Method of Predicting Flow Conductivity of Long-Term Acid-Etched Fractures in Carbonate Reservoirs in Shunbei Oilfield

-

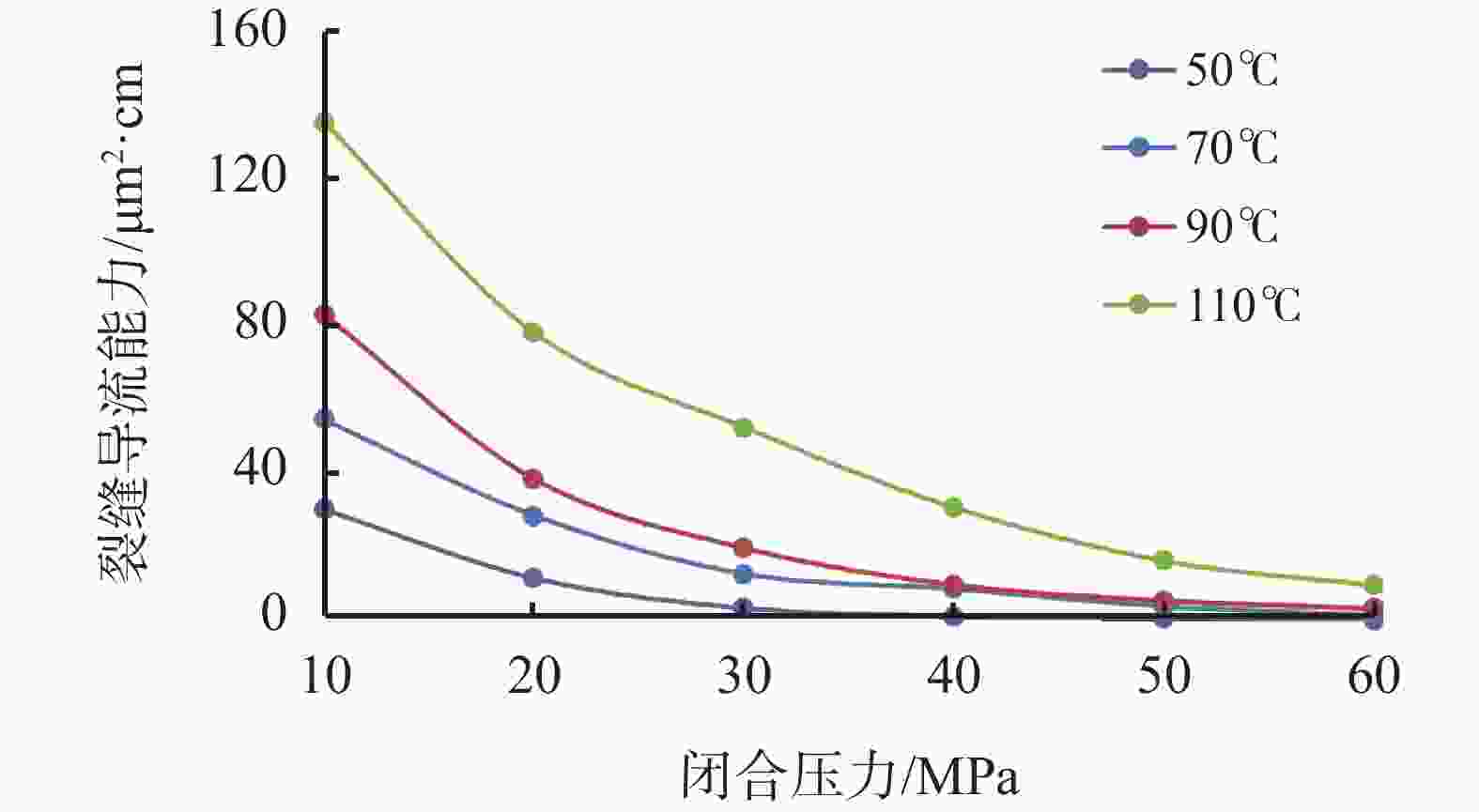

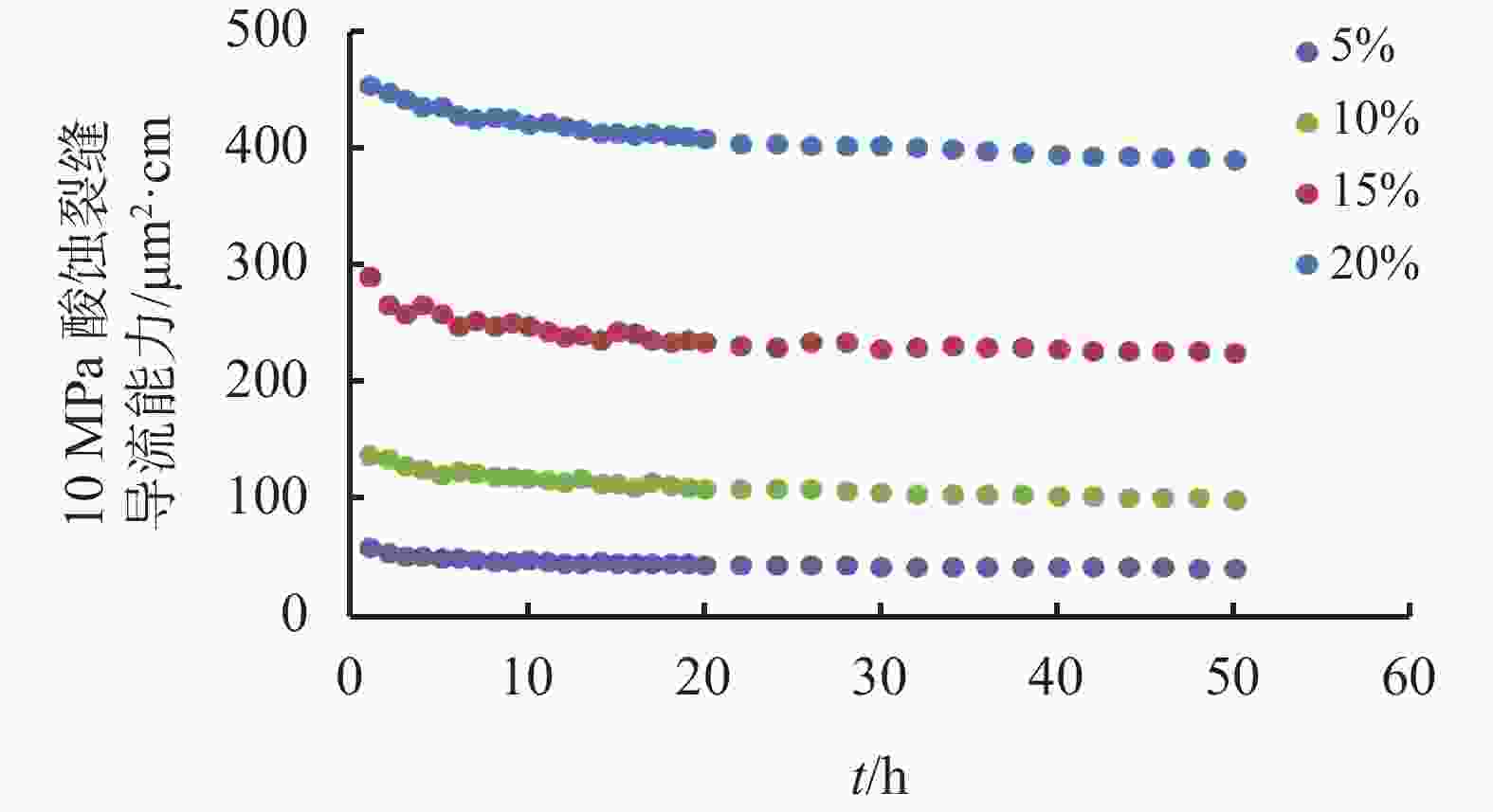

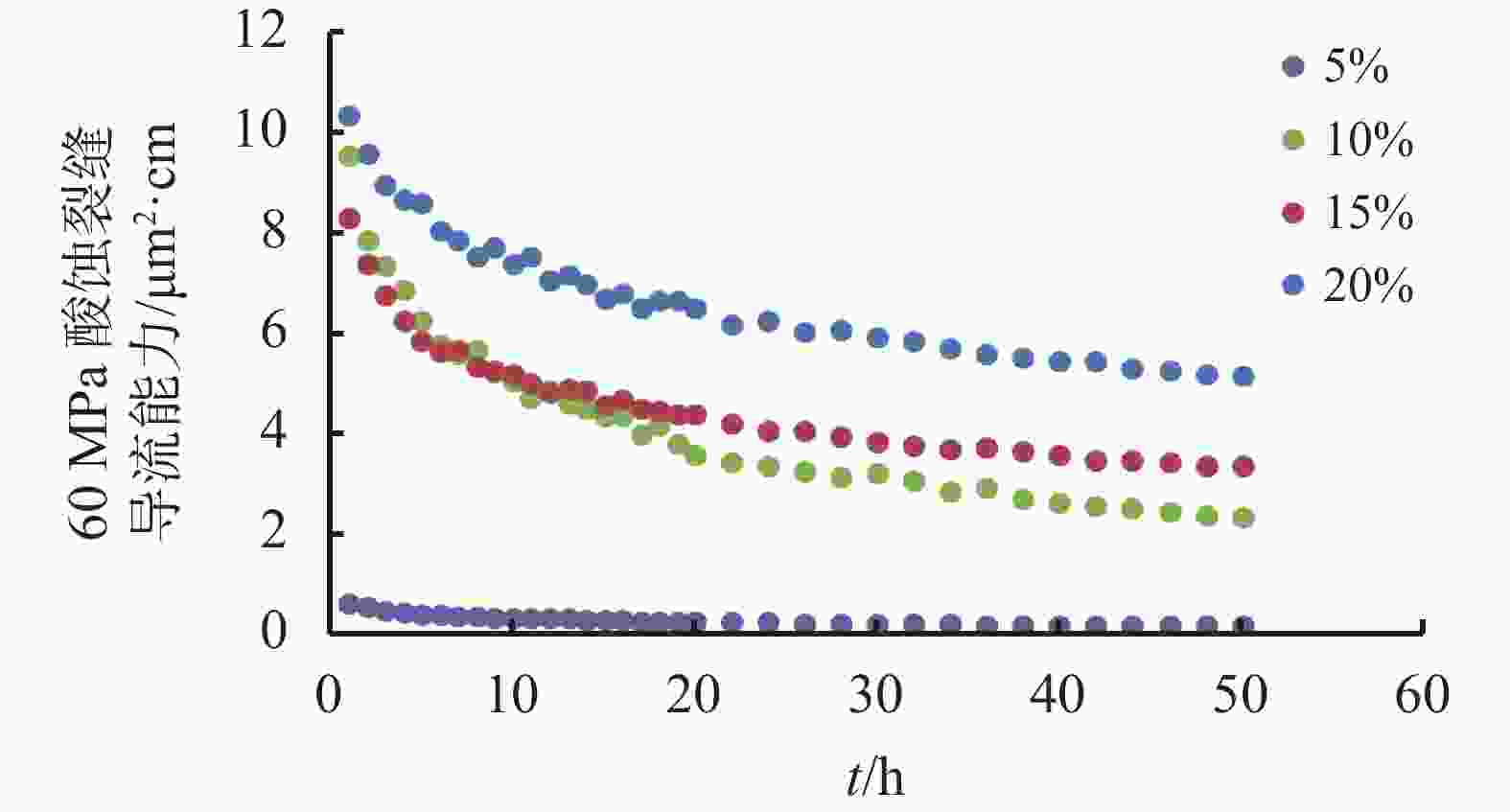

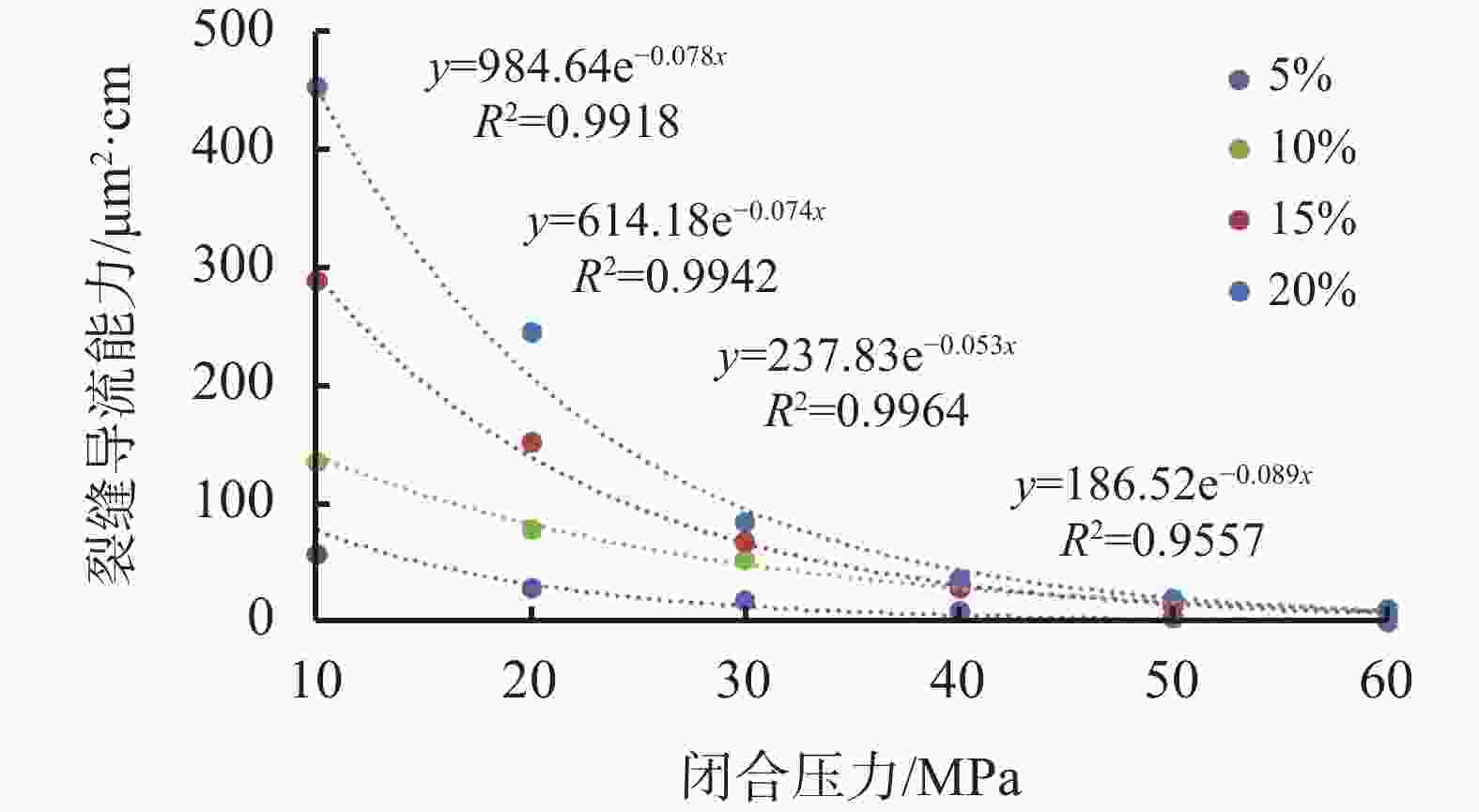

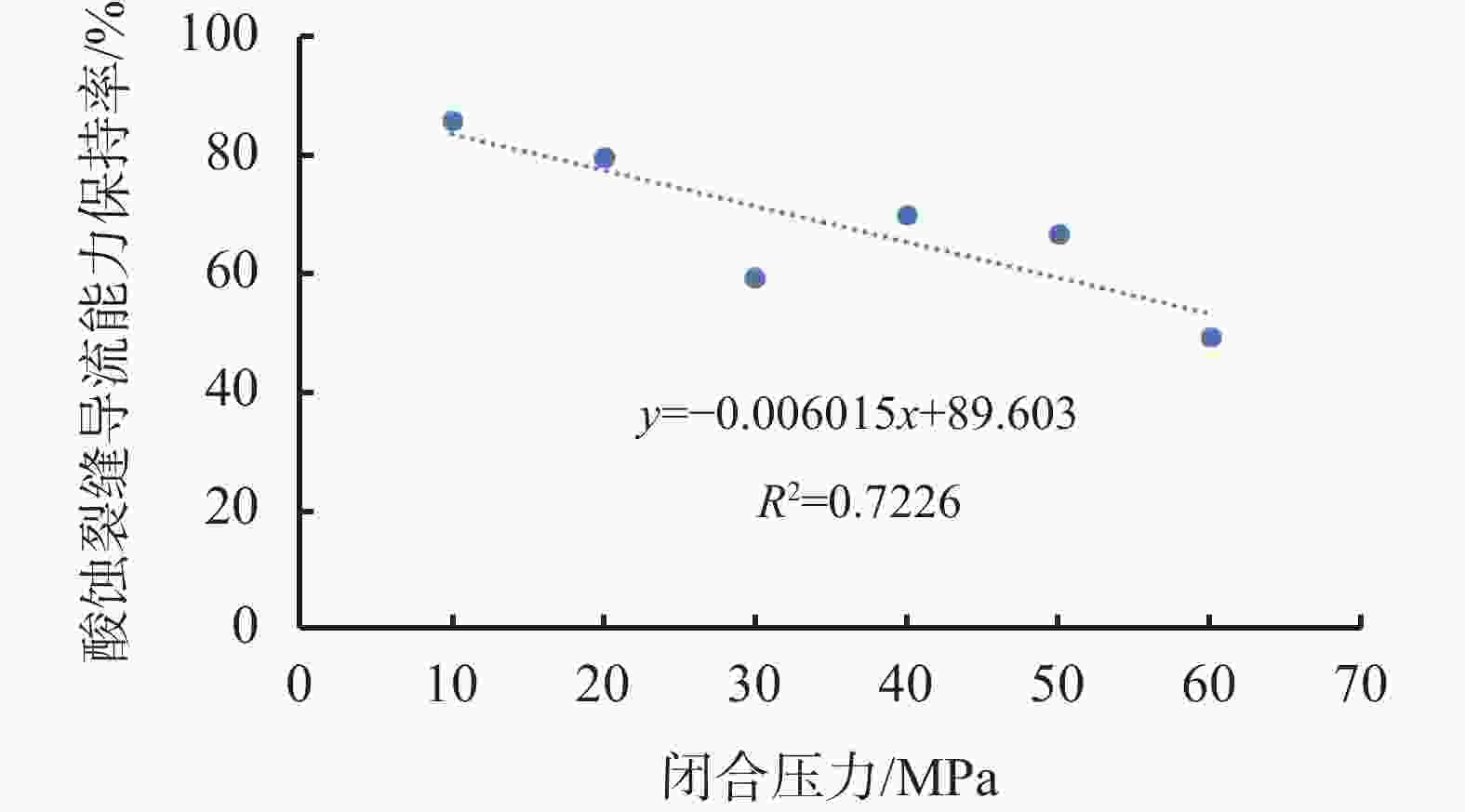

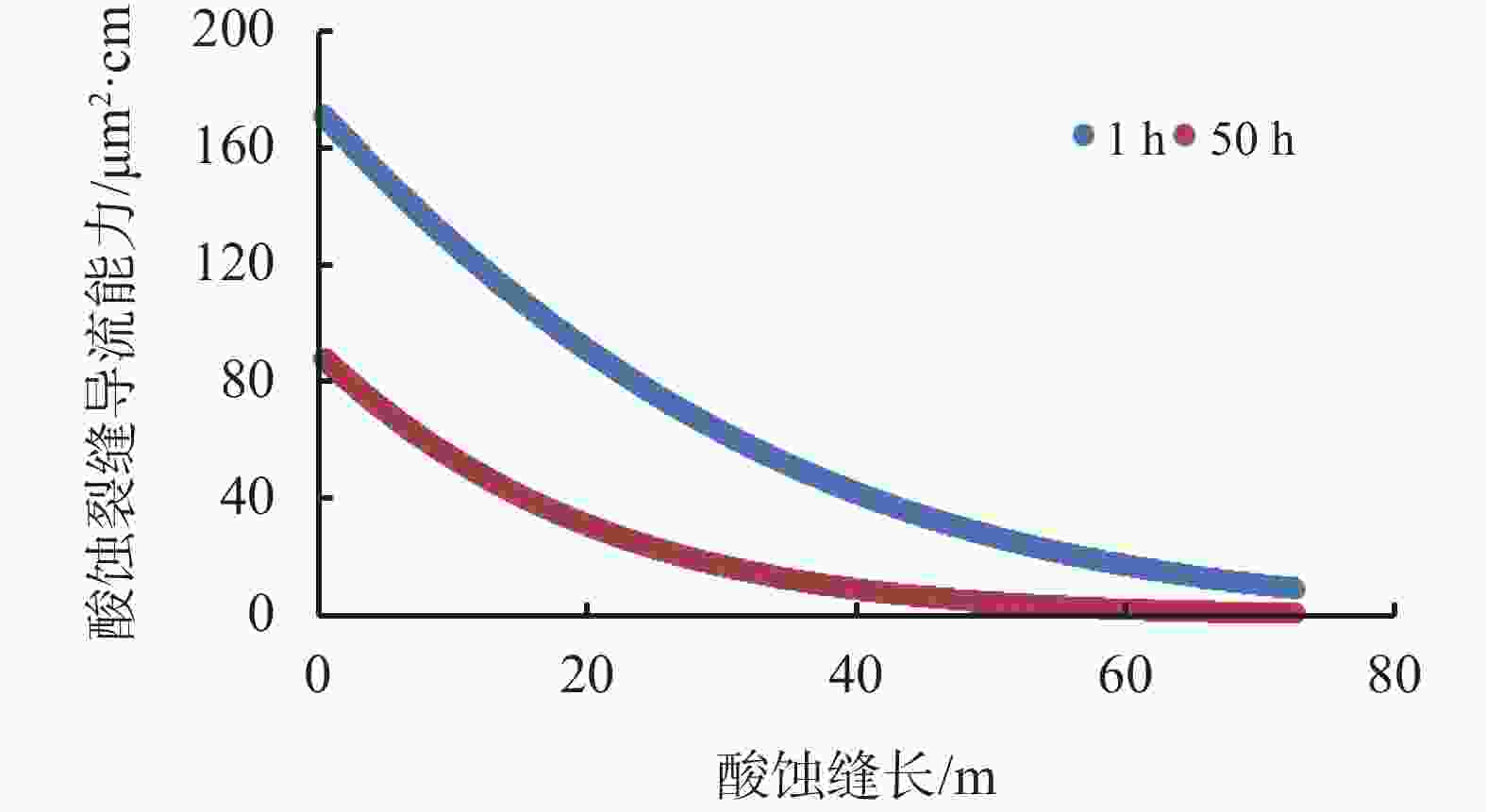

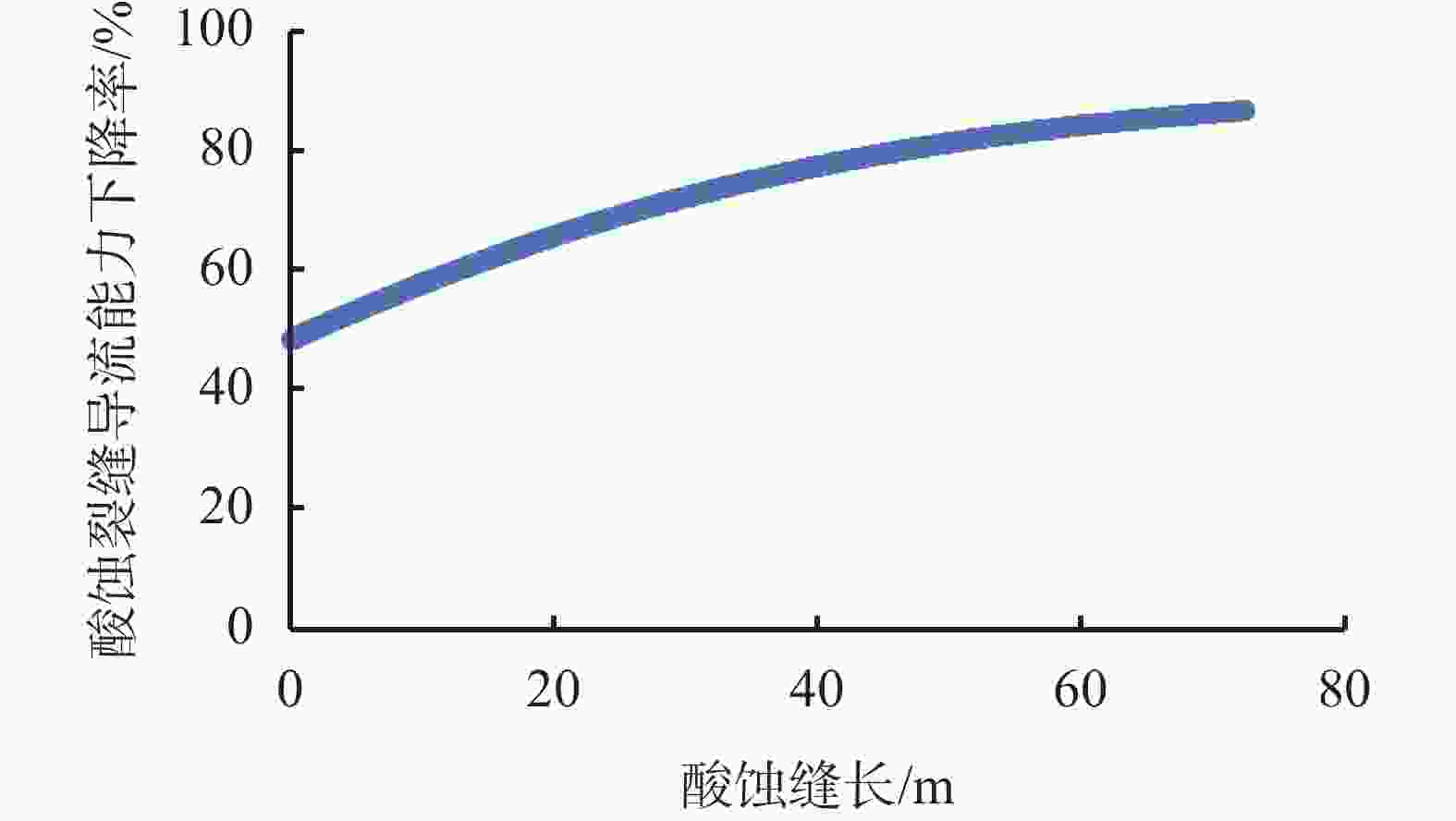

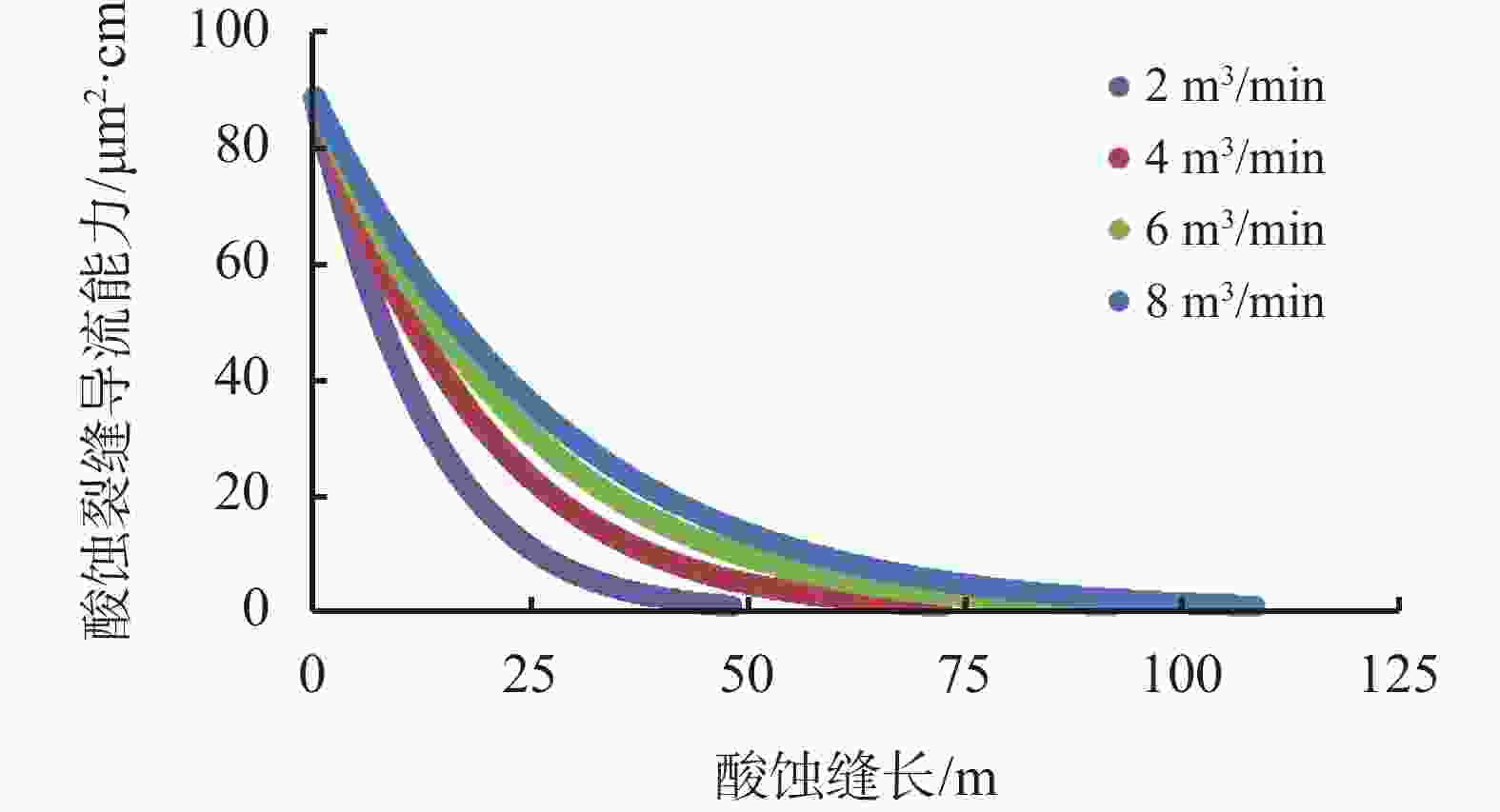

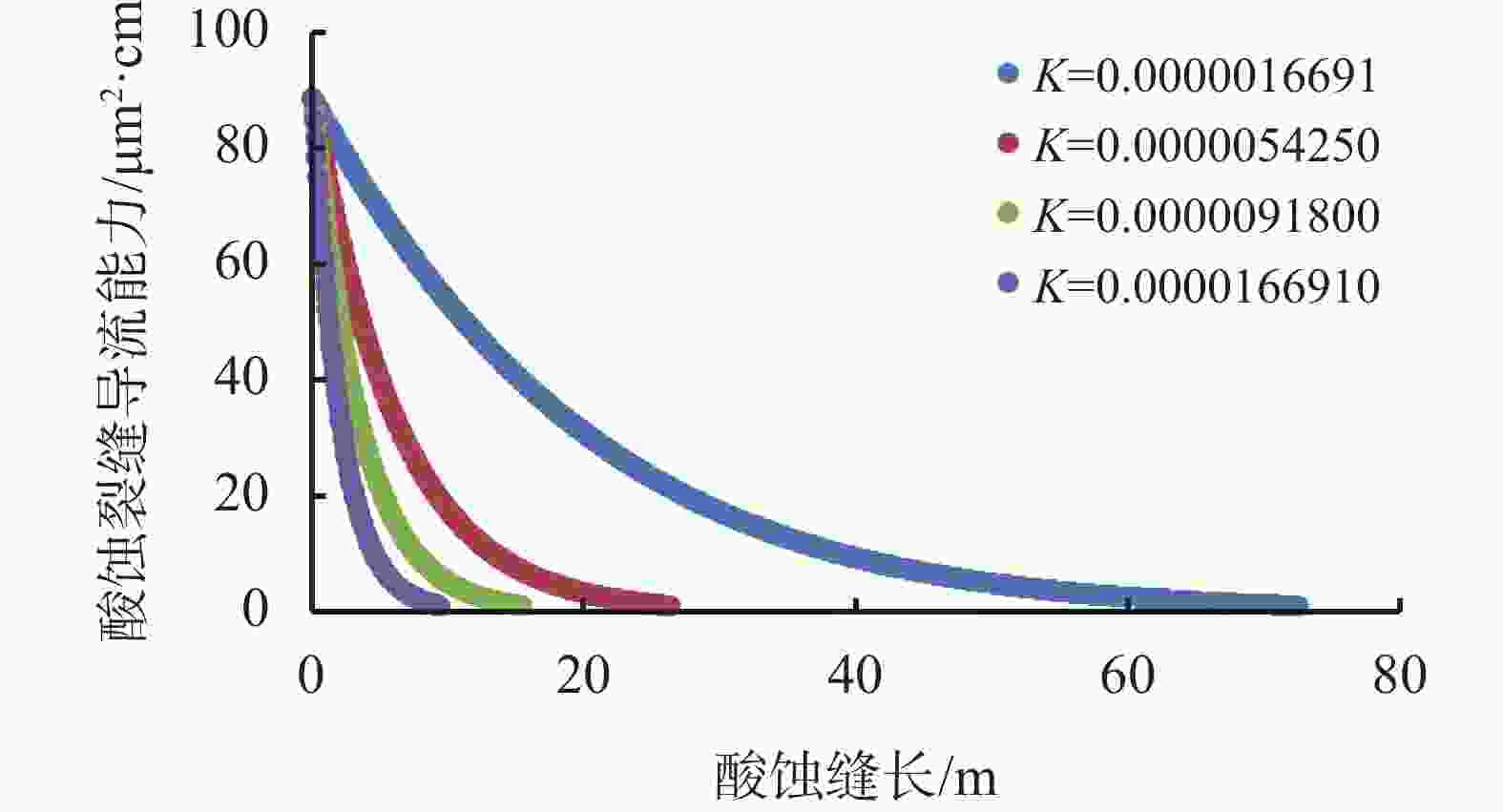

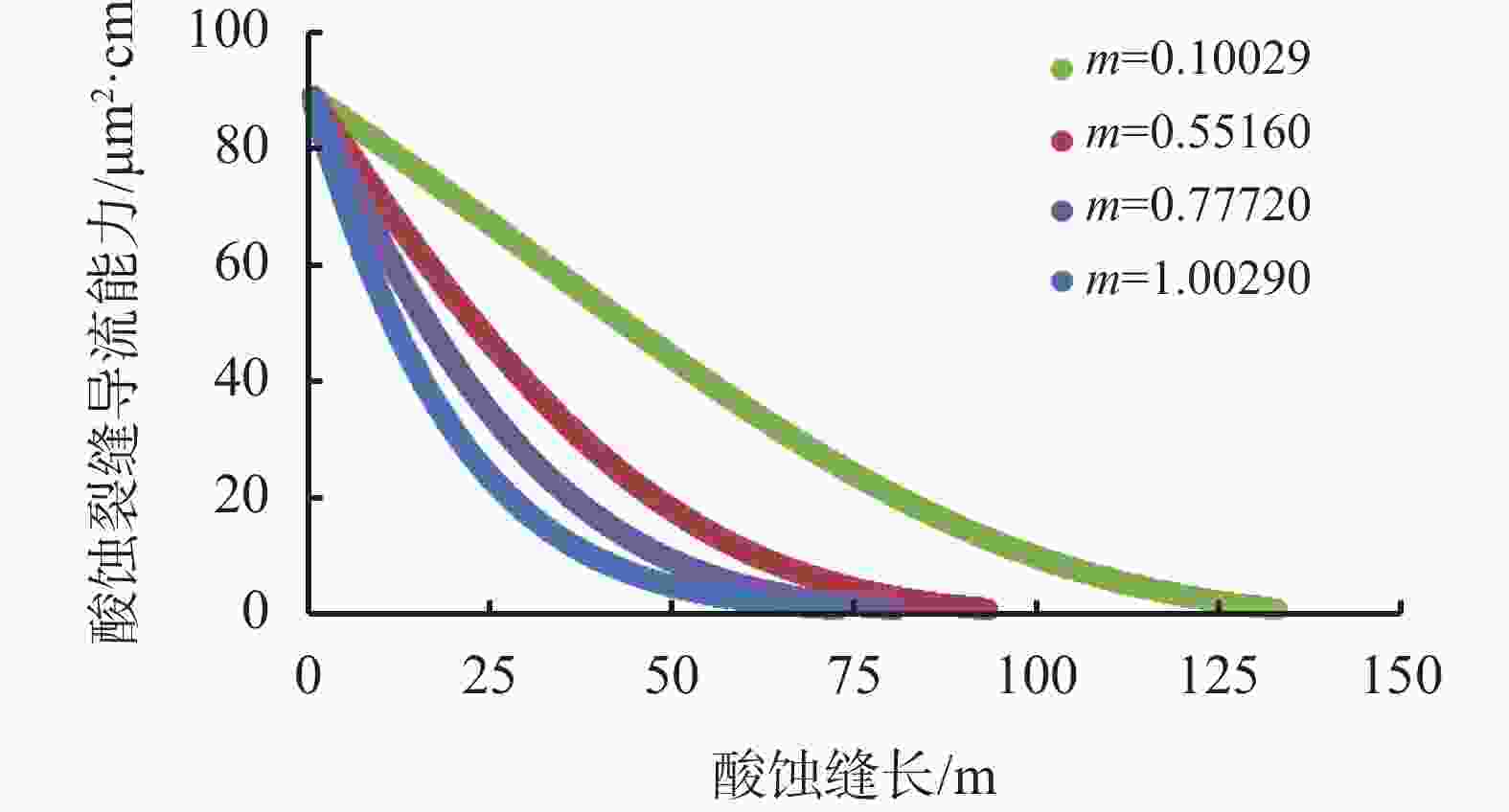

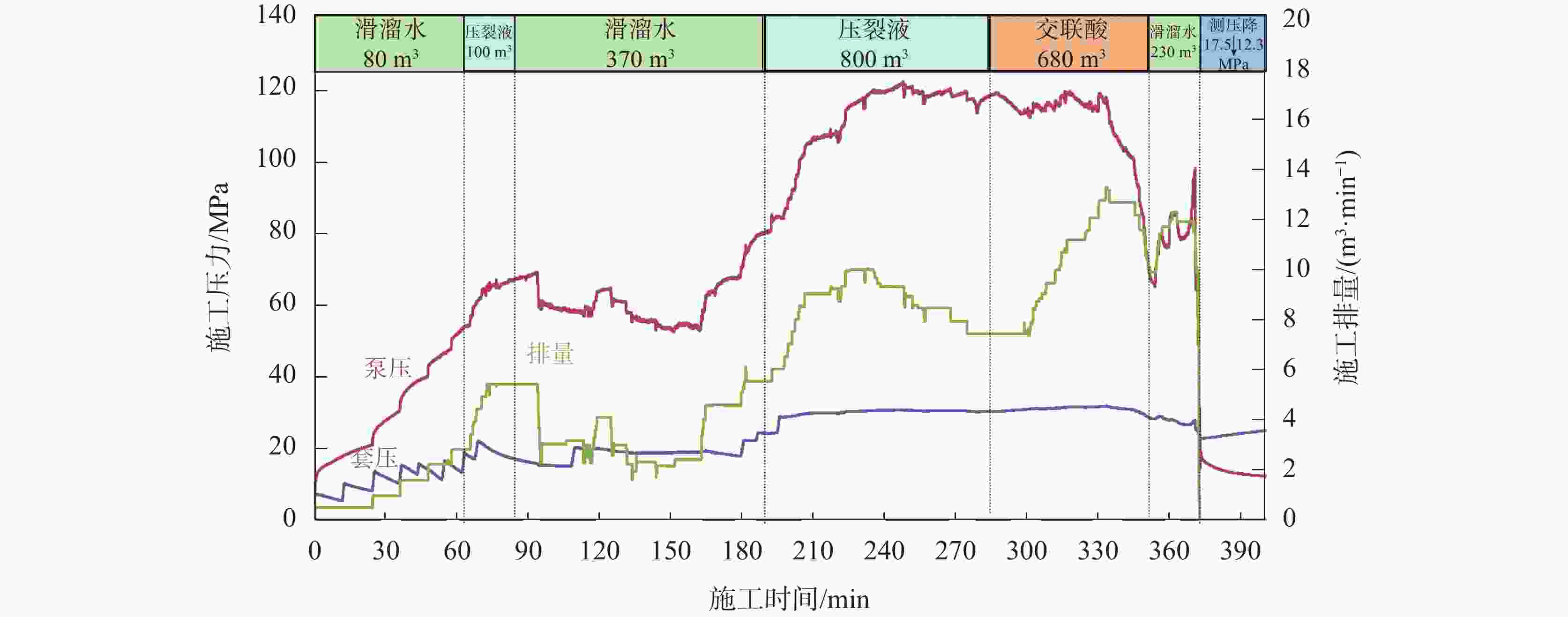

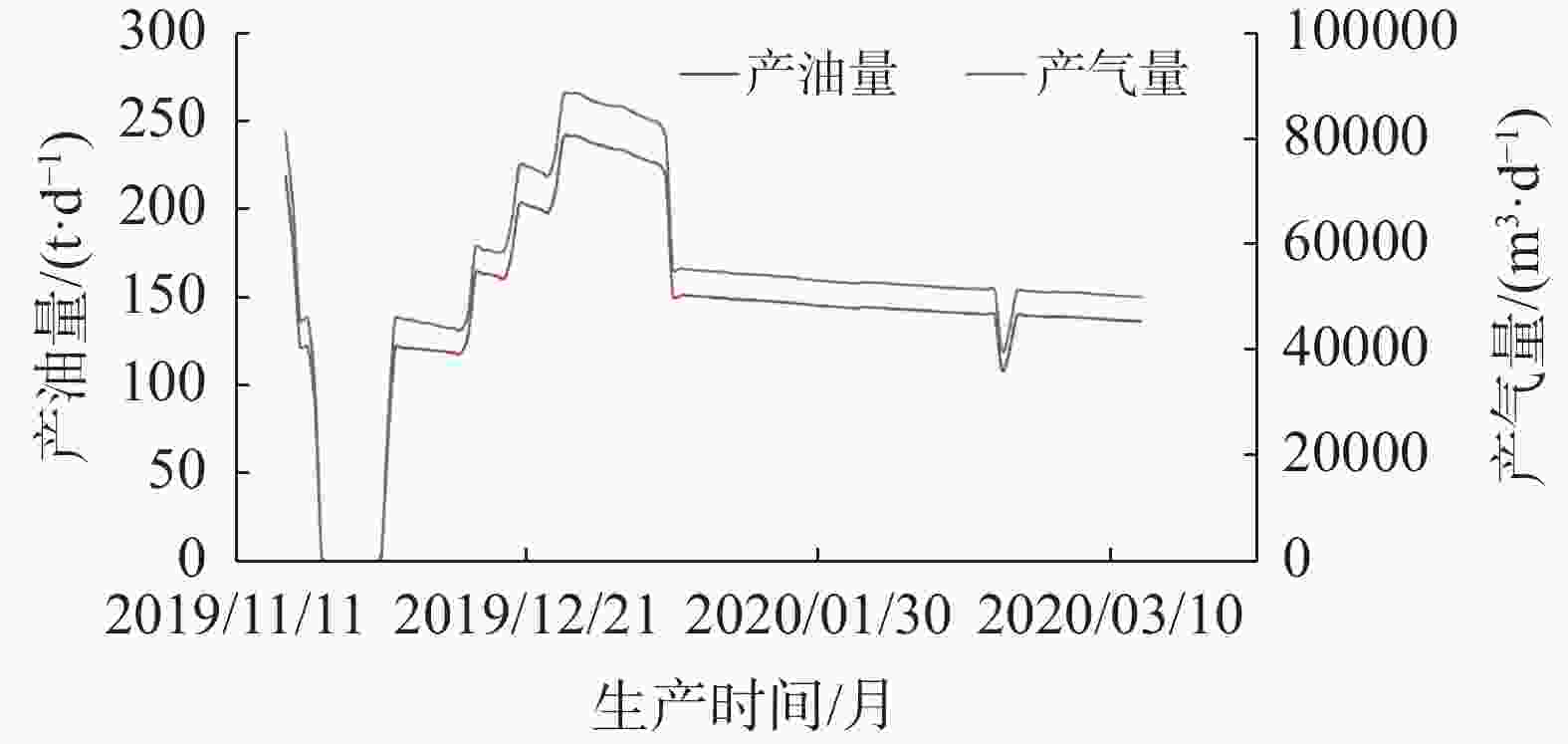

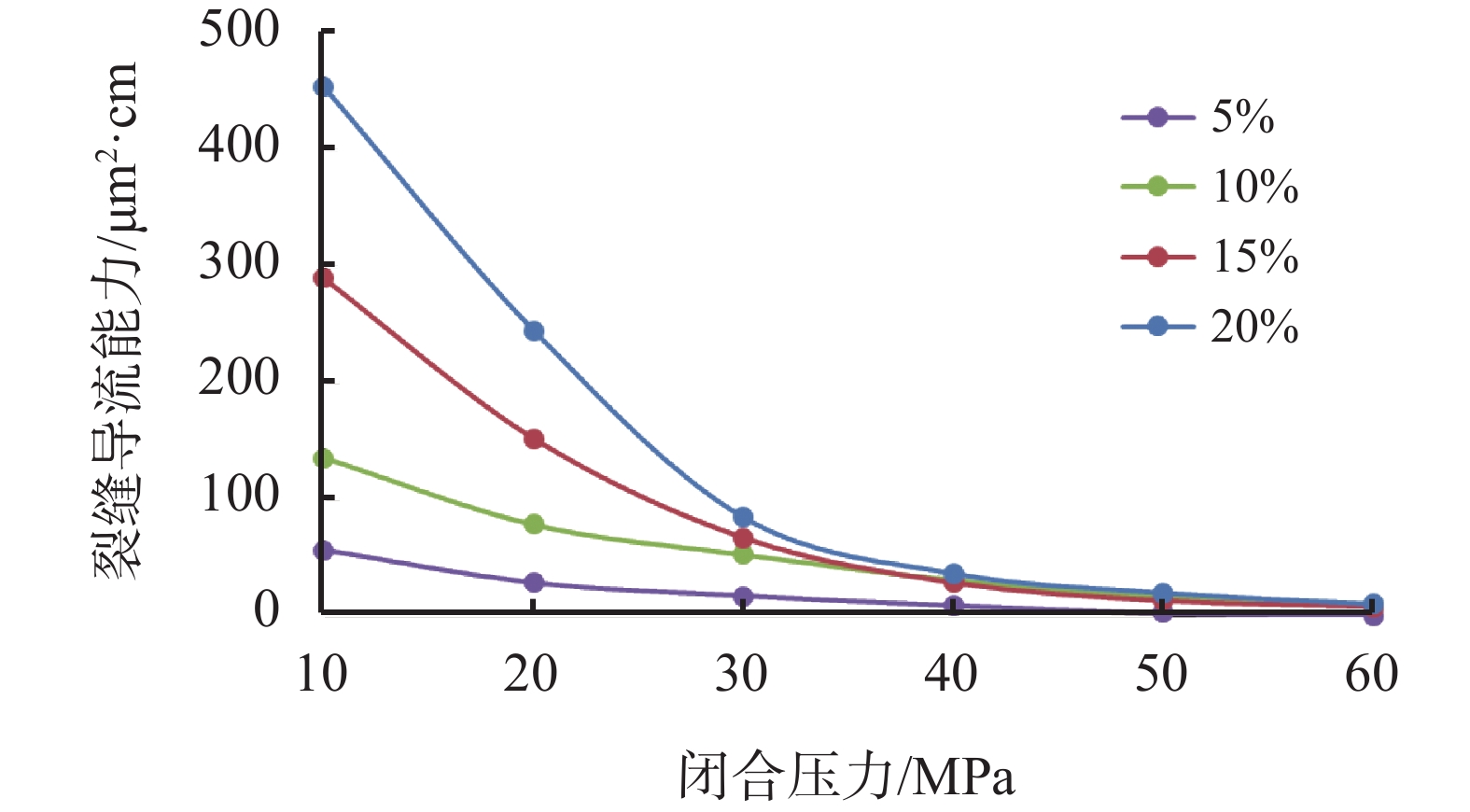

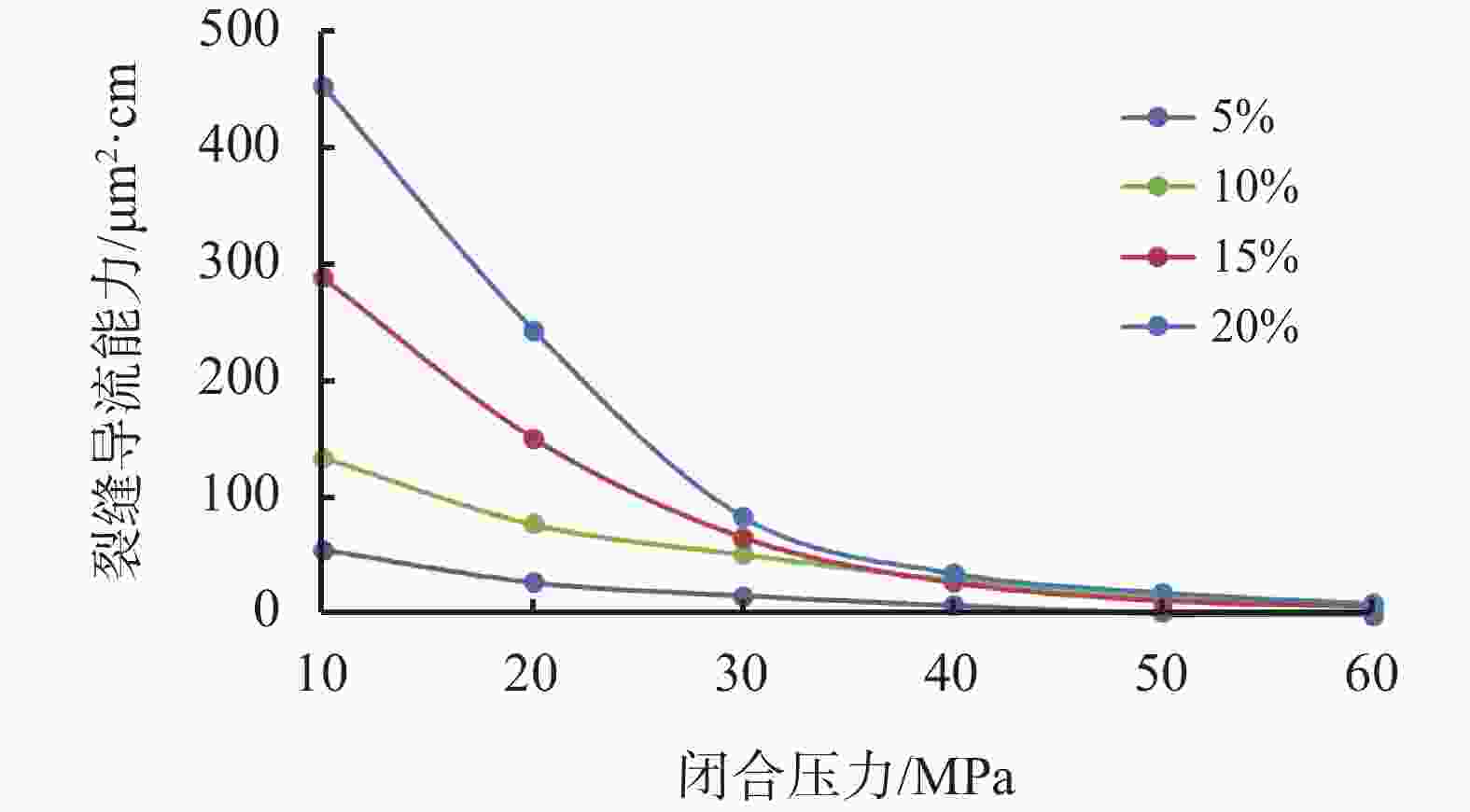

摘要: 顺北碳酸盐岩油气藏温度压力高,储层酸压改造难度大。为解决在闭合应力长期作用下,酸蚀裂缝导流能力损失,导致酸压效果大幅降低的问题。通过酸蚀裂缝导流能力评价实验,研究不同酸液质量分数、温度和闭合时间条件下的酸蚀裂缝导流能力变化规律。综合各条件下酸蚀裂缝导流能力关系式,建立并验证了顺北碳酸盐岩储层长期酸蚀裂缝导流能力预测方法,模拟计算了不同时间和排量下的酸蚀裂缝导流能力变化规律。结果表明:低闭合应力下,酸液反应速率是酸蚀裂缝导流能力主控因素。高闭合应力下,闭合应力、岩石特征和岩面非均匀性是酸蚀裂缝导流能力主控因素。闭合应力是影响岩石表面变形的主控因素,是长期酸蚀裂缝导流能力的决定因素。闭合应力长期作用时裂缝深部导流能力下降幅度比缝口大。人工裂缝中长期酸蚀裂缝导流能力分布规律受酸岩反应速率控制。Abstract: Acid fracturing has been performed with difficulties in the high temperature high pressure carbonate rock hydrocarbon reservoirs in the Shunbei block. The main problem is the dramatic reduction of the effect of acid fracturing resulted from the losses of the flow conductivity of the acid-etched fractures under the long-term action of the closure stresses. In laboratory experiment, the flow conductivity of acid-etched fractures is evaluated to study the changing patterns of the flow conductivity of the acid-etched fractures under different mass fractions of acid, temperatures and closure time. Based on the equations of the flow conductivity of acid-etched fractures under various conditions, a method for predicting the conductivity of long-term acid-etched fractures in Shunbei carbonate reservoir is established and verified. Use this method, the changing pattern of the flow conductivity of the acid-etched fractures at different lengths of time and flow rates is simulated. The simulation results show that at low closure stresses, the reaction rate of the acid is the dominant factor affecting the flow conductivity of the acid-etched fractures. At high closure stresses, however, the dominant factors affecting the flow conductivity of the acid-etched fractures include closure stress, rock characteristics and the nonuniformity of the rock surfaces. The closure stress, on the other hand, is the dominant factor controlling the deformation of the surfaces of the rocks and is also the decisive factor affecting the flow conductivity of the long-term acid-etched fractures. Under long-term action of closure stress, the flow conductivity of a fracture at the deep part of the fracture is decreased in an amplitude larger than the decrease in the flow conductivity of the fracture at its mouth. The distribution of the flow conductivity of artificial fractures produced under mid-term and long-term acid-etching is controlled by the rate of reaction between the acid and the rock.

-

Key words:

- Shunbei reservoirs /

- Carbonate Rock /

- Acid-eroded Fractures /

- Long-term Flow Conductivity

-

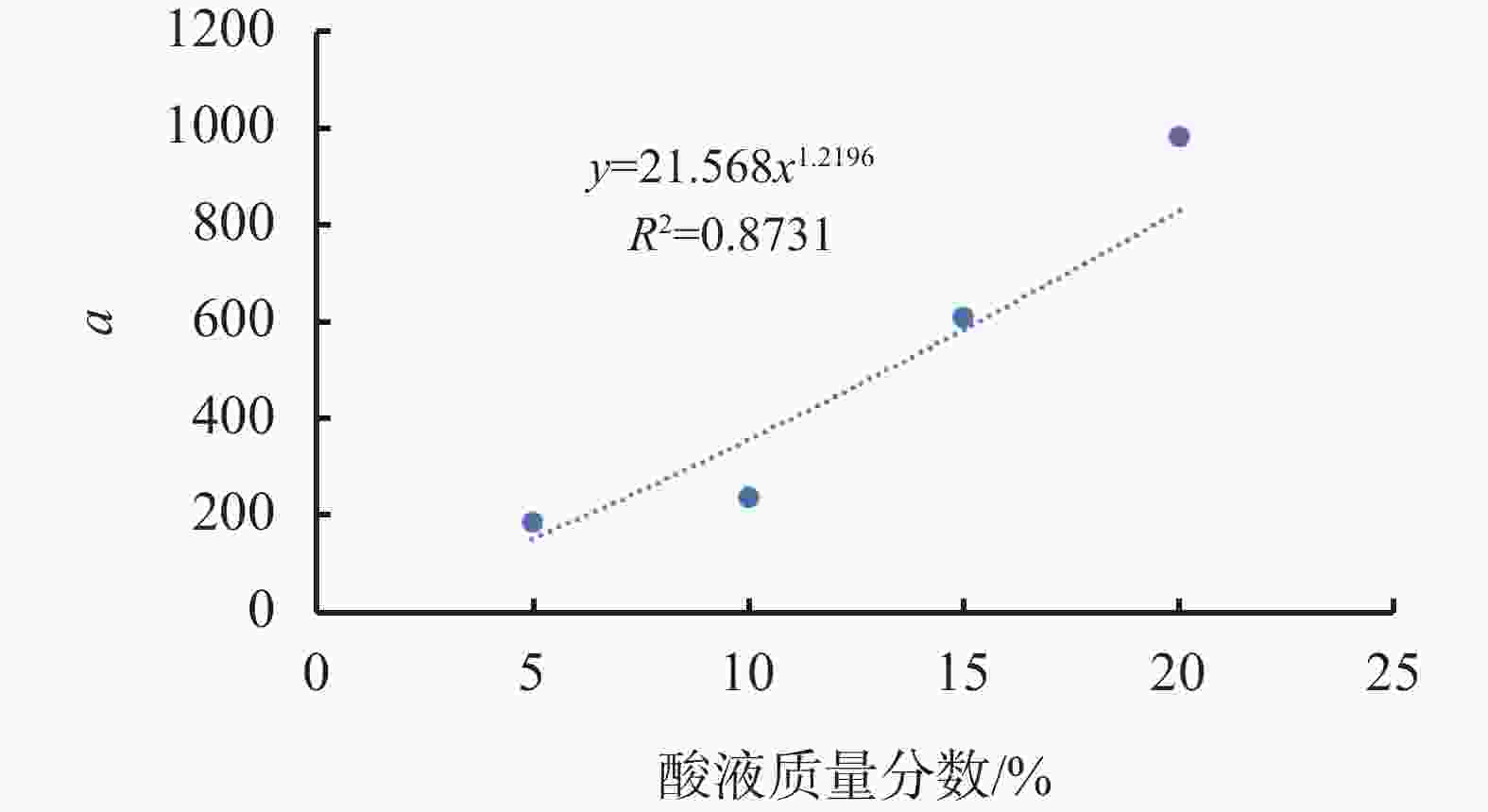

表 1 不同浓度酸蚀裂缝导流能力与 闭合压力指数关系式统计表

酸液浓

度/%不同酸液质量分数下

酸蚀裂缝导流能力与

闭合压力指数关系式指数关系式a、b值 a b 5 y=186.52e−0.089x 186.52 −0.089 10 y=237.83e−0.053x 237.83 −0.053 15 y=614.18e−0.074x 614.18 −0.074 20 y=984.64e−0.078x 984.64 −0.078 表 2 酸蚀裂缝导流能力预测值与实验值对比表

酸液质量

分数/%T/

℃闭合压力/

MPa闭合时

间/h酸蚀裂缝导流

能力/μm2∙cm误差率/

%预测值 实验值 20 130 60 50 13.568 14.736 7.93 5 130 60 50 0.986 0.895 10.17 -

[1] BEG M S, KUNAK A O, GONG M, et al. A systematic experimental study of acid fracture conductivity[J]. SPE Production & Facilities, 3109:8.1996. [2] RUFFET C S, FERY J J, ONAISI A. Acid-fracturing treatment: a surface-topography analysis of acid-etched fractures to determine residual conductivity[J]. SPE Journal, 3817:5.1997. [3] MALAGON C, POURNIK M, HILL A D. The texture of acidized fracture surfaces: implications for acid fracture conductivity[J]. SPE Production & Operations, 2008, 23(3): 343-352. [4] MELENDEZ M G, POURNIK M, ZHU D, et al. The effects of acid contact time and the resulting weakening of the rock surfaces on acid fracture conductivity[C]//European Formation Damage Conference. OnePetro, 2007. [5] NINO-PENALOZA A, AL-MOMIN A, ZHU D, et al. New insights about acid fracture conductivity at laboratory scale[C]//SPE Annual Technical Conference and Exhibition. OnePetro, 2015. [6] 陈星宇,杨兆中,李小刚,等. 酸蚀裂缝导流能力实验及预测模型研究综述[J]. 断块油气田,2012,19(5):618-621. doi: 10.6056/dkyqt201205018CHEN Xingyu, YANG Zhaozhong, LI Xiaogang, et al. Summary of research on conductivity of acid-etched fractures and prediction models[J]. Fault Block Oil & Gas Field, 2012, 19(5):618-621. doi: 10.6056/dkyqt201205018 [7] 彭 瑀,李勇明,赵金洲,等. 缝洞型碳酸盐岩油藏酸蚀裂缝导流能力模拟与分析[J]. 石油学报,2015,36(5):606-611,640. doi: 10.7623/syxb201505010PENG Yu, LI Yongming, ZHAO Jinzhou, et al. Simulation and analysis of acid-etched fracture conductivity of fractured-vuggy carbonate reservoirs[J]. Acta Petrolei Sinica, 2015, 36(5):606-611,640. doi: 10.7623/syxb201505010 [8] 钟小军,张锐,吴刚,等. 复杂非均质碳酸盐岩储层酸岩反应动力学特征及酸压对策研究[J]. 钻井液与完井液,2020,37(6):798-802. doi: 10.3969/j.issn.1001-5620.2020.06.021ZHONG Xiaojun, ZHANG Rui, WU Gang, et al. Study on dynamic characteristics of acid rock reaction and acid fracturing countermeasures in complex heterogeneous carbonate reservoirs[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):798-802. doi: 10.3969/j.issn.1001-5620.2020.06.021 [9] 吴亚红,吴虎,王明星,等. 基于导流能力评价实验的复合酸化压裂技术[J]. 科学技术与工程,2020,20(31):12776-12781. doi: 10.3969/j.issn.1671-1815.2020.31.014WU Yahong, WU Hu, WANG Mingxing, et al. Composite acid fracturing technology based on flow conductivity evaluation experiments[J]. Science Technology and Engineering, 2020, 20(31):12776-12781. doi: 10.3969/j.issn.1671-1815.2020.31.014 [10] 张路锋,牟建业,贺雨南,等. 高温高压碳酸盐岩油藏酸蚀裂缝导流能力实验研究[J]. 西安石油大学学报(自然科学版),2017,32(4):93-97.ZHANG Lufeng, MOU Jianye, HE Yunan, et al. Experimental study on conductivity of acid-etched fractures in high-temperature and high-pressure carbonate reservoirs[J]. Journal of Xi'an Shiyou University(Natural Science Edition) , 2017, 32(4):93-97. [11] 赵立强,高俞佳,袁学芳,等. 高温碳酸盐岩储层酸蚀裂缝导流能力研究[J]. 油气藏评价与开发,2017,7(1):20-26. doi: 10.3969/j.issn.2095-1426.2017.01.004ZHAO Liqiang, GAO Yujia, YUAN Xuefang, et al. Study on the conductivity of acid-etched fractures in high-temperature carbonate reservoirs[J]. Reservoir Evaluation and Development, 2017, 7(1):20-26. doi: 10.3969/j.issn.2095-1426.2017.01.004 [12] 刘享,伊向艺,吴元琴,李沁. 酸压裂缝中酸液微观流动数值模拟及分析[J]. 钻井液与完井液,2017,34(4):106-111. doi: 10.3969/j.issn.1001-5620.2017.04.020LIU Xiang, YI Xiangyi, WU Yuanqin, et al. Numerical simulation and analysis of acid flow in acid fractures[J]. Drilling Fluid & Completion Fluid, 2017, 34(4):106-111. doi: 10.3969/j.issn.1001-5620.2017.04.020 [13] 宋巍. ZG8-43井区鹰山组储层酸蚀裂缝导流能力影响因素研究[D]. 西南石油大学, 2016.SONG Wei. Research on influencing factors of conductivity of acid-etched fractures of Yingshan Formation reservoir in ZG8-43 well area[D]. Southwest Petroleum University, 2016. [14] 王玉芳,杜建军,牛新年,等. 碳酸盐岩酸压裂缝导流能力随缝长变化规律研究[J]. 地质力学学报,2015,21(4):546-554. doi: 10.3969/j.issn.1006-6616.2015.04.010WANG Yufang, DU Jianjun, NIU Xinnian, et al. Study on the variation of conductivity of acid-fractured fractures in carbonate rocks with fracture length[J]. Journal of Geomechanics, 2015, 21(4):546-554. doi: 10.3969/j.issn.1006-6616.2015.04.010 [15] 岳迎春,郭建春,冯松,等. 酸蚀裂缝导流能力数值模型研究[J]. 长江大学学报(自科版),2015,12(20):55-59. doi: 10.16772/j.cnki.1673-1409.2015.20.014YUE Yingchun, GUO Jianchun, FENG Song, et al. Numerical model research on conductivity of acid-etched fractures[J]. Journal of Yangtze University(Natural Science Edition) , 2015, 12(20):55-59. doi: 10.16772/j.cnki.1673-1409.2015.20.014 [16] 吴霞,伊向艺,黄文强,等. 酸蚀裂缝差异化刻蚀量化研究及影响因素探讨[J]. 钻井液与完井液,2019,36(198):250-256.WU Xia, YI Xiangyi, HUANG Wenqiang, et al. Discussion on the Quantitative Study and lmpact Factors of Differentialized Corrosion in Fractures Generated by Acid Corrosion[J]. Drilling Fluid & Completion Fluid, 2019, 36(198):250-256. [17] 顾亚鹏,伊向艺,戴亚婷,等. 酸岩反应有效作用距离确定新方法探讨[J]. 科学技术与工程,2015,15(27):34-37. doi: 10.3969/j.issn.1671-1815.2015.27.006GU Yapeng, YI Xiangyi, DAI Yating, et al. Discussion on a new method for determining the effective distance of acid rock reaction[J]. Science Technology and Engineering, 2015, 15(27):34-37. doi: 10.3969/j.issn.1671-1815.2015.27.006 [18] 李沁. 高黏度酸液酸岩反应动力学行为研究[D]. 成都理工大学, 2013.LI Qin. Study on the reaction kinetics of high-viscosity acid liquid and acid rock[D]. Chengdu University of Technology, 2013. -

下载:

下载: