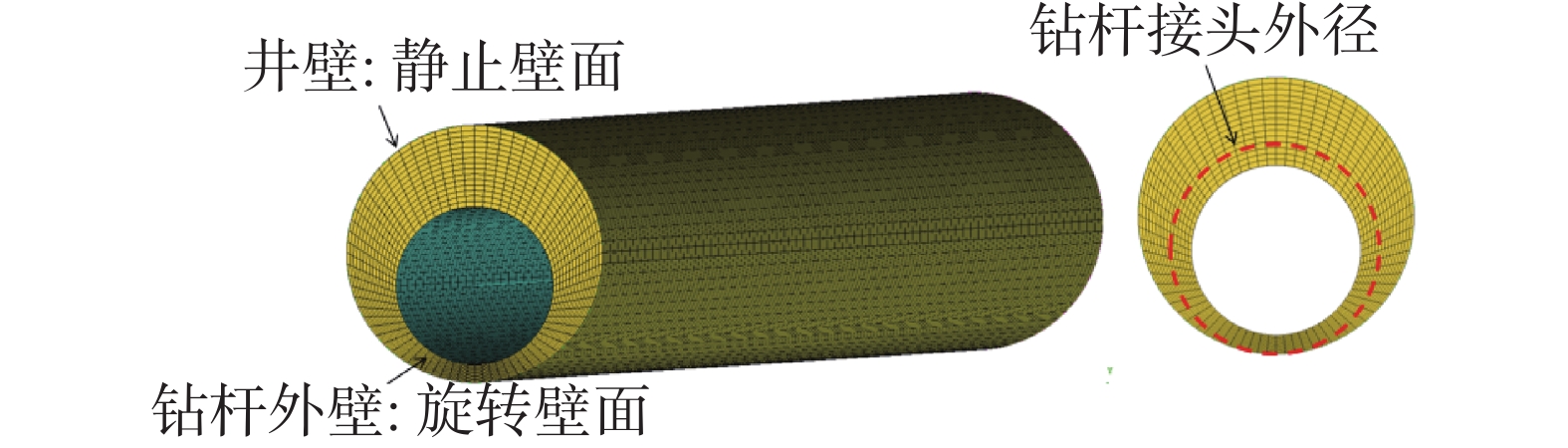

摘要: 新疆油田玛湖部分区块采用长水平段(超2000 m)小井眼技术进行钻井和开发。在钻井过程中,井眼不清洁导致的卡钻,井筒压力过大导致的漏失问题严重制约了该区块的高效经济开发。钻井液性能的优化是解决上述问题的关键方法之一。为此,采用了CFD数值模拟的方法,建立了环空固液两相流模型,探究了不同钻进参数下钻井液不同流变参数(赫巴流变模型)对岩屑运移和环空压耗的影响。根据数值模拟结果可知:①提升钻井液密度有利于提高携岩能力;②不同钻进参数下,钻井液流变参数对岩屑运移作用效果不同;③钻井液流变参数并非越大越有利于岩屑运移;④结合玛湖区块特征,确立了最优钻井液流变参数范围,并将该范围成功的应用于现场。Abstract: In Xinjiang Oilfield, part of the Mahu block is developed with long horizontal (exceeds 2000 m) slim holes. In drilling operation, pipe sticking resulted from poor hole cleaning and mud losses resulted from excessive wellbore pressure seriously restricted the efficient and economic development of the block. One of the key methods to solve these problems is the optimization of the drilling fluid properties. Using CFD numeric simulation method, a model describing the solid liquid two-phase flow in annular spaces was established, and the effects were investigated of different mud rheological parameters (Herschel-Bulkley rheological model) on the migration of the drilled cuttings and the annular pressure losses under different drilling parameters. Th numeric simulation results show that (1) an increase in drilling fluid density is beneficial to the carrying capacity of the drilling fluid; (2) the effects of the mud rheological parameters on the migration of drilled cuttings vary under different drilling parameters; (3) higher mud rheological parameters do not necessarily aid in cuttings migration; (4) an optimum mud rheology range was determined for the drilling operation in the Mahu block based on its characteristics, and the optimum mud rheology range has been successfully used in field operations.

-

表 1 两相流数值模拟模型选择

模型种类 模型选择 多相流模型 欧拉-欧拉模型(瞬态) 湍流模型 SST k-ω 湍流模型 剪切应力模型 固体剪切黏度 Gidaspow模型 动力黏度 Gidaspow模型 摩擦黏度 Schaeffer模型 曳力模型 Hulin-Gidaspow模型 升力模型 Saffman-Mei模型 钻井液流变模型 赫-巴流变模型 表 2 两相流数值模拟参数设定

模拟 环空返速/

m·s−1钻杆转速/

r·min−1机械钻速/

m·h−1ρ岩屑/

g·cm−3井斜

角/(°)1# 1.2 80 8.8 2.65 90 2# 1.2 40 3# 1.5 40 注:1#为现场参数,现场钻井液k=0.5505 Pa·sn,n=0.6411,τHB=2.55 Pa,密度为1.43 g/cm3 表 3 网格无关性测试结果

网格

数量稳态环空岩屑

剩余质量/kg相对误

差/%稳态环空压

耗梯度/(Pa·m−1)相对误

差/%4.8×105 1.522 1705.1 6.4×105 1.501 1.40 1686.2 1.10 8.0×105 1.494 0.47 1680.5 0.34 表 4 玛湖现场钻井液流变参数

井号 φ3 φ6 φ100 φ200 φ300 φ600 k/Pa·sn n τHB/Pa 现场情况 MaHW6XX0 5 6 32 49 64 100 0.3959 0.6914 2.550 井眼清洁 MHHW20XX1 3 5 29 42 56 90 0.6966 0.5741 1.530 井眼清洁 MHHW20XX9 6 8 37 57 76 123 0.4243 0.7048 3.060 压耗大,井漏 MHHW10XX4 1 2 16 28 39 66 0.1067 0.8322 0.511 井眼不清洁 -

[1] 路宗羽,赵飞,雷鸣,等. 新疆玛湖油田砂砾岩致密油水平井钻井关键技术[J]. 石油钻探技术,2019,47(2):9-14. doi: 10.11911/syztjs.2019029LU Zongyu, ZHAO Fei, LEI Ming, et al. Key technologies for drilling horizontal wells in glutenite tight oil reservoirs in the Mahu oilfield of Xinjiang[J]. Petroleum Drilling Techniques, 2019, 47(2):9-14. doi: 10.11911/syztjs.2019029 [2] 刘希圣,郑新权,丁岗. 大斜度井中岩屑床厚度模式的研究[J]. 石油大学学报(自然科学版),1991,15(2):28-35.LIU Xisheng, ZHENG Xinquan, DING Gang. Study on cuttings bed thickness pattern in highly deviated wells[J]. Journal of China University of Petroleum (Edition of Natural Science) , 1991, 15(2):28-35. [3] 汪海阁,刘希圣,丁岗. 水平井段岩屑床厚度模式的建立[J]. 石油大学学报(自然科学版),1993,17(3):25-31.WANG Haige, LIU Xisheng, DING Gang. The model of cuttings bed thickness in horizontal well section[J]. Journal of China University of Petroleum(Edition of Natural Science) , 1993, 17(3):25-31. [4] LARSEN T I, PILEHVARI A A, AZAR J J. Development of a new cuttings-transport model for high-angle wellbores including horizontal wells[J]. SPE Drilling & Completion, 1997, 12(2):129-135. [5] 相恒富,孙宝江,李昊,等. 大位移水平井段岩屑运移实验研究[J]. 石油钻采工艺,2014,36(3):1-6. doi: 10.13639/j.odpt.2014.03.001XIANG Hengfu, SUN Baojiang, LI Hao, et al. Experimental research on cuttings transport in extended-reach horizontal well[J]. Oil Drilling & Production Technology, 2014, 36(3):1-6. doi: 10.13639/j.odpt.2014.03.001 [6] 刘成文,李兆敏. 钻井过程中岩屑运移模型研究进展[J]. 钻井液与完井液,2019,36(6):663-671.LIU Chengwen, LI Zhaomin. Advances of Cuttings Transport Models During Oil Drilling[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):663-671. [7] 孙晓峰,闫铁,崔世铭,等. 钻杆旋转影响大斜度井段岩屑分布的数值模拟[J]. 断块油气田,2014,21(1):92-96. doi: 10.6056/dkyqt201401022SUN Xiaofeng, YAN Tie, CUI Shiming, et al. Numerical simulation of dillpipe rotation influence on cuttings distribution in highly inclined sections[J]. Fault-Block Oil & Gas Field, 2014, 21(1):92-96. doi: 10.6056/dkyqt201401022 [8] MANJULA E, ARIYARATNE W K H, RATNAYAKE C, et al. A review of CFD modelling studies on pneumatic conveying and challenges in modelling offshore drill cuttings transport[J]. Powder Technology, 2017, 305:782-793. doi: 10.1016/j.powtec.2016.10.026 [9] SORGUN M, MURAT OZBAYOGLU A, EVREN OZBAYOGLU M. Support vector regression and computational fluid dynamics modeling of Newtonian and Non-Newtonian fluids in annulus with pipe rotation[J]. Journal of Energy Resources Technology, 2015, 137(3):32901-32909. doi: 10.1115/1.4028694 [10] 邵兵, 闫怡飞, 毕朝峰, 等. 基于CFD-DEM 耦合模型的大粒径非常规岩屑颗粒运移规律研究[J]. 科学技术与工程, 2017, 17(27): 190-195.SHAO Bing, YAN Yifei, BI Chaofeng, et al. Migration of lrregular cuttings particles in big size by CFD-DEM coupled simulation model[J]. 2017, 17(27) : 190-195. [11] 王涛. 小井眼钻井水力参数优化设计模型的建立及软件开发[D]. 西安: 西安石油大学, 2015.WANG Tao. Establishment and software development of hydraulic parameter optimization design model for thin hole drilling [D]. Xi 'an: Xi 'an Shiyou University, 2015. [12] 袁兰峰. 考虑钻柱旋转和屈曲的超深井小井眼环空压力研究[D]. 成都: 西南石油大学, 2015.YUAN Lanfeng. Study on annulus pressure of ultra-deep slim hole considering rotation and buckling of drill string[D]. Chengdu: Southwest Petroleum University, 2015. [13] HAN S M, HWANG Y K, WOO N S, et al. Solid–liquid hydrodynamics in a slim hole drilling annulus[J]. Journal of Petroleum Science and Engineering, 2010, 70(3–4):308-319. doi: 10.1016/j.petrol.2009.12.002 [14] 张辉,樊洪海,逄淑君. 钻井液流变参数计算方法及现场应用软件开发[J]. 西部探矿工程,2008(2):72-74. doi: 10.3969/j.issn.1004-5716.2008.02.030ZHANG Hui, FAN Honghai, FENG Shujun. Calculation method of rheological parameters of drilling fluid and development of field application software[J]. West-China Exploration Engineering, 2008(2):72-74. doi: 10.3969/j.issn.1004-5716.2008.02.030 -

下载:

下载: