Development of Paraffin Microemulsion and Its Application in Water-Based Drilling Fluids

-

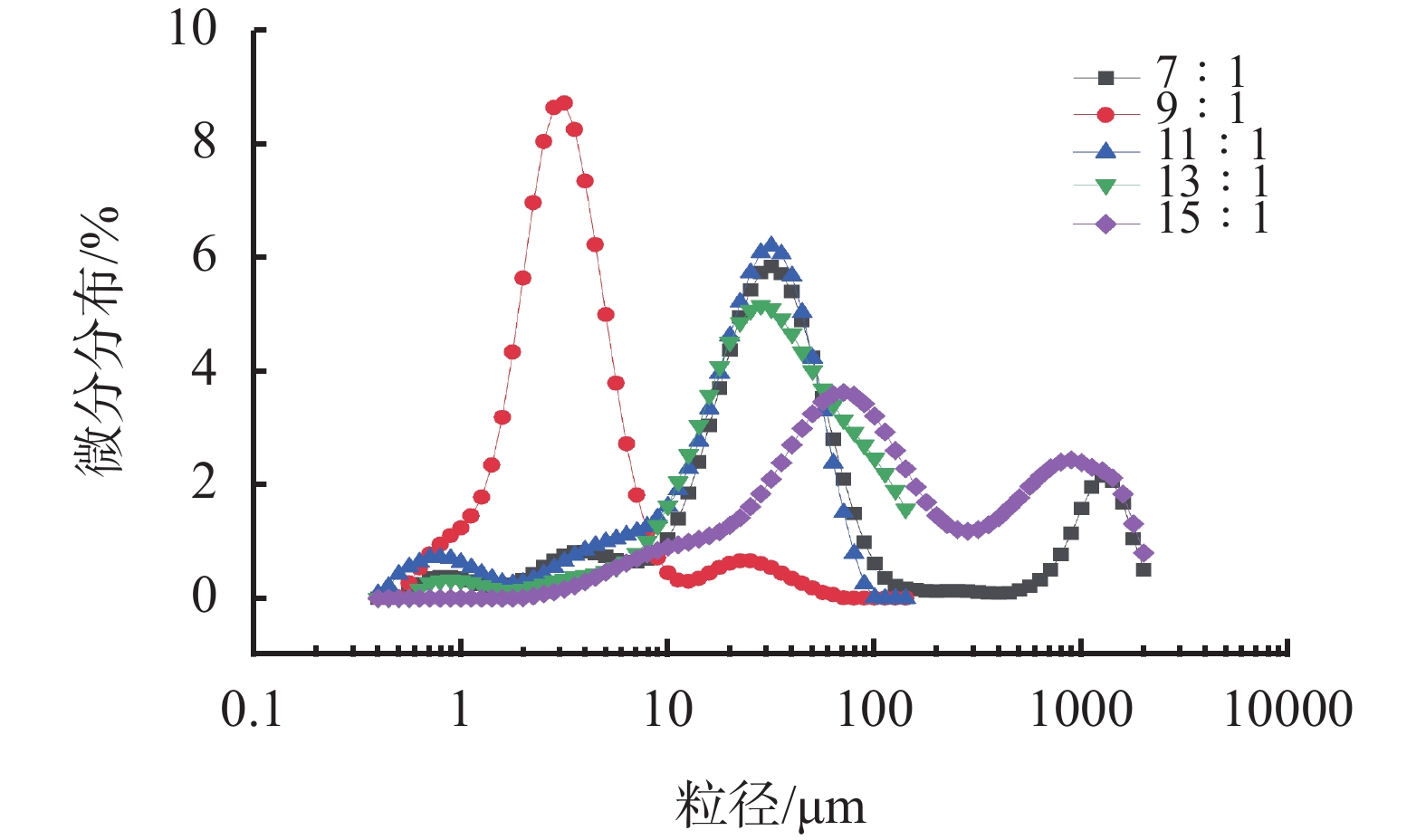

摘要: 对塔西南超深井钻井过程中出现的微纳米裂缝与孔隙渗漏的问题进行分析,发现现有钾基聚磺钻井液中的封堵剂不能有效封堵微纳米裂缝与孔隙。为提高封堵粒径级配,在室内制备一种石蜡微乳液,通过粒径比较法得出了最佳制备方案。方案表明制备的最佳比例为“S+A”∶石蜡=9∶1,最佳搅拌速度为1400 r/min,最佳温度为120 ℃。制备得到的石蜡微乳液D50粒径在2.9 μm左右,单分散颗粒尺寸在200~300 nm左右,表面张力在45.0~47.5 mN/m范围内,稳定时间长达30 d。采用石蜡微乳液对塔西南区块钾聚磺水基钻井液体系进行优化,从优化结果可以看出,石蜡微乳液的配伍性好;优化后钻井液体系表观黏度降低3.5 mPa·s;钻井液的滤失量减小3.5 mL;泥饼厚度减小1 mm,增强了钻井液的滤失造壁性能。采用压力传导法对石蜡微乳液的封堵性能进行评价,结果表明石蜡微乳液可以提高封堵承压能力,石蜡微乳液优化钻井液对克孜洛依组致密砂岩的封堵率为58.4%,具有较好的微纳米裂缝孔隙封堵能力。Abstract: Analyses of seepage losses through micron and nanometer fractures and pores encountered in ultra-deep drilling in the southwest Tarim Basin show that the plugging agents in the potassium based polymer sulfonate drilling fluid are unable to effectively plug these fractures and pores. To improve the particle sizing for better plugging, a paraffin microemulsion was developed in laboratory. The optimum conditions for the development of the microemulsion was determined through particle size comparison method. It was found through experiment that the optimum quantity ratio of “S+A” : paraffin is 9:1, the optimum agitation speed is 1400 r/min, and the optimum reaction temperature is 120 ℃. The microemulsion thus prepared has D50 particle size of about 2.9 μm, monodisperse particle sizes between 200 nm and 300 nm, surface tension between 45.0 mN/m and 47.5 mN/m, and stable time up to 30 d. The potassium based polymer sulfonate drilling fluid was then optimized with the microemulsion, and good compatibility between them was seen after mixing. The optimized drilling fluid has its apparent viscosity reduced by 3.5 mPa·s, filtration rate reduced by 3.5 mL, thickness of mud cake reduced by 1 mm, and the filtration and wall building performance of the drilling fluid was enhanced. Evaluation of the plugging capacity of the paraffin microemulsion by pressure transmission methos shows that the paraffin microemulsion can be used to improve the pressure bearing capacity of the formation; test of the paraffin microemulsion on plugging the Keziluoyi dense sandstone shows that 58.4% of the microfractures and pores were plugged, indicating that the paraffin microemulsion has good plugging capacity

-

Key words:

- Paraffin microemulsion /

- Ultradeep well /

- Drilling fluid /

- Plug /

- Optimize /

- Pressure transmission /

- Tarim

-

表 1 在钾聚磺钻井液体系中加入不同封堵剂的黏切性能

防塌

封堵剂ρ/

g·cm−3Gel/

Pa/PaAV/

mPa·sPV/

mPa·sYP/

Pa0 1.87 4.0/12.0 47.0 35 12.0 1%聚合醇PEG-400 1.82 5.0/12.5 51.0 39 12.0 1%纳米SiO2 1.87 0.5/10.0 45.6 28 17.6 1%石蜡微乳液 1..86 1.5/10.0 43.5 39 4.5 注:基浆配方:3%膨润土(胶液)+0.4%NaOH+ 0.5%PAC-LV+0.1%AP-220+4%SMP-3(胶液)+4% SPNH(胶液)+25%DYFT-2+2%Ft-1+3%KC1+重晶石 表 2 TM-1井使用钻井液优化前后的性能

井深 井号 钻井液 ρ/

g·cm-3AV/

mPa·sPV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mL泥饼HTHP/

mm4993~5228 S-1

(未优化)KCl-聚磺 1.4~1.5 54 43 11.0 (1.0~2.0)/(4.0~5.0) 8~14 2.3 5078~5329 TM-1

(优化后)KCl-聚磺 1.4~1.5 46~52 25~35 5.0~7.5 (1.0~1.5)/(4.0~5.5) 6~7.2 1.5 注:FLHTHP在120 ℃测定 -

[1] 刘金,王剑,张宝真,等. 吉木萨尔凹陷芦草沟组页岩储层微纳米孔隙成因及含油特征[J]. 新疆地质,2021,39(1):94-98.LIU Jin, WANG Jian, ZHANG Baozhen, et al. Genesis and oil-bearing characteristics of micro-nano pores in shale reservoir of the Lucaogou formation in Jimusar depression[J]. Xinjiang Geology, 2021, 39(1):94-98. [2] 刘喜亮,由福昌,吴素珍,等. 页岩井壁失稳机理分析及钻井液对策研究[J]. 当代化工,2020,49(1):129-133. doi: 10.3969/j.issn.1671-0460.2020.01.032LIU Xiliang, YOU Fuchang, WU Suzhen, et al. Analysis of shale borehole instability mechanism and research on drilling fluid countermeasures[J]. Contemporary Chemical Industry, 2020, 49(1):129-133. doi: 10.3969/j.issn.1671-0460.2020.01.032 [3] 薛湘湘. 润滑防塌的微/纳米封堵剂的研制及其性能研究[D]. 延安大学, 2016.XUE Xiangxiang. Development of lubricating and anti-slump micro/nano plugging agent and its performance research [D]. Yan'an University, 2016. [4] 夏鹏,蔡记华,范志军,等. 纳米二氧化硅对盐水钻井液性能的影响[J]. 钻井液与完井液,2015,32(3):9-12,103. doi: 10.3969/j.issn.1001-5620.2015.03.003XIA Peng, CAI Jihua, FAN Zhijun, et al. Effect of nano-silica on the properties of brine drilling fluids[J]. Drilling Fluid & Completion Fluid, 2015, 32(3):9-12,103. doi: 10.3969/j.issn.1001-5620.2015.03.003 [5] SENSOY T, CHENEVERT M E, SHARMA M M. Minimizing water invasion in shales using nanoparticles[C]//SPE annual technical conference and exhibition. OnePetro, 2009. [6] ARAMENDIZ J, IMQAM A, FAKHER S M. Design and evaluation of a water-based drilling fluid formulation using SiO and graphene oxide nanoparticles for unconventional shales[C]//International petroleum technology conference. OnePetro, 2019. [7] 盛勇,叶艳,朱金智,等. 纳米内核乳液用于塔西南地区钻井液的优化[J]. 钻井液与完井液,2021,38(2):170-175. doi: 10.3969/j.issn.1001-5620.2021.02.007SHENG Yong, YE Yan, ZHU Jinzhi, et al. Optimization of drilling fluids with nano-core emulsions in Southwest Tarim basin[J]. Drilling Fluid & Completion Fluid, 2021, 38(2):170-175. doi: 10.3969/j.issn.1001-5620.2021.02.007 [8] ELSHAMY S, KHADIZATUL K, UEMURA K, et al. Chitosan-based film incorporated with essential oil nanoemulsion foreseeing enhanced antimicrobial effect[J]. Journal of Food Science and Technology, 2021, 58(9):3314-3327. doi: 10.1007/s13197-020-04888-3 [9] KREUTZ T, CARNEIRO S B, SOARES K D, et al. Aniba canelilla (Kunth) Mez essential oil-loaded nanoemulsion: Improved stability of the main constituents and in vitro antichemotactic activity[J]. Industrial Crops and Products, 2021, 171:113949. doi: 10.1016/j.indcrop.2021.113949 [10] 代礼杨,李洪俊,苏秀纯,等. 石蜡微乳液的研究及应用[J]. 钻井液与完井液,2012,29(2):5-7. doi: 10.3969/j.issn.1001-5620.2012.02.002DAI Liyang, LI Hongjun, SU Xiuchun, et al. Research and application of paraffin microemulsion[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):5-7. doi: 10.3969/j.issn.1001-5620.2012.02.002 [11] 李红梅,李伟,于小龙,等. 纳米乳化石蜡钻井液在延长低渗油田的应用[J]. 石油化工应用,2012,31(11):37-40.LI Hongmei, LI Wei, YU Xiaolong, et al. Application of nano-emulsion paraffin drilling fluid in Yanchang low-permeability oilfield[J]. Petrochemical Application, 2012, 31(11):37-40. [12] 陈军,王学军,高远鹏,等. 石蜡微乳液钻井液技术在水平井中的应用[J]. 钻井液与完井液,2010,27(4):87-89. doi: 10.3969/j.issn.1001-5620.2010.04.029CHEN Jun, WANG Xuejun, GAO Yuanpeng, et al. Application of paraffin microemulsion drilling fluid technology in horizontal wells[J]. Drilling Fluid & Completion Fluid, 2010, 27(4):87-89. doi: 10.3969/j.issn.1001-5620.2010.04.029 [13] 晏军,于长海,梁冲,等. 纳米石蜡乳液封堵材料的合成与性能评价[J]. 钻井液与完井液,2018,35(2):73-77. doi: 10.3969/j.issn.1001-5620.2018.02.012YAN Jun, YU Changhai, LIANG Chong, et al. Synthesis and Evaluation of a Nanophase Wax Emulsion Plugging Material[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):73-77. doi: 10.3969/j.issn.1001-5620.2018.02.012 [14] 侯长军,刘勇,霍丹群,等. 具有良好稳定性的石蜡乳液的制备及改进[J]. 应用化工,2010(2):175-178,181. doi: 10.16581/j.cnki.issn1671-3206.2010.02.023HOU Changjun, LIU Yong, HUO Danqun, et al. Synthesis and performance evaluation of paraffin microemulsion plugging materials[J]. Applied Chemical Industry, 2010(2):175-178,181. doi: 10.16581/j.cnki.issn1671-3206.2010.02.023 [15] ALJABRI N M, SHI N, CAVAZOS A. Nanoemulsion: an emerging technology for oilfield applications between limitations and potentials[J]. Journal of Petroleum Science and Engineering, 2022, 208:109306. doi: 10.1016/j.petrol.2021.109306 [16] 张路锋,周福建,张士诚,等. 塔里木克深致密砂岩气藏基质钻井液伤害评价[J]. 钻井液与完井液,2019,36(1):126-132. doi: 10.3969/j.issn.1001-5620.2019.01.024ZHANG Lufeng, ZHOU Fujian, ZHANG Shicheng, et al. Damage evaluation of matrix drilling fluids in the deep tight sandstone gas reservoir in Tarim[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):126-132. doi: 10.3969/j.issn.1001-5620.2019.01.024 [17] CAI J, CHENEVERT M E, SHARMA M M, et al. Decreasing water invasion into Atoka shale using nonmodified silica nanoparticles[J]. SPE Drilling & Completion, 2012, 27(1):103-112. -

下载:

下载: