Development and Evaluation of a Self-Crosslinking Filter Loss Reducer for Oil Based Drilling Fluids

-

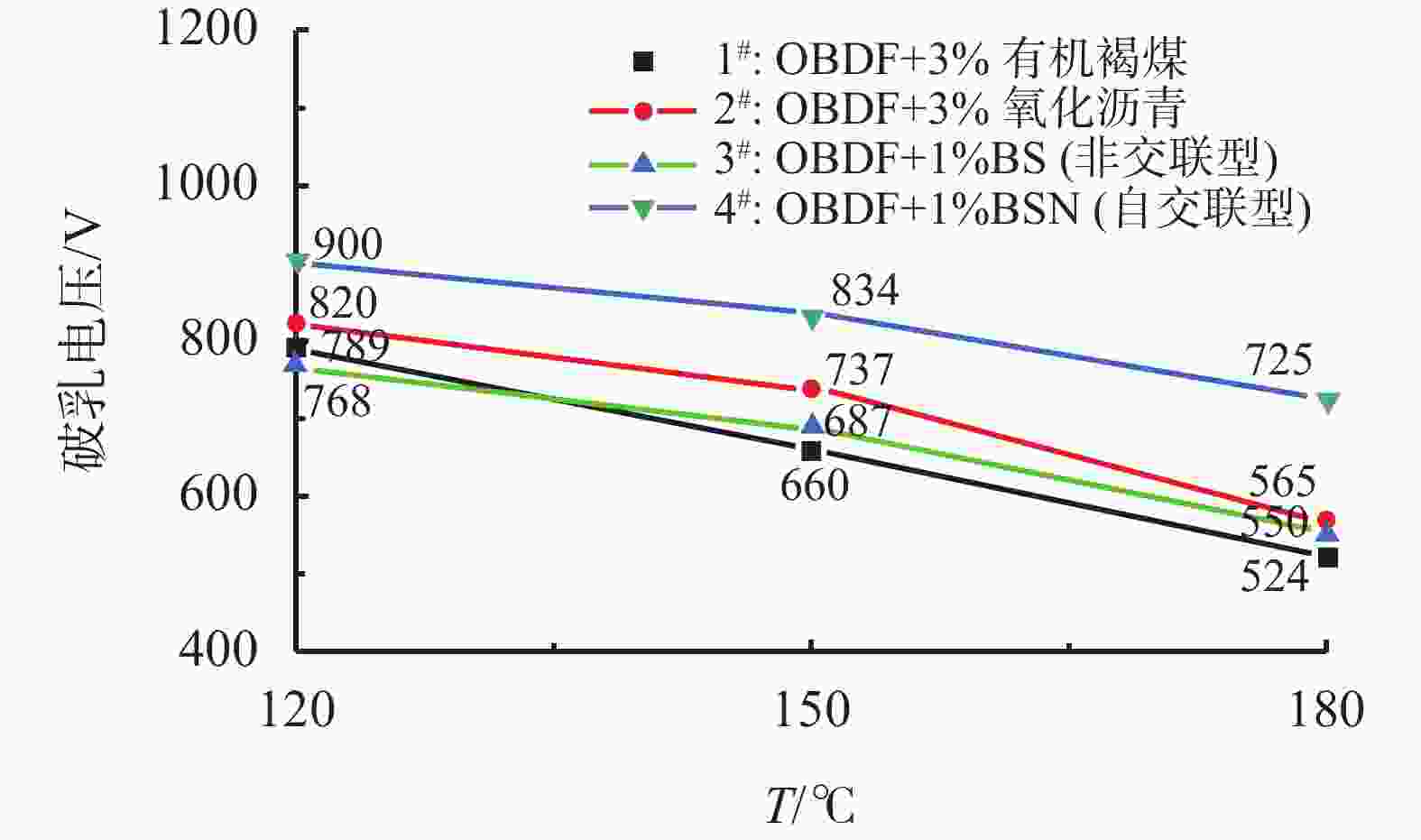

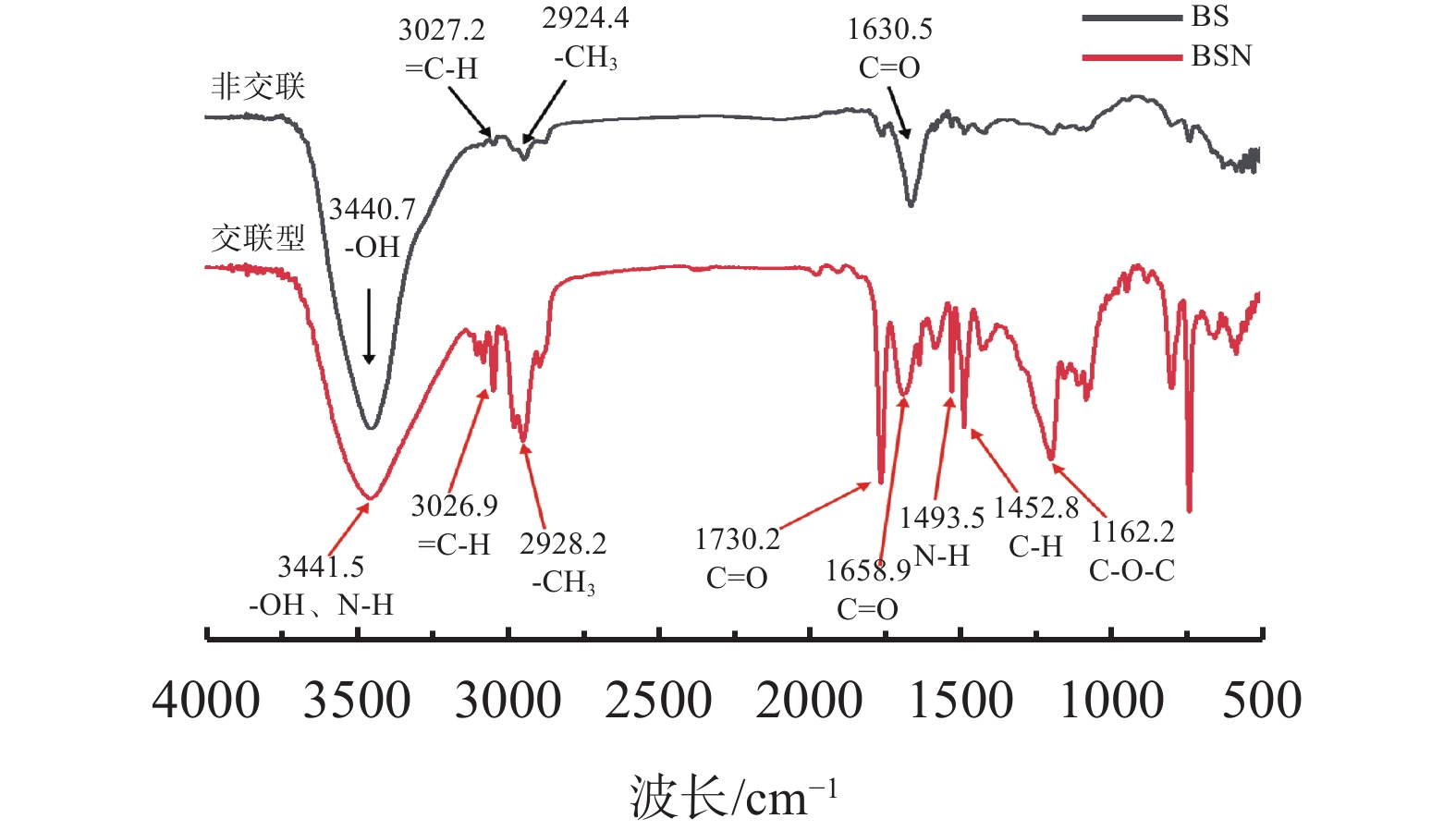

摘要: 针对传统油基钻井液降滤失剂耐温性能不足、影响体系流变等问题,基于自交联改性思路,以N-羟甲基丙烯酰胺为功能单体,与丙烯酸丁酯和苯乙烯进行乳液聚合,研制了一种自交联型油基钻井液降滤失剂(BSN)。通过红外光谱仪、激光粒度仪和透射电镜表征了BSN的主要官能团、微观形貌和自交联特征。实验结果表明,BSN含有自交联功能基团羟甲基,平均粒径为247 nm,颗粒间具有明显的交联结构。热重测试结果显示,BSN热稳定性良好,初始分解温度高达355 ℃,显著高于非自交联型的降滤失剂BS(278 ℃)。在油基钻井液体系中添加1%的BSN,不仅不影响体系流变参数而且能够提高破乳电压,180 ℃下的高温高压滤失量仅为4 mL,滤失控制能力明显优于非交联型的降滤失剂BS以及3%的传统油基钻井液降滤失剂有机褐煤和氧化沥青。Abstract: Conventional filter loss reducers for oil based drilling fluids have deficiencies such as low thermal stability and negative influence on mud rheology. To solve these problems, a new self-crosslinking filter loss reducer, BSN, for oil based drilling fluids was developed through emulsion polymerization with N-methylol acrylamide (a functional monomer), butyl acrylate and styrene. The main functional groups, micromorphology and self-crosslinking characteristics of BSN were characterized by infrared spectroscopy, laser particle size analyzer and transmission electron microscopy. It was found that BSN has self-crosslinking functional group of hydroxymethyl. The average particle size of BSN is 247 nm, and obvious particle-particle crosslinking structure can be seen. Thermalgravimetric test results have shown that BSN has good thermal stability, the initial decomposition temperature of which is 355 ℃, greatly higher than its non-self-crosslinking counterpart BS, which is 278 ℃. Addition of 1% BSN in an oil based drilling fluid not only had little effect on the rheology of the drilling fluid, but also improved the electrical stability of the drilling fluid. This oil based drilling fluid had HTHP filtration rate of only 4 mL, indicating that BSN was superior to BS and 3% other conventional filter loss reducers in controlling the filtration rate of oil based drilling fluids.

-

表 1 添加不同降滤失剂的油基钻井液体系基本性能对比

评价配方 T老化/

℃AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/Pa1#:OBDF+3%有机褐煤 常温 39.0 29.0 10.0 4.50/4.50 120 40.0 31.0 9.0 4.00/4.50 150 36.5 30.0 6.5 3.00/3.25 180 26.0 24.5 1.5 0/0.50 2#:OBDF+3%氧化沥青 常温 43.0 32.0 11.0 4.50/5.00 120 42.0 32.0 10.0 4.00/4.50 150 41.0 34.0 7.0 3.00/3.50 180 31.0 29.0 2.0 0.50/1.00 3#:OBDF+1%BS 常温 39.5 28.0 11.5 5.00/5.50 120 44.0 33.0 11.0 5.00/5.00 150 37.0 29.0 8.0 3.25/3.75 180 31.5 29.0 2.5 1.50/2.50 4#:OBDF+1%BSN 常温 41.0 29.0 12.0 5.50/7.00 120 45.5 33.5 12.0 5.00/6.00 150 42.0 31.5 10.5 5.00/5.50 180 34.5 28.0 6.5 4.00/5.00 注: 热滚时间为16 h、温度分别为120 、150 、180 ℃;流变测试温度为50 ℃ -

[1] 孙金声,黄贤斌,吕开河,等. 提高水基钻井液高温稳定性的方法、技术现状与研究进展[J]. 中国石油大学学报(自然科学版),2019,43(5):73-81.SUN Jinsheng, HUANG Xianbin, LYU Kaihe, et al. Methods, technology status and research progress of improving high temperature stability of water-based drilling fluids[J]. Journal of China University of Petroleum (Natural Science Edition) , 2019, 43(5):73-81. [2] JIANG G ,SUN J ,HE Y , et al. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs, Engineering (2021). [3] 王中华. 国内外超高温高密度钻井液技术现状与发展趋势[J]. 石油钻探技术,2011,39(2):1-7. doi: 10.3969/j.issn.1001-0890.2011.02.001WANG Zhonghua. Present situation and development trend of ultra-high temperature and high-density drilling fluid technology at home and abroad[J]. Petroleum Drilling Technology, 2011, 39(2):1-7. doi: 10.3969/j.issn.1001-0890.2011.02.001 [4] 周研,蒲晓林. 油基钻井液用降滤失剂研究现状[J]. 化学世界,2020,61(1):7-15.ZHOU Yan, PU Xiaolin. Research status of fluid loss control agents for oil-based drilling fluids[J]. Chemistry World, 2020, 61(1):7-15. [5] 黄津松,张家旗,王建华,等. 国内油基钻井液研发现状与思考[J]. 化工管理,2020(33):130-133. doi: 10.3969/j.issn.1008-4800.2020.33.064HUANG Jinsong, ZHANG Jiaqi, WANG Jianhua, et al. Current situation and thinking of domestic oil-based drilling fluid research and development[J]. Chemical Management, 2020(33):130-133. doi: 10.3969/j.issn.1008-4800.2020.33.064 [6] 孙金声,赵震,白英睿,等. 智能自愈合凝胶研究进展及在钻井液领域的应用前景[J]. 石油学报,2020,41(12):1706-1718. doi: 10.7623/syxb202012023SUN Jinsheng, ZHAO Zhen, BAI Yingrui, et al. Research progress of intelligent self-healing gel and its application prospect in drilling fluid field[J]. Chinese Journal of Petroleum, 2020, 41(12):1706-1718. doi: 10.7623/syxb202012023 [7] PANAMARATHUPALAYAM B. Crosslinked synthetic polymer-based reservoir drilling fluid: US20170198189 AI [P]. 2017-12-18. [8] 苟绍华,封明明,叶仲斌,等. 丙烯酰胺-双丙酮丙烯酰胺自交联聚合物凝胶的研究[J]. 油田化学,2013,30(3):366-370,375.GOU Shaohua, FENG Mingming, YE Zhongbin, et al. Study on self-crosslinked polymer gel of acrylamide-diacetone acrylamide[J]. Oilfield Chemistry, 2013, 30(3):366-370,375. [9] 吴鹏伟,杜文浩,邹琴,等. 丙烯酰胺基交联聚合物微球的制备及其对钻井液性能的影响[J]. 油田化学,2018,35(4):592-596,602.WU Pengwei, DU Wenhao, ZOU Qin, et al. Preparation of acrylamide-based cross-linked polymer microspheres and their effects on drilling fluid properties[J]. Oilfield Chemistry, 2018, 35(4):592-596,602. [10] 戎克生,杨彦东,徐生江,等. 抗高温微交联聚合物降滤失剂的制备与性能评价[J]. 油田化学,2018,35(4):582-586,591.RONG Kesheng, YANG Yandong, XU Shengjiang, et al. Preparation and performance evaluation of high temperature resistant micro-crosslinked polymer fluid loss reducer[J]. Oilfield Chemistry, 2018, 35(4):582-586,591. [11] 冯萍, 邱正松, 曹杰. 交联型油基钻井液降滤失剂的合成及性能评价[J]. 钻井液与完井液, 2012, 29(1): 9-11, 14.FENG Ping, QIU Zhengsong, CAO Jie. Synthesis and performance evaluation of cross-linked oil-based drilling fluid fluid loss control agent [J]. Drilling Fluid & Completion Fluid, 2012, 29(1): 9-11 , 14 . [12] 黄贤斌,蒋官澄,邓正强. 水性丙烯酸树脂在油包水钻井液中的作用[J]. 钻井液与完井液,2017,34(2):26-32. doi: 10.3969/j.issn.1001-5620.2017.02.005HUANG Xianbin, JIANG Guancheng, DENG Zhengqiang. The role of water-based acrylic resin in water-in-oil drilling fluids[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):26-32. doi: 10.3969/j.issn.1001-5620.2017.02.005 [13] 王国帅,蒋官澄,贺垠博,等. pH刺激响应型抗高温可逆转乳化剂研制与评价[J]. 钻井液与完井液,2021,38(5):552-559.WANG Guoshuai, JIANG Guancheng, HE Yinbo, et al. Development and evaluation of pH-stimulated responsive high temperature reversible emulsifier[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):552-559. [14] S KRISHNAN, A KLEIN, M S EL-AASSER, et al. Influence of chain transfer agent on the cross-linking of poly (n-butyl methacrylate-co-N-methylol acrylamide) latex particles and films[J]. Macromolecules, 36 (2003) : 3511–3518. [15] 蒋官澄,毛蕴才,周宝义,等. 暂堵型保护油气层钻井液技术研究进展与发展趋势[J]. 钻井液与完井液,2018,35(2):1-16. doi: 10.3969/j.issn.1001-5620.2018.02.001JIANG Guancheng, MAO Yuncai, ZHOU Baoyi, et al. Research progress and development trend of drilling fluid technology for temporary plugging protection of oil and gas layers[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):1-16. doi: 10.3969/j.issn.1001-5620.2018.02.001 [16] 张金波,鄢捷年. 钻井液中暂堵剂颗粒尺寸分布优选的新理论和新方法[J]. 石油学报,2004(6):88-91,95. doi: 10.3321/j.issn:0253-2697.2004.06.018ZHANG Jinbo, YAN Jienian. New theory and new method for optimization of particle size distribution of temporary plugging agent in drilling fluid[J]. Acta PetroChina, 2004(6):88-91,95. doi: 10.3321/j.issn:0253-2697.2004.06.018 -

下载:

下载: