Well Cementing with Low Friction Pressure Resistant Leaking Preventive Low Density Cement Slurry

-

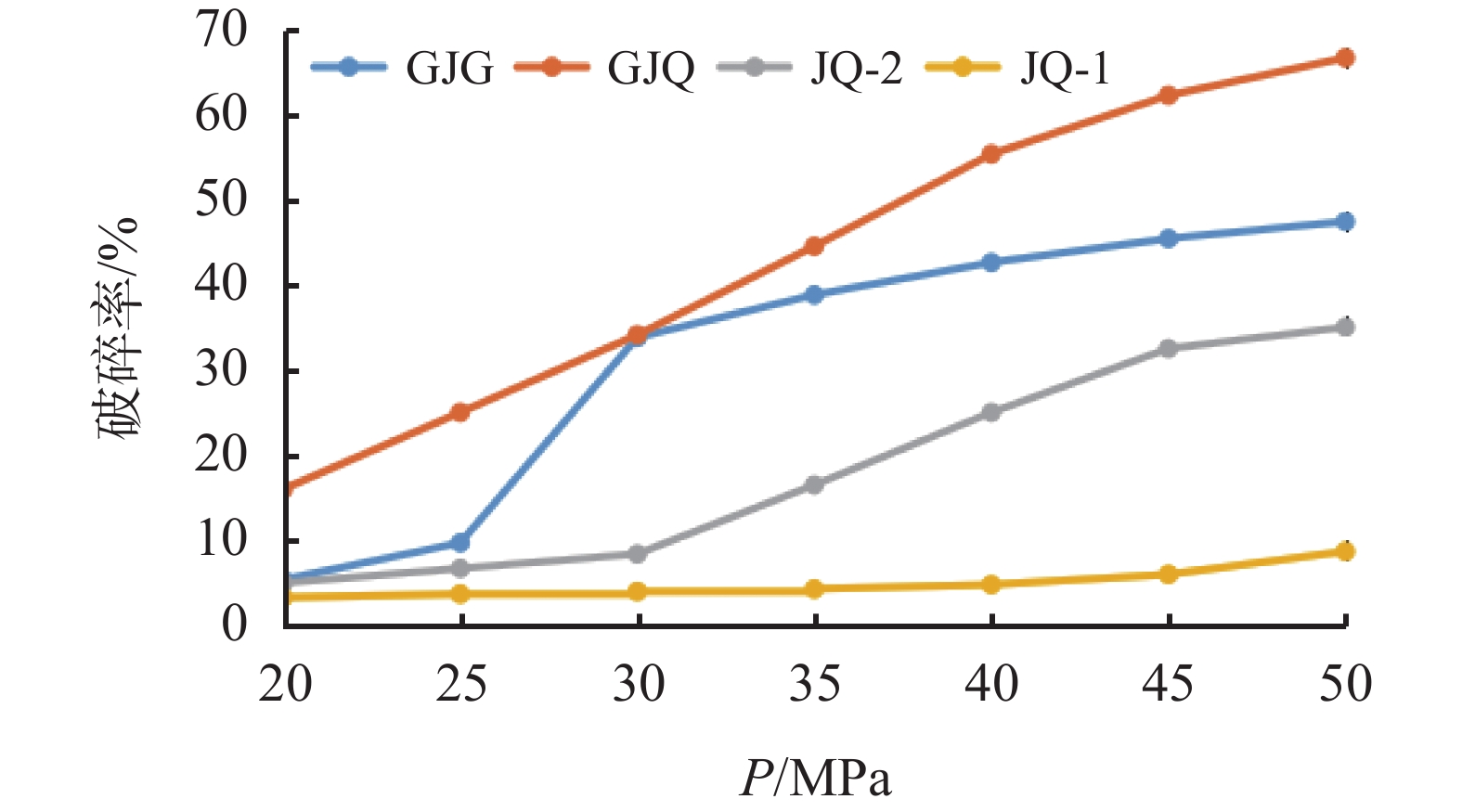

摘要: 长庆苏里格气田刘家沟组地层承压能力低,现有低密度水泥浆体系耐压性能差,受压后密度上升、流变性能差,施工压力高,易发生漏失,造成水泥浆返高不够、封固段固井质量差。为此设计研发了一种低摩阻耐压防漏低密度水泥浆体系,运用紧密堆积理论进行水泥浆四级颗粒级配,优选耐压性能优良的减轻材料,选用合适的外加剂形成低摩阻耐压防漏低密度水泥浆配方。水泥浆密度为1.25~1.35 g/cm3,范宁摩阻系数降低约50%;耐压性能良好,防漏效果明显,综合性能优良。开展混拌工艺研究,采用纯机械混拌工艺,混拌大样与小样性能吻合率达到99%,保证了混灰质量和效率。在苏里格气田试验应用4口井,固井施工正常,未发生漏失,固井质量合格;施工压力明显降低,固井质量显著提升,为低压易漏地层固井提供有力的技术支撑。Abstract: In the Sulige gas field in Changqing Oilfield, the Liujiagou formation is a low pressure formation, the low density cement slurries presently used in this area have poor pressure resistance; the cement slurries under high pressures will have their density increased and rheology deteriorated. In field operations with these cement slurries, the operation pressures were high, generally causing the cement slurries to be lost into the formations, and the cementing quality is poor because of less cement slurries in the annulus. To solve this problem, a new cement slurry with low friction low density was formulated. This new cement slurry is pressure resistant and has the property of preventing itself from being lost into formations. Using the close packing theory, particles of 4 sizes were selected. A light material with excellent pressure resistance and other appropriate additives were selected to formulate the target cement slurry. The density of the new cement slurry is adjustable between 1.25 g/cm3 and 1.35 g/cm3, the Fanning friction coefficient was reduced by about 50%. The new cement slurry has good pressure resistance and leaking preventive property. Study on the agitation and mixing techniques shows that mechanical agitation and mixing can be used, 99% of the properties of the bulk sample and those of the small sample coincide with each other, ensuring the qualification and efficiency of the cement mixing. In field operations in the Sulige gas field, four wells were cemented with success, no loss of cement slurry has ever happened, and the cementing job was qualified. During the cementing, the operational pressure was significantly reduced, and the job quality was obviously improved. This laboratory study and the field application provide a strong technical support to cementing wells penetrating low pressure formations into which cement slurries are easily lost.

-

Key words:

- Low friction /

- Particle sizing /

- Pressure resistance /

- Leaking prevention /

- Mixing technique /

- Well cementing

-

表 1 YB-G水泥的粒度分布

粒径/

μm粒度累计

频度/%粒径/

μm粒度累计

频度/%粒径/

μm粒度累计

频度/%≤0.41 0.47 ≤11.04 40 ≤42.09 90 ≤1.00 5.00 ≤14.98 50 ≤62.38 97 ≤1.75 10.00 ≤19.08 60 ≤73.88 98 ≤4.33 20.00 ≤23.94 70 ≤104.70 99 ≤7.46 30.00 ≤30.75 80 ≤150 100 表 2 YB-G水泥最紧密堆积粒度分布

粒径/

μm堆积粒度

累计频度/%粒径/

μm堆积粒度

累计频度/%粒径/

μm堆积粒度

累计频度/%≤0.41 13.98 ≤11.04 41.91 ≤42.09 65.47 ≤1.00 18.82 ≤14.98 46.40 ≤62.38 74.64 ≤1.75 22.68 ≤19.08 50.29 ≤73.88 78.97 ≤4.33 30.68 ≤23.94 54.24 ≤104.70 88.71 ≤7.46 36.77 ≤30.75 58.96 ≤150.00 100 表 3 水泥浆基浆配方

配方 材料配比 水灰比 ρ/(g·cm−3) 1# 12%JQ-1+8%JQ-2+

55%YB-G+25%TC-40.65 1.25 2# 11%JQ-1+6%JQ-2+

58%YB-G+25%TC-40.64 1.30 3# 10%JQ-1+5%JQ-2+

60%YB-G+25%TC-40.62 1.35 表 4 水泥浆配方基础性能

水泥浆 ρ/

g·cm−3初始稠度/

Bct稠化/

minFL/

mL游离液/

%1# 1.25 15 246 56 0.2 2# 1.30 16 239 52 0.2 3# 1.35 15 253 50 0.2 水泥浆 p24 h/

MPa

(45 ℃)p48 h/

MPa

(45 ℃)p24 h/

MPa

(75 ℃)p48 h/

MPa

(75 ℃)流动度/

cm1# 6.5 9.7 8.7 12.6 21.0 2# 7.1 10.5 9.2 13.1 21.5 3# 7.4 10.9 9.3 13.4 20.5 表 5 水泥浆承压前后性能

水泥浆 P/

MPaρ/

g·cm−3稠度/

Bc流动度/

cmn K/

Pa·sn范宁摩阻

系数fⅠ 常压 1.30 14 21.0 0.47 0.92 0.0356 40 1.47 20 17.0 0.36 3.60 0.0714 Ⅱ 常压 1.30 15 21.5 0.61 0.42 0.0323 40 1.32 16 20.5 0.60 0.48 0.0347 注:水泥浆体系Ⅰ为轻珠低密度水泥浆,水泥浆体系Ⅱ为低摩阻耐压防漏低密度水泥浆;养护条件为80 ℃养护30 min 表 6 水泥浆的防漏性能

水泥浆 不同漏层模型下的承压能力(稳压10 min)/MPa 20目孔隙+

1 mm缝隙20目孔隙+

2 mm缝隙20目孔隙+

3 mm缝隙Ⅰ 3.6 2.1 0.9 Ⅱ 5.5 4.2 2.9 表 7 低摩阻耐压防漏低密度小样与混配大样性能对比

样品 ρ/

g/cm3初始稠度/

Bct稠化/

minFL/

mL游离液/

%小样 1.30 16 239 52 0.2 大样1 1.30 15 242 52 0.2 大样2 1.30 16 238 52 0.2 样品 p24 h/

MPa

(45 ℃)p48 h/

MPa

(45 ℃)p24 h/

MPa

(75 ℃)p48 h/

MPa

(75 ℃)流动度/

cm小样 7.1 10.5 9.2 13.1 21.5 大样1 7.0 10.3 9.3 13.0 21.5 大样2 7.2 10.6 9.2 13.3 22.0 表 8 2种低密度水泥浆固井情况对比

组号 井号 井深/m 垂深/m 施工压力/MPa 水泥返出情况 封固段合格率% 封固段优质率% A S 36-*-* 3532 3496 0-24-30 正常 99.54 98.97 B S 36-*-*C4 3581 3500 0-28-33 正常 93.41 88.08 A S 14-*-*C4 3792 3579 0-23-28 正常 98.26 93.67 B S 14-*-*C2 3632 3581 0-28-33 漏失3 m3 91.99 85.75 A S 14-*-*C6 3740 3646 0-23-28 正常 99.66 96.65 B S 14-*-*C8 3836 3652 0-25-30 正常 97.26 87.71 A SD51-*C2 3479 3161 0-22-27 正常 98.25 94.24 B SD51-*C3 3342 3119 0-24-28 漏失5 m3 94.05 81.90 注:A组为使用低摩阻耐压防漏低密度水泥浆,B组为使用轻珠低密度水泥浆 -

[1] 黄柏宗. 紧密堆积理论优化的固井材料和工艺体系[J]. 钻井液与完井液,2001,18(6):1-9. doi: 10.3969/j.issn.1001-5620.2001.06.001HUANG Bozong. Cementing material and process system optimized by compact stacking theory[J]. Drilling Fluid & Completion Fluid, 2001, 18(6):1-9. doi: 10.3969/j.issn.1001-5620.2001.06.001 [2] 孙勤亮,付家文,杨远光,等. 超低密度水泥浆的粒度级配模型及应用研究[J]. 石油化工应用,2017,36(6):93-96. doi: 10.3969/j.issn.1673-5285.2017.06.020SUN Qinliang, FU Jiawen, YANG Yuanguang, et al. Study on particle size distribution model for ultra-low density cement slurry and its application[J]. Petrochemical Industry Appication, 2017, 36(6):93-96. doi: 10.3969/j.issn.1673-5285.2017.06.020 [3] 黄柏宗. 紧密堆积理论的微观机理及模型设计[J]. 石油钻探技术,2007,35(1):5-12. doi: 10.3969/j.issn.1001-0890.2007.01.002HUANG Bozong. Microscopic mechanisms and model design of close packing theory[J]. Drillng Petroleum Techniques, 2007, 35(1):5-12. doi: 10.3969/j.issn.1001-0890.2007.01.002 [4] 李韶利. 1.15 g/cm3超低密度水泥浆的研究与应用[J]. 钻井液与完井液,2020,37(5):644-650.LI Shaoli. Study and application of an ultra-low-density cement slurry[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):644-650. [5] 李明. 典型矿物材料对固井水泥性能影响的机理研究及应用[D]. 西南石油大学, 2011.LI Ming. Research and application of effect of typical mineral materials on the cement system[D]. Southwest Petroleum University, 2011. [6] 郑少军,王凯伦,刘思雨,等. 基于紧密堆积理论的低密度固井水泥浆设计[J]. 钻探工程,2021,48(3):94-100.ZHENG Shaojun, WANG Kailun, LIU Siyu, et al. Design of low density cementing slurry based on close packing theory[J]. Drilling Engineering, 2021, 48(3):94-100. [7] 刘崇建, 黄柏宗, 徐同台, 等. 油气井注水泥理论与应用[M]. 北京: 石油工业出版社, 2001.LIU Chongjian, HUANG Bozong, XU Tongtai, et al. Theory and application of cementing in oil and gas wells[M]. Beiing: Petroleum Industry Press, 2001. [8] 刘学鹏,刘仍光. 油井水泥降失水剂的作用机理研究[J]. 化学研究与应用,2017,29(12):1928-1932. doi: 10.3969/j.issn.1004-1656.2017.12.027LIU Xuepeng, LIU Rengguan. Mechanisms involved in fluid loss control of oilwell cement slurries by water-soluble polymer[J]. Chemical Research and Application, 2017, 29(12):1928-1932. doi: 10.3969/j.issn.1004-1656.2017.12.027 [9] 李宪国. 高温高压小间隙固井摩擦阻力的分析计算[J]. 石油天然气学报,2005,27(4):647-648.LI Xianguo. Analysis and calculation of high temperature high pressure(HTHP)and small clearance cementing friction drag[J]. Journal of Oil and Gas Technology, 2005, 27(4):647-648. [10] 冯青豪. 注水泥流动摩阻的准确计算方法研究与现场应用[D]. 成都: 西南石油大学, 2016: 22-39.FENG Qinhao. Research and field application of accurate calculation method of cement flow friction[D]. Chengdu: Southwest Petroleum University, 2016: 22-39. [11] 张文,张景富. 固井注水泥过程计算机仿真[J]. 科学技术与工程,2010,10(15):3767-3771.ZHANG Wen, ZHANG Jingfu. Computer simulation of cementing process[J]. ScienceTechnology and Engineering, 2010, 10(15):3767-3771. [12] 李波,魏周胜,周兵,等. 防渗漏水泥浆体系的研究与应用[J]. 钻井液与完井液,2012,29(1):60-62. doi: 10.3969/j.issn.1001-5620.2012.01.017LI Bo, WEI Zhousheng, ZHOU Bing, et al. Research and application on anti-leakage cement slurry system[J]. Drilling Fluid & Completion Fluid, 2012, 29(1):60-62. doi: 10.3969/j.issn.1001-5620.2012.01.017 [13] 闵江本,马学如,张战臣. 复合空心玻璃微珠水泥浆体系在长庆定吴区块的应用[J]. 石油地质与工程,2020,11,34(4):113-117. doi: 10.3969/j.issn.1673-8217.2020.06.023MIN Jiangben, MA Xueru, ZHANG Zhanchen. Application of composite hollow glass microsphere cement slurry system in Dingwu block of Changqing[J]. Petroleum Geology and Engineering, 2020, 11,34(4):113-117. doi: 10.3969/j.issn.1673-8217.2020.06.023 [14] 潘南林. 固井水泥灰干混层铺工艺及干混装置研究[J]. 石油机械,2005,33(11):51-53. doi: 10.3969/j.issn.1001-4578.2005.11.017PAN Nanlin. Study on laying technology and dry mixing device of cementing cement ash dry mixing layer[J]. China Petroleum Machinery, 2005, 33(11):51-53. doi: 10.3969/j.issn.1001-4578.2005.11.017 [15] 赵清忠. 自动混拌系统的研究与改进[J]. 中国石油和化工标准与质量,2012,32(S1):297.ZHAO Qingzhong. Research and improvement of automatic mixing system[J]. China Petroleum and Chemical Standard and Quality, 2012, 32(S1):297. -

下载:

下载: