Study on Property Control of High Density Drilling Fluids Based on Modified Alferd Model

-

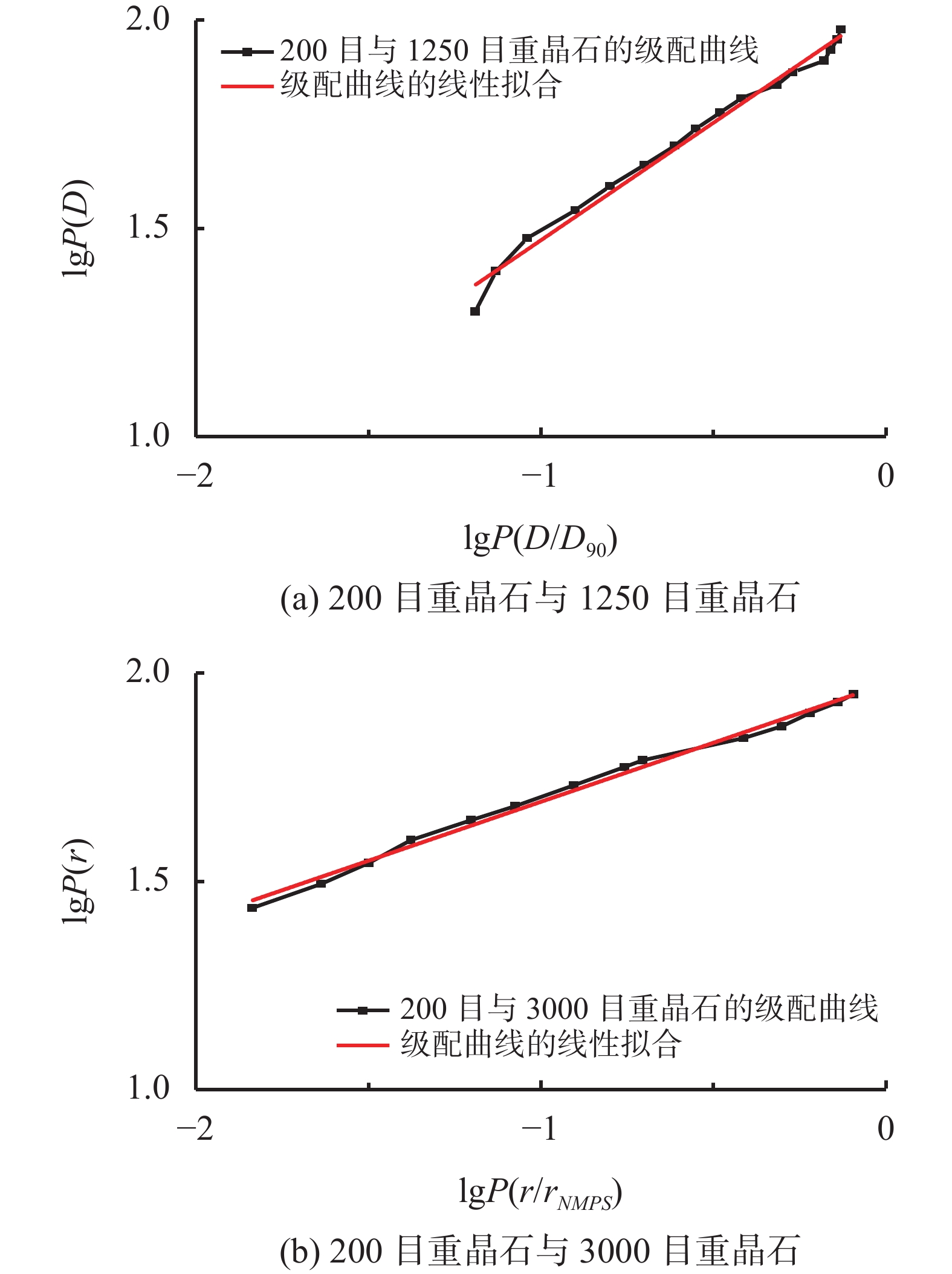

摘要: 针对深井高温高密度钻井液性能难以调控的问题,探讨了重晶石级配对高密度钻井液流变性和滤失性能的影响规律及作用机理。基于分形理论,对粉体堆积常用的Alfred方程进行修正,建立了适用于重晶石级配加重的粒度分布模型,计算了重晶石级配的理论最优配比,并通过实验验证了修正模型的可行性。实验表明,修正后的Alferd模型可以指导高密度钻井液的颗粒级配设计,确定加重材料最优级配比例。使用合理级配的重晶石加重,可以降低钻井液内部颗粒间的碰撞概率及储能模量,削弱体系的网架结构和流动阻力,并使重晶石的粒度分布更加合理,有利于形成致密泥饼,从而改善钻井液的流变性能和滤失性能。Abstract: The effect of barite particle sizing on the rheology and filtration property of a high density drilling fluid and the mechanisms of this effect are investigated to try to solve the difficulties encountered in controlling the performance of a high density drilling fluid used in drilling a deep high temperature well. Based on the fractal theory, the Alfred equation, which is generally used in powder packing calculation, was modified to establish a particle size distribution model suitable for weighting a drilling fluid with sized barite particles, the theoretical optimal quantity ratio of the sized barite particles was calculated, and the feasibility of the modified model was verified by experiment. Laboratory experiment shows that the modified Alferd model can be used to guide the design of the sizing of particles used to weight a drilling fluid and to determine the optimum quantity ratio of particles with different sizes. Weighting a drilling fluid with reasonably sized barite particles can reduce the probability of collision between particles in the drilling fluid and the storage modulus, weaken the network structure and the flow resistance of the system, and make the particle size distribution of barite more appropriate; it is beneficial to the formation of dense mud cakes, and to the improvement of drilling fluid rheology and filtration property.

-

Key words:

- Drilling fluid /

- Barite /

- Alferd model /

- Particle size distribution /

- Rheological property /

- Filtration property

-

表 1 不同粒径重晶石的粒度分布

粒径/目 D10/μm D50/μm D90/μm 200 1.881 11.530 39.500 1250 1.662 3.879 18.420 3000 0.365 1.593 4.413 表 2 200目与1250目重晶石级配 加重对实验浆流变性的影响

200目重晶石/

%老化条件

(180 ℃/16 h)AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/Pa100 老化前 80.0 62 18.0 3.5/8.5 老化后 70.0 64 6.0 2.5/6.0 80 老化前 77.0 61 16.0 5.0/8.5 老化后 87.0 60 7.0 2.7/6.5 70 老化前 74.5 66 8.5 4.0/8.0 老化后 65.0 59 6.0 2.7/6.0 50 老化前 68.5 58 10.5 4.0/10.0 老化后 58.0 52 6.0 2.7/5.0 30 老化前 72.0 60 12.0 4.0/8.0 老化后 59.5 53 6.5 2.5/5.0 20 老化前 76.0 62 14.0 6.0/8.5 老化后 56.5 52 4.5 2.5/4.5 0 老化前 84.0 68 16.0 8.0/12.5 老化后 63.5 60 3.5 4.5/8.0 注:流变性能测试温度为49 ℃;中压和高温高压滤失量测试条件分别为室温、0.7 MPa和150 ℃、3.5 MPa 表 3 200目与3000目重晶石级配 加重对实验浆流变性的影响

200目重晶石/

%老化条件

(180℃/16h)AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/Pa100 老化前 80.0 62 18.0 3.5/8.5 老化后 70.0 64 6.0 2.5/6.0 80 老化前 64.0 52 12.0 4.0/8.0 老化后 50.0 44 6.0 2.5/4.5 70 老化前 60.0 49 11.0 4.0/8.0 老化后 49.0 42 7.0 5.5/9.5 50 老化前 61.5 49 12.5 3.5/7.0 老化后 49.5 40 9.5 3.5/7.0 30 老化前 76.0 62 14.0 6.0/8.5 老化后 65.5 52 12.0 2.5/4.5 20 老化前 93.0 63 30.0 16.0/25.5 老化后 65.5 48 17.5 11.5/23.5 注:当3000目加量为100%时,黏度过高无法测量;流变性能测试温度为49 ℃;中压和高温高压滤失量测试条件分别为室温、0.7 MPa和150 ℃、3.5 MPa -

[1] 邱正松,赵冲,张现斌,等. 超高温高密度油基钻井液研究与性能评价[J]. 钻井液与完井液,2021,38(6):663-670.QIU Zhengsong, ZHAO Chong, ZHANG Xianbin, et al. Research and performance evaluation of ultra-high temperature and high density oil-based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):663-670. [2] STAMATAKIS E, YOUNG S, STEFANO G D. Meeting the ultra HTHP fluids challenge [C]. Society of Petroleum Engineers, 2012. [3] 李雄,董晓强,金军斌,等. 超高温高密度钻井液体系的研究与应用[J]. 钻井液与完井液,2020,37(6):694-700. doi: 10.3969/j.issn.1001-5620.2020.06.003LI Xiong, DONG Xiaoqiang, JIN Junbin, et al. Research and application of ultra-high temperature and high density drilling fluid system[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):694-700. doi: 10.3969/j.issn.1001-5620.2020.06.003 [4] 蔡勇,郭保雨,何兴华,等. 新型高密度钻井液加重剂的性能评价及应用[J]. 钻采工艺,2020,43(1):106-109. doi: 10.3969/J.ISSN.1006-768X.2020.01.30CAI Yong, GUO Baoyu, HE Xinghua, et al. Performance evaluation and application of new high density drilling fluid weighting agent[J]. Drilling and Production Technology, 2020, 43(1):106-109. doi: 10.3969/J.ISSN.1006-768X.2020.01.30 [5] 李炎军,马二龙,张万栋,等. 莺琼盆地高温高密度水基钻井液流变性调控方法[J]. 科学技术与工程,2020,20(26):10740-10744. doi: 10.3969/j.issn.1671-1815.2020.26.027LI Yanjun, MA Erlong, ZHANG Wandong, et al. Rheological control method of high temperature and high density water-based drilling fluid in Yingqiong basin[J]. Science Technology and Engineering, 2020, 20(26):10740-10744. doi: 10.3969/j.issn.1671-1815.2020.26.027 [6] 夏孝杰. 塔中北坡地区抗高温超高密度钻井液优化实验研究[D]. 中国石油大学(华东) , 2019.XIA Xiaojie. Experimental study on optimization of high temperature resistant ultra-high density drilling fluid in the northern slope of Tazhong[D]. China University of Petroleum (East China), 2019 [7] 潘谊党,于培志,马京缘. 高密度钻井液加重材料沉降问题研究进展[J]. 钻井液与完井液,2019,36(1):1-9. doi: 10.3969/j.issn.1001-5620.2019.01.001PAN yidang, YU Peizhi, MA Jingyuan. Research progress on heavy material settlement of high density drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):1-9. doi: 10.3969/j.issn.1001-5620.2019.01.001 [8] AHMAD H M, KAMAL M S, AL-HARTHI M A. High molecular weight copolymers as rheology modifier and fluid loss additive for water-based drilling fluids[J]. Journal of Molecular Liquids, 2018, 252:133-143. doi: 10.1016/j.molliq.2017.12.135 [9] KONAKAWA Y, ISHIZAKI K. The particle size distribution for the highest relative density in a compacted body[J]. Powder Technology, 1990, 63(3):241-246. doi: 10.1016/0032-5910(90)80049-5 [10] BARRY M M, JUNG Y, LEE J K, et al. Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids[J]. Journal of Petroleum Science & Engineering, 2015, 127:338-346. [11] AL-YASIRI M , AWAD A , PERVAIZ S , et al. Influence of silica nanoparticles on the functionality of water-based drilling fluids[J]. Journal of Petroleum Science and Engineering, 2019. [12] 黄维安,邱正松,徐加放,等. 重晶石粒度级配对加重钻井液流变性的影响[J]. 钻井液与完井液,2010,27(4):23-25.HUANG Wei'an, QIU Zhengsong, XU Jiafang, et al. The effect of barite particle size distribution on the fluidity of heavy drilling fluid[J]. Drilling Fluid & Completion Fluid, 2010, 27(4):23-25. [13] 苗海龙,邱正松,李自立,等. 重晶石粉颗粒级配对高密度钻井液性能影响的实验探讨[J]. 当代化工,2021,50(5):1090-1095.MIAO Hailong, QIU Zhengsong, LI Zili, et al. Experimental discussion on the influence of barite powder particle size distribution on the performance of high density drilling fluid[J]. Contemporary Chemical Industry, 2021, 50(5):1090-1095. [14] FURNAS C C. The relations between specific volume, voids, and size composition in systems of broken solids of mixed sized, department of commerce, bureau of mines[J]. Reports of investigations, 1928:1-10. [15] WESTMAN A, HUGILL H R. The packing of particlesl[J]. Journal of the American Ceramic Society, 2010, 13(10):767-779. [16] SUZUKI M, OSHIMA T. Co-ordination number of a multi-component randomly packed bed of spheres with size distribution[J]. Powder Technology, 1985, 44(3):213-218. doi: 10.1016/0032-5910(85)85002-6 [17] DINGER D R, FUNK J E. Particle-packing phenomena and their application in materials processing[J]. MRS Bulletin, 2013, 22(12):19-23. -

下载:

下载: