High Temperature High Density Cement Slurry with Corrosion Inhibition Property

-

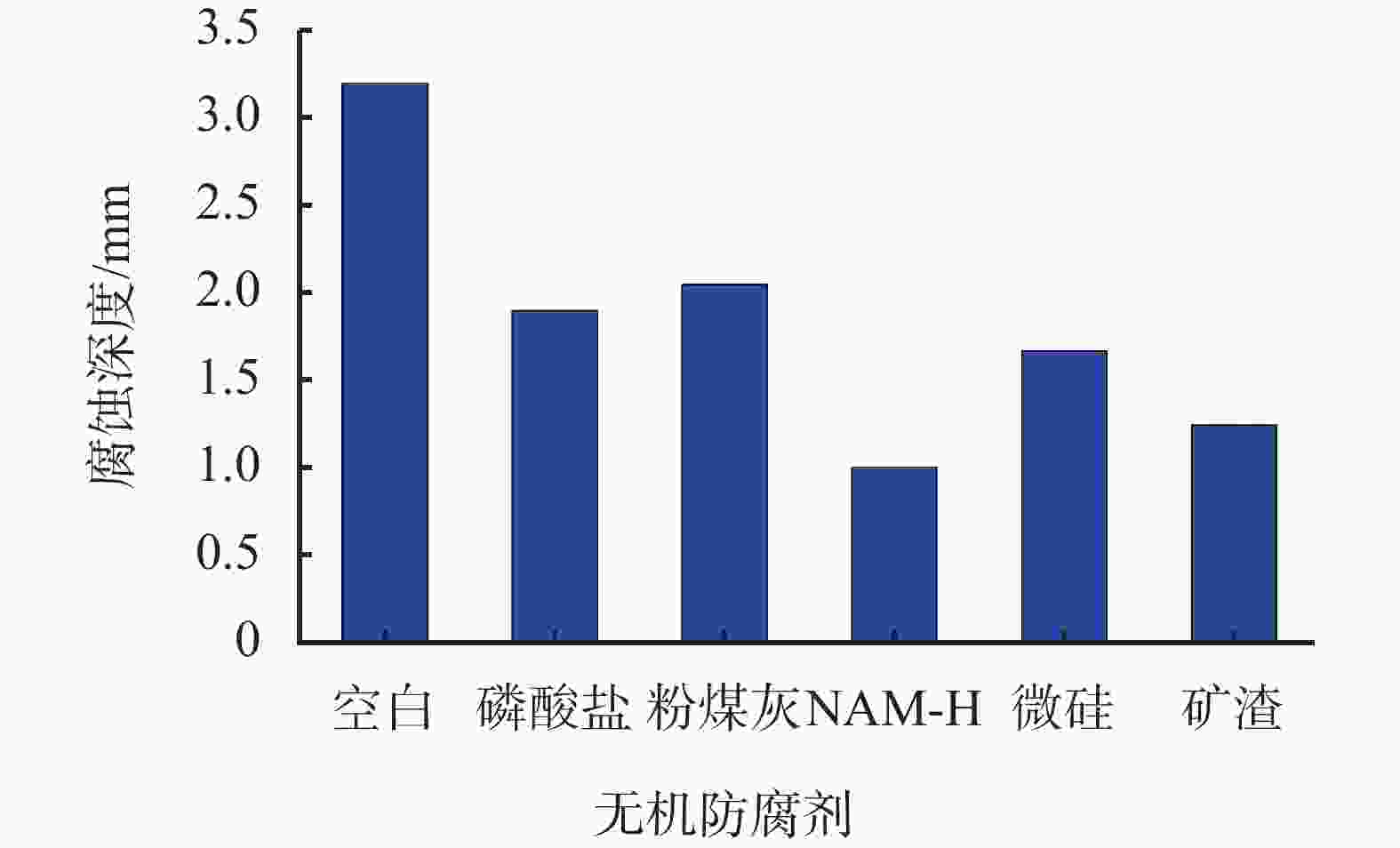

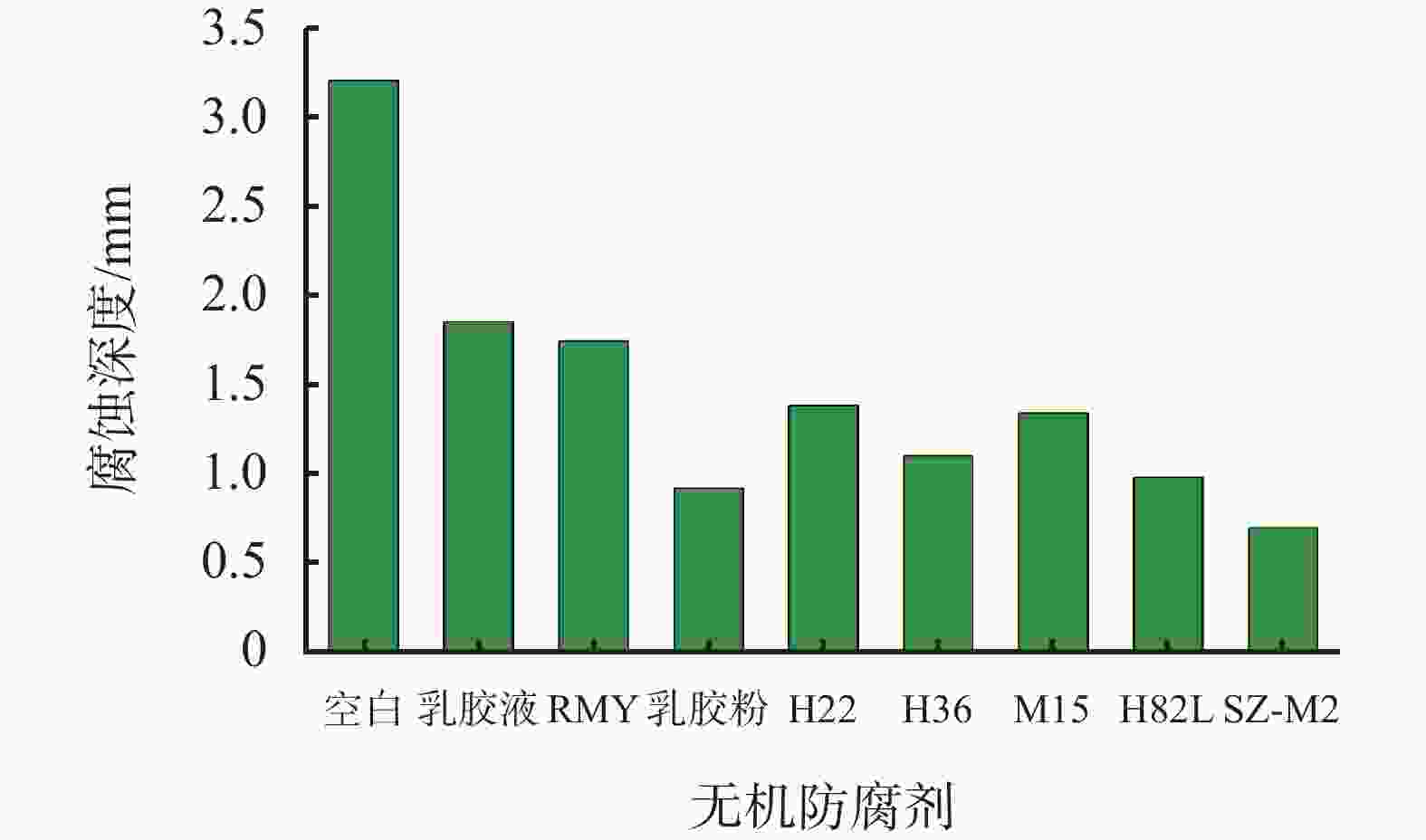

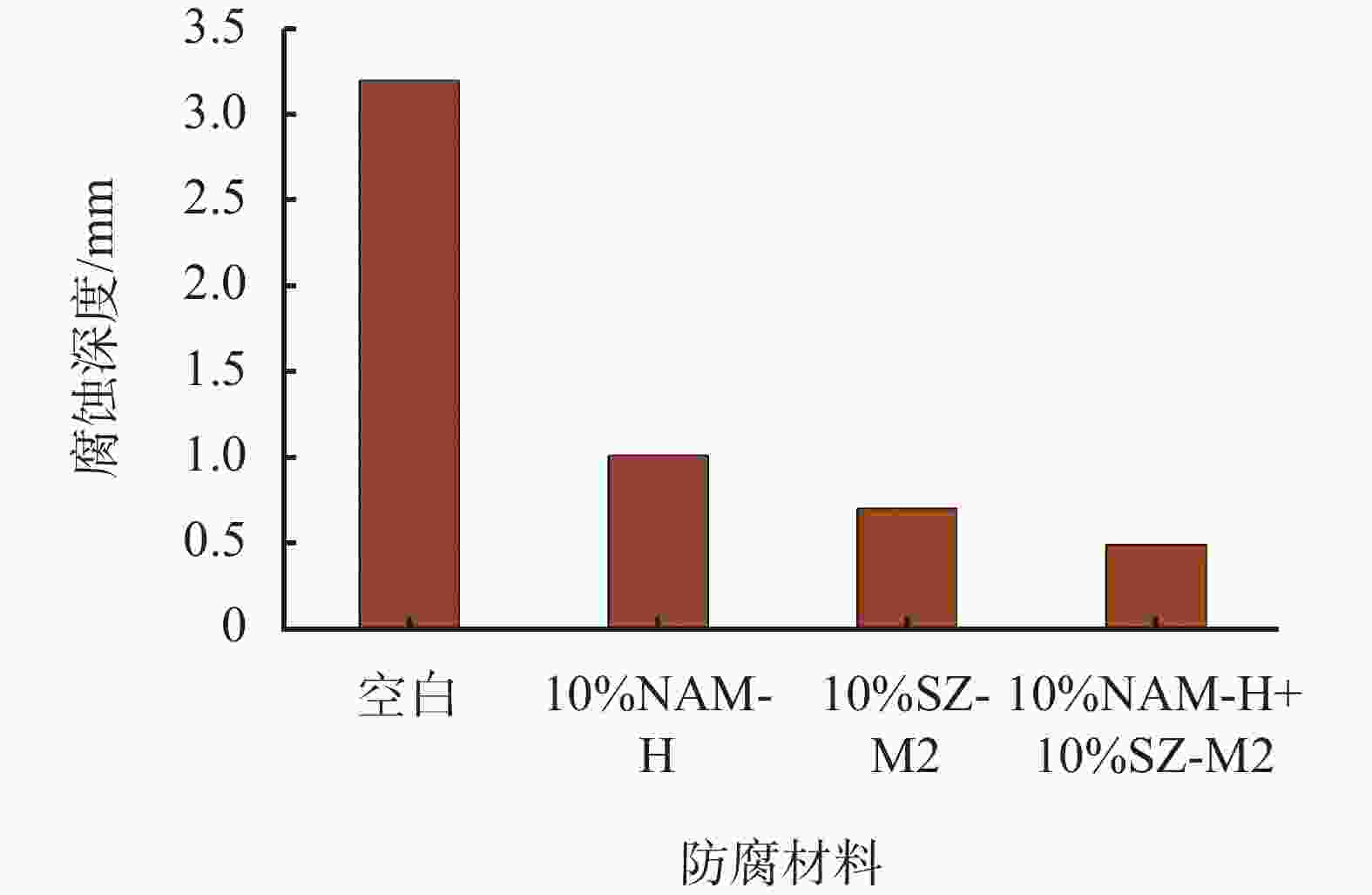

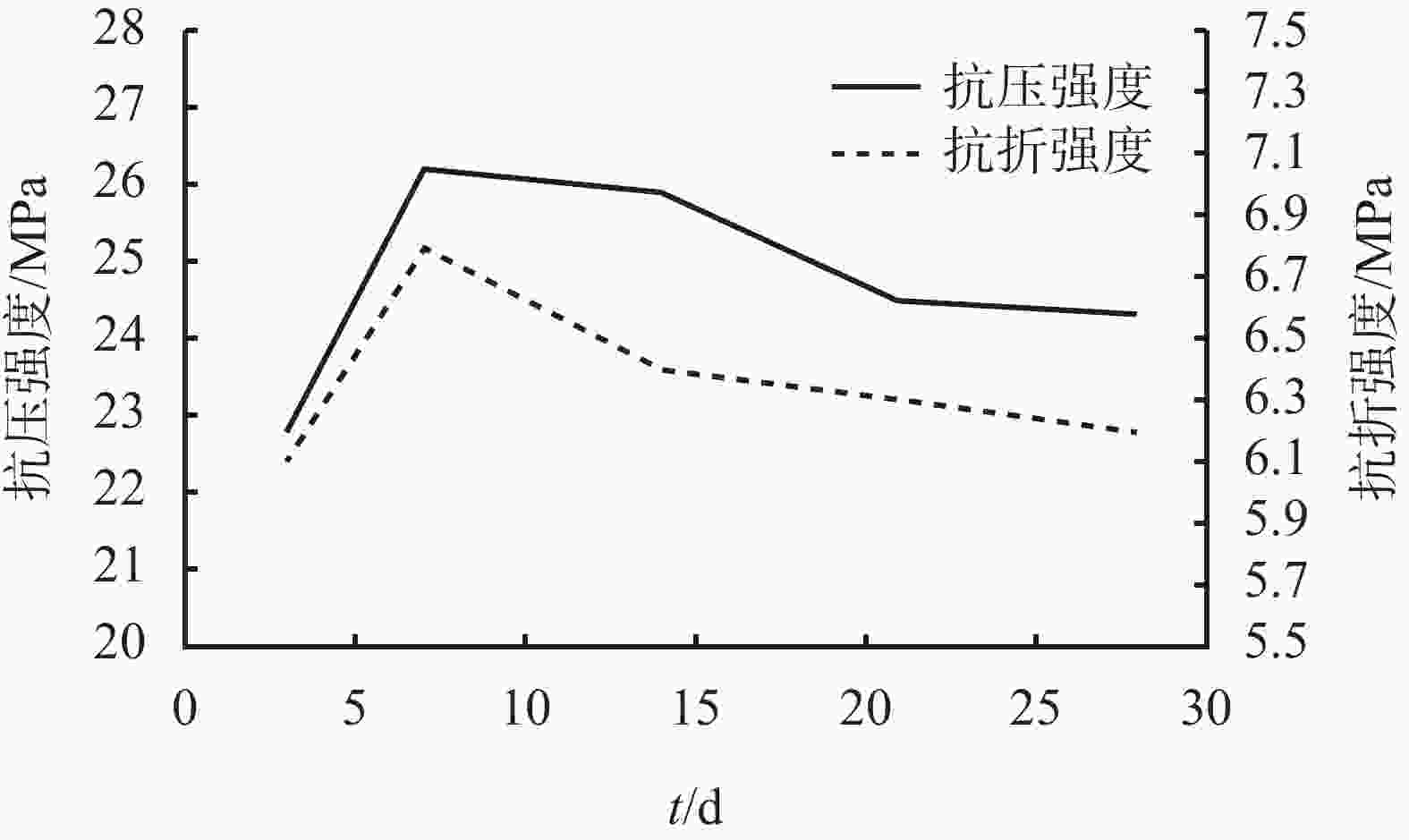

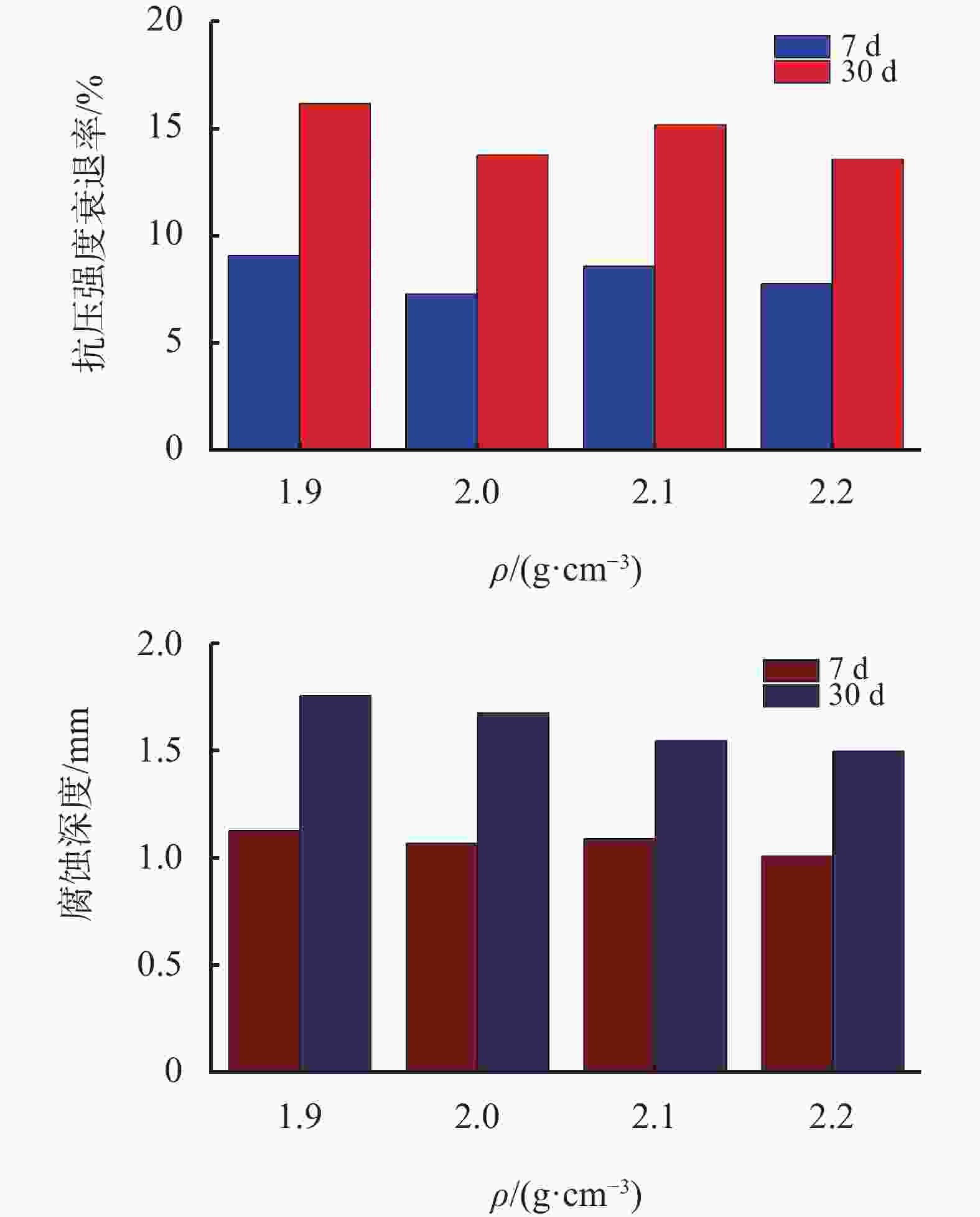

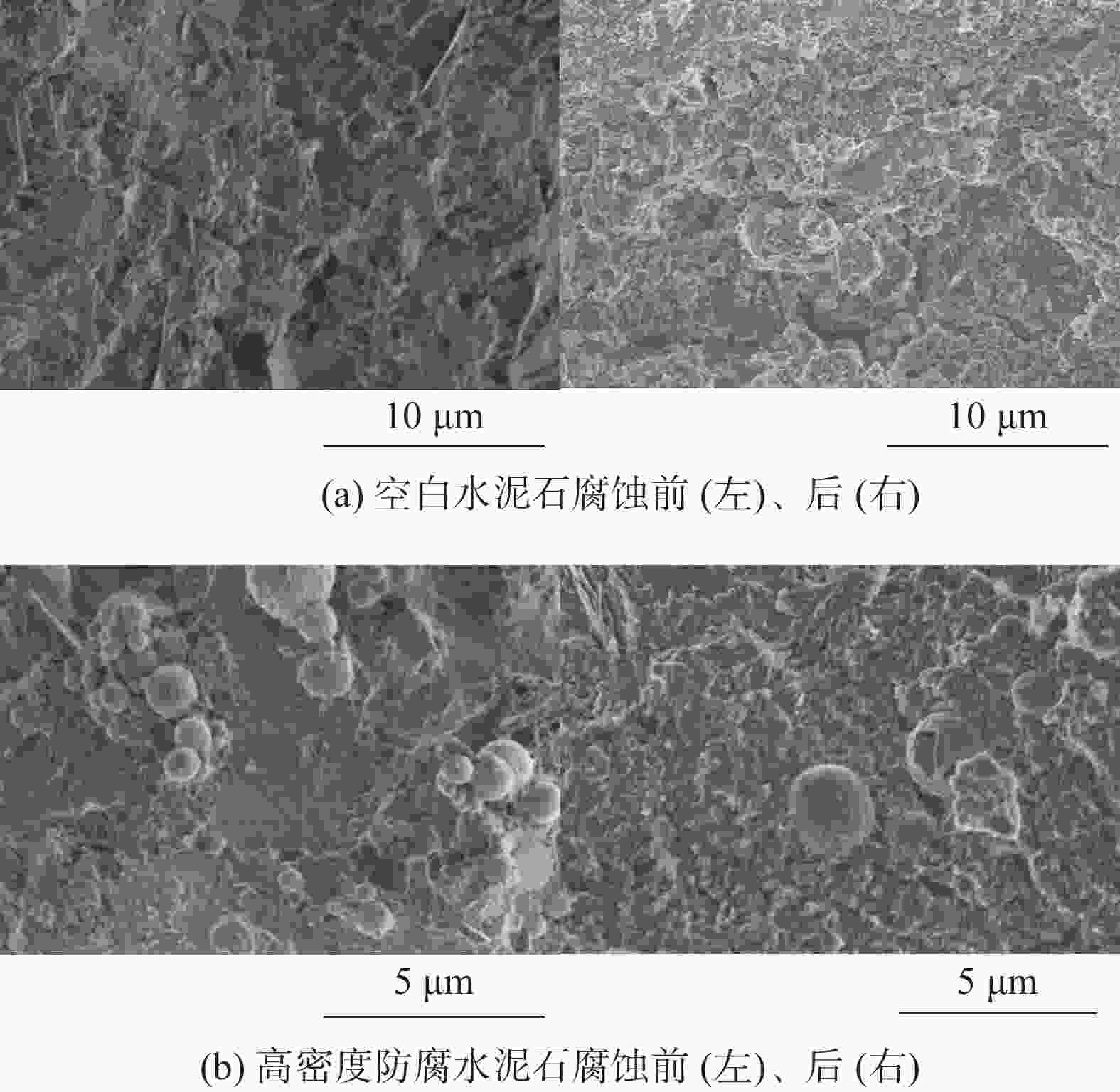

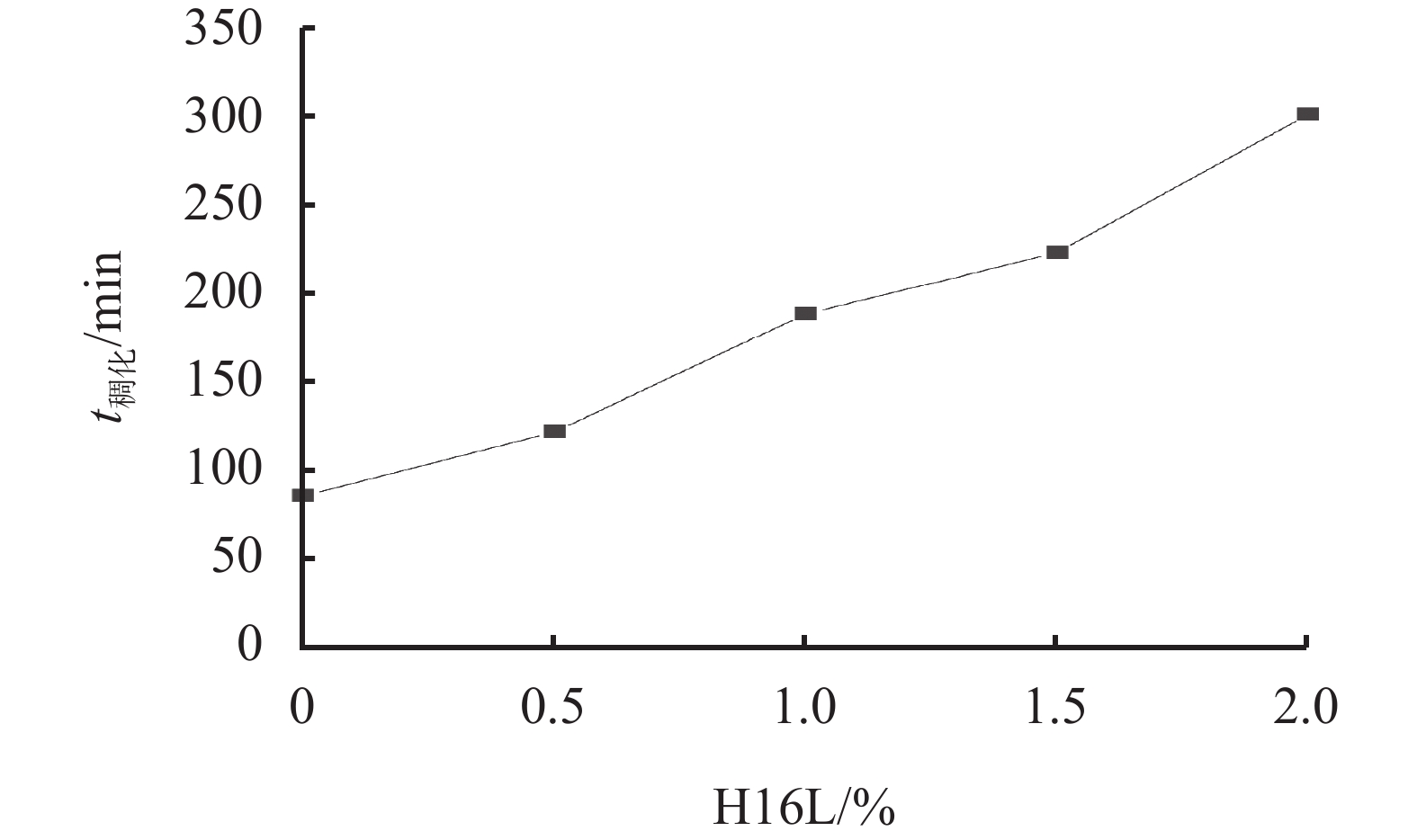

摘要: 深层含酸性气体油气井中,高温、高压含CO2气体环境易腐蚀水泥石,破坏水泥环密封完整性。为开发具有防腐能力的高温高密度固井水泥浆体系,对水泥浆关键材料进行研究,构建了抗高温高密度防腐水泥浆体系,分析了水泥浆性能和微观形貌。实验结果表明,锰矿粉加重剂能显著提高水泥浆密度,制备的水泥浆体系高温下抗腐蚀能力较好;研究的降失水剂JS18L、缓凝剂H16L在高温下能降低水泥浆失水量,调节稠化时间。将无机复合防腐剂NAM-H、聚合物防腐剂SZ-M2结合使用,作为防腐材料可增强水泥石防腐性能。使用研究的添加剂材料构建密度为1.90~2.20 g/cm3的抗高温高密度防腐水泥浆,水泥浆体系流变性好,稳定性高,失水量小于50 mL,稠化时间在3~5 h可调,满足固井作业要求。高密度水泥石高温下力学性能稳定,防腐能力强,水泥石腐蚀30 d的抗压强度衰退率在25%以内,腐蚀深度小于1.5 mm。该研究成果可为高温高压酸性气井以及二氧化碳地质封存井固井作业提供技术支持。Abstract: CO2 gas in the deeper part of a high temperature high pressure well generally causes corrosion to the set cement and damages the sealing integrity of the cement sheath. To develop a high temperature high density cement slurry with high corrosion inhibitive capacity, studies were conducted on the key cement materials, and a high temperature high density cement slurry with high corrosion inhibitive capacity was formulated. Analyses of the performance and micro morphology of the cement slurry show that manganese ore powder weighting material can remarkably increase the density of a cement slurry, and the cement slurry also has good corrosion inhibition property at high temperature. In formulating the cement slurry, a filter loss reducer JS18L was used to control high temperature filtration rate, and a cement retarder H16L was used to control thickening time. The corrosion inhibitive capacity of the cement slurry was improved with the use of an inorganic corrosion inhibitor NAM-H and an organic corrosion inhibitor SZ-M2. Using these materials, a high temperature high density (1.90-2.20 g/cm3) cement slurry was formulated. The new cement slurry has good rheology, good stability, low filter loss of less than 50 mL and thickening time adjustable between 3 h and 5 h. The high density set cement at high temperatures has stable mechanical properties and good corrosion inhibitive capacity. The deterioration rate of the 30 d compressive strength of the set cement is less than 25%, and the depth of corrosion is less than 1.5 mm. The results of the study provide technical support to the cementing of high temperature high pressure wells with acid gases and CO2 geological sequestration wells.

-

Key words:

- Well cementing /

- Cement slurry /

- High temperature /

- High density /

- Corrosion inhibition

-

表 1 不同加重剂水泥浆的性能(150 ℃)

加重剂 ρ/(g·cm−3) φ300 p24 h/MPa 30 d腐蚀深度/mm 重晶石 2.03 275 22.3 8.33 铁矿粉 2.11 248 25.6 5.52 锰矿粉 2.10 176 28.6 5.24 表 2 JS18L加量对水泥浆性能的影响(150 ℃)

JS18L/% p24 h/MPa FL/mL 0 26.1 96 2 25.8 74 4 25.2 55 6 24.7 40 8 23.5 31 表 3 不同缓凝剂水泥浆的稠化时间(150 ℃×70 MPa)

缓凝剂 t稠化/min 稠化过渡时间/min 空白 66 22 H16L 213 9 G45L 119 15 JA-21 192 12 M142 158 14 表 4 抗高温高密度防腐水泥浆体系施工性能评价

ρ/

g·cm-3流变性(93 ℃) FL/

mLt 稠化

(150 ℃×70 MPa)/minn K/Pa·sn 1.9 0.88 0.48 40 253 2.0 0.89 0.46 37 287 2.1 0.90 0.45 38 292 2.2 0.92 0.47 35 243 -

[1] 王雯娟,雷霄,鲁瑞彬,等. 南海西部异常高温高压气藏区域产能预测技术[J]. 地球科学,2019,44(8):2636-2642.WANG Wenjuan, LEI Xiao, LU Ruibin, et al. Regional productivity prediction technology for abnormal high temperature and high pressure gas reservoirs in western south China sea[J]. Earth Science, 2019, 44(8):2636-2642. [2] 赵健,赵俊峰,任康绪,等. 巴西桑托斯盆地高含CO2油气藏类型、特征及成因模式[J]. 吉林大学学报(地球科学版),2021,51(6):1654-1664.ZHAO Jian, ZHAO Junfeng, REN Kangxu, et al. Main types, characteristics and genetic model of oil & gas reservoirs with high CO 2 content in Santos basin, Brazil[J]. Journal of Jilin University(Earth Science Edition) , 2021, 51(6):1654-1664. [3] 朱忠锋. 蓬莱油田油套管腐蚀机理研究[D]. 北京: 中国石油大学(北京), 2019.ZHU Zhongfeng. Study on corrosion mechanism of oil casing in Penglai oilfield analysis[D]. Beijing: China University of Petroleum (Beijing), 2019. [4] BIHUA X, BIN Y, YONGQING W, et al. H2S-CO2 mixture corrosion-resistant Fe2O3-amended wellbore cement for sour gas storage and production wells[J]. Construction and Building Materials, 2018, 188:161-169. doi: 10.1016/j.conbuildmat.2018.08.120 [5] BRUCKDORFER R A. Carbon dioxide corrosion in oil well cements[A] //Rocky Mountain Regions ed. Meeting of the Society of Petroleum Engineers[C]. SPE 15176, 1986: 1–9. [6] SHEB J C. Effect of CO2 attack on cement in hightemperrature applications[A]//SPE/IADC Drilling Conference[C]. Dallas, Texas, American, SPE/IADC18618, 1989: 1-8. [7] OMOTAYO O, HIMANSHU M, RAMADAN A, et al. Experimental study of the effects of CO2 concentration and pressure at elevated temperature on the mechanical integrity of oil and gas well cement[J]. Journal of Natural Gas Science and Engineering, 2017, 44:299-313. doi: 10.1016/j.jngse.2017.04.009 [8] ZHENG Guanyi ,GUO Xiaoyang , LI Zaoyuan , et al. Design and evaluation of high temperature well cementing slurry system based on fractal theory[J]. Energies, 2021, 14(22):7552. doi: 10.3390/en14227552 [9] 李光辉. 超高密度水泥浆体系实验研究与应用[J]. 科学技术与工程,2016,16(11):147-151.LI Guanghui. Experimental research and application of ultra high density cement slurry system[J]. Science Technology and Engineering, 2016, 16(11):147-151. [10] 赵军,徐璧华,邱汇洋,等. 抗高温防CO2和H2S腐蚀水泥浆体系研发与应用[J]. 中国海上油气,2017,29(3):91-94.ZHAN Jun, XU Bihua, QIU Huiyang, et al. Development and application of high temperature resistant and CO2 and H2S resistant cement slurry system[J]. China Offshore Oil and Gas, 2017, 29(3):91-94. [11] GB/T 19139—2012, 油井水泥试验方法[S].GB/T 19139—2012, Test method for oil well cement [S]. [12] SY/T 6466—2000,油井水泥石抗高温性能评价方法[S].SY/T 6466—2000, Evaluation method of high temperature resistance of oil well cement [S]. [13] PATHANIA, A, SHUKLA, A, VASHISHT, R. Influence of mineral additives on the packing density of ternary mix[J]. Cement Wapno Beton, 2020, 25(2):153-161. [14] KNOP, Y, PELED, A, COHEN, R. Influences of limestone particle size distributions and contents on blended cement properties[J]. Construction and Building Materials, 2014, 71:26-34. doi: 10.1016/j.conbuildmat.2014.08.004 [15] 郭锦棠,刘振兴,何军,等. 新型耐温抗盐降失水剂LX-1的研制与性能评价[J]. 天津大学学报(自然科学与工程技术版),2021,54(3):318-323.GUO Jintang, LIU Zhenxing, HE Jun, et al. Synthesis and properties of a new high-temperature and salt-resistant fluid loss additive LX-1[J]. Journal of Tianjin University(Science and Technology) , 2021, 54(3):318-323. [16] 夏修建,于永金,陈洲洋,等. 一种新型超高温固井水泥浆缓凝剂[J]. 天然气工业,2021,41(9):98-104.XIA Jianjian, YU Yongjin, CHEN Zhouyang, et al. A new type of super high temperature cement slurry retarder[J]. Natural Gas Industry, 2021, 41(9):98-104. [17] 邹建龙,屈建省,许涌深,等. 油井水泥缓凝剂研究进展[J]. 油田化学,2008,25(4):386-390.ZOU Jianlong, QU Jiansheng, XU Yongshen, et al. Research progress of oil well cement retarder[J]. Oilfield Chemistry, 2008, 25(4):386-390. [18] 张聪,张景富,乔宏宇,等. 深井高温抗二氧化碳腐蚀水泥浆体系设计与优选[J]. 石油钻采工艺,2010,32(5):39-43.ZHANG Cong, ZHANG Jingfu, QIAO Hongyu, et al. Design and select of resisting corrosion cement slurries by carbon dioxide for high temperature deep well[J]. Oil Drilling & Production Technology, 2010, 32(5):39-43. [19] 张易航,宋旭辉,许明标,等. 固井水泥石腐蚀防治研究进展[J]. 应用化工,2019,48(10):2450-2455.ZHANG Yihang, SONG Xuhui, XU Mingbiao, et al. Research progress on corrosion prevention of cementing cement stone[J]. Applied Chemical Industry, 2019, 48(10):2450-2455. [20] 高浩. 矿物掺合料对混凝土防腐性能影响的研究[D]. 武汉: 武汉大学, 2017.GAO Hao. Study on the influence of mineral admixtures on the anti-corrosion performance of concrete [D]. Wuhan: Wuhan University, 2017. [21] 张红丹. 水溶性树脂水泥浆体系的抗腐蚀性能研究[D]. 成都: 西南石油大学, 2016.ZHANG Hongdan. Study on corrosion resistance of water soluble resin cement slurry system [D]. Chengdu: Southwest Petroleum University, 2016. [22] 宋鹤,杨威,唐俊峰,等. 耐高温高压超高密度水泥石力学性能[J]. 钻井液与完井液,2021,38(6):771-777.SONG he, YANG Wei, TANG Junfeng, et al. Mechanical properties of high temperature and high pressure resistant ultra-high density cement paste[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):771-777. [23] ELAHEH A, TERRY B, GIANG D. Evaluation of cement sheath integrity subject to enhanced pressure[J]. Journal of Petroleum Science and Engineering, 2018, 170:1-13. -

下载:

下载: