Study on Mechanisms of a Highly Adsorptive Polyol Ester Bonded Lubricant for Water Based Drilling Fluids

-

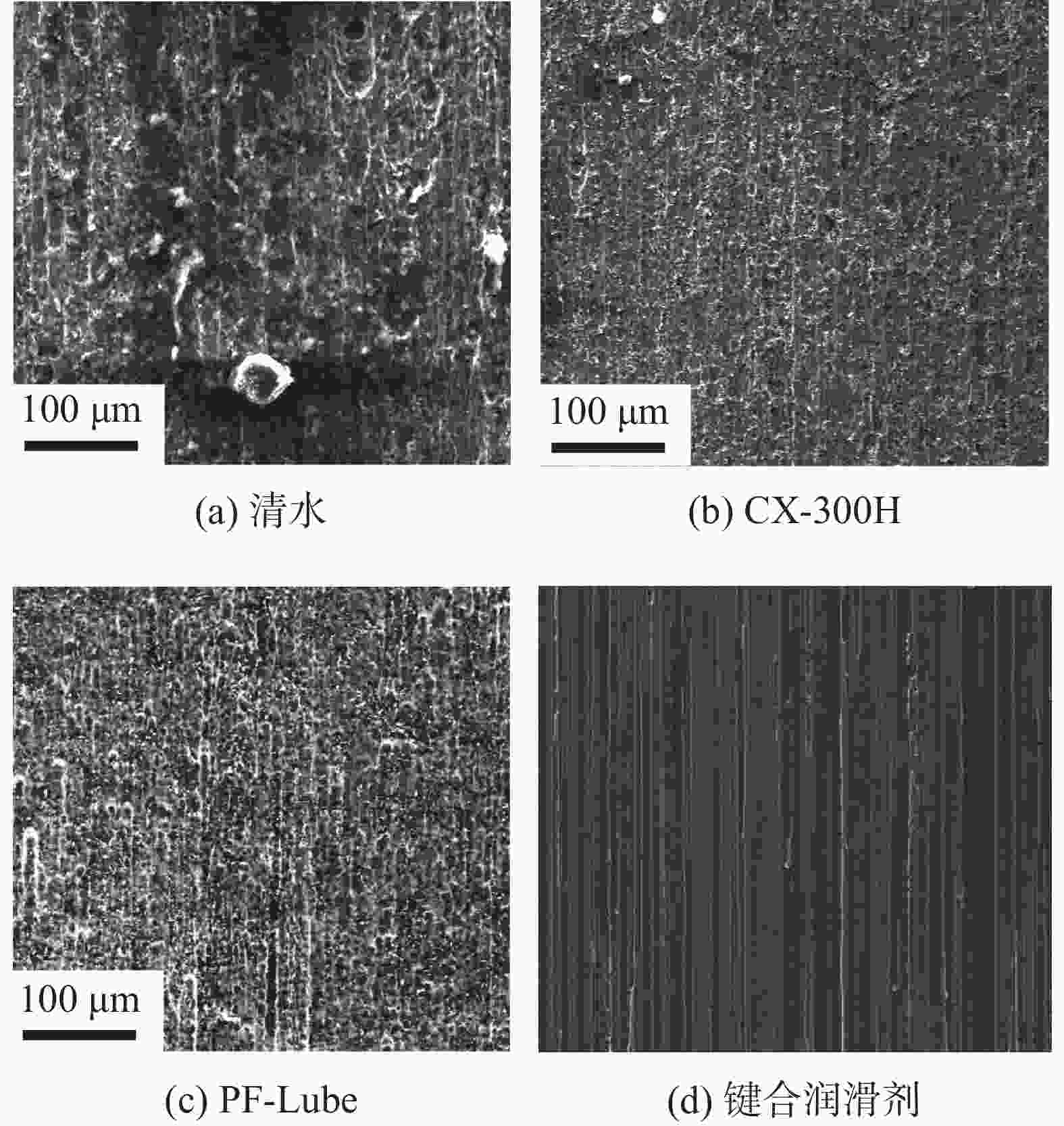

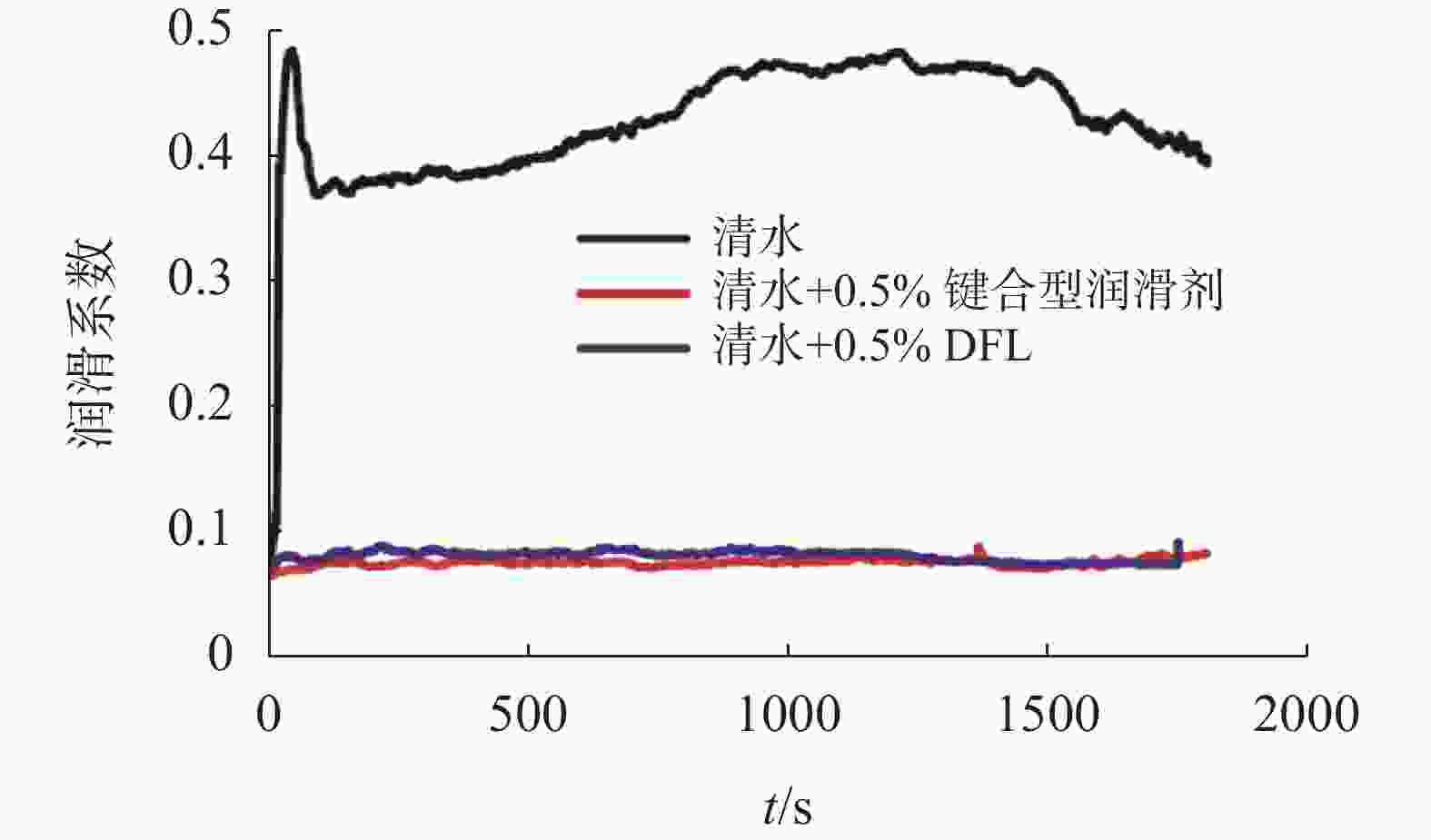

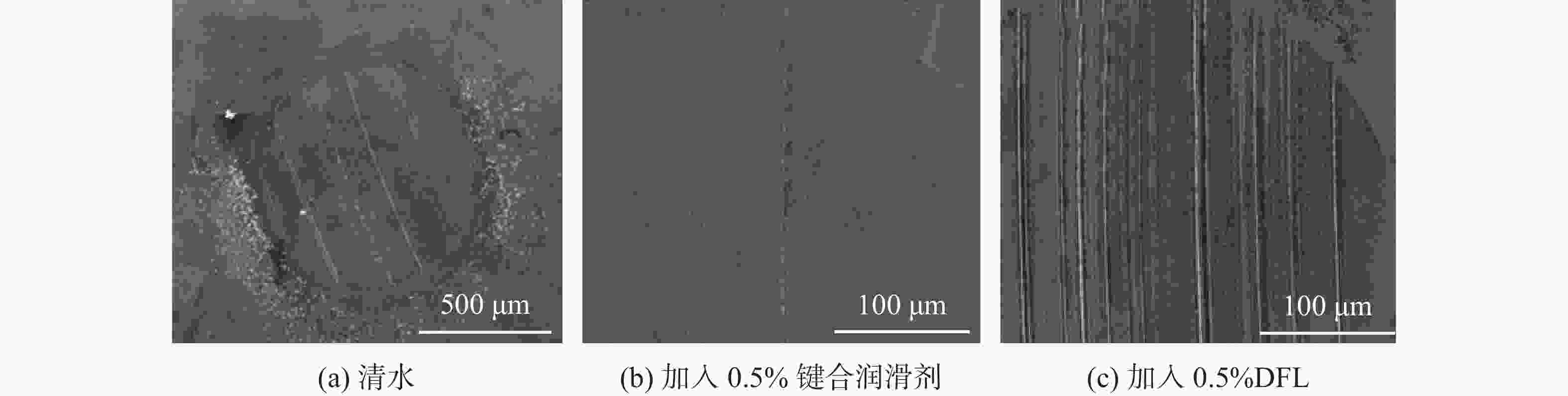

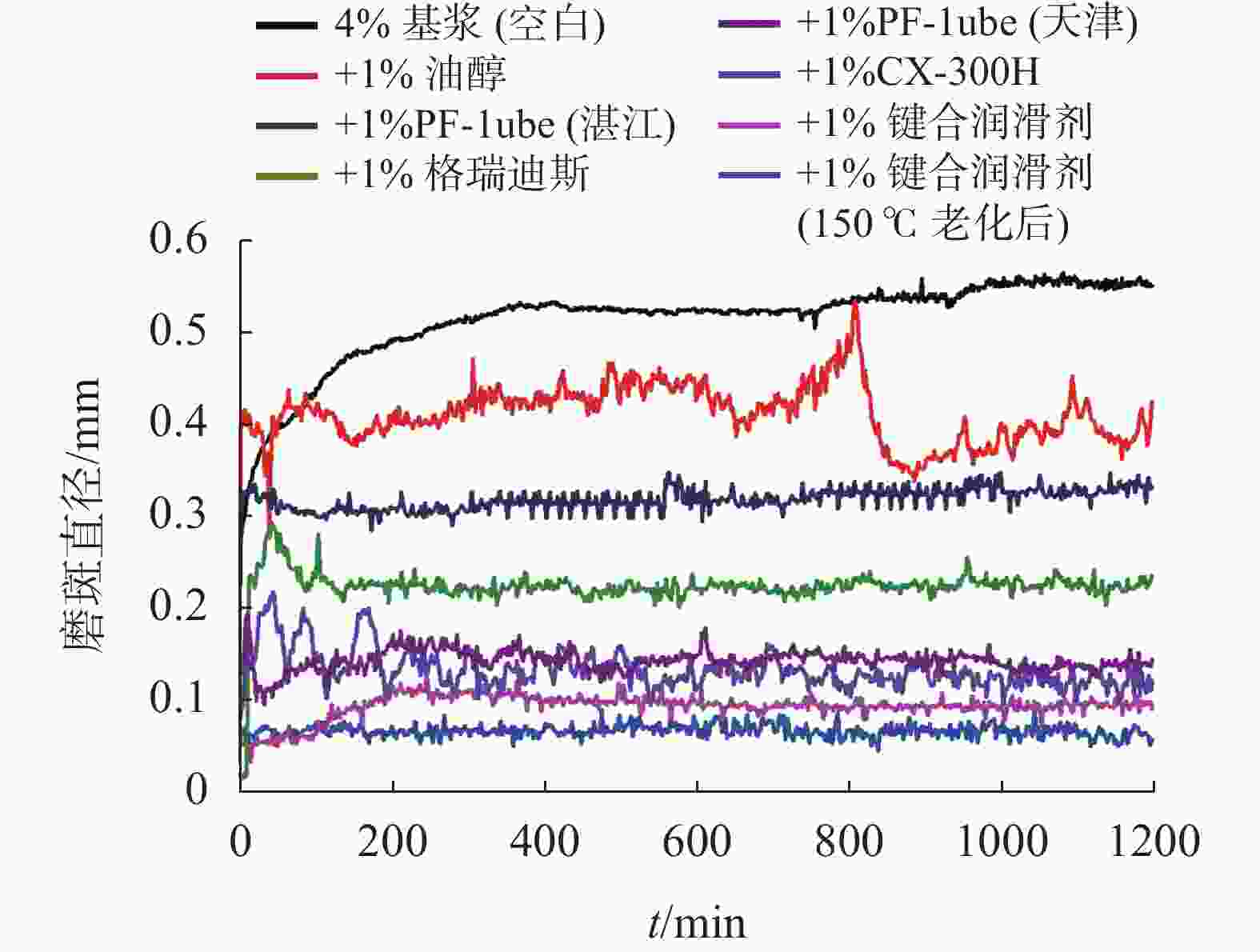

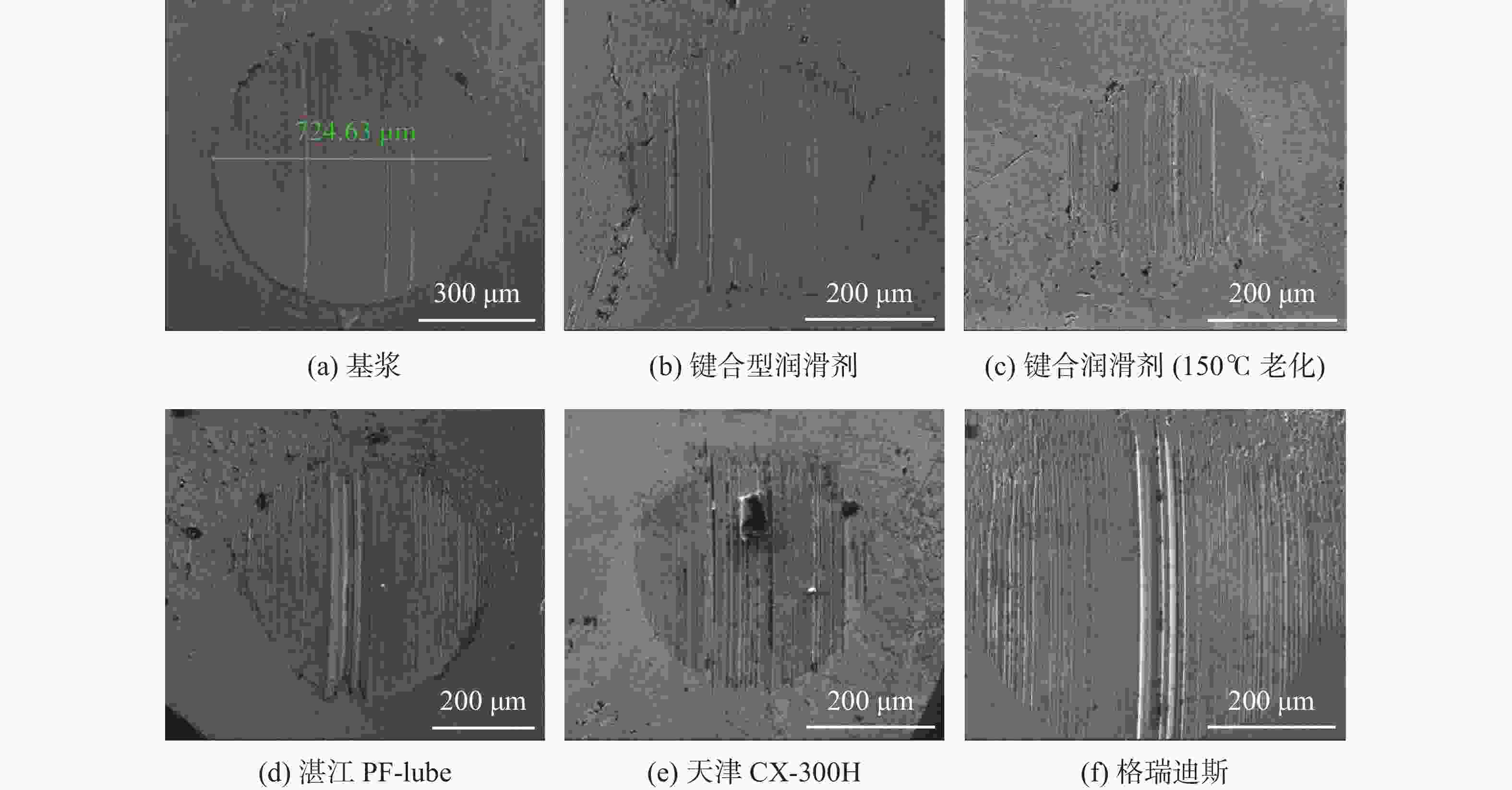

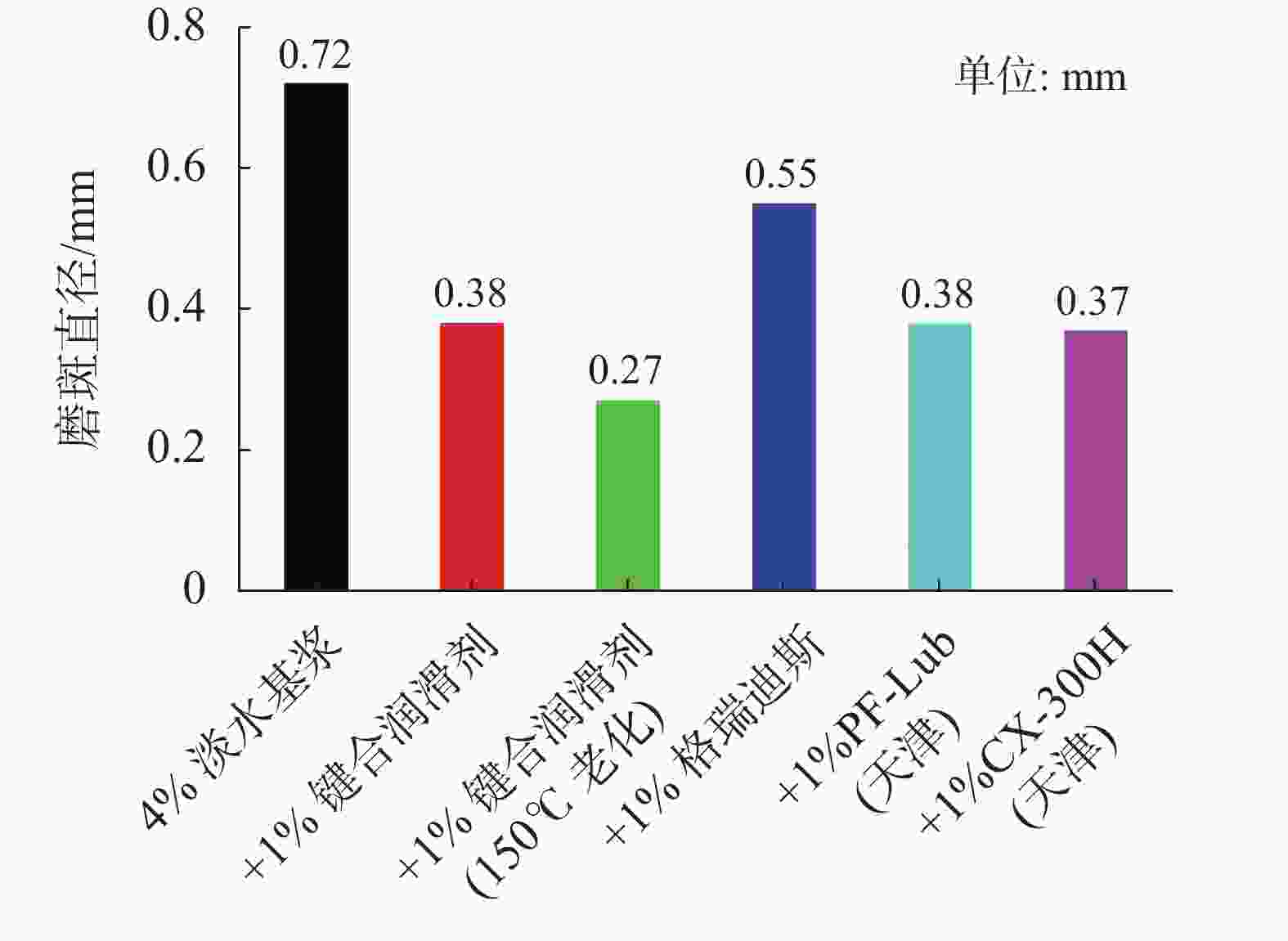

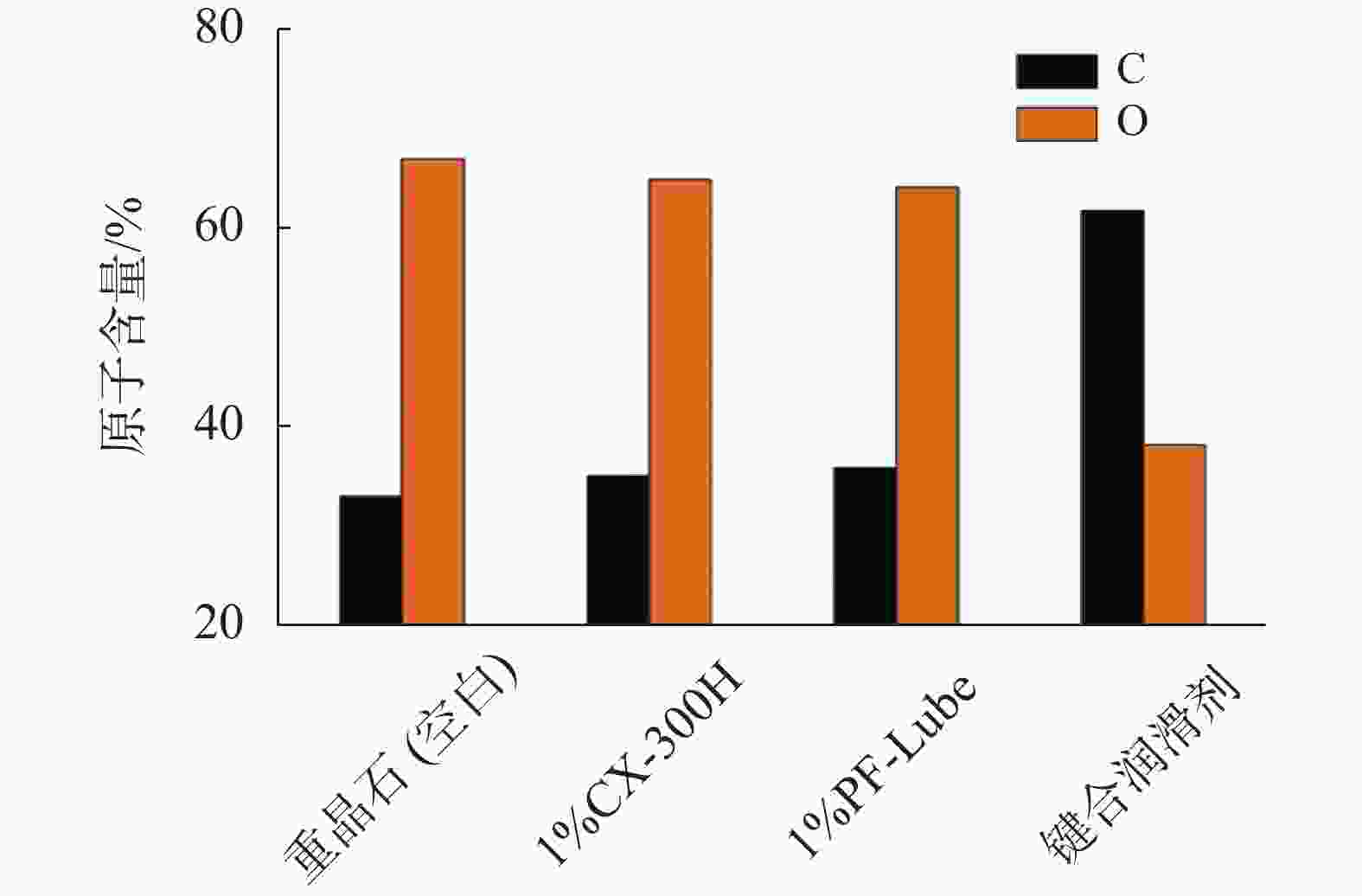

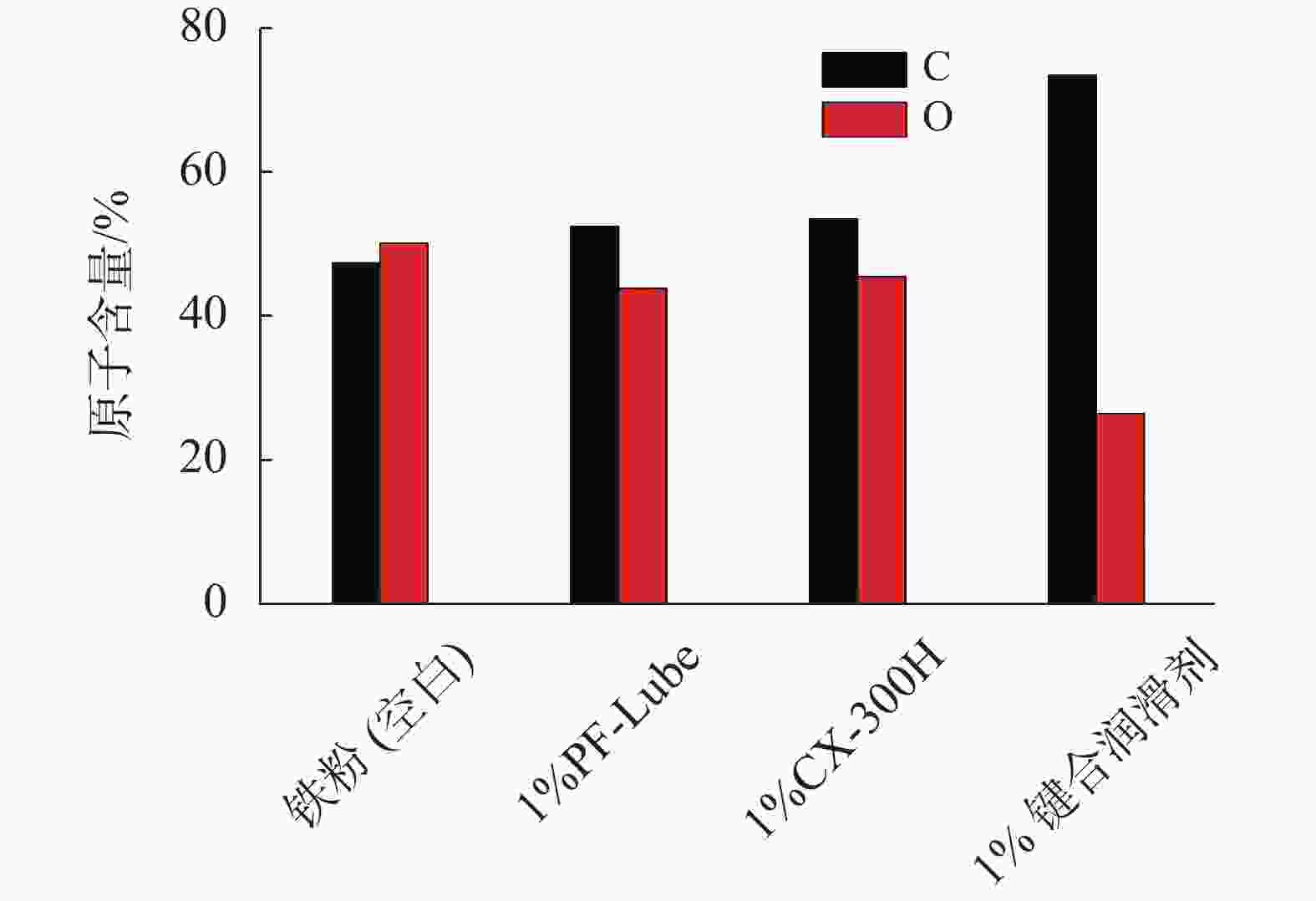

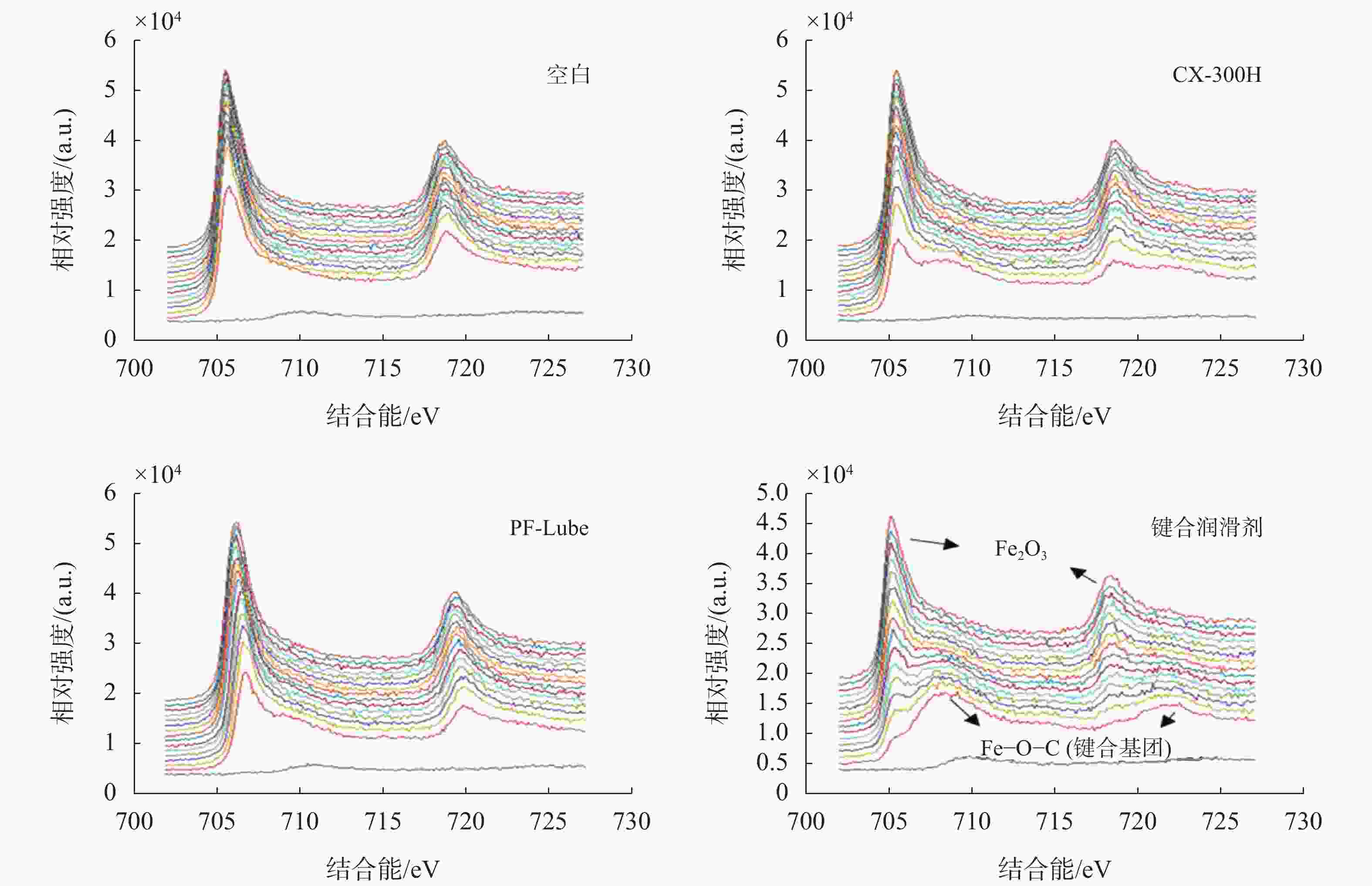

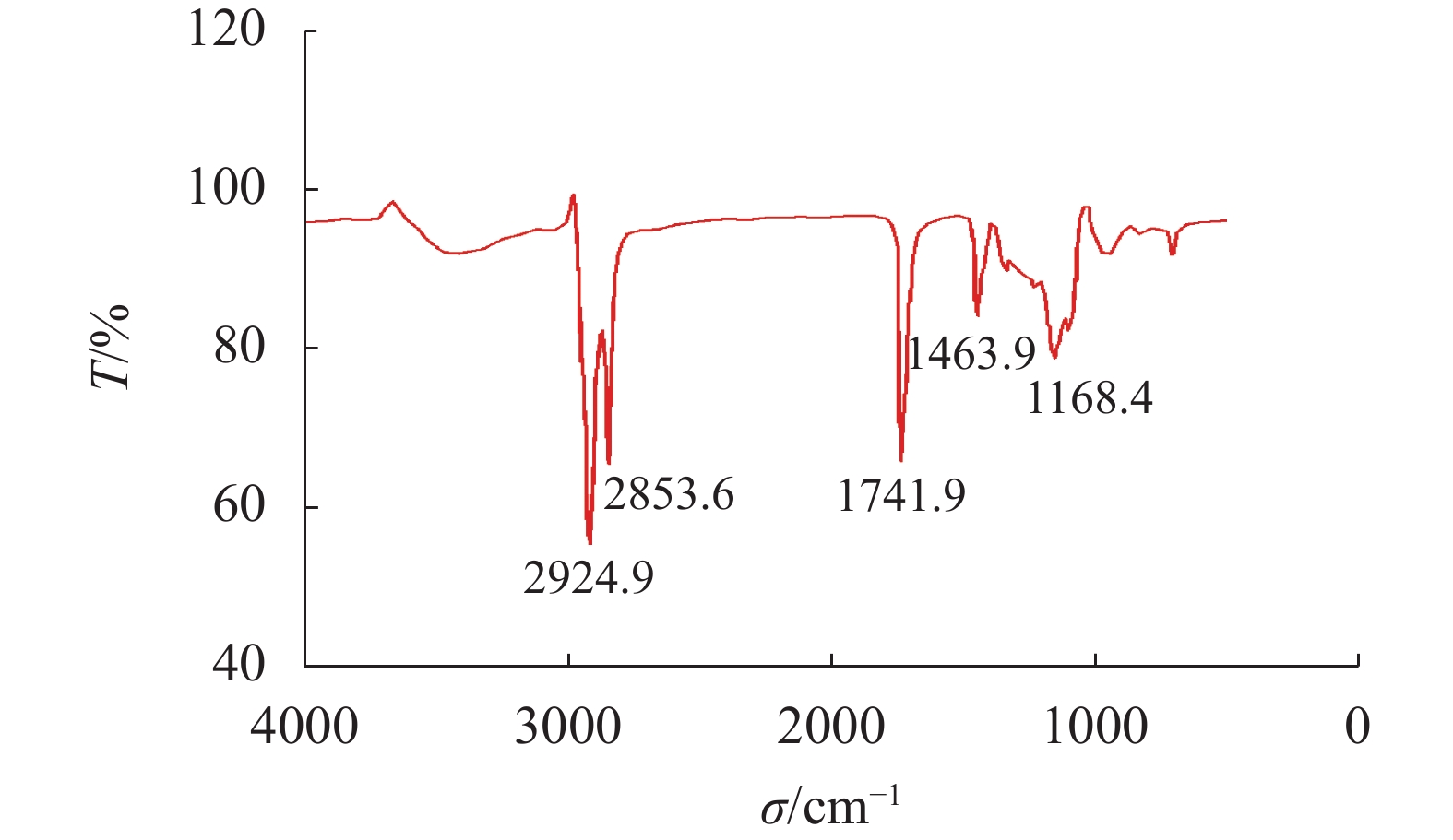

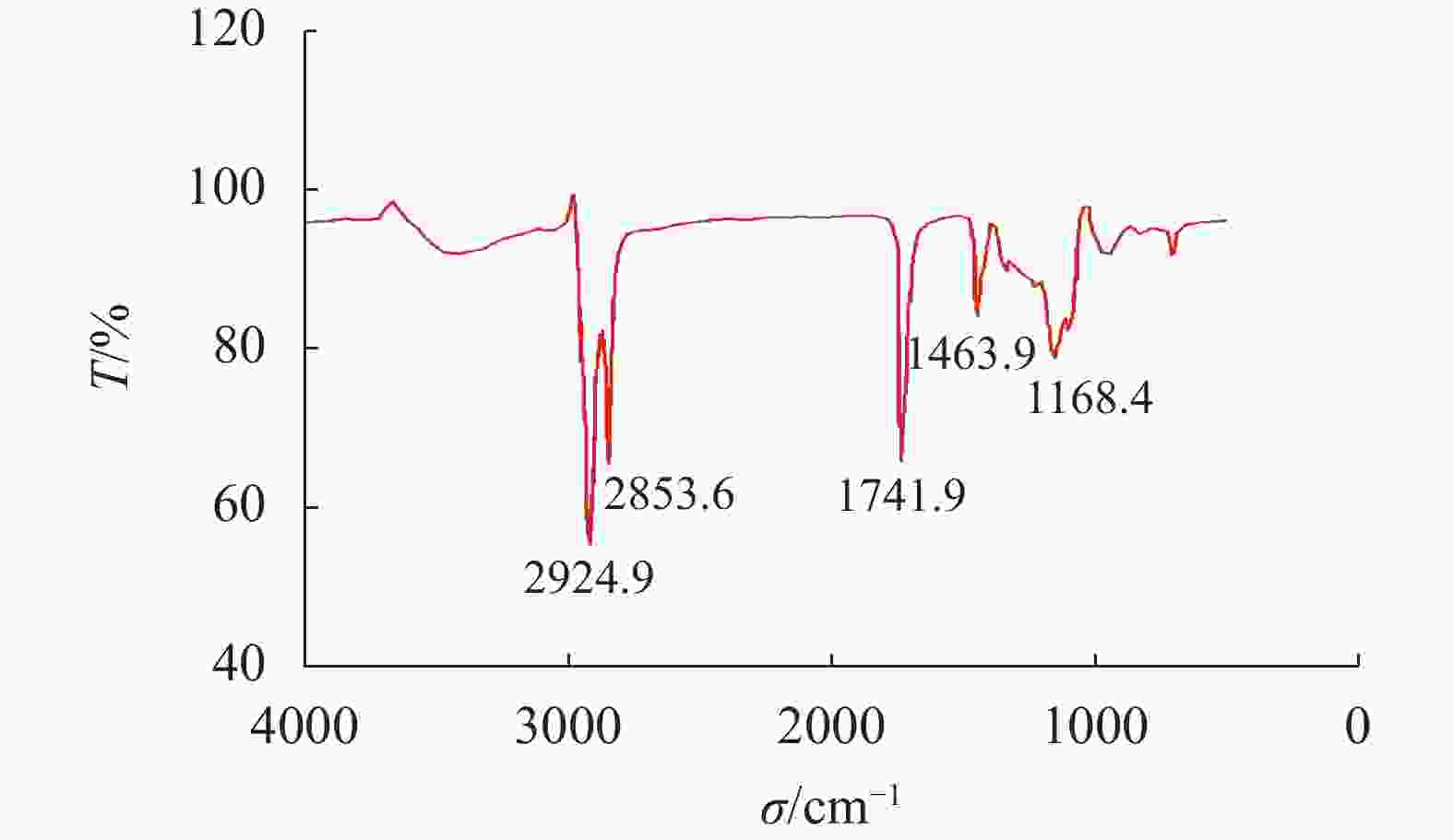

摘要: 常用水基钻井液润滑剂在金属摩擦界面上的吸附力弱,难以形成致密、且耐剪切的润滑膜,导致钻井摩阻、扭矩高,引发阻卡、卡钻等井下事故。为提高润滑剂在金属钻具表面的吸附能力,以多元醇和长链脂肪酸为原料,通过脱水缩合制备了一种多元醇酯键合润滑剂,其极压摩擦、滤饼黏附及“点对点”摩擦的润滑性能均优于国内外同类产品,抗温达150 ℃;通过四球摩擦实验、扫描电镜观察、X射线光电子能谱等研究了键合润滑剂的作用机理,表明其多羟基结构可与Fe元素形成强于普通物理吸附的键合吸附,从而可在金属钻具表面形成厚度约45 nm的致密、抗剪切润滑膜;同时也可吸附在重晶石表面,利于降低钻井液内摩擦。Abstract: Common lubricants used in water based drilling fluids have weak adsorption on the friction interfaces of metals, and therefore are difficult to form dense and shear-resistant lubricating films thereon, which leads to high friction and torque during drilling. High friction and torque generally result in pipe sticking and high overpull or resistance during tripping of drill string. To improve the adsorption of drilling fluid lubricants on the surfaces of drilling tools, a polyol ester bonded lubricant was developed with a polyol and a long-chain fatty acid through dehydration condensation reaction. This new lubricant worked better in extreme pressure friction test, filter cake adhesion test and “point-to-point” friction test than similar products both from China and abroad. It can be used at temperatures up to 150 ℃. The working mechanisms of the lubricant were studied through four-ball friction test, SEM observation and X-ray photoelectron spectroscopy etc. It was concluded that the polyhydroxy structure of the lubricant can form bonded adsorption on the surface of Fe, which is stronger than the general physical adsorption, it thus can form a dense and shear-resistant lubricating film, having a thickness of about 45 nm, on the surfaces of drilling tools. The lubricant can also be adsorbed onto the surfaces of barite particles, thereby reducing the internal friction of a drilling fluid.

-

Key words:

- Water based drilling fluid /

- Lubricant /

- Polyol /

- Adsorption on metal surface /

- Lubricating film

-

表 1 在4%膨润土基浆中分别加入1%不同润滑剂的极压润滑系数对比

老化前 150 ℃老化后 润滑剂 EP 降低率/

%起泡

情况EP 降低率/

%起泡

情况CX-300H 0.08 84 不起泡 0.07 86 微泡 DFL 0.11 78 不起泡 0.08 84 不起泡 PF-Lube 0.13 74 微泡 0.11 78 微泡 多元醇

酯键合0.05 91 不起泡 0.04 93 不起泡 表 2 清水中加入不同润滑剂的极压膜强度及EP极压润滑系数

润滑剂 最终扭矩/(N·m) EP极压润滑系数 清水 4.294 0.30 0.5% PF-lube 12.430 0.28 0.5% CX-300H 12.430 0.28 0.5%多元醇酯键合 24.860 0.08 表 3 在4%膨润土基浆中加入1%不同润滑剂对滤饼黏附系数的影响

润滑剂 老化前 150 ℃老化后 扭矩max/(N·m) 黏附系数 黏附系数降低率/% 扭矩max/(N·m) 黏附系数 黏附系数降低率/% 0 13.5 0.1225 13.4 0.1098 CX-300H 9.0 0.0818 33.20 8.5 0.0697 36.6 DFL 8.0 0.0728 40.57 8.0 0.0655 40.4 多元醇酯键合润滑剂 7.0 0.0631 48.50 7.5 0.0613 44.2 -

[1] ELROD S H, NANCE W B. Aqueous drilling fluid and lubricant composition [M]. US. 1980. [2] NANCE W B, CALKINS J M. Lubricating wellbore fluid and method of drilling [M]. US. 1985. [3] PATEL A D. Silicone based fluids for drilling applications [M]. US. 1998. [4] MUELLER H, HEROLD C P, VON TAPAVICZA S. Use of selected fatty alcohols and their mixtures with carboxylic acid esters as lubricant components in water-based drilling fluid systems for soil exploration [M]. US. 2004. [5] JAMES F V, KERCHEVILE J D, POBER K W. Silicic acid mud lubricants [M]. 2006. [6] NAVARRO A R, DANNELS W R. Maximizing drilling operations by mitigating the adverse affects of friction through advanced drilling fluid technology [M]. 2011. [7] 孙启忠,胥洪彪,刘传清,等. 聚合醚润滑剂HLX在胜利油田海上钻井中的应用[J]. 钻井液与完井液,2003,20(3):44-46.SUN Qizhong, XU Hongbiao, LIU Chuanqing, et al. Application of polyether lubricant Hlx in offshore drilling in Shengli oilfield[J]. Drilling Fluid & Completion Fluid, 2003, 20(3):44-46. [8] 肖稳发,罗春芝. 改性聚合多元醇水基润滑剂的研究[J]. 钻采工艺,2005,28(4):87-89.XIAO Wenfa, LUO Chunzhi. Study on modified polyol water-based lubricant[J]. Drilling and Production Technology, 2005, 28(4):87-89. [9] 赵道汉,陈娟,孙庆林,等. 钻井液用水基润滑剂NSR-1的研究与评价[J]. 油田化学,2007,24(2):97-99.ZHAO Daohan, CHEN Juan, SUN Qinglin, et al. Research and evaluation of water-based lubricant nsr-1 for drilling fluid[J]. Oilfield Chemistry, 2007, 24(2):97-99. [10] 郑义平,黄治中,张兴国,等. 钻井液用生物油润滑剂的研究与应用[J]. 钻井液与完井液,2013,30(4):19-20.ZHENG Yiping, HUANG Zhizhong, ZHANG Xingguo, et al. Research and application of bio oil lubricant for drilling fluid[J]. Drilling Fluid & Completion Fluid, 2013, 30(4):19-20. [11] 李广环,龙涛,田增艳,等. 利用废弃动植物油脂合成钻井液用润滑剂的研究与应用[J]. 油田化学,2014,31(4):488-491.LI Guanghuan, LONG Tao, TIAN Zengyan, et al. Research and application of lubricant for drilling fluid synthesized from waste animal and vegetable oils[J]. Oilfield Chemistry, 2014, 31(4):488-491. [12] 祁亚男,吕振华,严波,等. 新型植物油钻井液润滑剂的研究与应用[J]. 钻井液与完井液,2015,32(3):39-41.QI Yanan, LYU Zhenhua, YAN Bo, et al. Research and application of new vegetable oil drilling fluid lubricant[J]. Drilling Fluid & Completion Fluid, 2015, 32(3):39-41. [13] 王琳,董晓强,杨小华,等. 高密度钻井液用润滑剂SMJH-1的研制及性能评价[J]. 钻井液与完井液,2016,33(1):28-32.WANG Lin, DONG Xiaoqiang, YANG Xiaohua, et al. Development and performance evaluation of lubricant smjh-1 for high density drilling fluid[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):28-32. [14] GUANCHENG JIANG, JINSHENG SUN, YINBO HE, et al. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs[J]. Engineering, 2021. [15] YUELIANG LIU, ZHENHUA RUI. A storage-driven CO2 EOR for a net-zero emission target[J]. Engineering, 2022. -

下载:

下载: