A Medium-Low Temperature Epoxy Based Workover Fluid

-

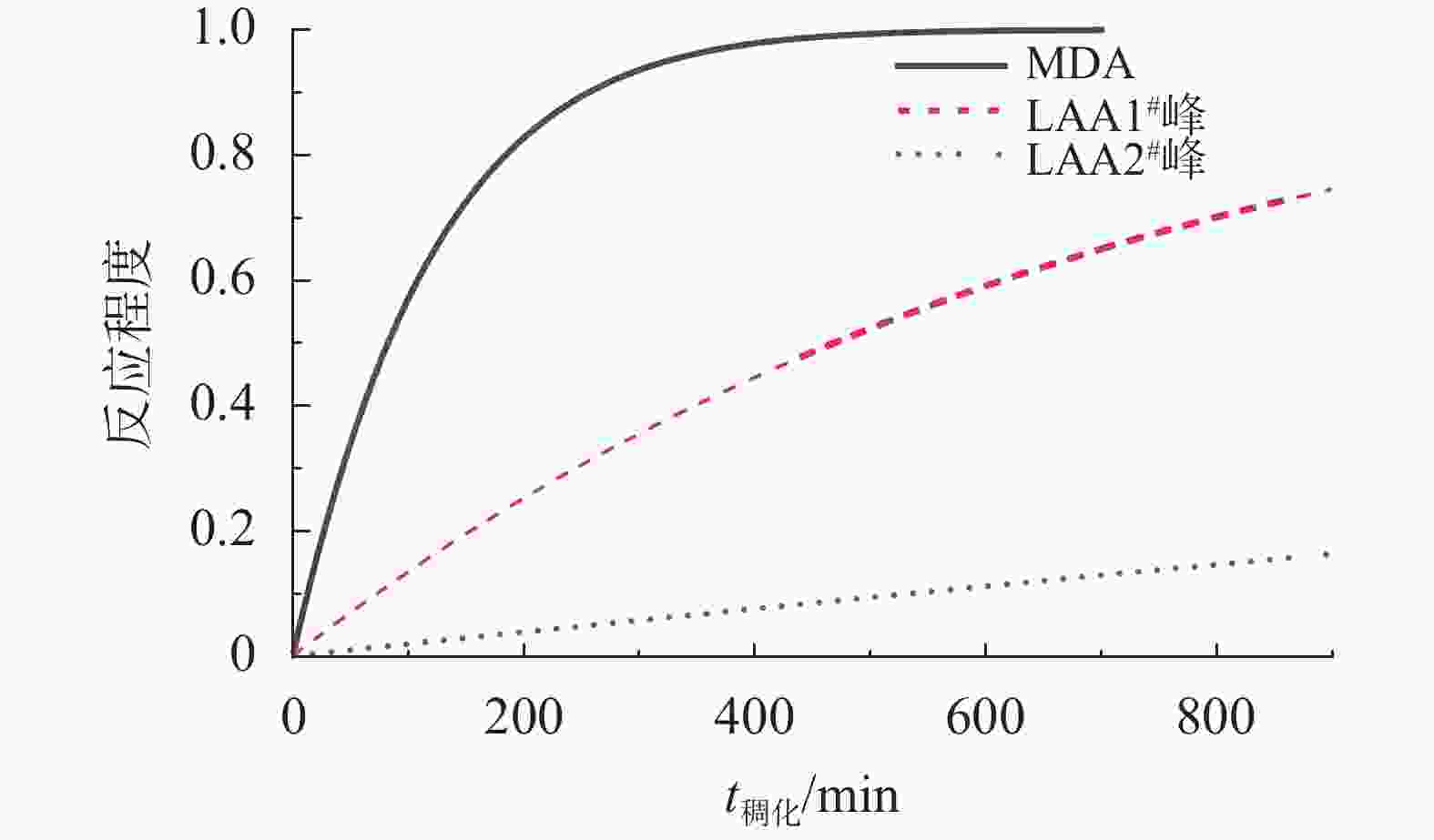

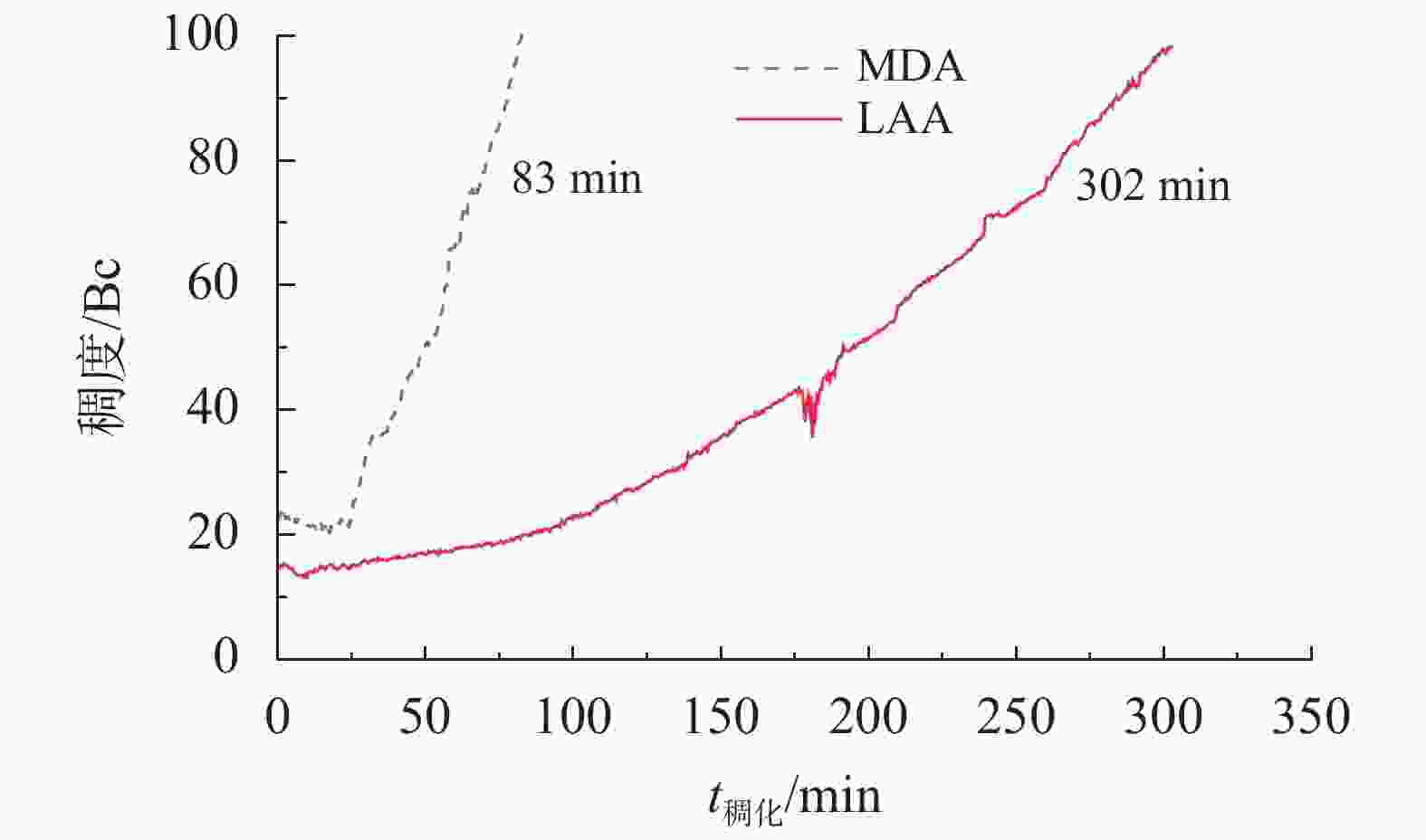

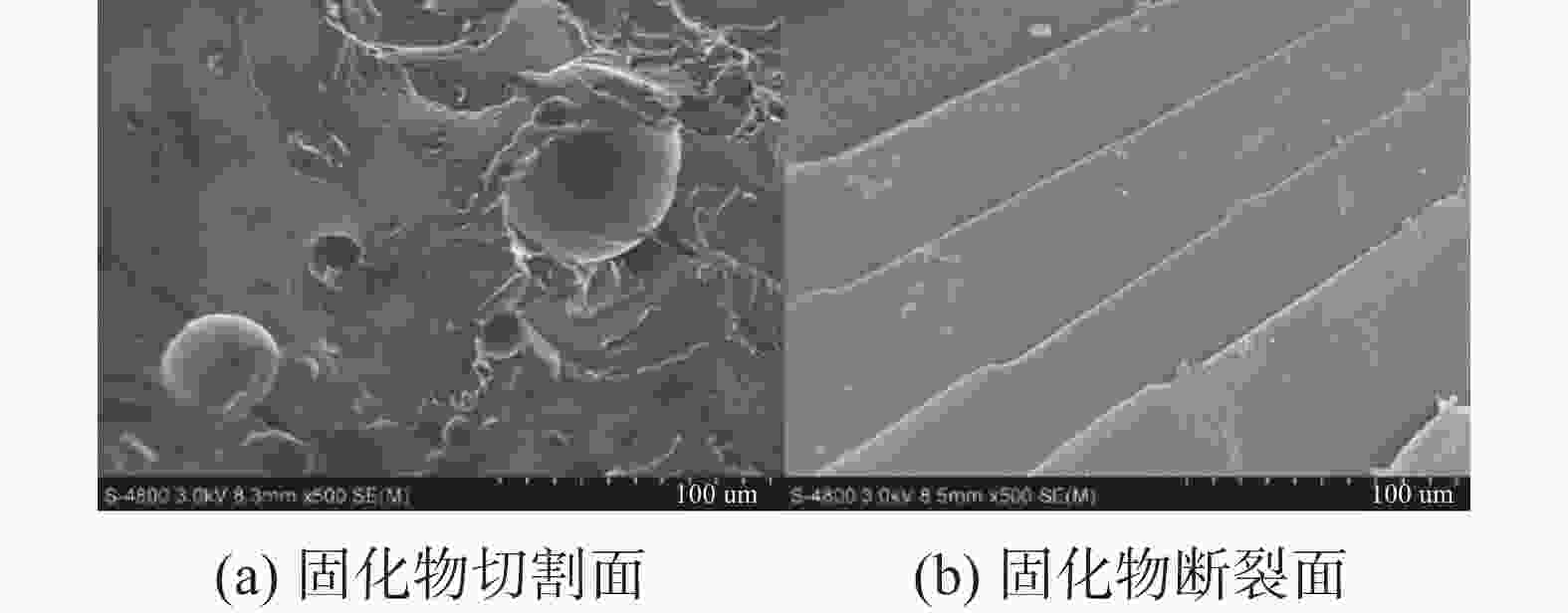

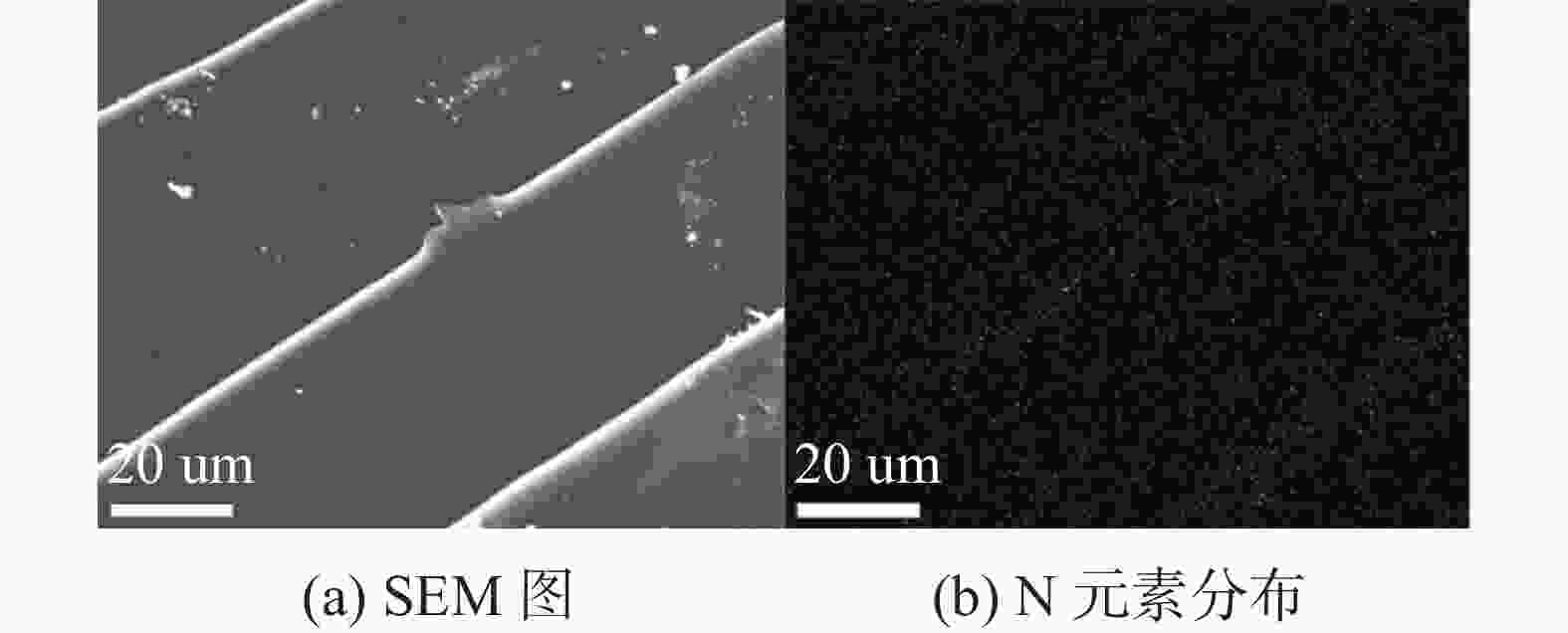

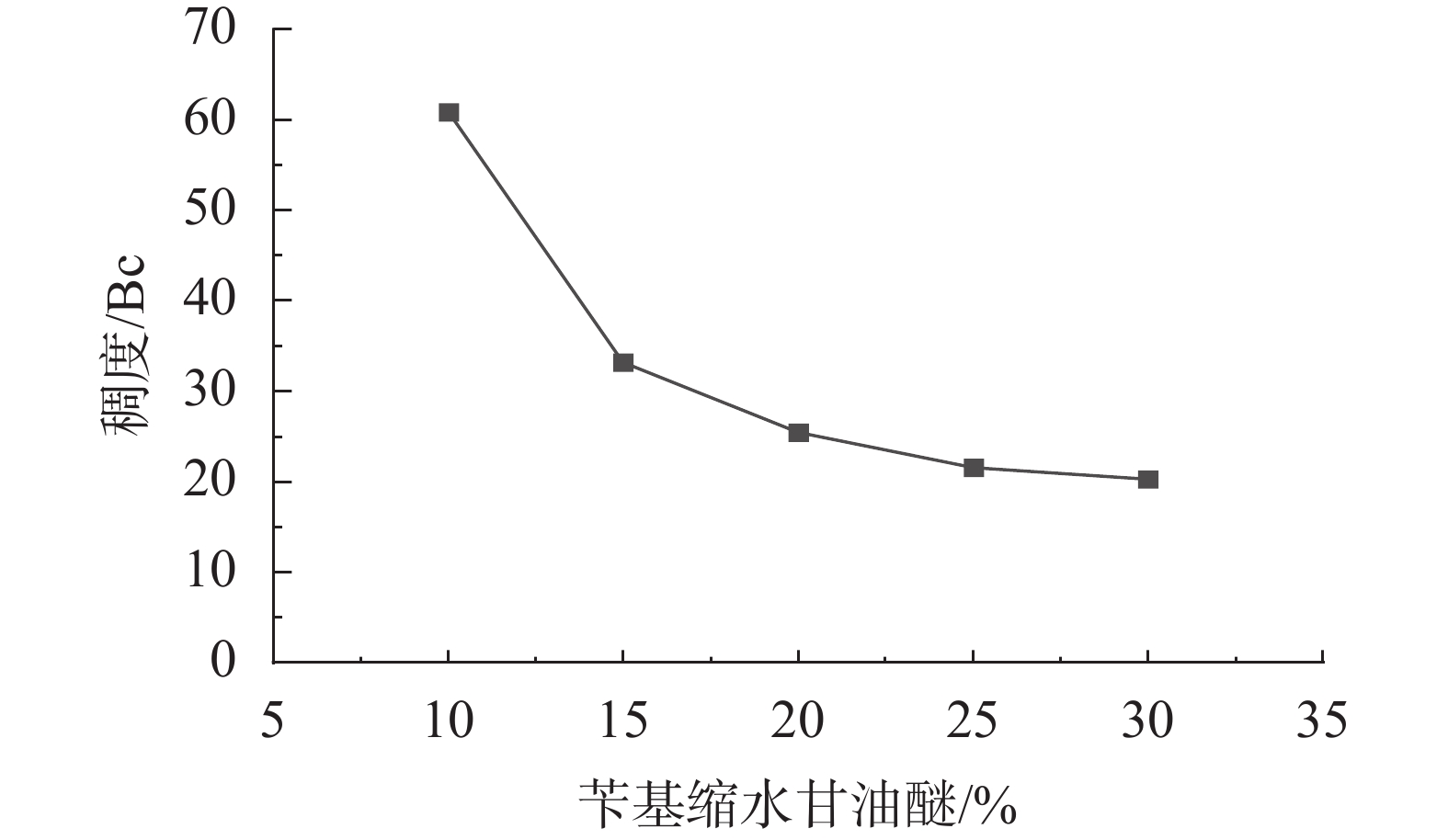

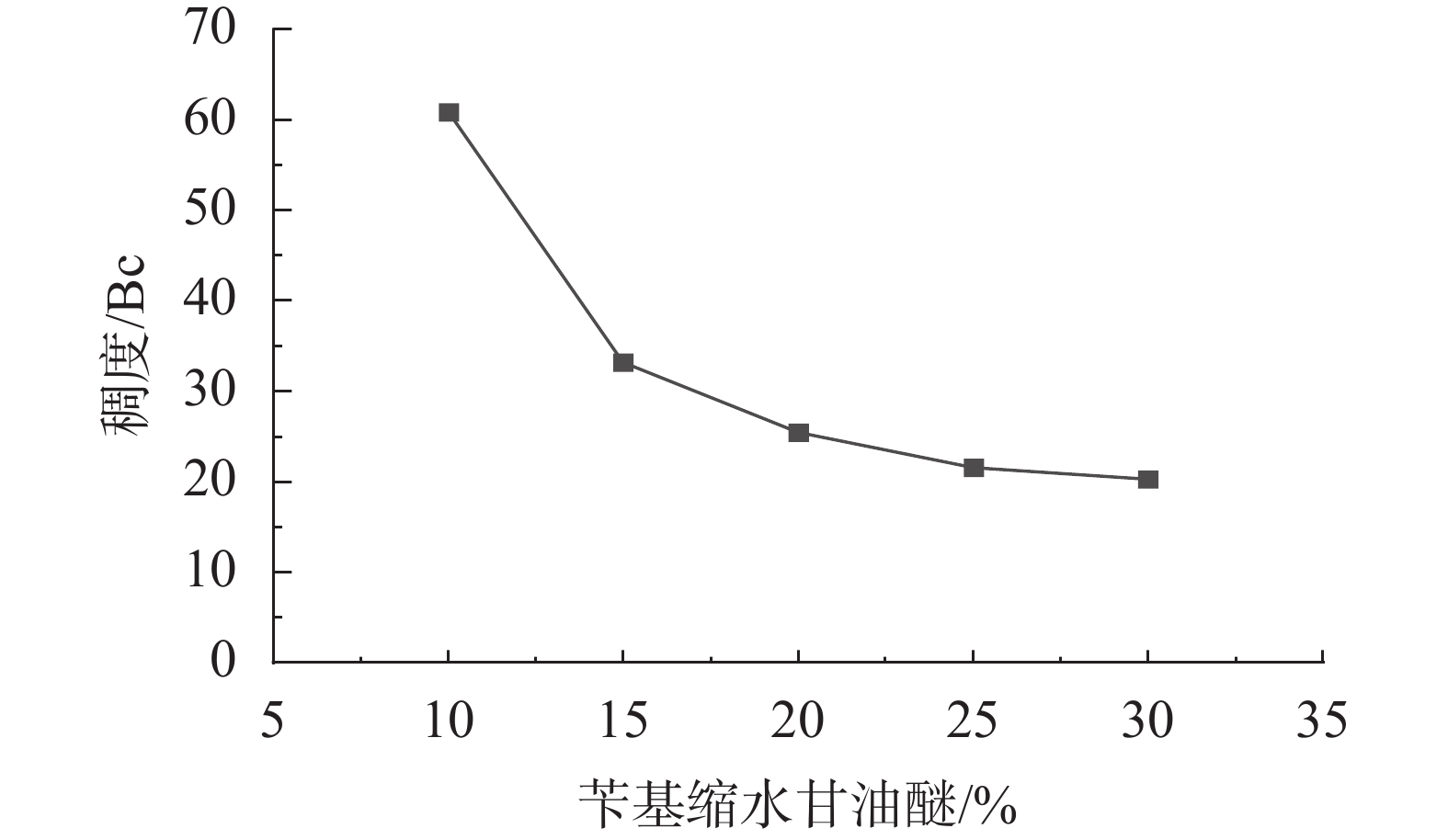

摘要: 石油天然气的消耗量急剧增加,同时伴随着常规油气井开发的减少,非常规油气井,如深井、海洋井、页岩气井等的开发迫在眉睫。这些复杂地质环境都有极大可能破坏水泥环的密封完整性,形成环空窜流,对生产造成阻碍和危险,产生极大的经济损失。环氧树脂体系可以作为一种修井液来代替水泥浆进行修井工作,解决水泥浆无法渗透入微小孔隙的缺陷。目前环氧树脂修井液体系配方繁多,普适性差,为同时满足不同温度地层的修井需求,便于现场施工的运输、存储和调配,提高修井经济性和推动工业化进程,设计了以液态芳香胺(LAA)为主要固化剂的体系。进行了组分优选和性能评价,对稠化性能、动力学和固化物的抗压强度和微观形貌进行了表征。结果表明,LAA体系初始稠度小于30 Bc,稠化时间在2~5 h之间可调,抗压强度在不同温度下都高于20 MPa,可以满足30~90 ℃普适性的修井需要。Abstract: Presently the consumption of oil and natural gas has increased sharply, while the development of conventional oil and gas is reducing, this makes the development of unconventional oil and gas, such as oil and gas from deep wells, offshore wells and shale gas wells more and more imminent. In the development of unconventional oil and gas, the sealing integrity of cement sheath may probably be damaged, leading to oil and gas channeling in the annulus which imposes great hindrances and risks to oil and gas production and causes great economic losses. Epoxy based workover fluid can be used to replace cement slurry in workover job to solve the problem of inability of cement slurries to penetrate micro pores. Epoxy based workover fluids have many compositions and poor adaptability. To simultaneously satisfy the needs of workover operation in different formations with different temperatures, facilitate the transportation, storage and deployment of field operation, and improve the economy of workover and promote the industrialization process, a workover fluid was developed with liquid aromatic amine (LAA) as the main curing agent. The performance of the workover fluid was evaluated, the thickening performance and the kinetics of the workover fluid, and the compressive strength and micromorphology of the set product were characterized. The results show that the LAA system has initial consistency of less than 30 Bc, thickening time that is adjustable between 2 h and 5 h, compressive strength that is greater than 20 MPa at various temperatures, and it is able to satisfy the needs of workover operation at temperatures between 30 ℃ and 90 ℃.

-

Key words:

- Epoxy resin /

- Well workover /

- Amine cure agent /

- Kinetics

-

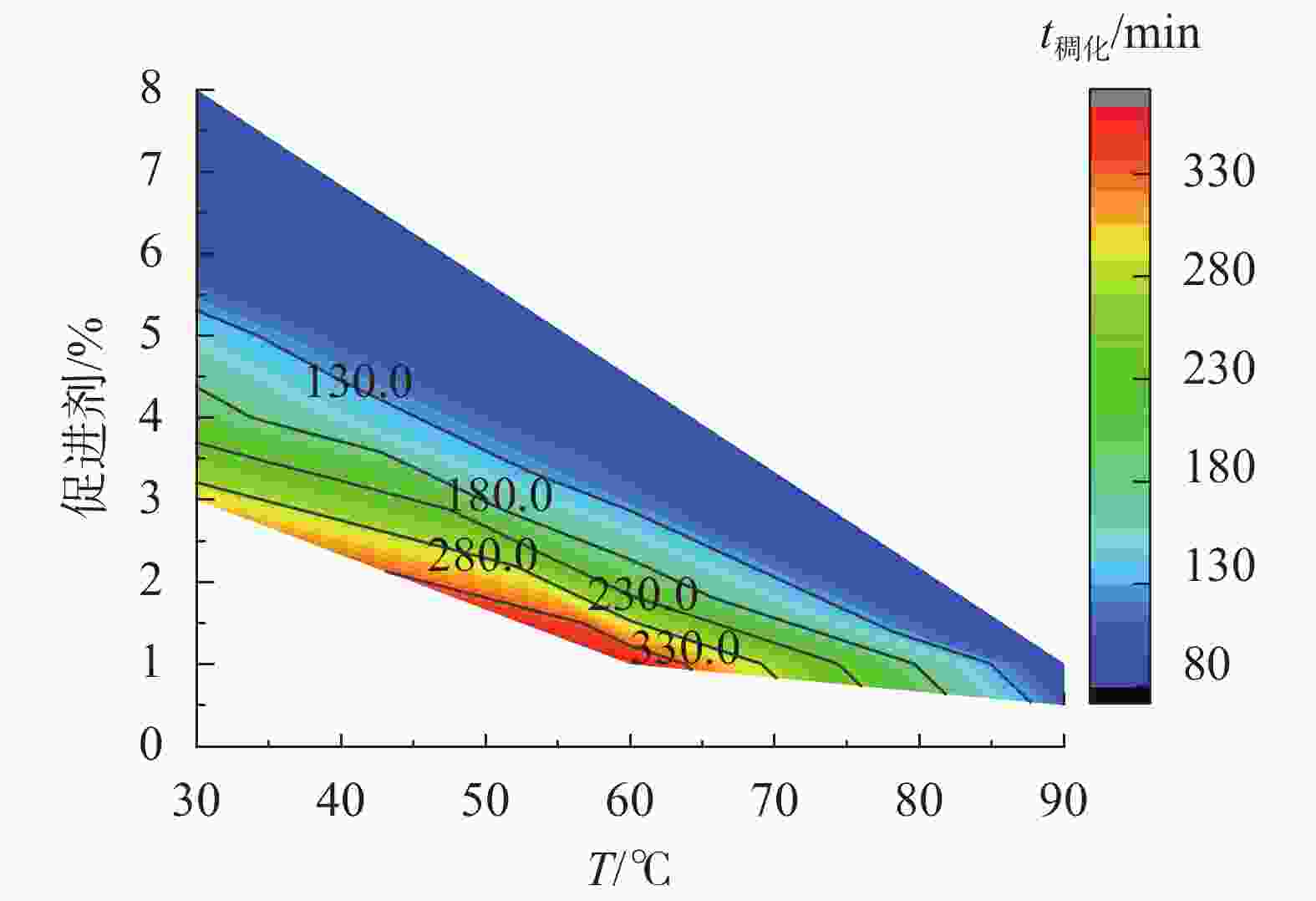

表 1 不同温度和促进剂加量下工作液稠化曲线参数

实验号 T/℃ 促进剂/% t稠化/min 初始稠度/Bc 3T8 30 8 87 28 3T6 30 6 90 26 3T5 30 5 148 16 3T4 30 4 199 19 3T3 30 3 302 15 4T6 40 6 87 25 4T5 40 5 106 27 6T3 60 3 119 20 6T2 60 2 203 16 6T1 60 1 366 22 9T1 90 1 82 16 9T0.5 90 0.5 110 15 表 2 不同温度和促进剂加量下水泥石的抗压强度

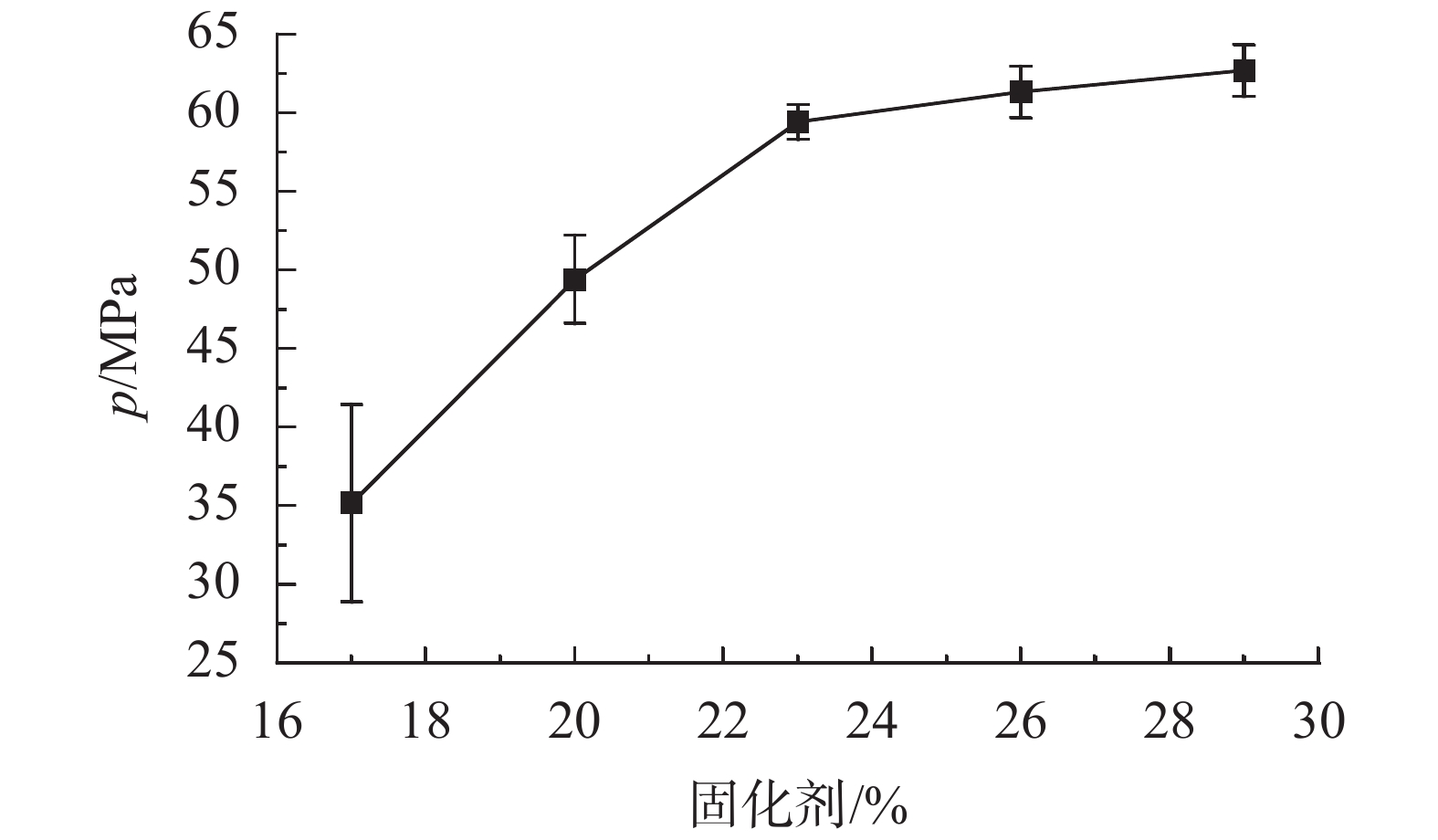

T养护/℃ 促进剂/% p7 d/MPa 30 8 >69.75 30 6 >69.75 30 5 >69.75 30 4 >69.75 30 3 >69.75 40 6 >69.75 40 5 >69.75 60 3 >69.75 60 2 >69.75 60 1 >69.75 70 1 61.78±6.95 80 1 33.28±4.99 90 1 21.93±3.44 90 0.5 20.35±4.19 表 3 不同温度和复配固化剂加量的抗压强度

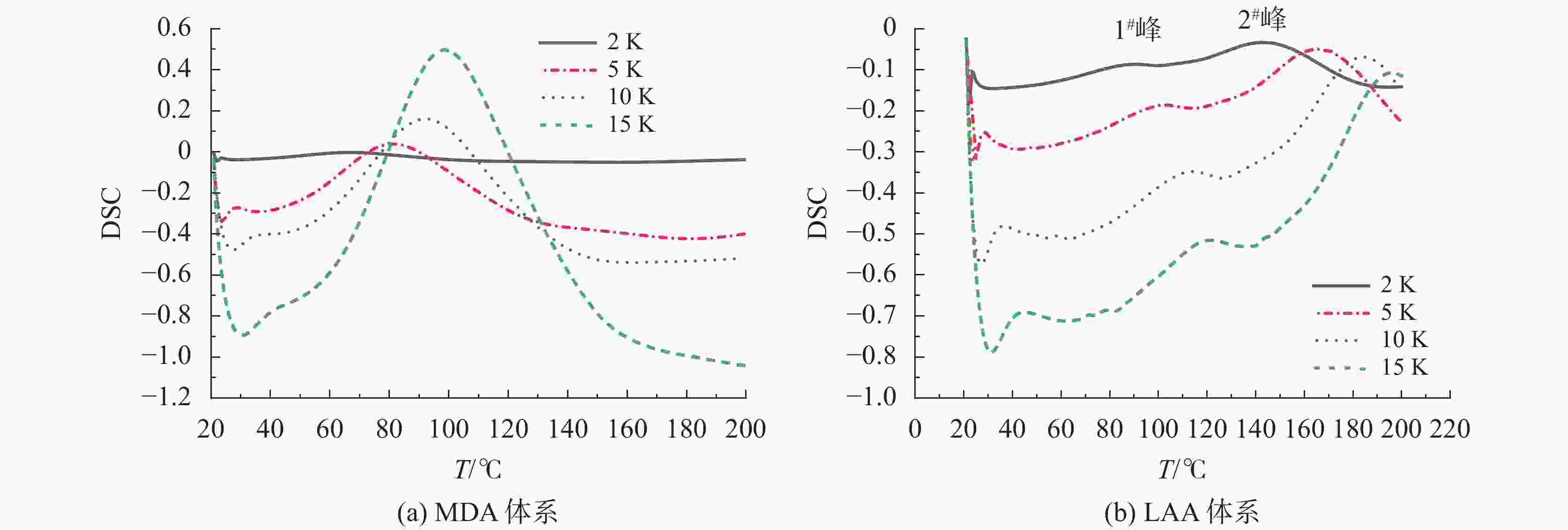

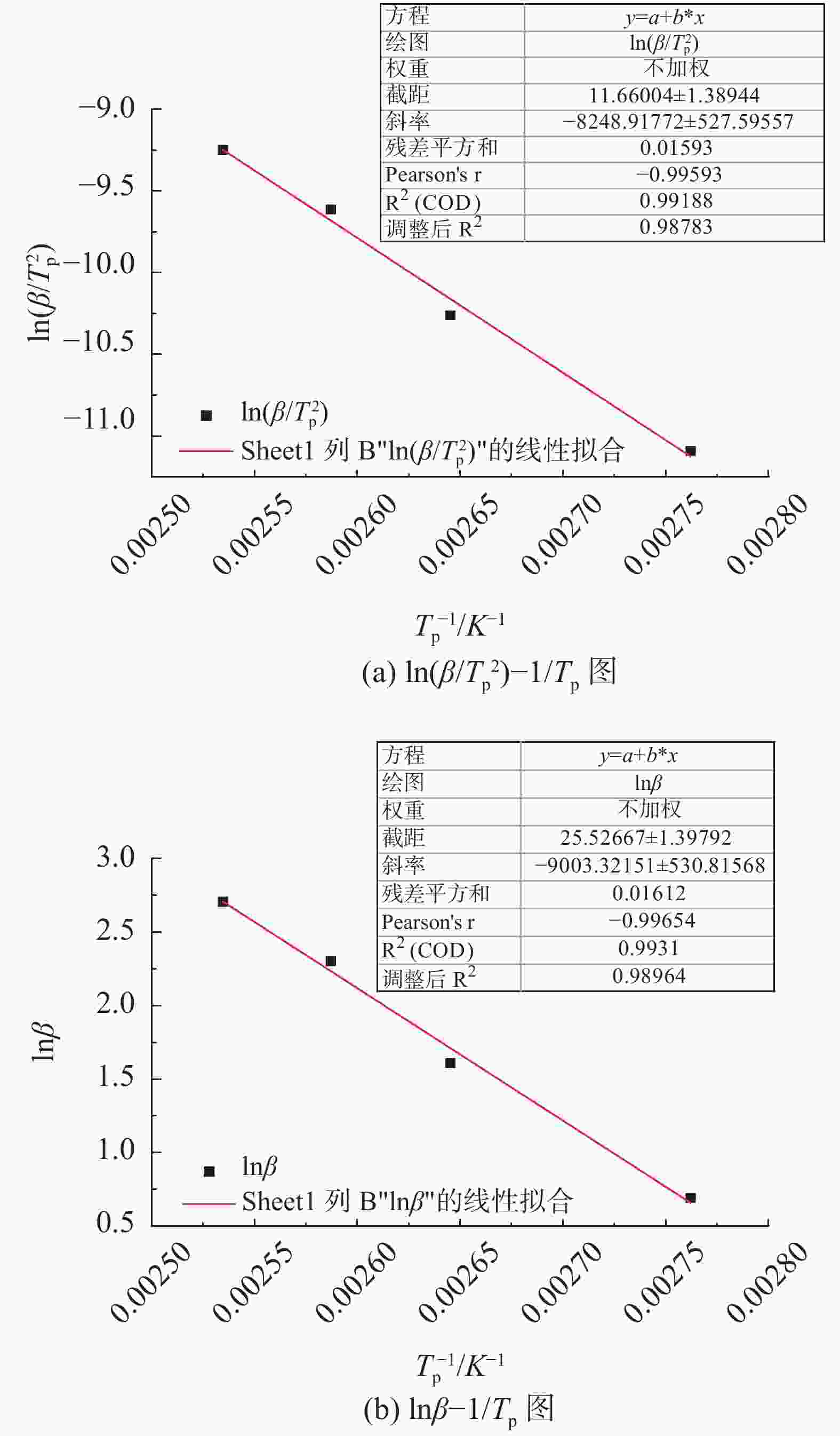

T养护/℃ LAA/% SAA/% 促进剂/% p7 d/MPa 60 23 0 1 >69.75 70 21 2 1 >69.75 80 19 4 1 >69.75 90 17 6 1 63.73±3.62 表 4 MDA和LAA体系峰值温度和动力学参数

峰值温度或

动力学参数MDA体系 LAA体系 1#峰 2#峰 2 K-Tp/K 340.60 362.05 417.05 5 K-Tp/K 355.10 378.05 437.05 10 K-Tp/K 365.10 386.55 457.05 15 K-Tp/K 371.60 394.55 465.05 Ea/(kJ·mol-1) 62.68 68.58 55.28 A 5.213×108 9.556×108 6.657×105 n 0.9139 0.9163 0.8827 -

[1] 王波,王太,王荣. 海上油井压裂风险及应对[J]. 产业创新研究,2020(14):130-131.WANG Bo, WANG Tai, WANG Rong. Offshore oil well fracturing risks and countermeasures[J]. Industrial Innovation, 2020(14):130-131. [2] 张聪,张景富,乔宏宇,等. CO2腐蚀油井水泥石的深度及其对性能的影响[J]. 钻井液与完井液,2010,27(6):49-51. doi: 10.3969/j.issn.1001-5620.2010.06.014ZHANG Cong, ZHANG Jingfu, QIAO Hongyu, et al. Corrosion depth and effect on oil well cement stone by CO2[J]. Drilling Fluid & Completion Fluid, 2010, 27(6):49-51. doi: 10.3969/j.issn.1001-5620.2010.06.014 [3] ZHANG Y, SONG X, XU M, et al. Review of research on corrosion prevention and control of oilwell cement[J]. Applied Chemical Industry, 2019, 48(10):2450-2455. [4] 李进,龚宁,李早元,等. 射孔完井工况下固井水泥环破坏研究进展[J]. 钻井液与完井液,2016,33(6):10-16. doi: 10.3969/j.issn.1001-5620.2016.06.002LI Jin,GONG Ning,LI Zaoyuan,et al. Progress in studying cement sheath failure in perforated wells[J]. Drilling Fluid & Completion Fluid, 2016, 33(6):10-16. doi: 10.3969/j.issn.1001-5620.2016.06.002 [5] 韩耀图,李进,张磊,等. 聚能射孔对水泥环的冲击损伤试验及数值模拟[J]. 石油机械,2019,47(8):1-7. doi: 10.16082/j.cnki.issn.1001-4578.2019.08.001HAN Yaotu, LI Jin, ZHANG Lei, et al. Experiment and numerical simulation on the damage to the cement sheath during shaped perforation[J]. China Petroleum Machinery, 2019, 47(8):1-7. doi: 10.16082/j.cnki.issn.1001-4578.2019.08.001 [6] 卢海川,李宗要,高继超,等. 油气井用合成树脂胶凝材料研究综述[J]. 钻井液与完井液,2018,35(5):1-7. doi: 10.3969/j.issn.1001-5620.2018.05.001LU Haichuan, LI Zongyao, GAO Jichao, et al. Review of studies on synthetic resin cementitious materials used in oil and gas wells[J]. Drilling Fluid & Completion Fluid, 2018, 35(5):1-7. doi: 10.3969/j.issn.1001-5620.2018.05.001 [7] 符军放,赵琥,项先忠. 一种固井合成水泥石的研制与室内评价[J]. 钻井液与完井液,2015,32(2):61-63. doi: 10.3969/j.issn.1001-5620.2015.02.016FU Junfang, ZHAO Hu, XIANG Xianzhong. Development and evaluation of a compound set cement for well cementing[J]. Drilling Fluid & Completion Fluid, 2015, 32(2):61-63. doi: 10.3969/j.issn.1001-5620.2015.02.016 [8] 郭锦棠,杜江波,冯杰,等. 高温高压钻井用堵漏材料的制备及性能研究[J]. 天津大学学报(自然科学与工程技术版),2021,54(6):593-598.GUO Jintang, DU Jiangbo, FENG Jie, et al. Preparation and performance of plugging material for high-temperature and high-pressure drilling[J]. Journal of Tianjin University(Science and Technology) , 2021, 54(6):593-598. [9] JONES P J,KARCHER J D,RUCH A. Rigless operation to restore wellbore integrity using synthetic-based resin sealants[C]//SPE/EAGE European Unconventional Resources Conference and Exhibition: Unlocking European Potential: proceedings, 25-27 February 2014 Reed Messe Wien, Vienna, Austria: Society of Petroleum Engineers, 2014: 1-9. [10] ELYAS O,ALYAMI A,WAGLE V,et al. Use of polymer resins for surface annulus isolation enhancement[C]// SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, 2018. [11] SANABRIA A E , KNUDSEN K , LEON G A . Thermal activated resin to repair casing leaks in the Middle East[C]// Abu Dhabi International Petroleum Exhibition & Conference, 2016. [12] QIN J,ZHANG G,SUN R,et al. Synthesis of aromatic amine curing agent containing non-coplanar rigid moieties and its curing kinetics with epoxy resin[J]. Journal of Thermal Analysis & Calorimetry, 2014, 117(2):831-843. [13] MORONI A, MIJOVIC J, PEARCE E M, et al. Cure kinetics of epoxy resins and aromatic diamines[J]. Journal of Applied Polymer Science, 1986, 32(2):3761-3773. doi: 10.1002/app.1986.070320231 [14] KISSINGER H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry, 1957, 29(11):1702-1706. doi: 10.1021/ac60131a045 [15] CRANE L W,DYNES P,KAELBLE D. Analysis of curing kinetics in polymer composites[J]. Journal of Polymer Science:Polymer Letters Edition, 1973, 11(8):533-540. doi: 10.1002/pol.1973.130110808 -

下载:

下载: