Borehole Wall Strengthening with Micron and Nano Materials in “Dabadong” Area of Changning

-

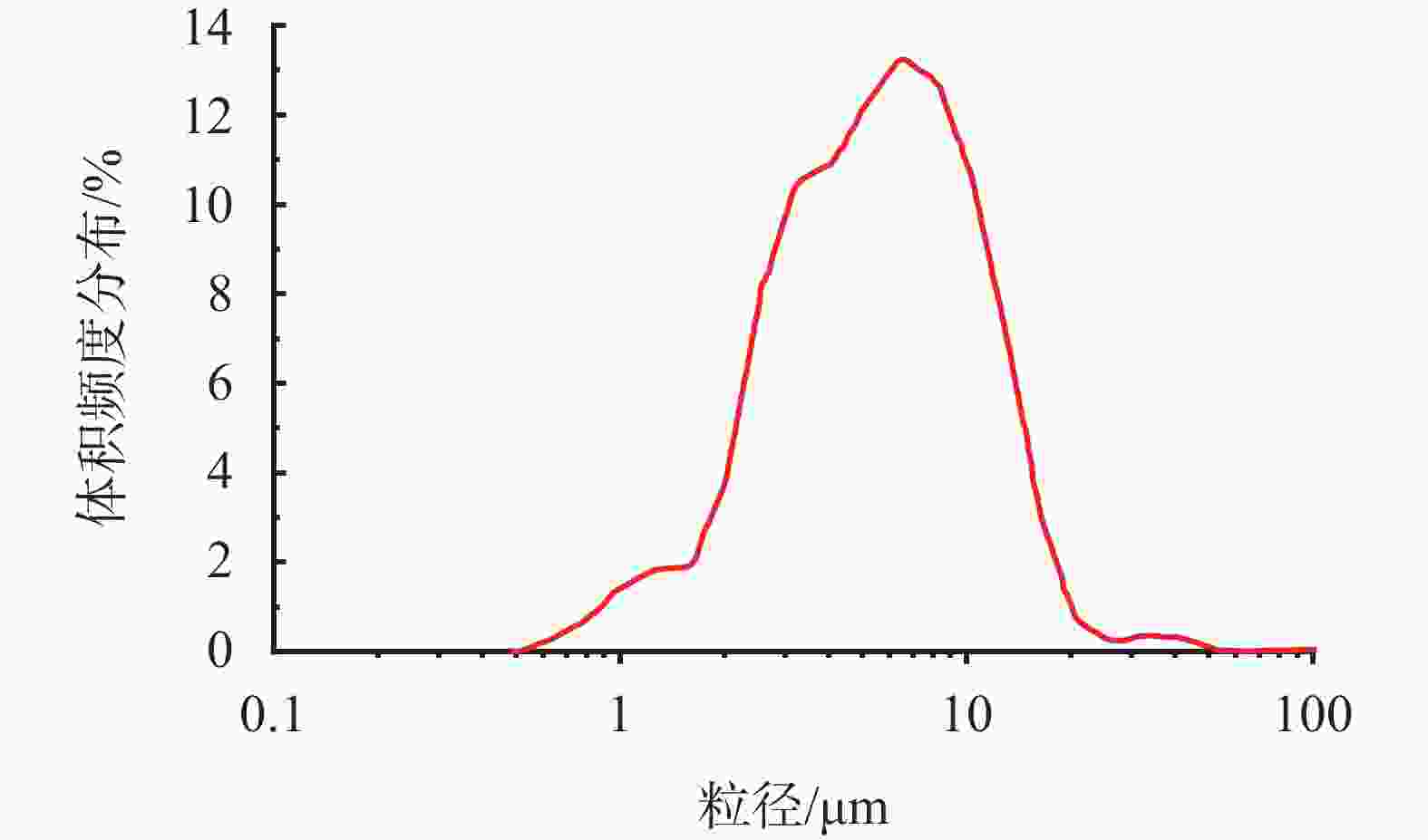

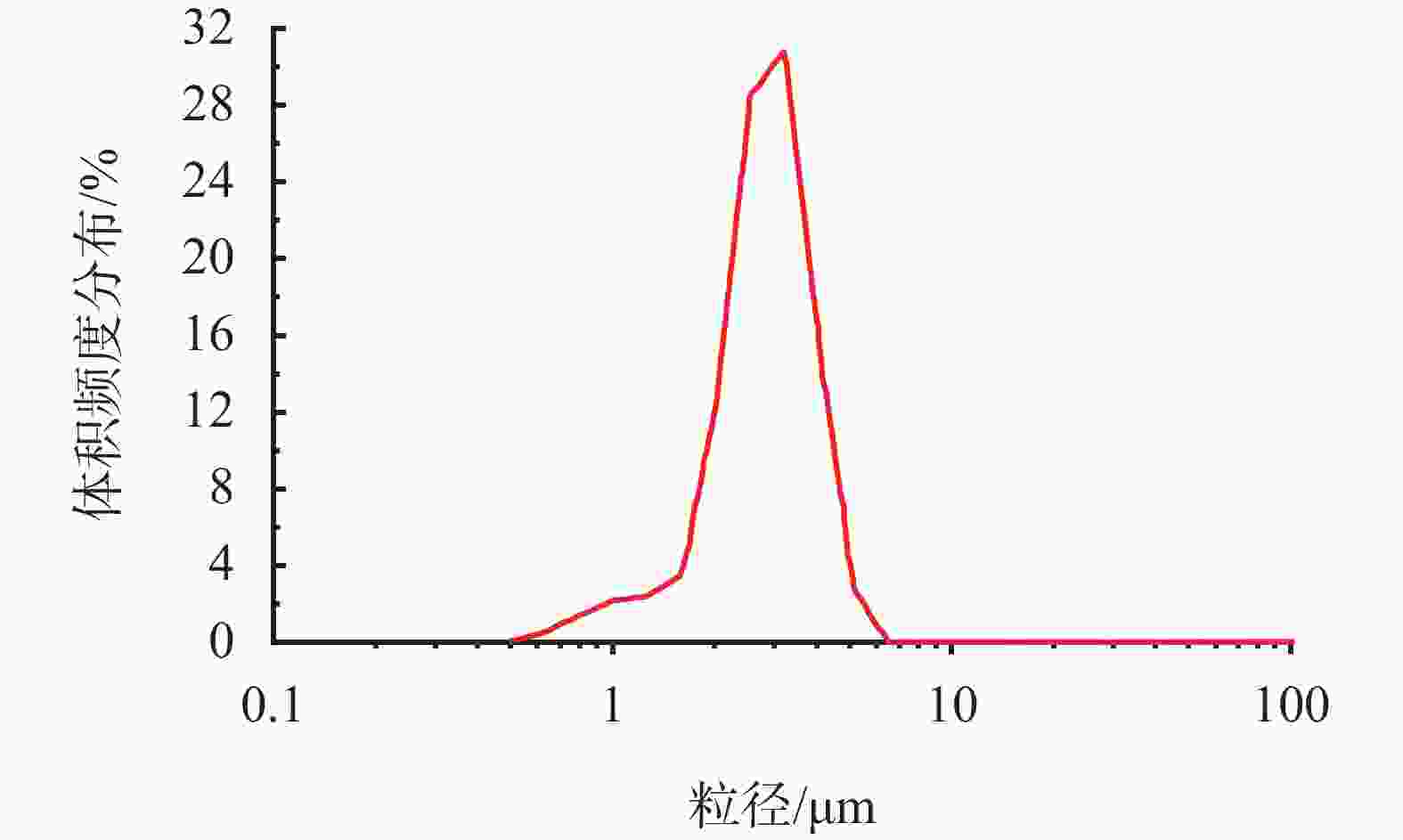

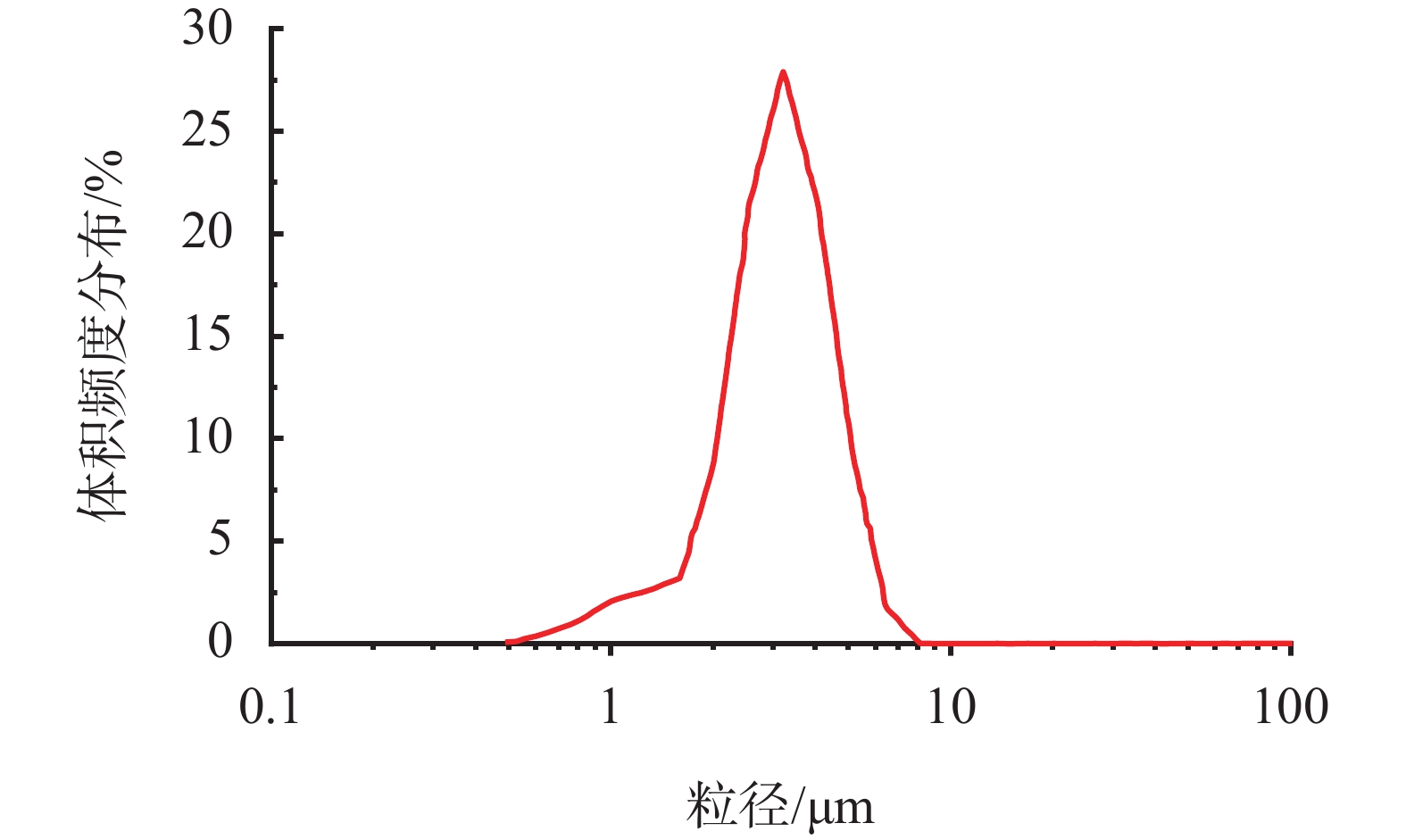

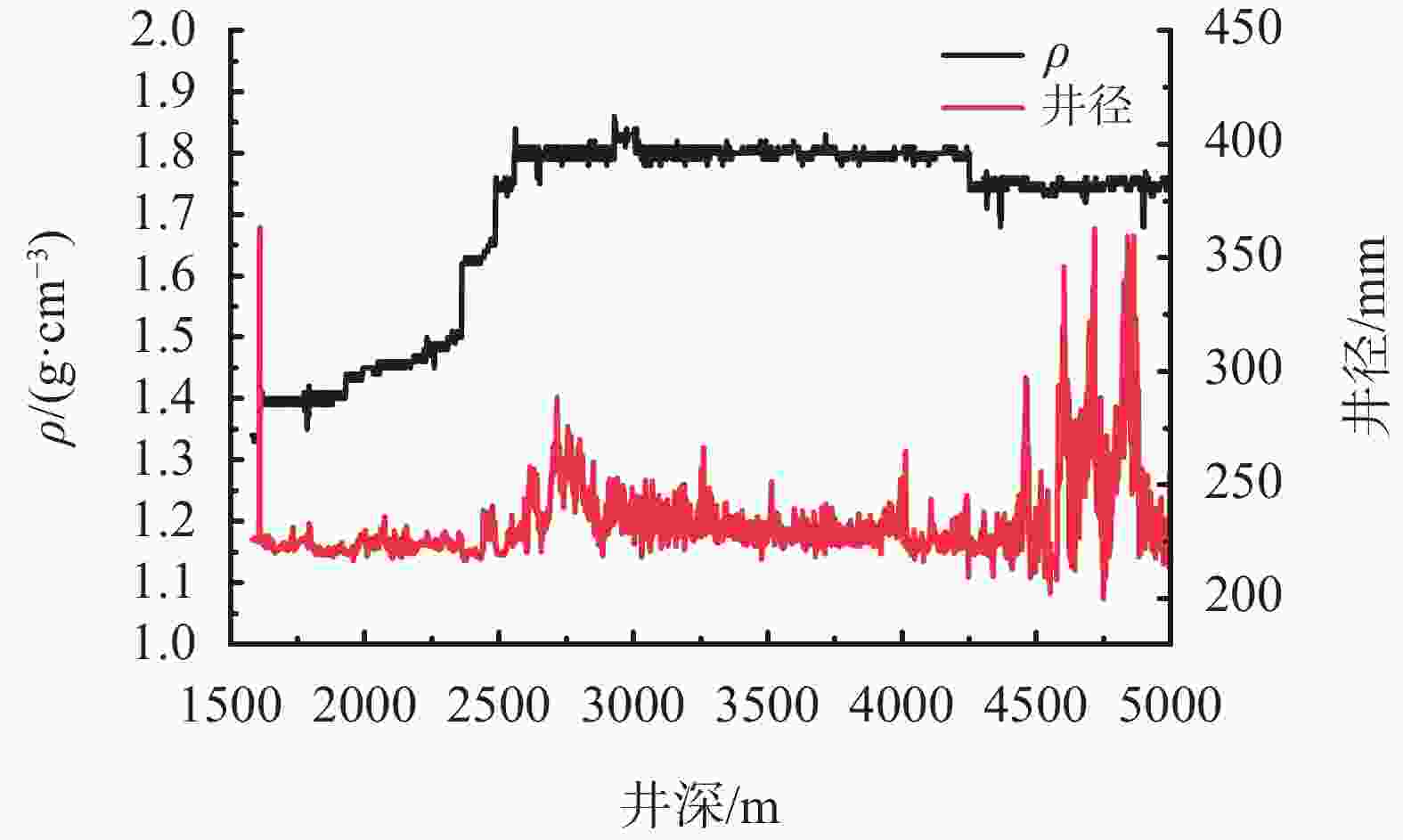

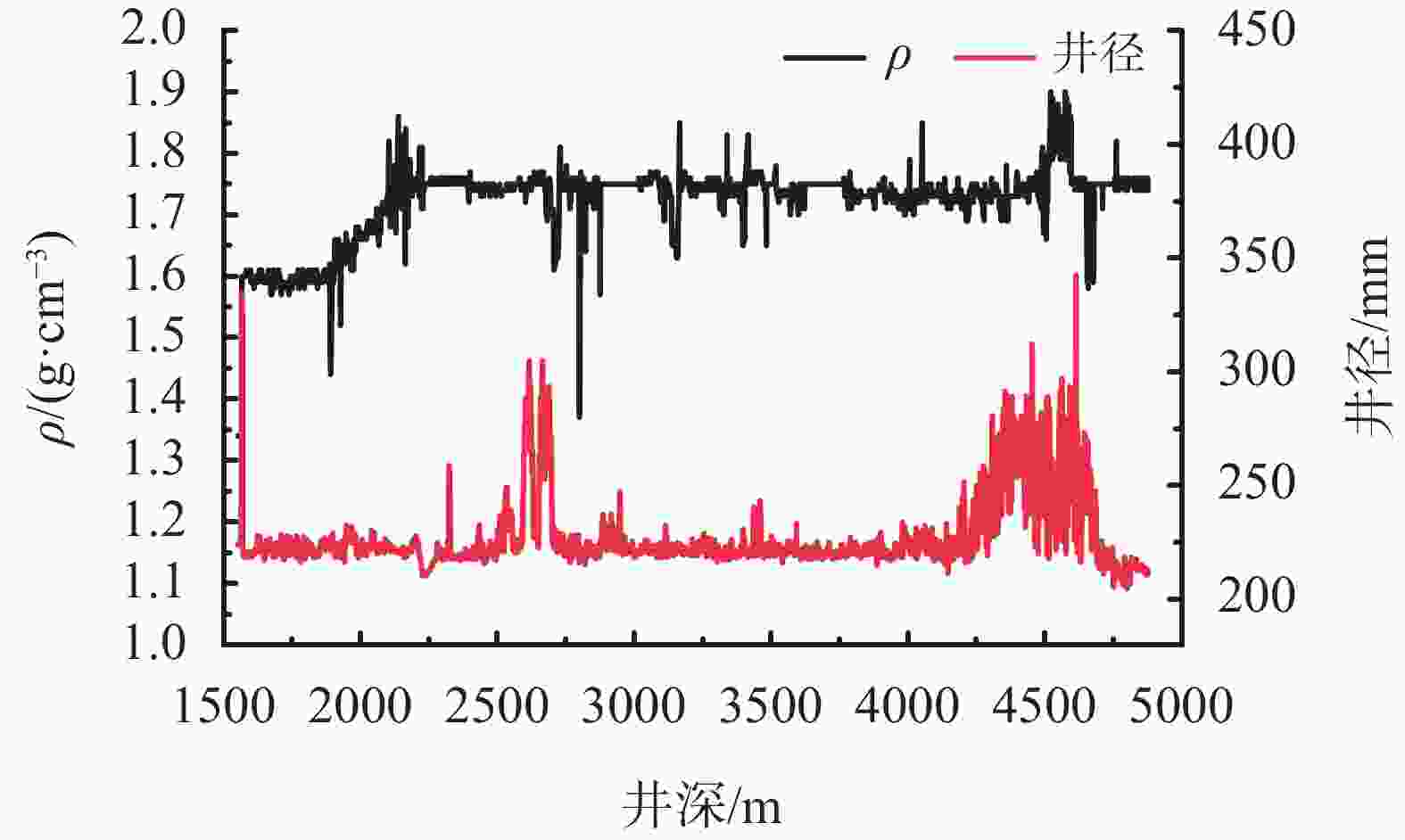

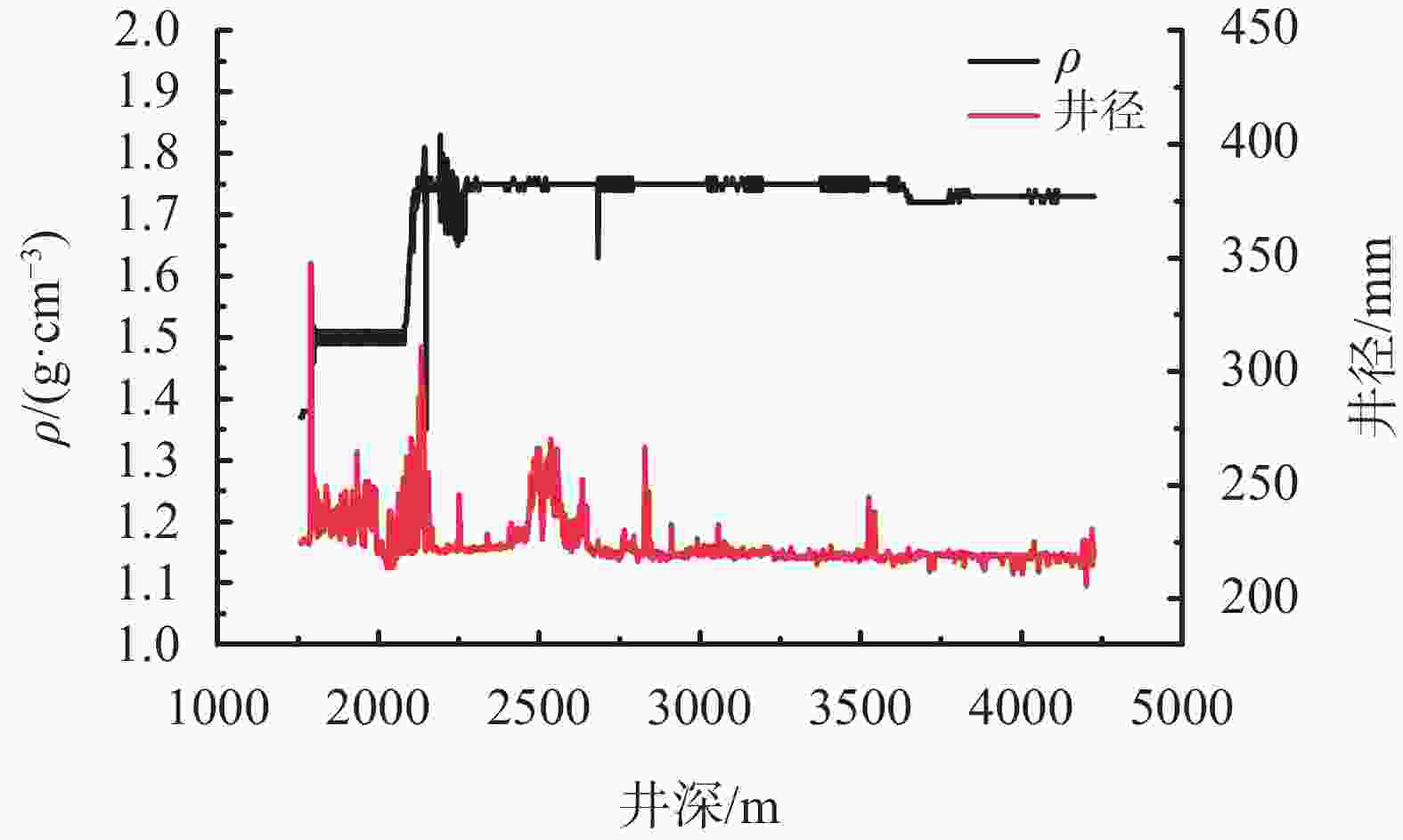

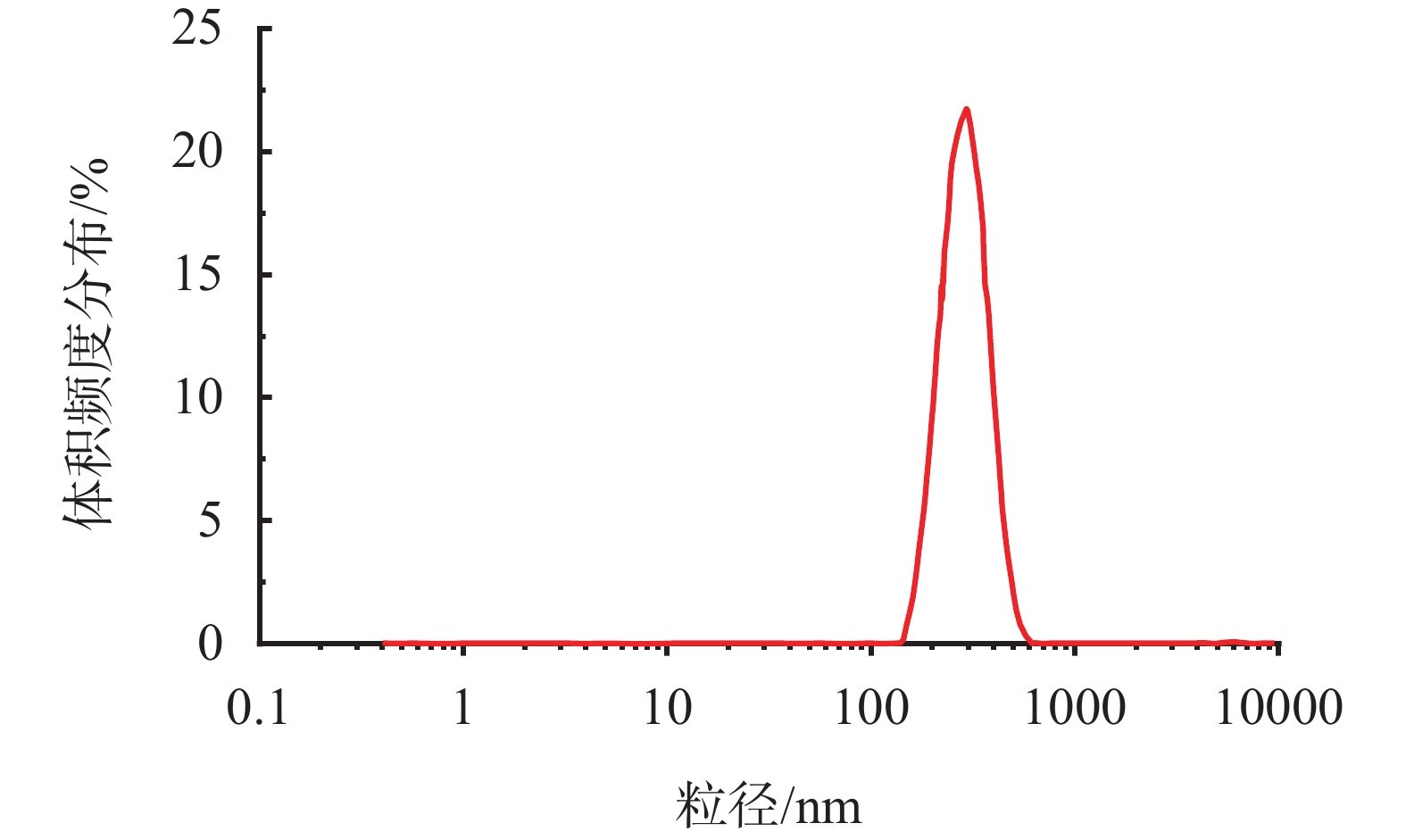

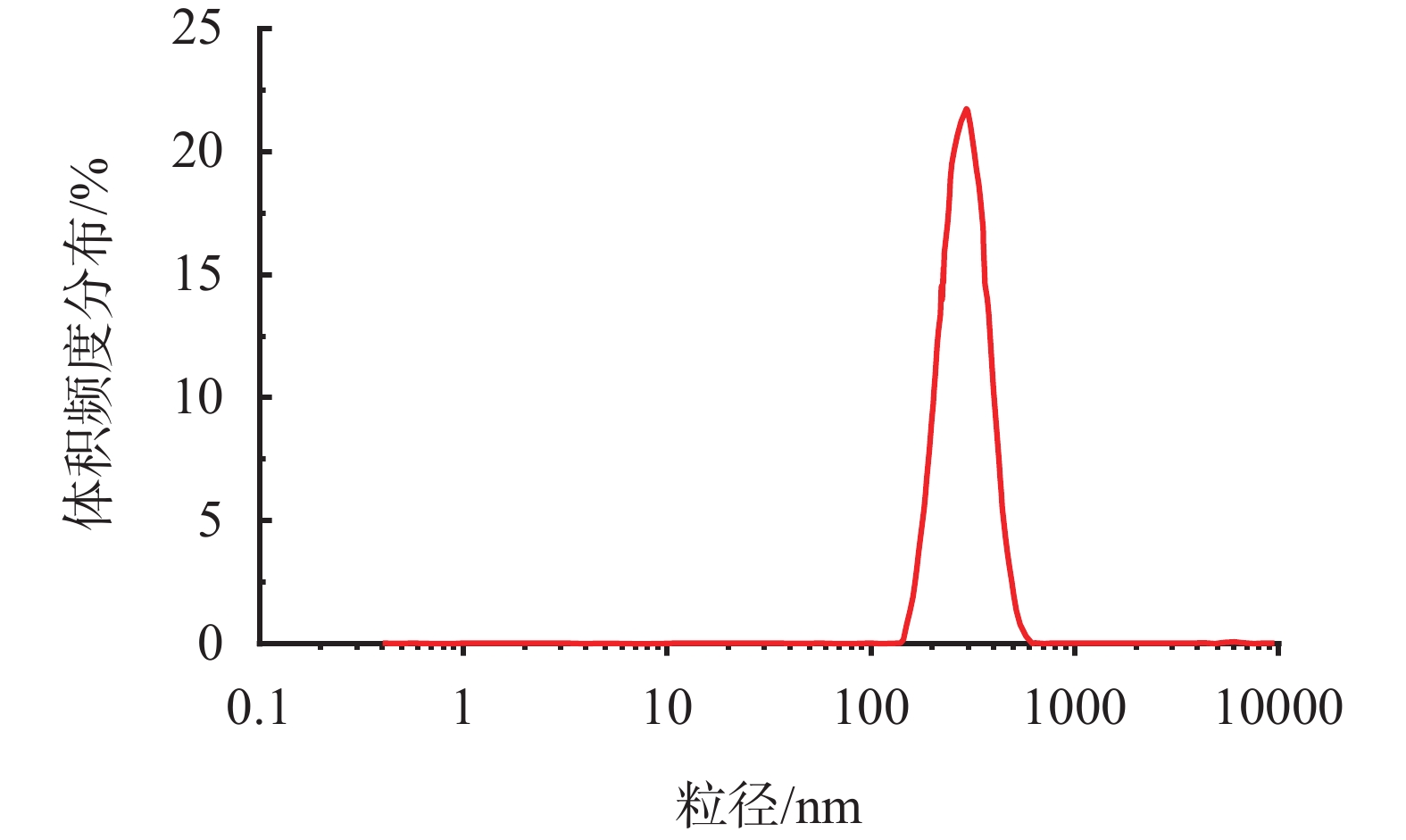

摘要: 长宁公司“大坝东”区域受构造作用、岩性组分等因素影响,龙马溪组微裂缝发育,原生孔径主要分布在0.05~2 μm之间,地层稳定性差,钻进过程阻卡严重,单纯通过上提钻井液密度,未能有效控制井眼垮塌,且钻井现场的封堵类添加剂属于微米级,缺乏纳米级封堵添加剂,不能有效封堵纳米级孔缝,同时不利于形成渗透率更低的封堵层,阻缓井筒压力向地层传递。引入纳米级石墨烯封堵剂,补全钻井液微观固相级配,配合地质力学建模,确定合理的密度,匹配性能调控工艺,形成微纳米井壁强化技术。在宁209H69平台现场应用过程中,钻井液性能稳定,全井段无事故复杂,平均井眼扩大率不大于8%,井径规则,有效地预防了井眼垮塌。Abstract: The Longmaxi formation in Changning is highly developed with microfractures because of the tectonic action in the “Dabadong” area and the formation rock components. The sizes of the primary pores are distributed in a range of 0.05-2 μm. The formation stability is very poor and overpull and resistance have been frequently encountered during drilling. Increase in mud weight only cannot control wellbore instability. The drilling fluids presently in use only contain micron-sized plugging agents and are unable to effectively plug the nanometer pores. The lack of nanometer plugging agents cannot help form low permeability plugging layers to hinder the transmission of borehole pressure into the formations. By introducing a nanometer graphene plugging agent, the drilling fluid has both micron-sized and nano-sized plugging agents. Furthermore, the mud weight was determined through geomechanics model. With all these technologies and mud property control, the borehole wall was strengthened. Application of the borehole wall strengthening technology in the well Ning-209H69 showed that the properties of the drilling fluid were stable, no downhole troubles were encountered in the whole drilling process, the average percent hole enlargement was less than 8%, and the borehole wall collapse was effectively eliminated.

-

Key words:

- Micron and nanometer /

- Graphene /

- Microfracture /

- Borehole collapse /

- Borehole stability /

- Dabadong /

- Longmaxi

-

表 1 在基浆中加入不同含量SMXFT对体系性能的影响

SMXFT/

%φ600 φ300 φ6 φ3 PV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V0 73 43 7.0 6.0 30 6.5 4.5/6.5 3.6 825 0.25 76 44 8.0 6.0 32 6.0 4.0/6.5 3.4 872 0.50 77 44 7.5 5.0 33 5.5 4.0/6.5 3.2 917 0.75 78 45 7.0 5.5 33 6.0 4.0/6.0 3.2 953 1.00 84 48 8.0 7.0 36 6.0 4.5/7.5 3.6 998 注:钻井液密度为1.40 g/cm3,FLHTHP测试条件为120 ℃、3.5 MPa 表 2 不同颗粒复配对钻井液性能的影响

配方 φ600 φ300 φ6 φ3 PV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V基浆 73 43 7.0 6.0 30 6.5 4.5/6.5 3.6 965 1# 76 43 8.0 6.0 33 5.0 4.5/6.5 2.8 816 2# 75 43 7.5 6.0 32 5.5 4.0/6.5 2.6 832 3# 78 45 9.0 7.0 33 6.0 4.5/7.0 1.8 782 4# 80 46 9.0 7.5 34 6.0 4.5/7.5 1.2 808 注:1#:基浆+1.5%XNZD-1+1.5%XNZD-2;2#:基浆+1.5%XNZD-1+1.5%XNZD-3;3#:1#+1.5%XNZD-3;4#:1#+1.5%XNZD-3+0.75%SMXFT;钻井液密度为1.40 g/cm3,FLHTHP测试条件为120 ℃,3.5 MPa 表 3 技术配方A对宁209H69-1井井浆的影响

配方 ρ/

g·cm-3φ600 φ300 φ6 φ3 PV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mLES/

V井浆 1.73 78 45 7 6 33 6.0 3/7 1.8 933 井浆+A 1.73 82 46 9 7 36 5.0 3.5/9 1.4 808 注:配方A:1.5%XNZD-1+1.5%XNZD-2+1.5%XNZD-3+0.75%SMXFT;FLHTHP在120 ℃、3.5 MPa下测定 -

[1] 董大忠,施振生,孙莎莎,等. 黑色页岩微裂缝发育控制因素: 以长宁双河剖面五峰组—龙马溪组为例[J]. 石油勘探与开发,2018,45(5):763-774. doi: 10.11698/PED.2018.05.02DONG Dazhong, SHI Zhensheng, SUN Shasha, et al. Factors controlling microfractures in black shale: A case study of Ordovician Wufeng formation-Silurian Longmaxi formation in Shuanghe profile, Changning area, Sichuan basin, SW China[J]. Petroleum Exploration and Development, 2018, 45(5):763-774. doi: 10.11698/PED.2018.05.02 [2] MCLELLAN P J, CORMIER K. Borehole instability in fissile, dipping shales, northeastern British columbia[C]//SPE Gas Technology Symposium. OnePetro, 1996. [3] 王星媛,舒小波,王兰,等. 长宁-威远龙马溪组地层微纳米防漏堵漏技术研究与应用[J]. 第 32 届全国天然气学术年会 (2020) 论文集,2020.WANG Xingyuan, SHU Xiaobo, WANG Lan, et al. Research and application of micron-nano-sized anti-leak technology in Changning-weiyuan Longmaxi formation[J]. National Natural Gas Academic Annual Conference Proceedings, 2020. [4] 郭建春,陶亮,陈迟,等. 川南地区龙马溪组页岩混合润湿性评价新方法[J]. 石油学报,2020,41(2):216-225. doi: 10.7623/syxb202002007GUO Jianchun, TAO Liang, CHEN Chi, et al. A new method for evaluating the mixed wettability of shale in Longmaxi formation in the southern Sichuan[J]. Acta Petrolei Sinica, 2020, 41(2):216-225. doi: 10.7623/syxb202002007 [5] 曹文科,邓金根,蔚宝华,等. 基于多孔介质热弹性理论的井壁诱导缝成因[J]. 天然气工业,2017,37(6):79-85. doi: 10.3787/j.issn.1000-0976.2017.06.011CAO Wenke, DENG Jingen, WEI Baohua, et al. Genesis of induced fractures on borehole walls based on the thermo-poroelasticity theory[J]. Natural Gas Industry, 2017, 37(6):79-85. doi: 10.3787/j.issn.1000-0976.2017.06.011 [6] 易成林,杨逸群,江金强,等. 颗粒乳化剂的研究及应用[J]. 化学进展,2011,23(1):65-77.YI Chenglin, YANG Yiqun, JIANG Jinqiang, et al. Research and application of particle emulsifiers[J]. Progress in Chemistry, 2011, 23(1):65-77. [7] 王辉,王富华. 纳米技术在钻井液中的应用探讨[J]. 钻井液与完井液,2005,22(2):50-54.WANG Hui, WANG Fuhua. Discussion the application of nanotechnology in drilling fluid[J]. Drilling Fluid & Completion Fluid, 2005, 22(2):50-54. [8] 王毅,唐成磊,蓝强. 纳米技术在钻井完井液中的应用前景[J]. 钻井液与完井液,2008,25(1):69-71. doi: 10.3969/j.issn.1001-5620.2008.01.023WANG Yi, TANG Chenglei, LAN Qiang. Application prospect of nanotechnology in drilling fluid and completion fluid[J]. Drilling Fluid & Completion Fluid, 2008, 25(1):69-71. doi: 10.3969/j.issn.1001-5620.2008.01.023 [9] 姚如钢,蒋官澄,李威,等. 新型抗高温高密度纳米基钻井液研究与评价[J]. 钻井液与完井液,2013,30(2):25-28. doi: 10.3969/j.issn.1001-5620.2013.02.008YAO Rugang, JIANG Guancheng, LI Wei, et al. Research and evaluation of a novel high-temperature resistant high-density Namiki drilling fluid[J]. Drilling Fluid & Completion Fluid, 2013, 30(2):25-28. doi: 10.3969/j.issn.1001-5620.2013.02.008 [10] 黄红玺,张峰,许明标,等. 油包水乳状液稳定性影响因素分析[J]. 断块油气田,2009,16(6):99-101.HUANG Hongxi, ZHANG Feng, XU Mingbiao, et al. Main influence factors of water-in-oil emulsion stability[J]. Fault-Block Oil & Gas Field, 2009, 16(6):99-101. -

下载:

下载: